- Summary

- Table Of Content

- Methodology

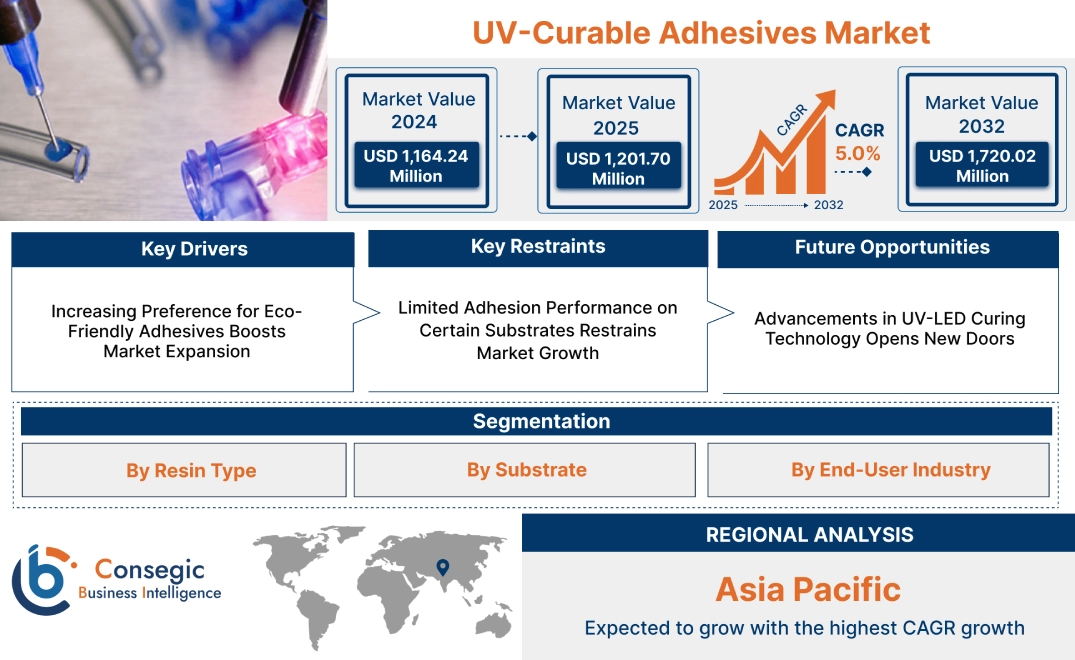

UV-Curable Adhesives Market Size:

UV-Curable Adhesives Market size is estimated to reach over USD 1,720.02 Million by 2032 from a value of USD 1,164.24 Million in 2024 and is projected to grow by USD 1,201.70 Million in 2025, growing at a CAGR of 5.0% from 2025 to 2032.

UV-Curable Adhesives Market Scope & Overview:

The adhesives are used to cure rapidly upon exposure to ultraviolet (UV) light, offering superior bonding strength and versatility across various substrates. These adhesives, composed of oligomers, monomers, and photoinitiators, are widely used in applications requiring precise and fast bonding. Key characteristics include their high transparency, low shrinkage, excellent thermal resistance, and suitability for complex geometries. Its benefits are reduced processing time, enhanced product quality, and eco-friendliness due to the absence of solvents. Applications span electronics assembly, medical devices, optical bonding, and packaging, where strong, reliable, and quick-curing adhesives are critical. The end-use industries include electronics, healthcare, automotive, and aerospace, driven by increasing advancement for efficient assembly solutions and advancements in UV curing technologies.

