- Summary

- Table Of Content

- Methodology

Zinc Stearate Market Size:

Zinc Stearate Market size is estimated to reach over USD 1,547.02 Million by 2032 from a value of USD 1,015.76 Million in 2024 and is projected to grow by USD 1,052.52 Million in 2025, growing at a CAGR of 5.4% from 2025 to 2032.

Zinc Stearate Market Scope & Overview:

Zinc stearate is a versatile chemical compound made by combining zinc with stearic acid. It is widely recognized for its hydrophobicity, lubricity, and non-toxicity. This white, powdery substance is insoluble in water but soluble in aromatic hydrocarbons and alcohols, making it suitable for various industrial applications.

Key characteristics of this compound include excellent thermal stability, water-repelling properties, and ease of dispersion. These features enhance its utility as a lubricant, release agent, and stabilizer across different processes and formulations.

The benefits of zinc stearate include improved product performance, enhanced manufacturing efficiency, and reduced wear on processing equipment. Its anti-caking and anti-static properties further enhance its functionality in specific formulations.

It is used in applications such as plastics, rubber, coatings, cosmetics, and pharmaceuticals. In the plastics industry, it serves as a mold-release agent and stabilizer. In rubber manufacturing, it functions as a lubricant and anti-tack agent. Its role in cosmetics includes acting as a texture enhancer and pigment dispersant.

End-use industries for zinc stearate encompass construction, automotive, consumer goods, and healthcare. Its versatile applications and beneficial properties make it an essential ingredient in several manufacturing processes and product formulations.

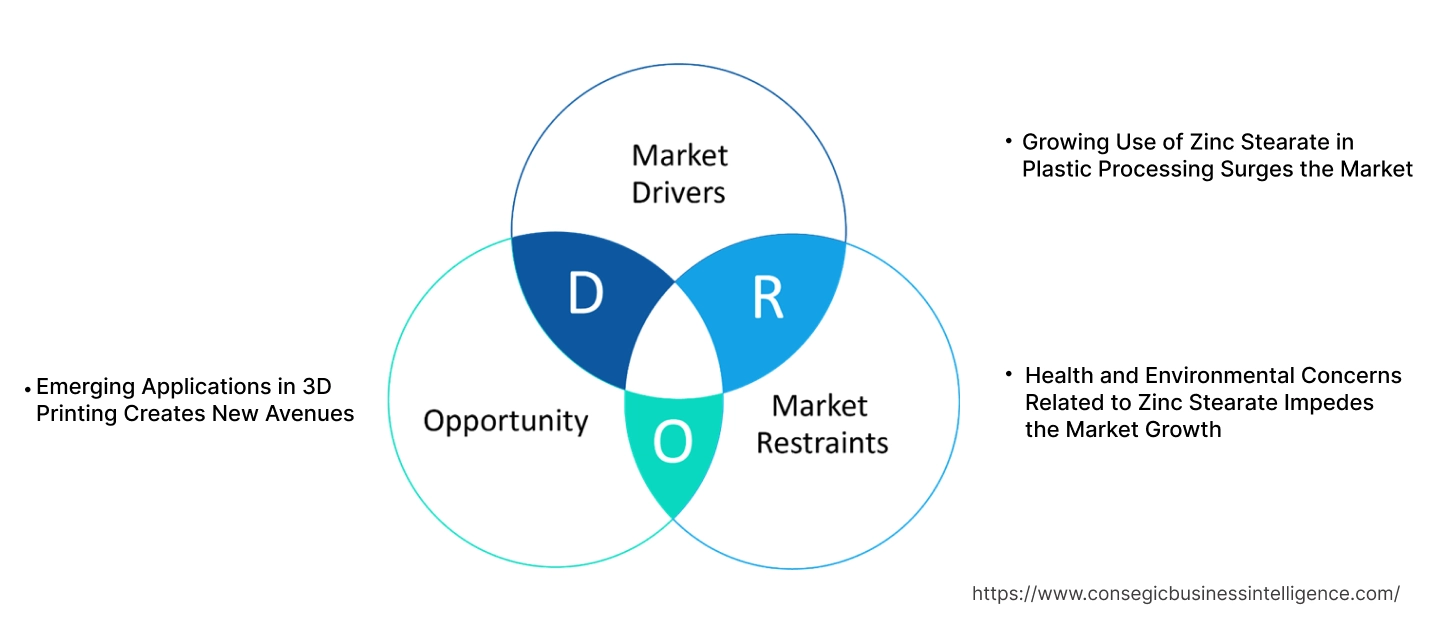

Key Drivers:

Growing Use of Zinc Stearate in Plastic Processing Surges the Market

Zinc stearate is widely utilized in plastic processing due to its excellent lubricating and release agent properties. It helps reduce friction during molding and extrusion processes, ensuring a smooth surface finish and preventing damage to plastic components. Its use is especially prominent in polyvinyl chloride (PVC) applications, where it enhances stability and improves processing efficiency.

