- Summary

- Table Of Content

- Methodology

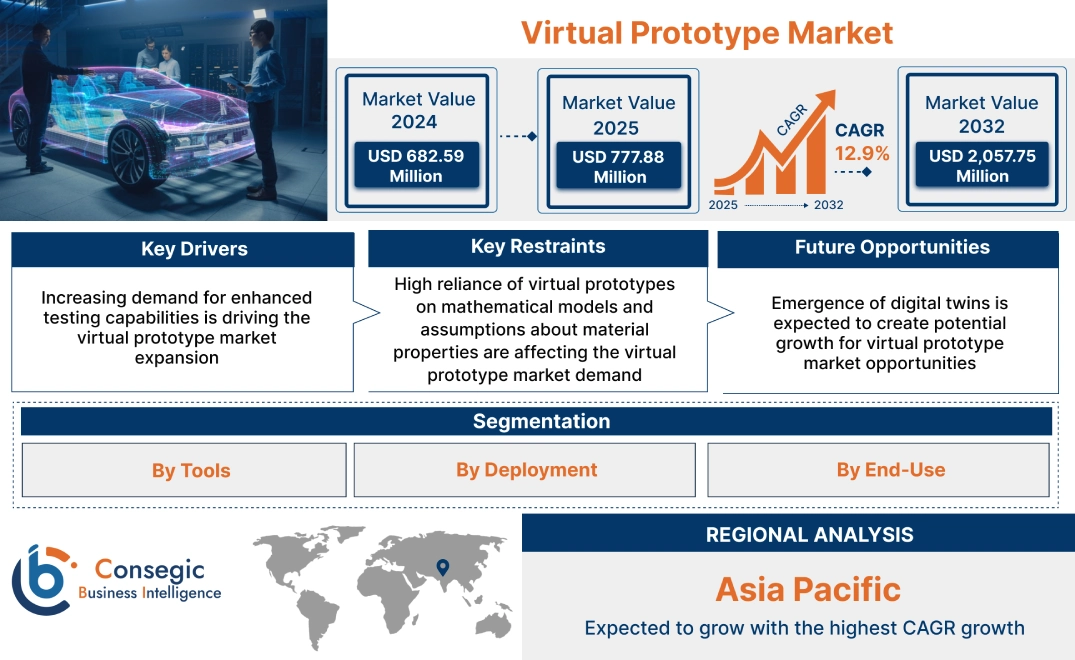

Virtual Prototype Market Size:

Virtual Prototype Market Size is estimated to reach over USD 2,057.75 Million by 2032 from a value of USD 682.59 Million in 2024 and is projected to grow by USD 777.88 Million in 2025, growing at a CAGR of 12.9% from 2025 to 2032.

Virtual Prototype Market Scope & Overview:

Virtual prototype is a process that uses computer-aided design (CAD) and simulation software to create a digital model of a product or system. The virtual model can then be used to test and analyze the product's performance, behavior, and functionality under various conditions, all without the need to build a physical prototype. Additionally, this approach allows engineers to identify and correct design flaws early in the development process, saving time and money. By simulating real-world behaviors such as stress responses, thermal dynamics, fluid movement, and mechanical actions, virtual prototyping solutions enable early detection of potential challenges in the development phase, greatly enhancing the design process. These simulations not only optimize product performance but also minimize expenses and development duration, establishing them as essential instruments in product innovation.