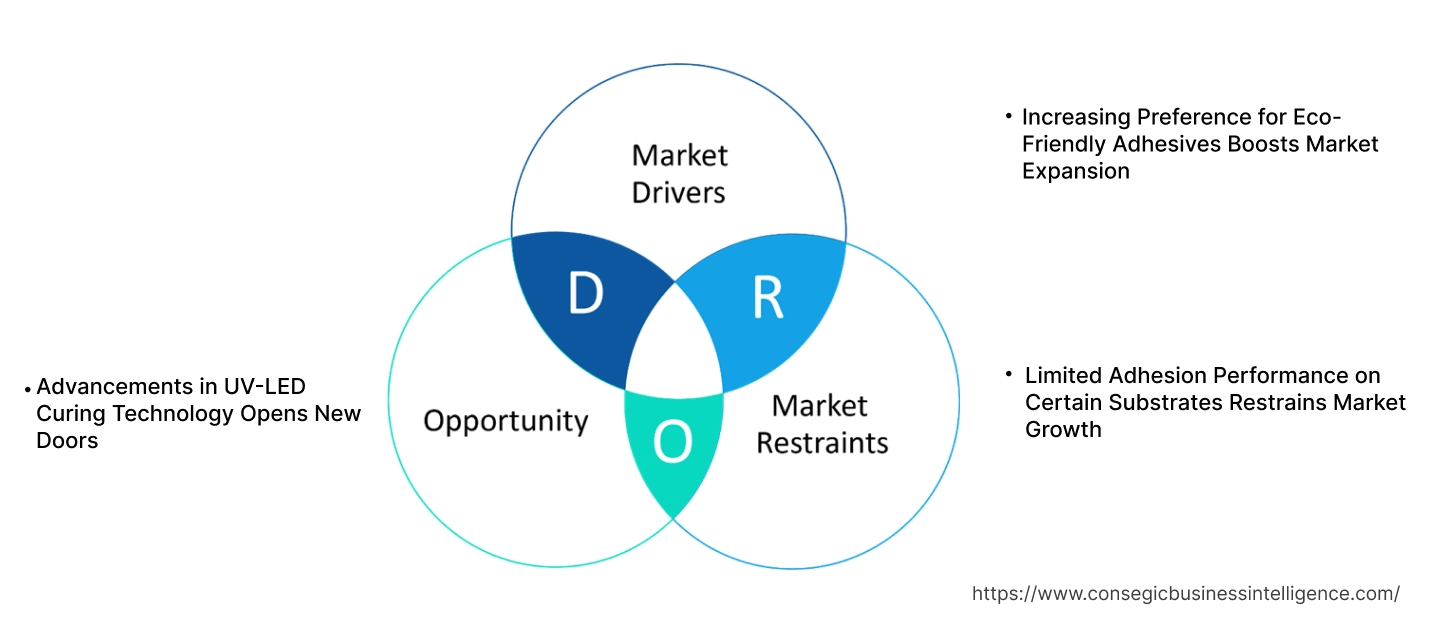

Key Drivers:

Increasing Preference for Eco-Friendly Adhesives Boosts Market Expansion

The rising demand for eco-friendly adhesives is driving UV-curable adhesives market expansion, as these products align with global sustainability goals and stringent environmental regulations. Unlike solvent-based adhesives, these are solvent-free and do not emit volatile organic compounds (VOCs) during the curing process, reducing their environmental impact. This characteristic makes them an ideal choice for industries seeking sustainable manufacturing practices, such as electronics, automotive, and medical device manufacturing.

Additionally, regulatory frameworks like the European Union’s REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and the U.S. EPA’s Clean Air Act are encouraging the adoption of adhesives with reduced environmental footprints. Manufacturers are also investing in research and development to improve the bio-based content of adhesives, further enhancing their appeal as green alternatives. The increasing consumer and industrial focus on eco-friendly products is expected to fuel the trends for UV-curable, positioning them as a preferred solution in multiple applications.

Key Restraints:

Limited Adhesion Performance on Certain Substrates Restrains Market Growth

One of the key challenges for the UV-curable adhesives market expansion is their limited adhesion performance on certain substrates, particularly opaque or UV-blocking materials. UV-curable rely on the penetration of UV light for effective curing. Substrates that absorb or reflect UV light, such as metals, ceramics, or heavily pigmented plastics, can impede the curing process, leading to incomplete bonding and reduced strength.

This limitation restricts the use of UV-curable adhesives in industries that require bonding on challenging materials. Manufacturers often need to combine it with other bonding techniques or modify the substrate surface, increasing the complexity and cost of the application process. Addressing this issue requires further innovation in adhesive formulations and curing technologies to enable effective performance on a broader range of substrates. Without such advancements, the may face growth constraints in applications where alternative adhesives offer superior performance.

