- Summary

- Table Of Content

- Methodology

Wire Wound Surface Mount Market Introduction :

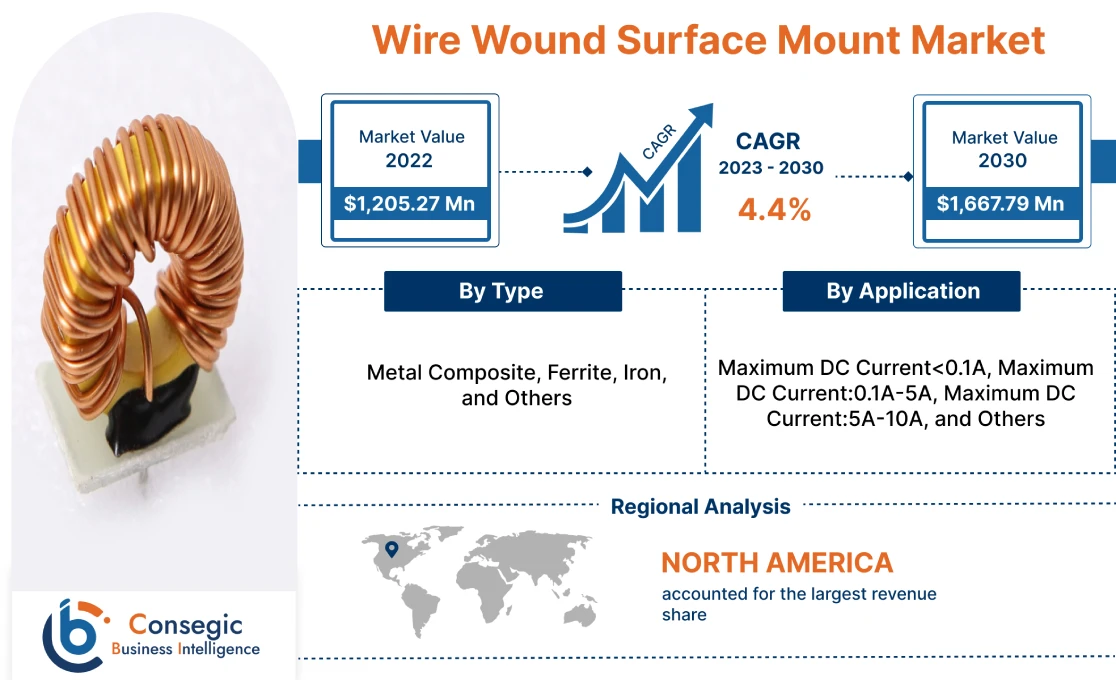

Wire Wound Surface Mount Market is estimated to reach over USD 1,667.79 Million by 2030 from a value of USD 1,205.27 Million in 2022, growing at a CAGR of 4.4% from 2023 to 2030.

Wire Wound Surface Mount Market Definition & Overview:

Wire wound surface mount refers to a type of electronic component that combines wire-wound technology with surface mount packaging. The components are designed to be mounted directly onto a printed circuit board (PCB) without the need for through-hole connections. Additionally, wire wound surface mounts consist of a coil of wire wound around a core material suitable for applications including inductors, transformers, and resistors. Moreover, the surface mount packaging allows for efficient assembly and compact designs in electronic devices.

Wire Wound Surface Mount Market Insights :

Key Drivers :