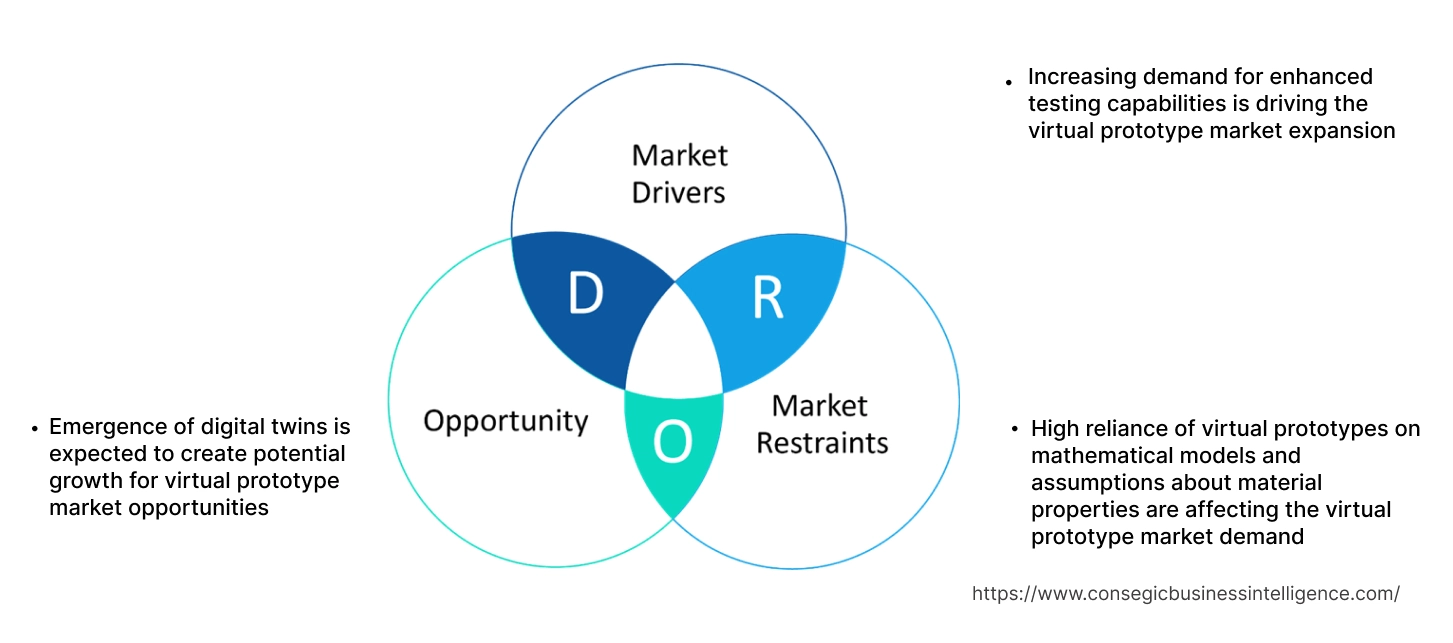

Key Drivers:

Increasing demand for enhanced testing capabilities is driving the virtual prototype market expansion

Modern products, especially in industries like automotive, aerospace, and electronics, are becoming increasingly complex, which makes physical prototyping expensive and time-consuming. Virtual prototypes allow for early testing and identification of issues, reducing the reliance on physical prototypes. Additionally, companies are under constant pressure to release products faster and virtual prototypes accelerate the design and testing process, enabling companies to bring products to market more quickly. Moreover, virtual prototypes also reduce the need for multiple physical prototypes, saving companies significant costs. Furthermore, virtual testing allows for the identification of design flaws and performance issues early in the development process, preventing costly rework later on.

- For instance, in September 2022, Synopsys launched ZeBu EP1, a unified hardware system for emulation and prototyping, designed to boost performance and flexibility in SoC verification and early software development. This combines the speed of ZeBu EP1, the fastest million-gate emulation system, with added prototyping capabilities, allowing customers to use a single verification hardware platform throughout the entire chip development process.

Thus, according to the virtual prototype market analysis, the growing testing capabilities are driving the virtual prototype market size and trends.

Key Restraints:

High reliance of virtual prototypes on mathematical models and assumptions about material properties are affecting the virtual prototype market demand

Mathematical models do not fully capture the complex behaviors of real-world materials. Assumptions about material properties can introduce further inaccuracies, especially under extreme conditions or in complex environments. These limitations can lead to discrepancies between virtual simulations and real-world performance, potentially undermining the reliability of virtual prototypes. Additionally, validating virtual prototypes is difficult due to the lack of direct physical comparisons. Physical testing precisely verifies the accuracy of virtual results, which increase development time and costs. This reduces the perceived value of virtual solutions and limits their adoption, further hampering the growth of the virtual prototype market size.