For instance, manufacturers in the automotive and consumer goods industries rely on zinc stearate to produce high-quality plastic parts with consistent performance. The compound’s ability to function as a heat stabilizer further strengthens its relevance in producing thermoplastics and other heat-sensitive materials.

The increasing trend for lightweight and durable plastic components across various industries has elevated the importance of zinc stearate in achieving superior production outcomes.

Key Restraints:

Health and Environmental Concerns Related to Zinc Stearate Impedes the Market Growth

Zinc stearate’s dust-forming nature raises health and environmental concerns, limiting its adoption in certain regions with strict regulatory frameworks. Inhalation of fine zinc stearate particles has been linked to respiratory irritation, posing challenges for workers in industrial environments. These health hazards necessitate the use of safety equipment and protocols, increasing operational costs for manufacturers.

Environmental concerns also emerge from the improper disposal of zinc stearate residues, as its biodegradation process is slow. Regulatory bodies are implementing stricter guidelines to mitigate these impacts, which hinders its widespread use, particularly in countries with advanced environmental policies.

These challenges surrounding health and environmental impacts act as significant restraints to the zinc stearate market growth.

Future Opportunities :

Emerging Applications in 3D Printing Creates New Avenues

The increasing adoption of 3D printing technologies presents new Zinc Stearate Market opportunities for zinc stearate in enhancing material performance. As a lubricating and flow-enhancing agent, zinc stearate can improve the consistency and printability of polymer-based materials used in additive manufacturing. Its ability to reduce friction and enhance layer adhesion makes it suitable for producing complex and precise components.

The rise of 3D printing in sectors like healthcare, aerospace, and consumer goods is expected to drive trend for advanced materials with improved processing characteristics. Innovations in zinc stearate formulations tailored for additive manufacturing applications are anticipated to expand its scope in this emerging technology.

Future developments in 3D printing materials will create significant growth prospects for zinc stearate in this high-potential application area.

Zinc Stearate Market Segmental Analysis :

By Form:

Based on form, the zinc stearate market is segmented into powder and granules.

The powder segment accounted for the largest revenue share in 2024 and is expected to register the fastest CAGR during the forecast period.

- Zinc stearate in powder form is widely used as a lubricant, release agent, and anti-caking agent in various industries, including plastics, rubber, and cosmetics.

- The powder form is preferred for its easy dispersion in products like PVC compounds, paints, and coatings, enhancing product quality and ease of manufacturing.

- It also plays a significant role in enhancing the performance of products by improving flow properties, preventing sticking, and providing a smooth finish.

- The increasing trend for powder-based zinc stearate in applications like cosmetics, personal care, and food packaging further drives its adoption.

- The powder form is highly versatile, with significant use in medical and pharmaceutical applications as well, where it is used in tablet formulations and as an excipient in drug manufacturing.

- Furthermore, its use in rubber and tire manufacturing ensures the consistency of the final product, which contributes to widespread Zinc Stearate Market demand.

- Powder-based zinc stearate is particularly popular in applications requiring high precision, such as electronics and high-performance plastics.

- Therefore, according to Zinc Stearate Market analysis, the powder form continues to dominate the market due to its versatile applications and ease of use, ensuring that it remains a preferred choice across various industries. Its growth is driven by both traditional and emerging sectors looking for performance-enhancing solutions.

By Application:

Based on application, the zinc stearate market is segmented into lubricants, release agents, stabilizers, thickeners, emulsifiers, and others.

The lubricants segment accounted for the largest revenue share in 2024 and is expected to register the fastest CAGR during the forecast period.

- Zinc stearate is extensively used as a lubricant in the plastics and rubber industries to enhance processing, reduce friction, and extend the life of machinery.

- The growing demand for lubricants in automotive, electrical, and manufacturing industries, especially in high-performance applications, drives the adoption of zinc stearate.