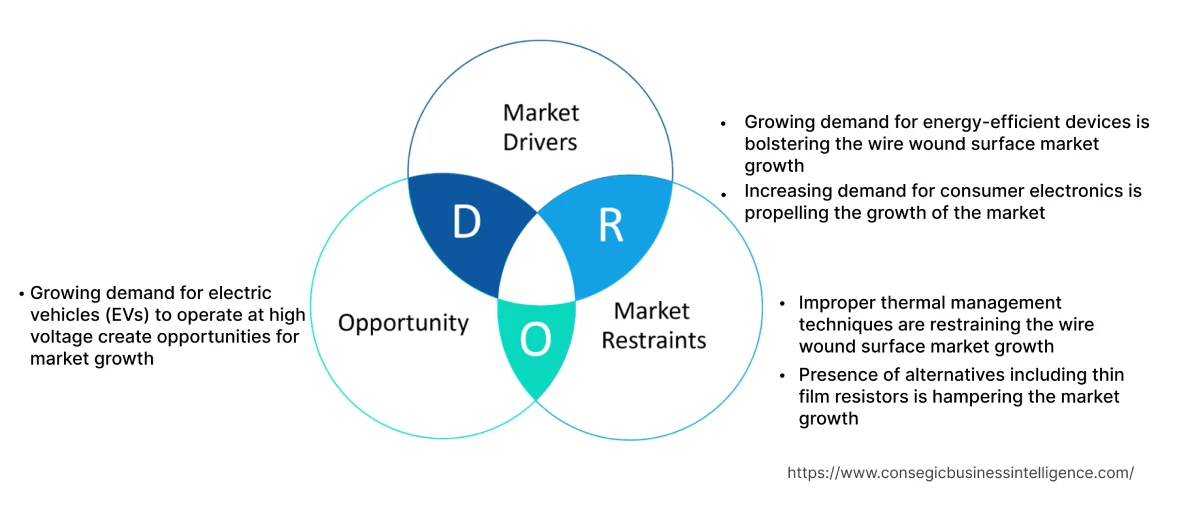

Growing demand for energy-efficient devices is bolstering the wire wound surface market growth

Wire wound surface mount components are known for the high power-handling capabilities as compared to other components including through-hole and chassis mount. The ability of surface mounts to handle large currents is ideal for energy-efficient devices requiring efficient power transfer and control including power supplies, motor drives, and energy storage systems. In addition, wire wound surface mount components offer less resistance to the flow of electric current resulting in reduced power losses and improved energy efficiency in devices. Moreover, governments across the globe are launching several programs to encourage the adoption of energy-efficient devices. For instance, in May 2023, according to the Bureau of Energy Efficiency, Indian Ministry of Power launched a Star-rated appliances program to promote the growth of energy-efficient devices. Consequently, the surge in government initiatives compelling users to adopt energy-efficient devices is driving the growth of the wire wound surface mount market.

Increasing demand for consumer electronics is propelling the growth of the market

Consumer electronics including smartphones, tablets, wearables, and smart home devices require compact designs to enhance portability and convenience. Wire wound surface mount components offer miniaturization due to the small form factor and surface mount packaging. Furthermore, surface mount components allow a higher level of integration on PCBs, enabling the incorporation of multiple functions into a single device. Subsequently, the compact size of the wire wound surface mount components enables easy designing of the assembly in electronic systems, leading to enhanced functionality and improved user experiences. Furthermore, the increasing demand for consumer electronics namely smartphones and tablets are contributing significantly in accelerating the growth of the wire wound surface mount market. For instance, according to SellCell data, 1516.4 million units of smartphones sold globally in the year 2022.

Key Restraints :

Improper thermal management techniques are restraining the wire wound surface market growth

The major factor restraining the growth of the wire wound surface mount market is due to the generation of excessive heat by the components during operation. The compact size and surface mounting of the wired components results in heat dissipation leading to potential issues including overheating of the electronic device. Consequently, the generation of additional heat due to improper thermal management techniques is impeding the growth of the global wire wound surface mount market.

Presence of alternatives including thin film resistors is hampering the market growth

Thin film resistors provide improved precision and accuracy due to the uniform resistive film deposition and well-controlled manufacturing processes as compared to wire wound surface mount components. In addition, thin film resistors offer low-temperature coefficients of resistance (TCR), resulting in more accurate and stable resistance operations suitable for applications including medical devices, instrumentation, and communication equipment. Moreover, thin film resistors exhibit low noise and low distortion characteristics, for sensitive applications namely audio amplifiers, signal processing, and sensor circuits. In conclusion, the ability of thin film resistors to offer improved precision and low noise distortion as compared to wire wound surface mount is hampering the growth of the market.