Future Opportunities :

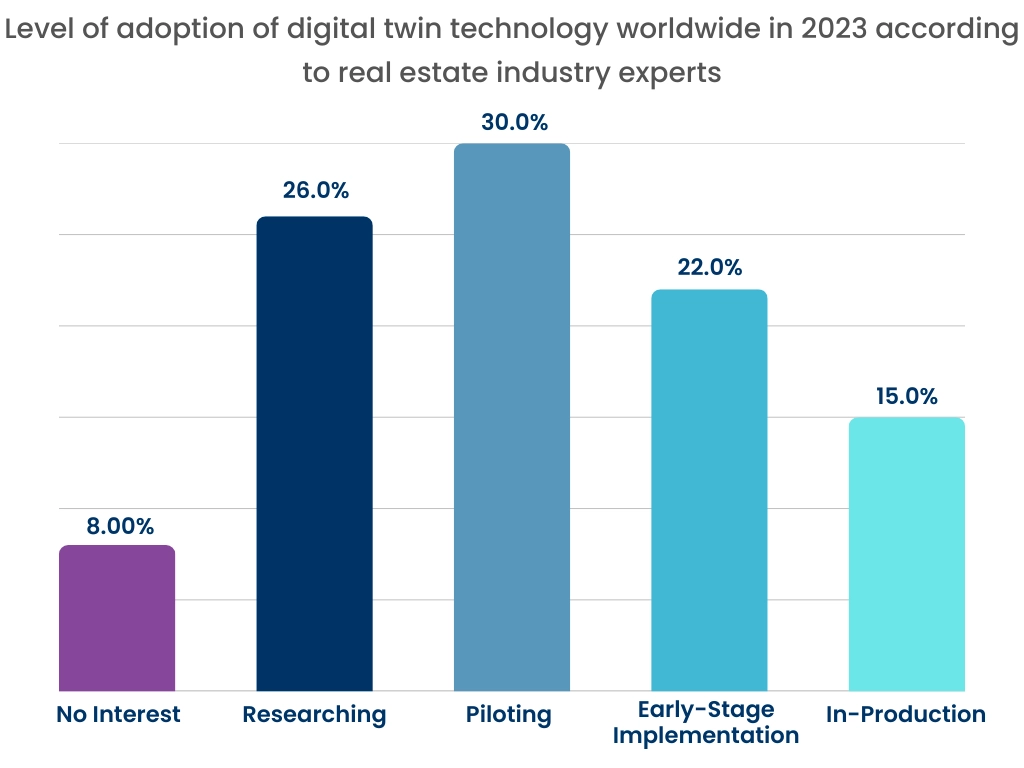

Emergence of digital twins is expected to create potential growth for virtual prototype market opportunities

Digital twins connect virtual prototyping solutions to real-world physical assets through sensors and IoT devices, allowing for the integration of real-time data into the virtual model. This addresses the limitations of relying solely on mathematical models and assumptions in traditional virtual solutions. Additionally, the continuous flow of data between the physical and virtual worlds enables closed-loop feedback, where changes in the physical asset are reflected in the digital twin, and vice versa. This allows for continuous optimization and refinement of virtual prototyping solutions, leading to higher accuracy and predictive capabilities. Moreover, digital twins provide a direct link between the virtual and physical worlds, enabling easier validation and verification of virtual prototyping solutions. By comparing the behavior of the digital twin with the real asset, engineers can identify discrepancies and improve the accuracy of the virtual model.

- For instance, in February 2024, Sev1Tech launched Vertasyn, an AI-powered digital twin platform that leverages a multi-agent generative intelligence engine called MAGIE. By integrating live and historical data, Vertasyn creates virtual representations of real-world entities and processes, enabling more accurate simulations of future outcomes. This technology allows commercial and defense organizations to enhance operational simulations in a more efficient and cost-effective manner compared to traditional physical prototypes.

Thus, based on the above analysis, the emergence of digital twins is expected to play a crucial role in shaping the future of the virtual prototype market opportunities and trends.