Future Opportunities:

Advancements in UV-LED Curing Technology Opens New Doors

Advancements in UV-LED curing technology are bolstering the UV-curable adhesives market growth by enhancing the efficiency and sustainability of the curing process. Unlike traditional mercury-based lamps, UV-LED systems offer longer operational lifespans, energy efficiency, and reduced heat output, making them suitable for heat-sensitive substrates and precision applications. These systems also eliminate the use of hazardous mercury, aligning with environmental regulations such as the Minamata Convention on Mercury.

The development of UV-LED systems with variable wavelength capabilities further expands the range of applications for UV-curable adhesives, enabling effective curing on materials that were previously challenging. Additionally, the compact size and portability of UV-LED curing systems allow manufacturers to integrate them seamlessly into production lines, improving process efficiency and reducing downtime.

The increasing adoption of UV-LED technology is expected to drive innovation in adhesive formulations, as manufacturers develop products optimized for LED curing. This trend is creating new opportunities for the market across industries, including electronics, automotive, and packaging, where precision and sustainability are key priorities.

UV-Curable Adhesives Market Segmental Analysis:

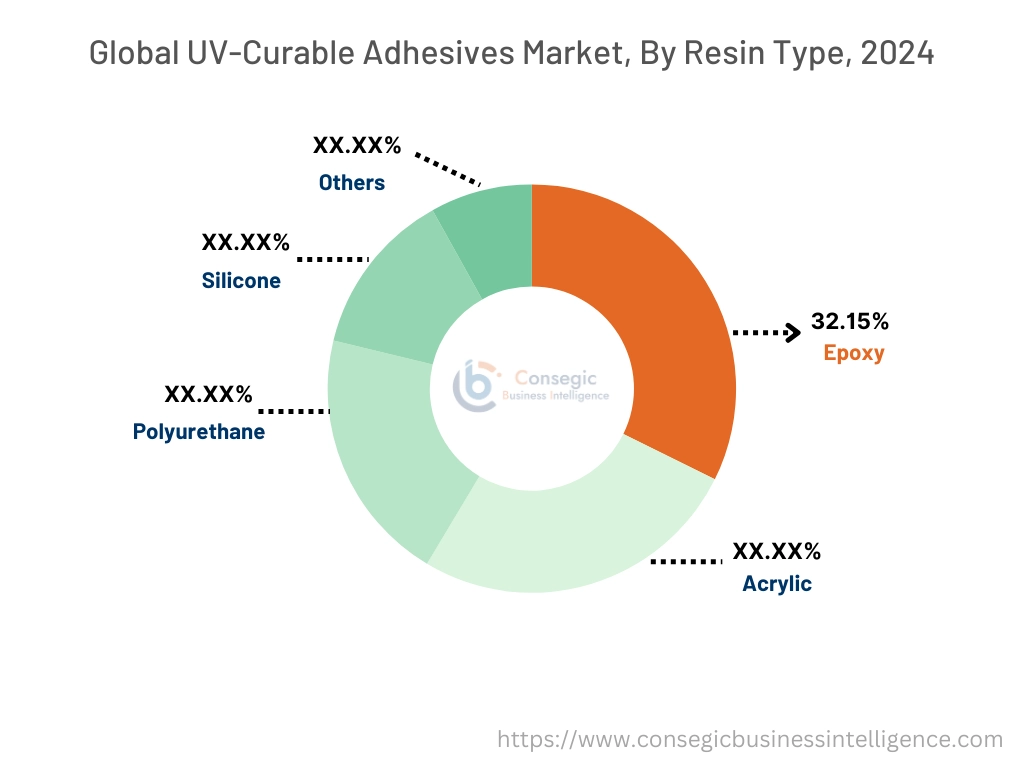

By Resin Type:

Based on resin type, the market is segmented into epoxy, acrylic, polyurethane, silicone, and others.

The epoxy segment accounted for the largest revenue in UV-curable adhesives market share of 32.15% in 2024.