Future Opportunities :

Growing demand for electric vehicles (EVs) to operate at high voltage create opportunities for market growth

Electric vehicles rely on advanced power electronics systems to control and manage the flow of electrical energy. Wire wound surface mount components namely inductors, transformers, and resistors play a crucial role in power conversion, filtering, energy storage, and motor control. In addition, electric vehicles operate at high voltages and currents that raises the demand for wire wound surface mount components requiring components to handle high power levels efficiently. The components handle high currents while maintaining low resistance, suitable for applications in EV charging systems, battery management systems, motor drives, and powertrain electronics. In conclusion, the increasing demand for wire wound surface mount components to effectively regulate power electronic system and also to handle high power in electric vehicles is expected to create opportunities for the wire wound surface market growth.

Wire Wound Surface Mount Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2017-2030 |

| Market Size in 2030 | USD 1,667.79 Million |

| CAGR (2023-2030) | 4.4% |

| By Type | Metal Composite, Ferrite, Iron, and Others |

| By Application | Maximum DC Current<0.1A, Maximum DC Current:0.1A-5A, Maximum DC Current:5A-10A, and Others |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | Bourns, Inc., TDK Electronics AG, BI Technologies, Cooper Bussmann, KEMET Corporation, Murata Manufacturing Co., Ltd., NIC Components, TE Connectivity, Vishay Intertechnology, Inc., Panasonic Holdings Corporation |

Wire Wound Surface Mount Market Segmental Analysis :

Based on the Type :

