- Summary

- Table Of Content

- Methodology

Vanadium Market Size:

Vanadium Market size is growing with a CAGR of 4.8% during the forecast period (2025-2032), and the market is projected to be valued at USD 3.61 Billion by 2032 from USD 2.49 Billion in 2024. Additionally, the market value for the 2025 attributes to USD 2.60 Billion.

Vanadium Market Scope & Overview:

Vanadium is a silvery-grey, ductile, and malleable transition metal. It is known for its strength, hardness, and resistance to corrosion. Its key properties include multiple oxidation states, catalytic activity, and the ability to enhance the strength of steel. It is primarily produced through the reduction of V₂O₅ via aluminothermic or carbothermic processes. Its main product types include ferrovanadium, vanadium oxide, vanadium alloys, vanadium electrolytes, and other specialty chemicals. These products find diverse applications, for strengthening steel in automotive and construction, as catalysts in chemical synthesis, in high-performance alloys for aerospace, and as the active material in vanadium redox flow batteries for energy storage. The end-uses span automotive, construction, chemical industries, energy storage, and aerospace & defense.

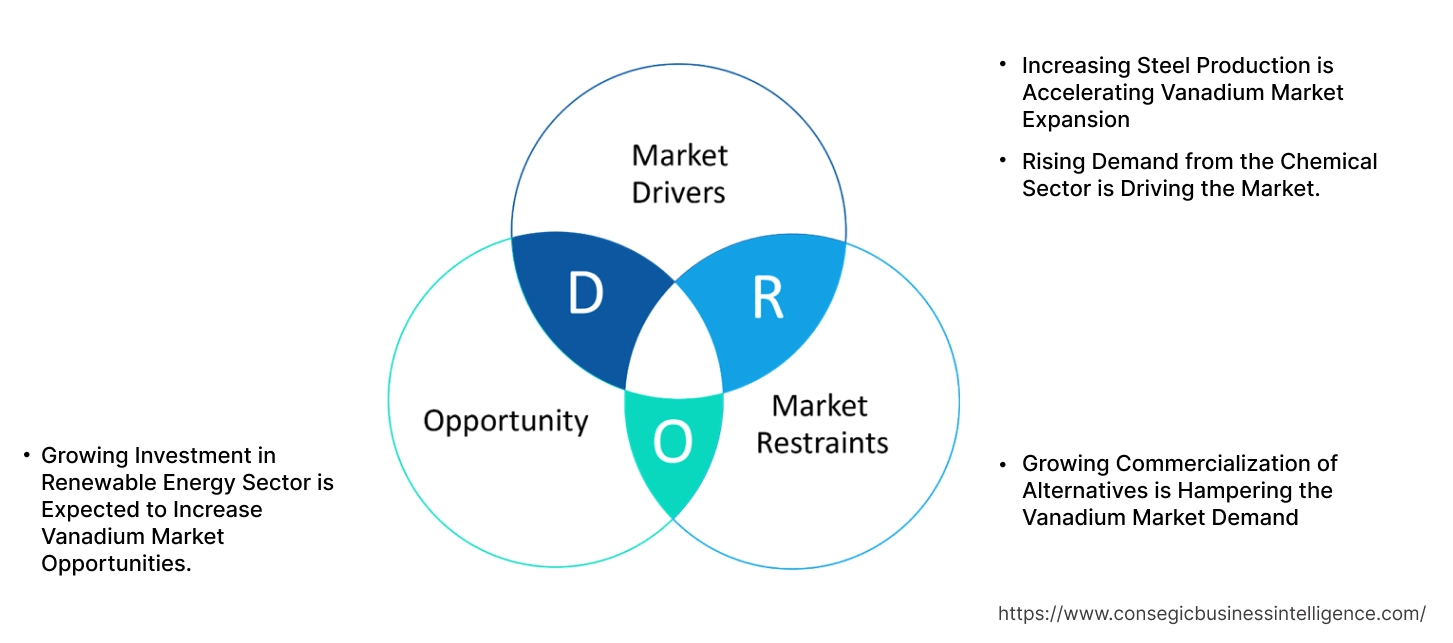

Key Drivers:

Increasing Steel Production is Accelerating Vanadium Market Expansion

Vanadium is a metallic element, which plays a crucial role in steel production. Even in small amounts, it increases steel's strength and hardness. It also provides resistance to wear, shock, and corrosion. This allows for the production of high-strength, low-alloy (HSLA) steels, requiring less material for the same structural performance, thus reducing weight and cost. Rapid industrialization is driving increased steel production, consequently boosting demand for this metallic element.