Virtual Prototype Market Segmental Analysis :

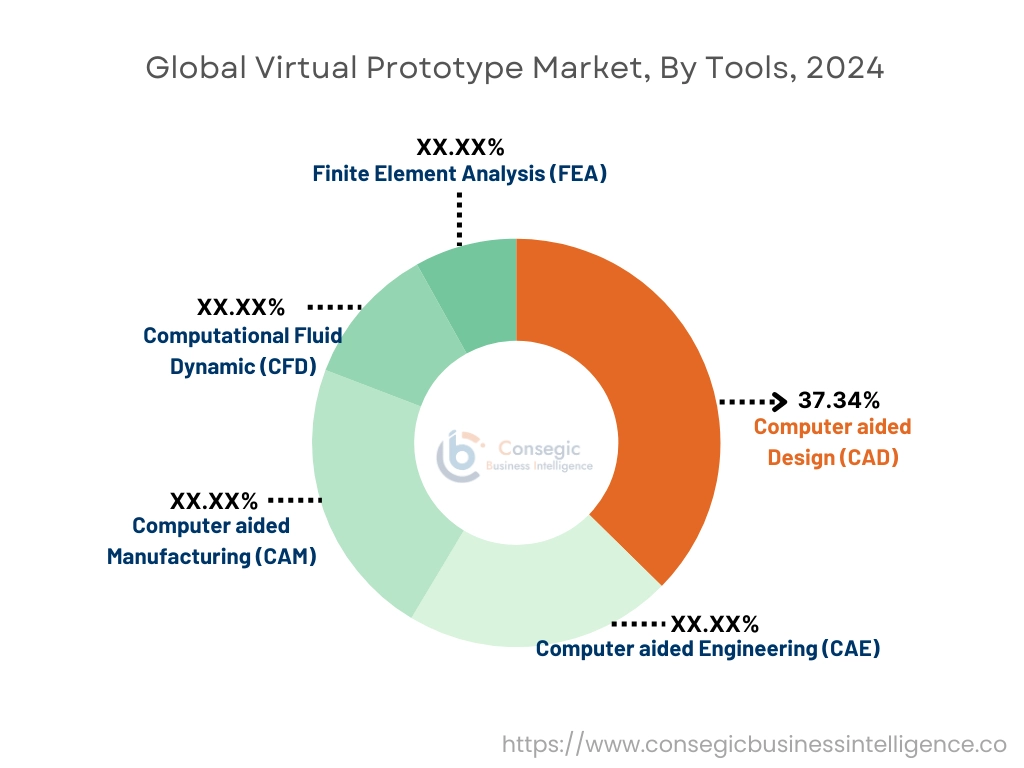

By Tools:

Based on tools, the virtual prototype market is segmented into Computer aided Design (CAD), Computer aided Engineering (CAE), Computer aided Manufacturing (CAM), Computational Fluid Dynamic (CFD), and Finite Element Analysis (FEA).

Trends in the Tools:

- Artificial intelligence is increasingly utilized to streamline numerous tasks associated with developing virtual prototyping solutions, while significantly enhancing the efficiency and speed of prototype creation.

- Virtual reality and augmented reality are employed to produce engaging virtual prototypes, enabling users to interact with the product or system in a more lifelike manner.

- The use of virtual prototyping can accelerate the product development timeline, helping businesses launch their offerings to the market more swiftly.

- Thus, based on analysis, factors such as growing adoption of AI would further drive the virtual prototype market during the forecast period.

The computer aided design (CAD) segment accounted for the largest revenue share of 37.34% in the year 2024.

- CAD software plays a vital role in the product design process across various industries, equipping designers with indispensable tools for the creation and alteration of 3D models.

- Its widespread use has cemented its status as a key element in the virtual prototyping workflow. In addition to design capabilities, CAD software encompasses a range of functions including simulation, analysis, and planning for manufacturing processes.

- This versatility establishes it as an essential resource for product development. Moreover, features such as technological maturity, interoperability, and smooth integration with other software systems have rendered it a highly desirable tool for manufacturers.

- For instance, in February 2022, Oracle Cloud PLM collaborated with GoSaaS CAD Vault, a computer-aided design (CAD) software offered by GoSaaS. This collaboration resulted in the integration of CAD and PLM, enabling features like BOM data generation and extraction.

- Thus developments such as rising smart manufacturing with adoption of IoT technologies would further drive the future of virtual prototype market growth.

The computer aided manufacturing (CAM) segment is anticipated to register the fastest CAGR during the forecast period.