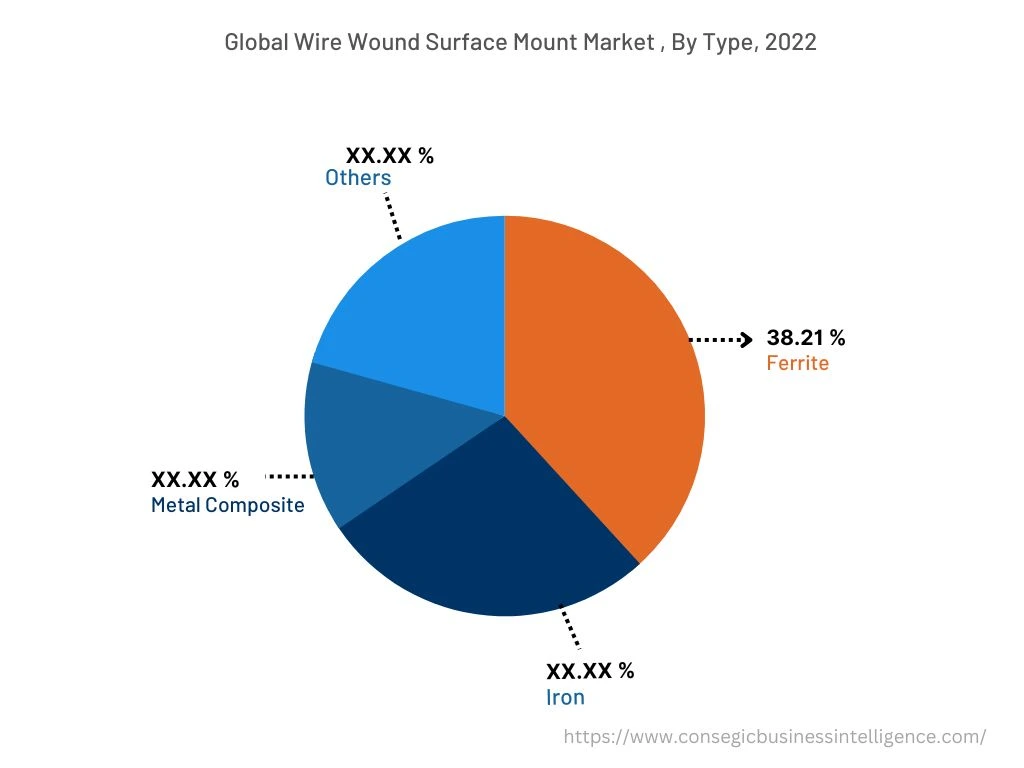

The type segment is classified into metal composite, ferrite, iron, and others. Ferrite material accounted for the largest market share of 38.21% in 2022 as ferrite materials have excellent magnetic properties that are highly effective in suppressing high-frequency noise in electronic circuits. The material is used as ferrite beads, which act as filters by attenuating unwanted electromagnetic interference (EMI) and radio frequency interference (RFI). In addition, ferrite wire wound surface mount components are widely employed in various industries and electronic devices including power supplies, DC-DC converters, motor drives, filters, sensors, and telecommunications equipment. In conclusion, the increasing adoption of ferrite material in several applications by suppressing high-frequency noise is contributing significantly in driving the growth of the wire wound surface mount market.

Metal composites are projected to witness the fastest CAGR during the forecast period owing to high current handling capacity, low resistance, and excellent thermal characteristics. The metal components, particularly aluminum and copper effectively handle high currents flow while maintaining low resistance values suitable for industrial and automotive applications that require efficient energy transfer and minimal power losses. For instance, in August 2021, KEMET launched three hybrid aluminum polymer capacitor series namely PHA225, PHH225, and A780. The A780 is a surface mounted capacitor with aluminum wire designed to withstand heavy vibrations in automotive powertrains, thus contributing significantly in accelerating the growth of metal composites during the forecast period.

Based on the Application :

The application segment is categorized into maximum DC Current<0.1A, maximum DC Current:0.1A-5A, maximum DC Current:5A-10A, and others. Wire wound surface mount components with a DC current range of 0.5A-5A accounted for the largest market share in 2022 as the specified DC current range is appropriate for power electronics applications for the handling of moderate to high power levels. In addition, the components also offer high resistance to heat, humidity, mechanical shock, and pressure to efficiently handle the power demands of various electronic devices and systems. For instance, in April 2020, Bourns launched Model CC322522A Series, a wire-wounded chip inductor with a maximum DC current of 0.15-1.35. The product is designed to offer high resistance to humidity, heat, pressure, and mechanical shock required for various applications including cable modems, cellular phones, and set-top boxes .

Wire wound surface mount components with a DC current range of 5A-10A is expected to witness the fastest CAGR during the forecast period. The growth is endorsed by the ability of 5A-10A surface mount components to meet the power demands of advanced power electronics systems, including high-power motor drives, industrial automation, and renewable energy applications. In addition, the 5A-10A wire wound surface mount components are also deployed at EV charging stations that require components to handle high currents efficiently and effectively. Consequently, the increasing adoption of wire wound surface mount components to effectively meet the power demand in various end-use industries, particularly the automotive industry is expected to drive the wire wound surface market growth in upcoming years.

Based on the Region :

The regional segment includes North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

North America accounted for the largest revenue share in the year 2022 as the region has a robust electronics and semiconductor industry with several major electronics manufacturers who invest in research and development for the production of electronic components, including wire wound surface mount components. In addition, the early adoption of advanced technologies, particularly in the United States for the development of energy-efficient devices is also driving the market growth. Consequently, the presence of key players, adoption of advanced technologies, and the expanding semiconductor industry are the key drivers for the growth of the wire wound surface mount market in North America. For instance, in November 2022, according to the State of Industry (SIA) Report, the United States accounted nearly half the global market share of 46% in 2021.