For instance,

- According to the Tehran Times, Iran's steel production saw a 5.8% increase in 2023 compared to the previous year.

Overall, the growing steel production is significantly boosting the vanadium market expansion.

Rising Demand from the Chemical Sector is Driving the Market.

Vanadium is primarily used as a catalyst in the production of various chemicals such as sulfuric acid and maleic anhydride amongst others. It is also used in the synthesis of certain polymers and organic substances such as ethanol. Its advantages include high catalytic activity and selectivity, leading to efficient and cost-effective chemical processes. The rising need for chemicals from various end-use industries such as packaging, pharmaceuticals, and agriculture is leading to sector growth, influencing the demand for vanadium.

For instance,

- According to BASF, chemical production in Asia saw an expansion of 4.2% in 2022 when compared to the output of the preceding year.

Thus, rising chemical manufacturing is accelerating the global vanadium market growth.

Key Restraints:

Growing Commercialization of Alternatives is Hampering the Vanadium Market Demand

The presence of substitute materials poses a significant restraint on the market. In the steel sector, niobium serves as a direct alternative to micro-alloying. It improves the strength and durability of steel, but niobium is preferred in regions where it is more readily available and cost-effective. Moreover, in the energy storage sector, lithium-ion batteries represent a substitute for vanadium redox flow batteries (VRFBs). Additionally, newer technologies such as zinc-bromine flow batteries are emerging as competitors, offering similar benefits with potentially lower costs. The ongoing development and commercialization of these alternatives limit market penetration in new applications. Hence, the growing commercialization of alternatives is hampering the vanadium market demand.

Future Opportunities :

Growing Investment in Renewable Energy Sector is Expected to Increase Vanadium Market Opportunities.

Vanadium plays a crucial role in the renewable energy sector through vanadium redox flow batteries (VRFBs). These rechargeable batteries utilize vanadium ions in liquid electrolytes to store and release electricity via redox reactions. VRFBs boast a near-infinite lifespan, high scalability, and enhanced safety. This makes them ideal for large-scale energy storage. Globally, governments are increasing investment in renewable energy projects as they reduce air and water pollution compared to fossil fuels. This fuels the demand for VRFBs for efficient energy storage.

For instance,

- In 2024, the S. Department of Energy invested USD 149.87 million in clean energy projects across 28 U.S. states.

Overall, growing investment in the renewable energy sector is expected to increase vanadium market opportunities.

Vanadium Market Segmental Analysis :

By Product Type:

Based on product type, the market is categorized into ferrovanadium, vanadium oxide, vanadium alloys, vanadium electrolytes, and others.

Trends in Product Type:

- Ferrovanadium remains the largest segment due to its essential role in enhancing steel strength and durability for the construction and automotive sectors.

- The aerospace industry's need for lightweight and high-strength materials is driving the need for aluminum-vanadium and titanium-vanadium alloys.

The ferrovanadium segment accounted for the largest market share in 2024.

- The ferrovanadium segment dominated the vanadium market trends. It is an iron-vanadium alloy with a vanadium content typically ranging from 35% to 85%.

- It's a crucial additive in steel production, acting as a universal hardener, and strengthener. It also enhances corrosion resistance and high-temperature performance, allowing for lighter and more durable steel structures and components.

- Growing requirements for steel, fueled by the increasing need for infrastructure and construction projects in rapidly developing economies, is a significant driver of the segment in the market.

- For instance, according to the International Trade Administration, global steel production in June 2021 showed a significant increase of 13.2% compared to the same month in the previous year.