- CAM software streamlines the accurate conversion of digital designs into tangible products, allowing manufacturers to enhance production workflows, minimize waste, and boost efficiency in manufacturing.

- Furthermore, the growing use of additive manufacturing technologies necessitates advanced CAM solutions to manage intricate part shapes and refine build settings.

- With the digital transformation of manufacturing gaining momentum, CAM has become an essential element of smart factories, facilitating real-time data analysis and automation of processes. This evolution has resulted in a greater embrace of CAM tools by production companies.

- Thus based on analysis, the aforementioned factors would further drive the virtual prototype market demand during the forecast period.

By Deployment:

Based on deployment, the virtual prototype market is segmented into on-premises and cloud.

Trends in deployment:

- Cloud-based platforms are gaining traction for the deployment of virtual prototyping, enabling designers and engineers to collaborate on these prototypes from any location worldwide.

- Digital twins serve as virtual replicas of physical assets, facilitating the monitoring and management of the asset's performance.

- Utilizing virtual prototyping solutions can accelerate the product development cycle, empowering companies to launch their products more swiftly.

- Thus, as per analysis, factors such as growing adoption of digital twin in the deployment segment would further drive the virtual prototype market trends and share during the forecast period.

The on-premises segment accounted for the largest revenue share in the year 2024.

- The segment growth can be attributed to the rising concerns surrounding security and intellectual property regarding new product developments. For example, organizations in the aerospace, defense, and automotive sectors place a high emphasis on rigorous data security measures.

- On-premises deployment provides enhanced control over data, intellectual property, and system configurations, effectively reducing the risks typically associated with cloud-based options.

- Additionally, several enterprises have well-established IT infrastructures and legacy systems. On-premises deployment integrates smoothly with these existing setups, minimizing the complexities and expenses related to system migration. As the threat of cyberattacks grows, a greater number of industries are anticipated to transition to on-premises deployment for their prototyping solutions.

- Thus, factors and developments such as enhanced data security for intellectual property are driving the virtual prototype market growth.

The cloud segment is anticipated to register the fastest CAGR during the forecast period.

- Cloud platforms serve as a unified hub for the storage and management of virtual prototyping, ensuring they are readily available to remote teams and stakeholders.

- Cloud-driven collaboration tools empower teams to simultaneously engage with virtual prototyping, irrespective of their physical locations. This promotes immediate feedback and speeds up the design workflow.

- Cloud computing allows organizations to adjust their computing resources dynamically, guaranteeing peak performance for intricate simulations and analyses.

- For instance, in January 2025, Hexagon’s manufacturing intelligence division introduced a new cloud-native solution to test, train, and validate ADAS and autonomous vehicle systems. By leveraging hyperscale computing and automation, Virtual Test Drive X (VTDx) empowers the automotive sector to automatically assess the quality and functionality of software across thousands of real-world scenarios, thereby hastening the market launch of safe mobility innovations.

- Thus, based on aforementioned developments and analysis, the cloud deployment would further create the need for virtual prototyping solutions during the forecast period.

By End Use:

Based on the end use, the market is segmented into aerospace, manufacturing, automotive, healthcare, consumer electronics, telecom, electronics and semiconductors, energy & utilities, construction, and others.

Trends in the end use:

- Virtual prototyping facilitates extensive testing and evaluation, resulting in enhanced product quality and dependability.

- Virtual prototype enables companies to lower expenses related to physical prototypes and testing processes.

- Key sectors such as aerospace and healthcare rely on precision and accuracy in their products, including aircraft parts and sophisticated diagnostic equipment. The significant manufacturing costs, the necessity to adhere to strict consumer safety standards, and increased operational risks drive manufacturers to embrace the latest advancements in prototyping technology.

- Thus, based on the above factors, the global market demand and trends will grow during the forecast period.

The automotive segment accounted for the largest revenue in the year 2024.

- Virtual prototypes serve as tools to mimic the functioning of vehicle elements and systems, including the engine, transmission, and suspension. This allows engineers to detect possible issues and enhance performance.

- Virtual prototype can also be employed to model manufacturing workflows and pinpoint potential bottlenecks. This contributes to increased production efficiency and cost reduction.

- Digital twins, representing virtual counterparts of actual vehicles, are gaining traction. They can be utilized to oversee and manage the vehicle's performance in real time.