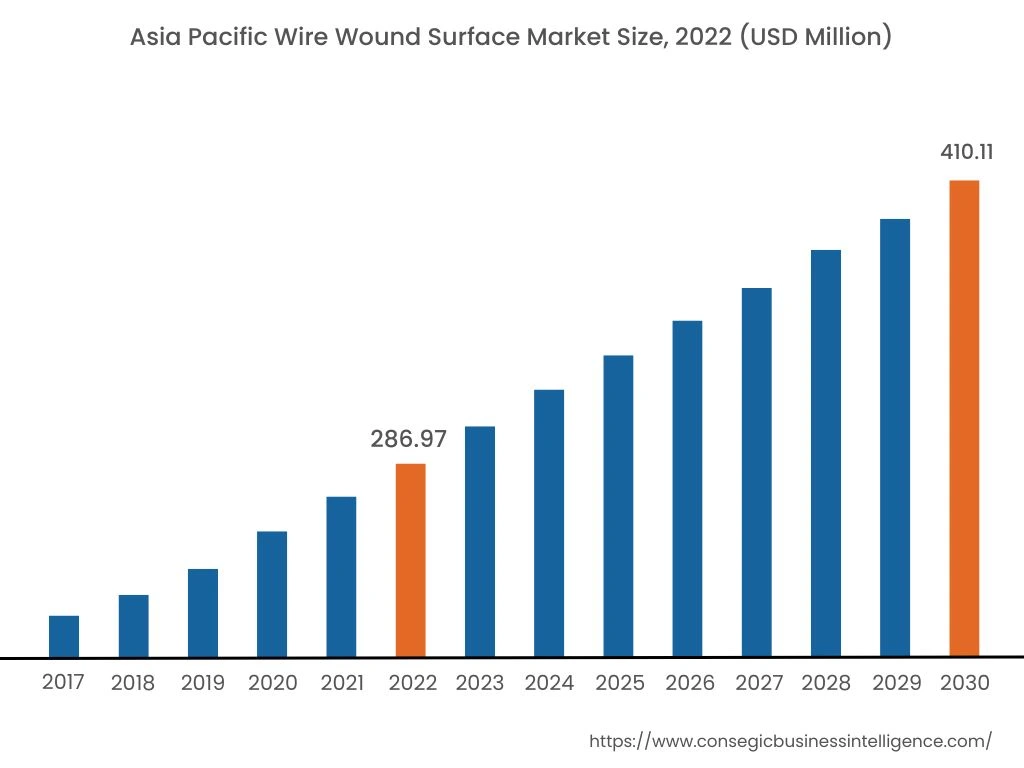

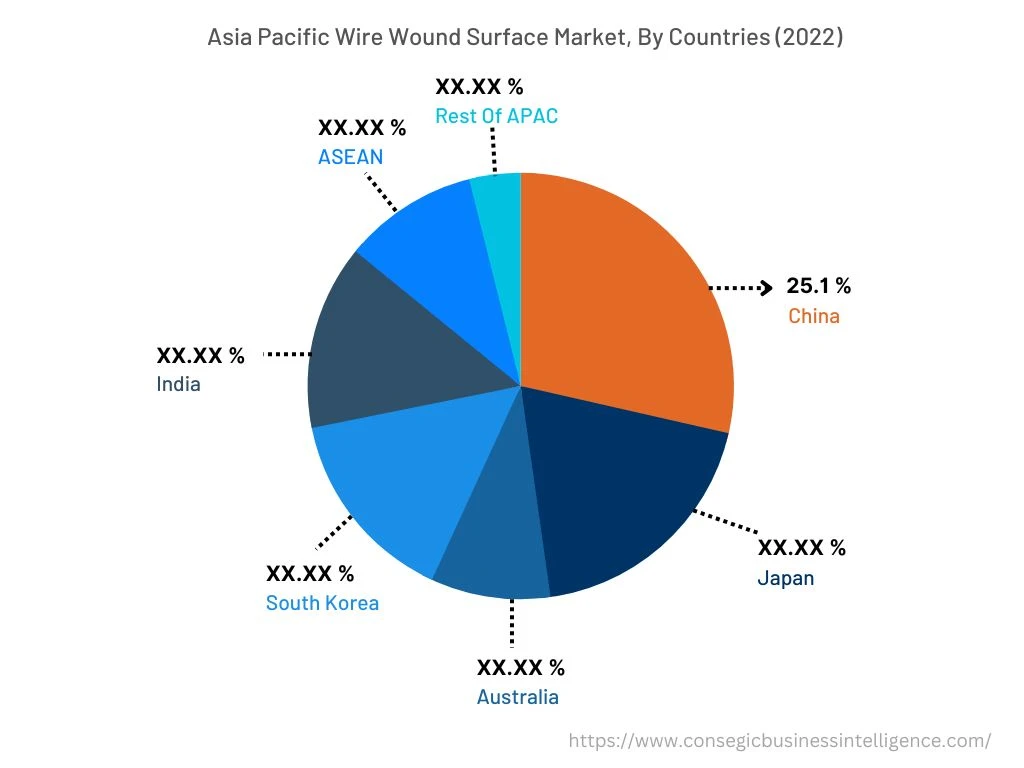

Asia Pacific accounted for a revenue share of USD 286.97 Million in 2022 and is expected to reach USD 410.11 Million in 2030, registering a CAGR of 4.8% during the forecast period. In addition, in the region, China accounted for the maximum revenue share of 25.1% in the year 2022. The growth is attributed to the growing consumer electronics industry in Asia Pacific countries including China, South Korea, Japan, and Taiwan. The expansion of the industry increases the production of smartphones, tablets, televisions, and other electronic devices and wire wound surface mount components are integral to the production of such devices, leading to increased wire wound surface market growth. In addition, the advancements in infrastructure development including power distribution, industrial automation, transportation, and renewable energy are also contributing significantly in accelerating the wire wound surface market growth in upcoming years.

Top Key Players & Market Share Insights:

The competitive landscape of the wire wound surface mount market has been analyzed in the report, along with the detailed profiles of the major players operating in the industry. Further, the surge in Research and Development (R&D), product innovation, various business strategies, and application launches have accelerated the growth of the wire wound surface mount market. Key players in the market include -

- Bourns, Inc.

- TDK Electronics AG

- TE Connectivity

- Cooper Bussmann

- KEMET Corporation

- BI Technologies

- Murata Manufacturing Co., Ltd.

- NIC Components

- Vishay Intertechnology, Inc.

- Panasonic Holdings Corporation

Recent Industry Developments :

- In August 2021, Bourns launched Model CWF1610 and Model CW2414 series of wire wound inductors made of ferrite offering high resonant-frequency and inductance. The product is equipped with noise filters and is used in various mobile electronic devices.