- Overall, as per the market analysis, the increased steel manufacturing is driving a segment in vanadium market growth.

The vanadium electrolytes segment is expected to grow at the fastest CAGR over the forecast period.

- The vanadium electrolytes segment is emerging in the market trends. It is a liquid solution containing vanadium ions in different oxidation states.

- Their primary use is within VRFBs for large-scale energy storage, enabling the storage and release of electricity for grid stabilization, renewable energy integration (such as solar and wind), and backup power systems.

- VRFBs using these electrolytes offer exceptional longevity with near-infinite charge/discharge cycles and a long lifespan (over 20 years).

- There is a growing need for grid-scale energy storage to ensure grid stability and intermittency, thus influencing segments in the market.

- According to the vanadium market analysis, the growing need for efficient energy storage solutions will drive segmental growth in the upcoming years.

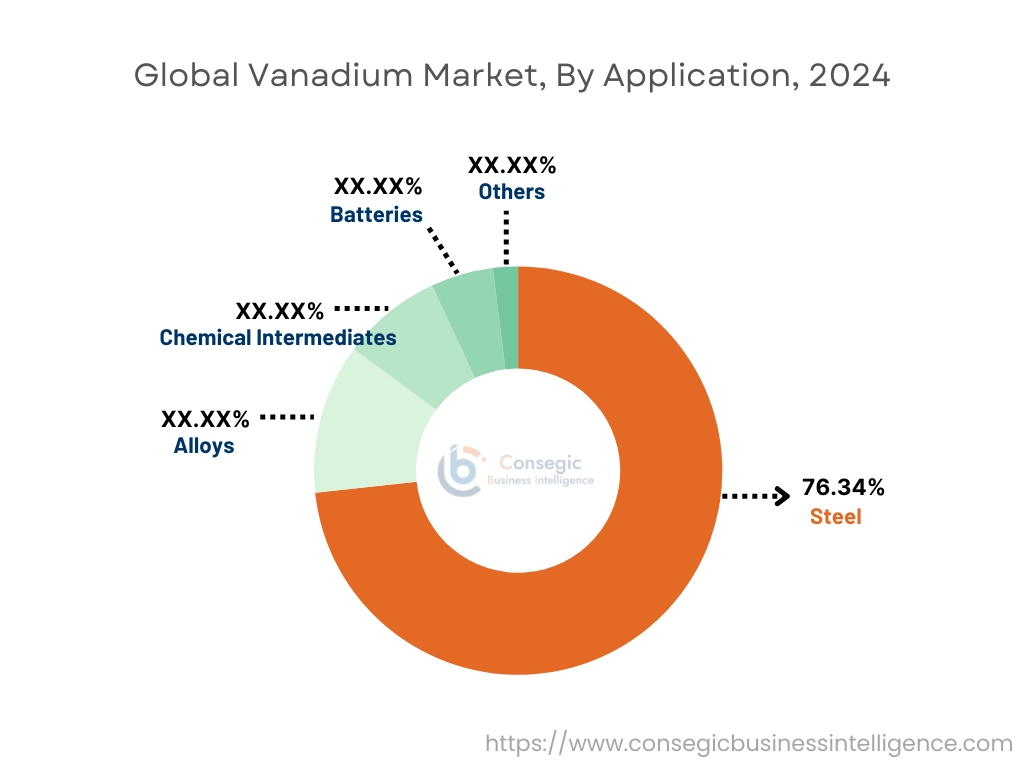

By Application:

Based on application, the market is categorized into steel, alloys, chemical intermediates, batteries, and others.

Trends in Application:

- Ongoing research explores new vanadium-based catalysts for more efficient and environmentally friendly chemical processes.

- Vanadium's ability to enhance the strength and temperature resistance of titanium alloys is crucial for advanced aircraft components.

The steel segment accounted for the largest market share of 76.34% in 2024.

- The steel segment dominated the vanadium market trends. Vanadium, which is a metallic element, forms carbides, and nitrides within the steel, which strengthen it and make it more resistant to breaking.

- Moreover, the presence of this metallic element makes steel more resistant to wear and tear, especially in applications such as construction machinery, tools, and automotive components.