- Zinc stearate lubricants help to prevent sticking, improve product surface finish, and reduce wear and tear on production machinery.

- The increased focus on manufacturing efficiency and automation in industrial sectors is contributing to the need for advanced lubricant solutions.

- The automotive industry, in particular, benefits from zinc stearate as it improves the durability and efficiency of tires, rubber seals, and other components.

- The shift towards electric vehicles (EVs) and the development of high-performance polymers also creates significant opportunities for zinc stearate lubricants, as these materials require specialized lubrication to ensure optimal performance and longevity.

- Additionally, zinc stearate lubricants play a crucial role in the manufacturing of wire and cable coatings, which require high precision and low friction properties.

- Thus, according to Zinc Stearate Market analysis, zinc stearate’s multifaceted role in lubrication, particularly in high-performance and specialized applications, ensures that it will continue to grow as the fastest-growing application segment. As industries increasingly demand efficient, cost-effective, and durable lubricants, this segment is set to expand rapidly.

By Function:

Based on function, the zinc stearate market is segmented into heat stabilizers, water repellents, anti-caking agents, thickening agents, and other functions.

The heat stabilizer segment accounted for the largest revenue share in 2024 and is anticipated to register the fastest CAGR during the forecast period.

- Zinc stearate serves as an effective heat stabilizer in PVC compounds and other polymers, enhancing their stability and durability under high temperatures.

- It prevents the degradation of polymers by minimizing the effects of heat during processing, particularly in the production of electrical cables, automotive parts, and construction materials.

- Its heat-stabilizing properties are essential in extending the lifespan of products used in high-temperature environments, contributing to its widespread use in industrial applications.

- The growing Zinc Stearate Market trend for heat-resistant materials in sectors such as construction, automotive, and electrical industries is expected to drive the market for zinc stearate heat stabilizers.

- As manufacturers focus on producing more durable and efficient materials, zinc stearate will continue to be a key component in ensuring the performance and longevity of these products.

- The rise in global construction activities, particularly in emerging economies, will further augment the trend for heat-stabilized products.

- Therefore, according to market analysis, Zinc stearate’s essential role in stabilizing materials under heat will ensure it remains a core component in the production of high-performance products. As industries demand increasingly durable materials capable of withstanding extreme conditions, the heat stabilizer function of zinc stearate will continue to be critical.

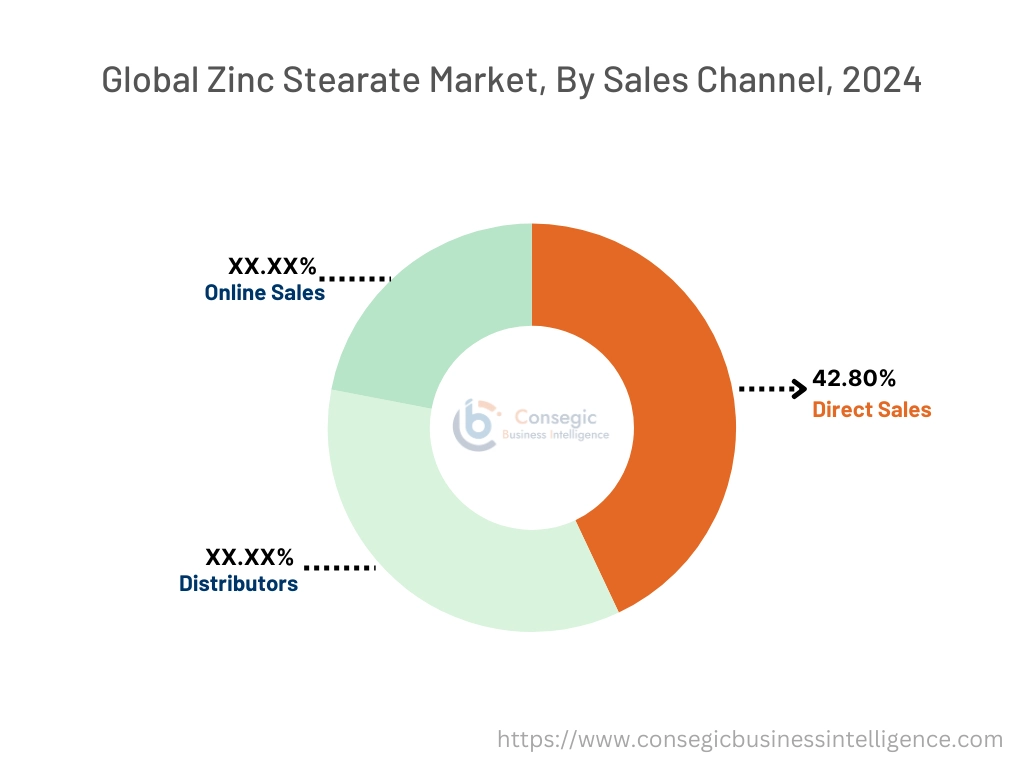

By Sales Channel:

Based on sales channel, the zinc stearate market is segmented into direct sales, distributors, and online sales.