- For instance, in March 2024, Arm Limited has unveiled its newest advancements in automotive software technologies and prototyping solutions. These cutting-edge, Armv9-based technologies, featuring the Arm Neoverse V3AE, Arm Cortex-A720AE, and Arm Mali-C720AE, will empower the automotive sector to harness artificial intelligence for vehicle innovation and accelerate the development timeline by up to two years.

- These trends and developments are anticipated to further drive the demand for virtual prototyping solutions in the global market during the forecast period.

The consumer electronics segment is anticipated to register the fastest CAGR during the forecast period.

- Virtual prototypes can be used to create 3D models of consumer electronics devices, evaluate their aesthetics, and optimize their ergonomic performance.

- Virtual prototypes can be used to simulate the behaviour of electronic components and systems, such as circuit boards, displays, and batteries. This helps engineers to identify potential problems and optimize performance.

- Virtual prototypes can be used to simulate user interactions and identify potential usability issues. This helps to ensure that the product is user-friendly and that it meets customer expectations.

- These trends in the consumer electronics industry would further drive the growth of the global market during the forecast period.

Regional Analysis:

The global market has been classified by region into North America, Europe, Asia-Pacific, MEA, and Latin America.

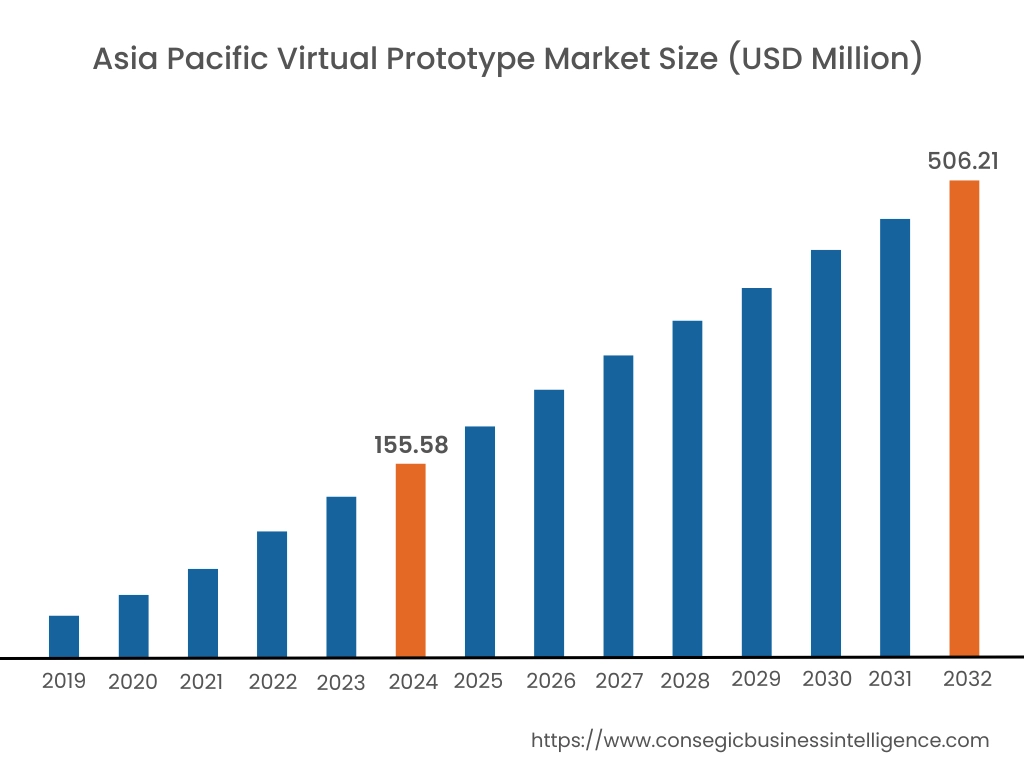

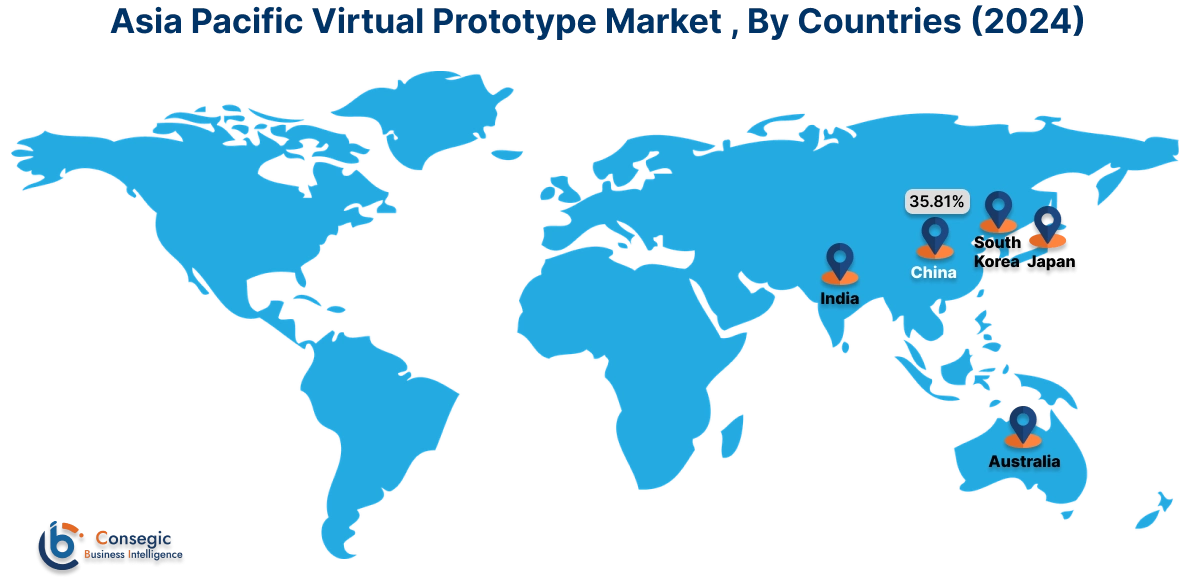

Asia Pacific virtual prototype market expansion is estimated to reach over USD 506.21 million by 2032 from a value of USD 155.58 million in 2024 and is projected to grow by USD 178.48 million in 2025. Out of this, the China market accounted for the maximum revenue split of 35.81%. The rise of numerous small and medium-sized enterprises (SMEs) increasingly embracing digitization and Industry 4.0 technologies, which has driven the demand for virtual prototyping solutions aimed at improving their product design and development capabilities. Furthermore, the expanding talent pool of engineers and designers in the region, alongside the growing utilization of cloud-based technologies, has facilitated smooth collaborations and remote