- Additionally, this metal helps control the grain sizing of steel, making it easier to heat-treat and improve its hardenability.

- Steel is used in a wide range of applications, including construction (bridges, buildings), transportation (automotive, aerospace), and manufacturing, and the increase in these sectors is driving the segment in the market.

- According to market analysis, the robust need for high-performance steel across different sectors is driving the segment in the market.

The batteries segment is expected to grow at the fastest CAGR over the forecast period.

- The batteries segment is emerging in market trends. The segment is primarily driven by the increasing adoption of VRFBs for large-scale energy storage.

- VRFBs utilize vanadium ions in different oxidation states within a liquid electrolyte to store and release electrical energy through reversible redox reactions.

- There is growing electricity demand and the need for a stable power supply, leading to increased integration of smart grids.

- For instance, according to the NC Clean Energy Technology Center, a total of 774 grid modernization actions were taken across all 50 U.S. states in 2023. This will require VRFBs, which are crucial for grid-scale energy storage needed to support a modernized and more resilient electricity infrastructure.

- Hence, as per the market analysis, the rising adoption of smart grids will drive the segment for the upcoming years.

By End-Use:

Based on the end-use, the market is categorized into automotive, construction, chemical, energy, aerospace & defense, and others.

Trends in the End-Use:

- Growing investments in infrastructure projects necessitate the use of vanadium-strengthened steel in bridges, buildings, and transportation networks for enhanced durability and safety.

- Vanadium compounds remain crucial catalysts in the chemical sector, with ongoing research exploring new catalytic applications.

The automotive segment accounted for the largest market share in 2024.

- The automotive segment is driven due to the metal's ability to enhance the properties of steel and alloys used in vehicle manufacturing.

- Vanadium is a key component in high-strength low-alloy steels and advanced high-strength steels, which are increasingly utilized in car bodies and chassis for lightweighting, improved fuel efficiency, and enhanced safety through better crash resistance.

- It is also used in critical components such as crankshafts, connecting rods, gears, axles, and suspension springs. The increasing popularity of electric vehicles (EVs) is leading to increased manufacturing in the sector, thus driving vanadium-containing steels.

- For instance, German Association of the Automotive Industry, the production of electric cars in Germany increased by 7%, when compared to the previous year.

- Overall, the increased automotive manufacturing is driving the segment in the vanadium industry.

The energy segment is expected to grow at the fastest CAGR over the forecast period.

- The energy sector is emerging in the market. The significance of the market trends in the energy sector is rapidly growing due to its crucial role in VRFBs.

- VRFBs effectively address the intermittency of renewable sources such as solar and wind, ensuring grid stability by storing excess energy and releasing it when needed.

- Their importance lies in their ability to mitigate the intermittency of solar and wind power, stabilize the electricity grid, and offer a sustainable and safer energy storage solution due to vanadium's abundance and electrolyte recyclability.

- Growing environmental concerns about pollution and climate change, coupled with the long-term economic benefits of stable energy prices and energy independence create potential for the segment.

- Thus, according to market analysis, the expanding investment in the energy sector will drive segmental growth for the forecasted years.