The direct sales segment accounted for the largest revenue share by 42.80% in 2024 and is expected to register the fastest CAGR during the forecast period.

- Direct sales allow manufacturers to engage closely with customers, offering tailored solutions and better control over product quality and delivery times.

- This segment is particularly relevant for large-scale industrial buyers who require consistent supply and customized products for specific applications.

- Direct sales also facilitate strong business relationships, which are crucial in industries that demand high-quality, specialty chemicals like zinc stearate.

- The trend towards personalized service, cost-effective solutions, and supply chain optimization is expected to enhance the growth of direct sales in the zinc stearate market.

- Online platforms are also becoming an increasingly important channel for smaller businesses, enabling more accessible transactions and expanding customer reach.

- Direct sales, however, remain critical for securing long-term contracts with large enterprises in sectors such as automotive, plastics, and pharmaceuticals.

- Therefore, according to market analysis, direct sales will continue to play a pivotal role in providing highly specialized products and fostering deep partnerships with industry leaders. As industrial and customer needs become more sophisticated, direct sales will remain crucial for driving market growth.

By End-Use Industry:

Based on end-use industry, the market is segmented into plastics and rubber, paints and coatings, cosmetics and personal care, pharmaceuticals, construction, and others.

The plastics and rubber industry accounted for the largest revenue share in 2024 and is expected to register the fastest CAGR during the forecast period.

- Zinc stearate is extensively used in the production of PVC, rubber products, and other polymers to improve processing efficiency and enhance the final product's properties.

- The growing trend for durable, high-quality plastics and rubber products in construction, automotive, and electronics applications is driving the market.

- It serves a crucial role in reducing friction during manufacturing, improving product surface finish, and ensuring consistent performance, especially in tire manufacturing.

- Additionally, zinc stearate is used to stabilize and enhance the heat resistance of rubber compounds, making it essential for high-performance automotive and industrial products.

- The increasing adoption of sustainable and eco-friendly practices in the plastics industry is also contributing to the demand for zinc stearate as a safer, more efficient stabilizer.

- Furthermore, zinc stearate helps improve the processing of biodegradable plastics, catering to the rising demand for sustainable materials.

- Therefore, according to market analysis, the plastics and rubber industry continues to dominate the market, and its rapid expansion in response to increasing demand for high-performance materials guarantees that zinc stearate will remain a key enabler in this sector.