working opportunities, thereby amplifying the need for virtual prototyping tools. Further, India has experienced significant growth in sectors such as automotive, consumer electronics, and healthcare, which has intensified the demand for virtual prototyping solutions to expedite product development, cut costs, and enhance production efficiency. In addition, government initiatives and investments in emerging technologies like AI, IoT, and additive manufacturing have fostered a conducive environment for market expansion. For example, the Production Linked Incentive (PLI) Scheme provides incentives to boost growth. These factors would further drive the regional virtual prototype market share during the forecast period.

- For instance, in April 2024, ESI Group announced the strategic partnership with FAW and Volkswagen TE to advance intelligent simulation technology within the automotive industry. This partnership has led to the establishment of an intelligent simulation and material testing laboratory in China, aimed at fostering innovations that ensure a safer, efficient, and environmentally friendly future for the automotive sector.

North America market is estimated to reach over USD 853.97 million by 2032 from a value of USD 284.25 million in 2024 and is projected to grow by USD 323.84 million in 2025. North America has the largest revenue share in the global market, primarily due to its robust automotive and aerospace sectors. These industries have historically depended on virtual prototyping technologies to improve product design and development. Further, the significant investments in research and development have propelled the advancement and enhancement of these tools. Given the essential nature of products in these fields, which necessitate comprehensive testing and validation, virtual prototyping is crucial. Additionally, the U.S. contributes a considerable portion of the regional market, leading the charge in adopting and integrating cutting-edge technologies across key sectors like automotive and electronics. The presence of major multinational companies such as General Motors, Ford, and Tesla has driven a strong need for virtual prototyping within the automotive sector. These factors and developments would further drive the regional virtual prototype market share and trends during the forecast period.