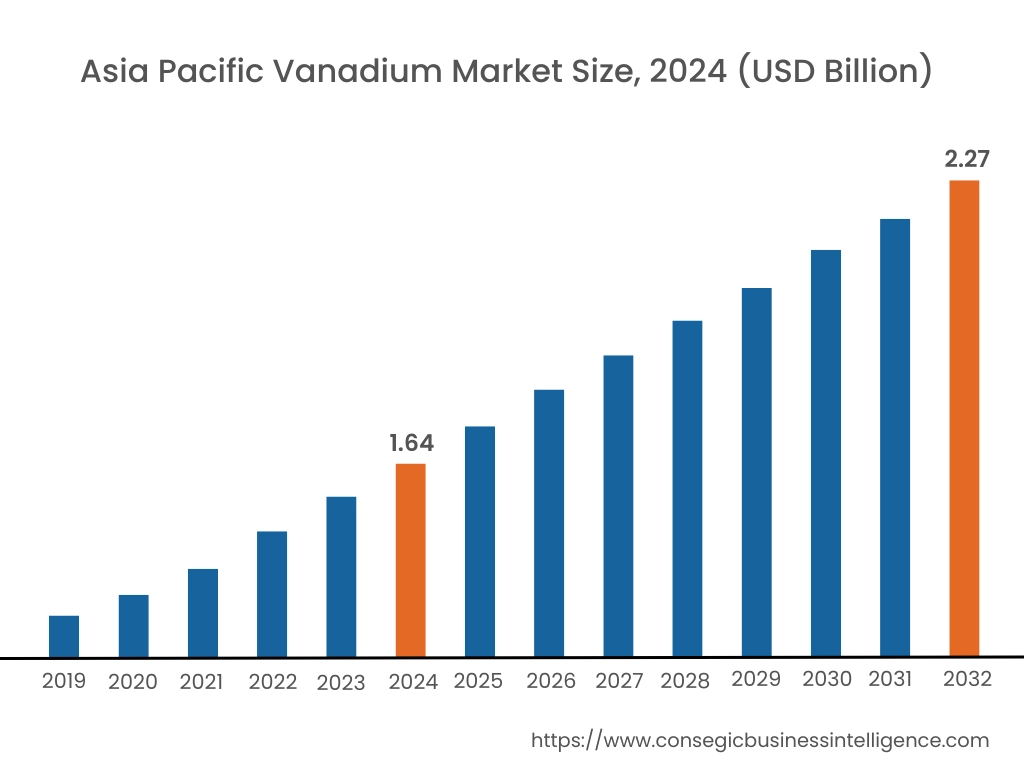

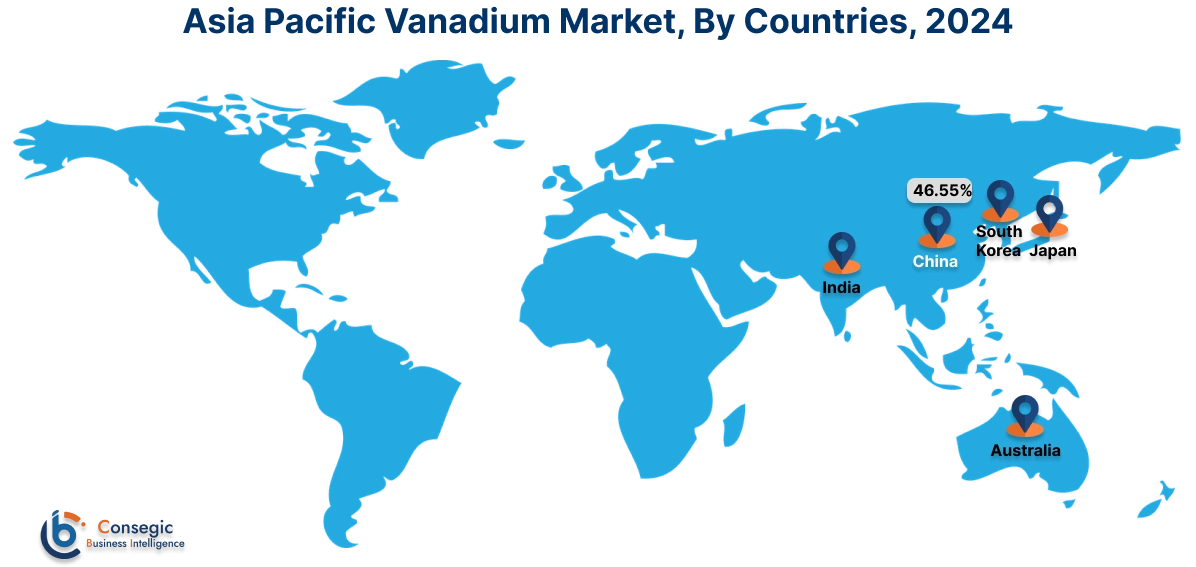

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, Asia Pacific accounted for the highest vanadium market share at 65.78% and was valued at USD 1.64 Billion and is expected to reach USD 2.27 Billion in 2032. In Asia Pacific, the China accounted for the vanadium market share of 46.55% during the base year of 2024. In the region, the strong and continuously growing steel production is a primary driver for the market. Rapid industrialization and massive infrastructure development projects across the region, particularly in China and India, necessitate enormous volumes of steel for construction (buildings, bridges, roads), transportation (automotive, railways), and manufacturing.