- In December 2020, TDK Corporation introduced ERU16 choke series to expand its surface mounted power inductors portfolio. The product is designed to operate efficiently between -40 °C and +150 °C and is widely used in hybrid and electric vehicles.

Key Questions Answered in the Report

What is wire wound surface mount? +

Wire wound surface mount refers to a type of electronic component that combines wire-wound technology with surface mount packaging. The components are designed to be mounted directly onto a printed circuit board (PCB) without the need for through-hole connections.

What specific segmentation details are covered in the wire wound surface mount market report, and how is the dominating segment impacting the market growth? +

The report consists of segments including type, application, and region. Each segment has a key dominating sub-segment being driven by industry trends and market dynamics. For instance, the type segment has witnessed ferrite material as the dominating segment in the year 2022, driven by the excellent magnetic properties that are highly effective in suppressing high-frequency noise in electronic circuits.

What specific segmentation details are covered in the wire wound surface mount market report, and how is the fastest segment anticipated to impact the market growth? +

The report consists of segments including type, application, and region. Each segment is projected to have the fastest-growing sub-segment driven by industry trends and drivers. For instance, in the application, wire wound surface mount with a DC current range of 5A-10A is anticipated to witness the fastest CAGR to meet the power demands of advanced power electronics systems, including high-power motor drives, industrial automation, and renewable energy applications.

Which region is anticipated to witness the highest CAGR during the forecast period, 2023-2030? +

Asia Pacific is anticipated to witness the fastest CAGR during the forecast period owing to the expanding consumer electronics industry