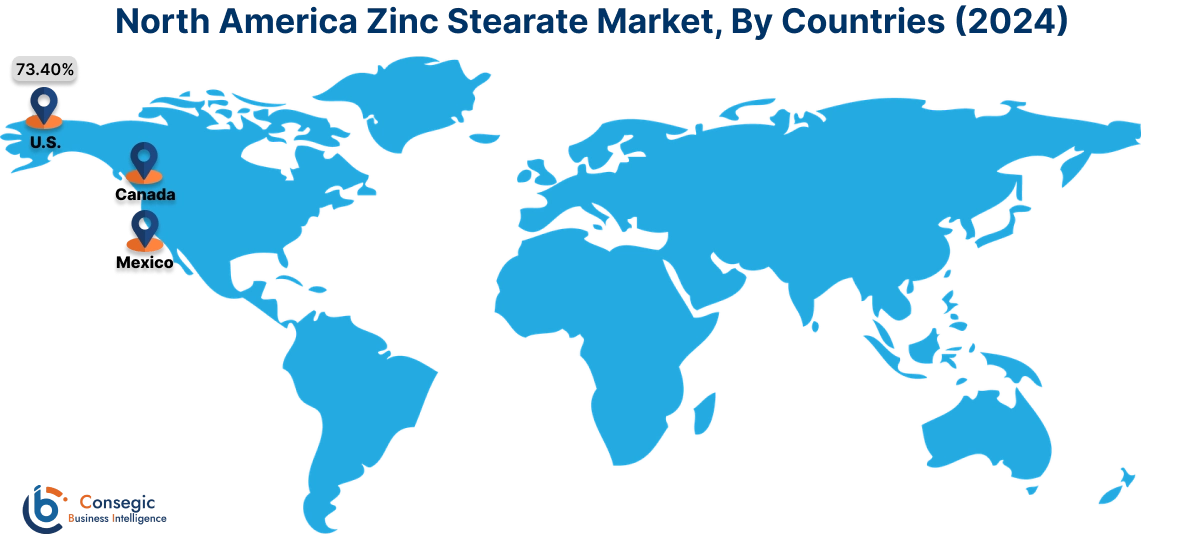

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, North America was valued at USD 336.94 Million and is expected to reach USD 501.39 Million in 2032. In North America, the U.S. accounted for the highest share of 73.40% during the base year of 2024. North America holds a prominent Zinc Stearate Market share. The demand is driven by its extensive use in industries such as plastics, rubber, and cosmetics. The U.S. is a key contributor due to the high consumption of zinc stearate in manufacturing processes. Moreover, increasing demand from the automotive and pharmaceutical industries supports market stability. Technological advancements and strict regulatory standards further influence the regional market.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 5.8% over the forecast period. Asia-Pacific is the fastest-expanding region in the zinc stearate market. Key countries, including China, India, and Japan, experience high demand for zinc stearate across various applications, particularly in the plastics and rubber industries. The region’s industrial growth, coupled with the rising manufacturing sector, plays a significant role in market development. According to market analysis, economic growth and urbanization also contribute to increased demand for personal care products, boosting the market further.

Europe remains a significant market for zinc stearate, with strong demand from the plastics, coatings, and pharmaceuticals industries. The presence of major manufacturing hubs in Germany, France, and Italy supports regional market growth. Environmental regulations concerning the use of chemicals in manufacturing processes, especially in personal care and cosmetics, shape market trends. The increasing focus on sustainability and eco-friendly alternatives impacts market dynamics in Europe.

The Middle East and Africa show moderate growth in the zinc stearate market. The demand in this region is largely driven by the construction, automotive, and plastics sectors. While limited by economic challenges in some areas, key countries like the UAE and Saudi Arabia are investing in industrial development, which is expected to boost demand for zinc stearate in the coming years. Zinc Stearate Market expansion is supported by rising production of rubber and plastic products.

Latin America is witnessing steady progress in the zinc stearate market, with Brazil and Mexico as major contributors. The market is influenced by the growing demand in the automotive, rubber, and plastics industries. Economic development, along with increasing industrial activities in these countries, strengthens market performance. However, limited awareness and regional economic challenges may affect the pace of market expansion.

Top Key Players and Market Share Insights:

The Global Zinc Stearate Market is highly competitive with major players providing FWA to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the Global Zinc Stearate Market. Key players in the Zinc Stearate Market industry include-

- Nouryon (Netherlands)

- Valiant Organics Ltd. (India)

- Peter Greven Physioderm GmbH (Germany)

- Reade International Corp. (United States)

- KLK OLEO (Malaysia)

- FACI S.p.A. (Italy)

- Baerlocher GmbH (Germany)

- Adeka Corporation (Japan)

- SunAce (Singapore)

- Everchem Specialty Chemicals (United States)

Zinc Stearate Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 1,547.02 Million |

| CAGR (2025-2032) | 5.4% |

| By Form |

|

| By Application |

|

| By Function |

|

| By Sales Channel |

|

| By End Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Zinc Stearate Market? +

In 2024, the Zinc Stearate Market was USD 1,015.76 million.

What will be the potential market valuation for the Zinc Stearate Market by 2032? +

In 2032, the market size of Zinc Stearate Market is expected to reach USD 1,547.02 million.

What are the segments covered in the Zinc Stearate Market report? +

The form, application, function, sales channel, and end-user industry are the segments covered in this report.

Who are the major players in the Zinc Stearate Market? +

Nouryon (Netherlands), Valiant Organics Ltd. (India), Peter Greven Physioderm GmbH (Germany), Reade International Corp. (United States), KLK OLEO (Malaysia), FACI S.p.A. (Italy), Baerlocher GmbH (Germany), Adeka Corporation (Japan), SunAce (Singapore), Everchem Specialty Chemicals (United States) are the major players in the Zinc Stearate market.