For instance,

- According to the Ministry of Steel, India's crude steel output reached 128.15 million tons during 2023, demonstrating a year-on-year growth of 12.1%.

This metal plays a crucial role as a strengthening agent in steel, even in small quantities, making it indispensable for meeting the high-performance requirements of these expanding sectors. Thus, expanding the steel sector is driving the market in the region.

In Europe, the vanadium market is experiencing the fastest growth with a CAGR of 6.8% over the forecast period. The surging need for vanadium redox flow batteries is a significant driver for the market. The region’s ambitious renewable energy targets for 2030 and beyond necessitate robust grid-scale energy storage solutions to integrate intermittent solar and wind power effectively. Several European countries are actively investing in and deploying VRFB technology due to its long lifespan, scalability, and safety advantages over other battery types. Government initiatives incentivize the adoption of VRFBs to enhance grid stability, reduce reliance on fossil fuels, and achieve climate neutrality.

North America vanadium market analysis indicates that several key trends are contributing to its growth in the region. The increasing need for high-performance, lightweight, and temperature-resistant alloys within the aerospace sector is a significant driver for the market in the region. Alloys, such as Ti-6Al-4V, are extensively used in critical aircraft parts such as engine turbines, airframes, and landing gear due to their exceptional strength-to-weight ratio and ability to withstand high operating temperatures. The continuous advancements in aircraft design and the ongoing requirements for more fuel-efficient and durable aircraft are fueling the need for these advanced alloys.

Middle East and Africa (MEA) region, the increase of chemical catalysis applications is a notable driver for the market. Ongoing research and development are continuously identifying new and improved applications for vanadium-based catalysts across various chemical processes. This includes the production of key chemicals such as sulfuric acid, as well as the synthesis of polymers and other industrial chemicals. The metal’s versatility and effectiveness in various oxidation and other reactions make it an attractive option for these expanding chemical manufacturing activities.

Latin America market presents a lucrative opportunity for the market. There is a growing recognition of the significant advantages offered by VRFBs for energy storage. Their long lifespan, inherent safety, scalability, and recyclability are increasingly appealing as the region explores solutions for grid stabilization and integrating renewable energy sources. Moreover, the implementation and enforcement of stringent building codes and infrastructure standards across Latin American countries are contributing to increased metal usage in the steel sector.

Top Key Players and Market Share Insights:

The Vanadium market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Vanadium market. Key players in The Vanadium industry include-

- Ansteel Group Corporation (China)

- Glencore (Switzerland)

- Stanford Advanced Materials (U.S.)

- Czech Vanadium, A.S. (Czechia)

- AMG Vanadium (U.S.)

- Vanadium Holding Company LLC (U.S.)

- GfE Gesellschaft für Elektrometallurgie mbH (Germany)

- American Elements (U.S.)

- Advanced Engineering Materials (China)

- Lorad (U.S.)

Vanadium Market Report Insights:

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 3.61 Billion |

| CAGR (2025-2032) | 4.8% |

| By Product Type |

|

| By Application |

|

| By End-Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Vanadium market? +

In 2024, the Vanadium market is USD 2.49 Billion.

Which is the fastest-growing region in the Vanadium market? +

Europe is the fastest-growing region in the Vanadium market.

What specific segmentation details are covered in the Vanadium market? +

Product Type, Application, and End-Use segmentation details are covered in the Vanadium market.

Who are the major players in the Vanadium market? +

Ansteel Group Corporation (China), Glencore (Switzerland), Vanadium Holding Company LLC (U.S.), GfE Gesellschaft für Elektrometallurgie mbH (Germany), and American Elements (U.S.) are some major players in the market.