- For instance, in June 2023, the Canadian government have invested around USD 4 million to establish an aerospace innovation hub at the University of Calgary, to foster prototyping and testing services. Canada's government is channeling investments into Alberta's aerospace sector and its supporting organizations to boost the competitiveness of this vital sector, generate well-paying employment opportunities, and diversify the province's economy.

According to the virtual prototype industry, the European market has experienced significant development during the forecast period. The region encompasses a broad and varied manufacturing landscape within advanced industrial economies, such as Germany, U.K., and France. The ongoing technological advancements and the prompt integration of these innovations by domestic manufacturers have opened numerous prospects for the implementation of virtual prototyping solutions. Furthermore, strong partnerships between manufacturers and technology suppliers have expedited the adoption and enhancement of these technologies in the region, while contributing to the substantial market share. Additionally, businesses across Latin America are progressively embracing cutting-edge technologies such as artificial intelligence, machine learning, and cloud computing. These innovations are being woven into virtual prototyping tools, boosting their functionality and delivering more precise simulations. Additionally, companies in the region are on the lookout for economic alternatives to refine their product development workflows. Additionally, countries in the MEA region are progressively integrating digital technologies into diverse sectors. This shift encompasses the implementation of sophisticated software and simulation tools for virtual prototyping, spurred by government initiatives and investments from the private sector in digital transformation. Further, major infrastructure endeavors throughout the area, such as those in transportation, energy, and urban development, are fueling the need for virtual prototyping to enhance design optimization, mitigate risks, and promote cost efficiency. Thus, on the above virtual prototype market analysis, these factors would further drive the regional virtual prototype market trends during the forecast period.

Top Key Players & Market Share Insights:

The global virtual prototype market is highly competitive with major players providing virtual prototyping solutions to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the market. Key players in the virtual prototype industry include-

- Synopsys, Inc. (U.S.)

- TWI Ltd. (U.K.)

- PTC (U.S.)

- Ansys (U.S.)

- Altair Engineering (U.S.)

- Autodesk Inc. (U.S.)

- Bentley Systems (U.S.)

- Hexagon AB (U.S.)

- Dassault Systemes (France)

- Siemens (Germany)

Recent Industry Developments :

Expansion:

- In September 2024, Siemens updated their Simcenter testlab software to increase collaboration and reduce reliance on physical prototypes. This allows development teams to evaluate various variations and configurations more swiftly than previously possible, thanks to new features in Simcenter Testlab that boost testing efficiency, broaden testing capabilities, and enhance collaboration and automation.

Virtual Prototype Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 2,057.75 Million |

| CAGR (2025-2032) | 12.9% |

| By Tools |

|

| By Deployment |

|

| By End Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Virtual Prototype market? +

Virtual Prototype Market Size is estimated to reach over USD 2,057.75 Million by 2032 from a value of USD 682.59 Million in 2024 and is projected to grow by USD 777.88 Million in 2025, growing at a CAGR of 12.9% from 2025 to 2032.

Which is the fastest-growing region in the Virtual Prototype market? +

Asia-Pacific is the region experiencing the most rapid growth in the market. The Asia-Pacific region is projected to witness the most significant growth in virtual prototyping, propelled by the swift embrace of digitization and Industry 4.0 technologies among small and medium-sized enterprises (SMEs). As these businesses aim to improve their product design and development processes, virtual prototyping solutions have emerged as vital tools. The increasing number of engineers and designers in the area, coupled with the rising adoption of cloud-based technologies, has made collaboration and remote work more accessible, driving the demand for virtual prototyping solutions across multiple sectors.

What specific segmentation details are covered in the Virtual Prototype report? +

The virtual prototype report includes specific segmentation details for tools, deployment, and end use, and region.

Who are the major players in the Virtual Prototype market? +

The key participants in the market are Synopsys, Inc. (U.S.), TWI Ltd. (U.K.), Autodesk Inc. (U.S.), Bentley Systems (U.S.), Hexagon AB (U.S.), Dassault Systemes (France), Siemens (Germany), PTC (U.S.), Ansys (U.S.), Altair Engineering (U.S.), and others.