- Epoxy-based adhesives are widely used due to their superior mechanical strength, chemical resistance, and excellent adhesion properties.

- These adhesives are ideal for applications requiring high durability and precision, such as in electronics, automotive, and aerospace industries.

- The appeal for epoxy adhesives is driven by their ability to provide high-performance bonding in extreme environments, including high temperature and chemical exposure.

- Additionally, advancements in epoxy formulations, such as fast-curing variants, are further enhancing their adoption across industries.

- Thus, epoxy adhesives analysis leads the UV-curable adhesive market trend, driven by their superior performance characteristics and extensive use in high-demand industries like electronics and automotive.

The acrylic segment is anticipated to register the fastest CAGR during the forecast period.

- Acrylic-based adhesives are gaining popularity due to their rapid curing times, flexibility, and strong bonding capabilities on various substrates, including plastics and metals.

- These adhesives are particularly favored in medical device manufacturing and packaging applications, where fast processing and reliable adhesion are critical.

- The increasing focus on sustainable solutions has also led to the development of low-VOC acrylic adhesives, aligning with stringent environmental regulations.

- Hence, acrylic adhesives are expected to grow rapidly, supported by their versatility, fast curing times, the UV-curable adhesive market analysis shows there is rise in growing adoption in medical and packaging applications.

By Substrate:

Based on substrate, the market is segmented into glass, plastic, metal, wood, and others.

The glass segment accounted for the largest revenue share in 2024.

- Glass substrates require high-performance adhesives for applications in industries such as electronics, medical devices, and automotive.

- UV-curable adhesives are preferred for bonding glass due to their transparency, UV resistance, and strong adhesion.

- These adhesives are widely used in optical devices, displays, and decorative glass applications.

- The increasing adoption of UV-curable adhesives in the production of smartphones, automotive displays, and medical equipment supports the advancement of this segment.

- As per the UV-curable adhesives market analysis, the growing use of the product in high-precision optical and electronic applications is driving the glass segment.

The plastic segment is anticipated to register the fastest CAGR during the forecast period.

- Plastics are extensively used in industries like electronics, automotive, and packaging, requiring adhesives that offer strong bonding and compatibility with various plastic materials.

- They meet these requirements with rapid curing, flexibility, and the ability to bond diverse plastic types, including polycarbonate and ABS.

- The increasing trends for lightweight materials in automotive and electronics, combined with the need for eco-friendly adhesive solutions, is driving the UV-curable adhesives market growth of this segment.

- Therefore, the analysis shows plastic substrates are expected to grow rapidly, fueled by their widespread use in lightweight materials and the versatility of UV-curables for plastic bonding.

By End-User Industry:

Based on end-user industry, the market is segmented into healthcare, electronics & semiconductors, automotive, packaging, construction, and others.

The electronics & semiconductors segment accounted for the largest UV-curable adhesives market share in 2024.

- They are integral to the electronics and semiconductor industries, where they are used for bonding, encapsulating, and sealing delicate components.

- These adhesives provide precision bonding, thermal resistance, and excellent electrical insulation properties, making them ideal for applications in circuit boards, sensors, and display assemblies.

- The growing techniques for miniaturized electronic devices and advancements in semiconductor technology are driving its adoption.

- Therefore, electronics & semiconductors dominate the UV-curable adhesives market trends, driven by increasing applications for precision bonding solutions in advanced electronic devices and semiconductor components.

The healthcare segment is anticipated to register the fastest CAGR during the forecast period.

- In the healthcare industry, UV-curable adhesives are widely used in medical device manufacturing, including syringes, catheters, and surgical instruments.

- Their biocompatibility, fast curing, and ability to bond diverse materials make them indispensable in this sector.

- The rising applications for disposable medical devices and advancements in healthcare technologies are fueling rise in this segment.

- Furthermore, stringent regulatory requirements for safe and reliable bonding solutions in medical devices are driving its adoption.

- The healthcare segment is expected to grow rapidly, supported by the increasing trends for disposable medical devices and advancements in healthcare technologies requiring reliable adhesive solutions.

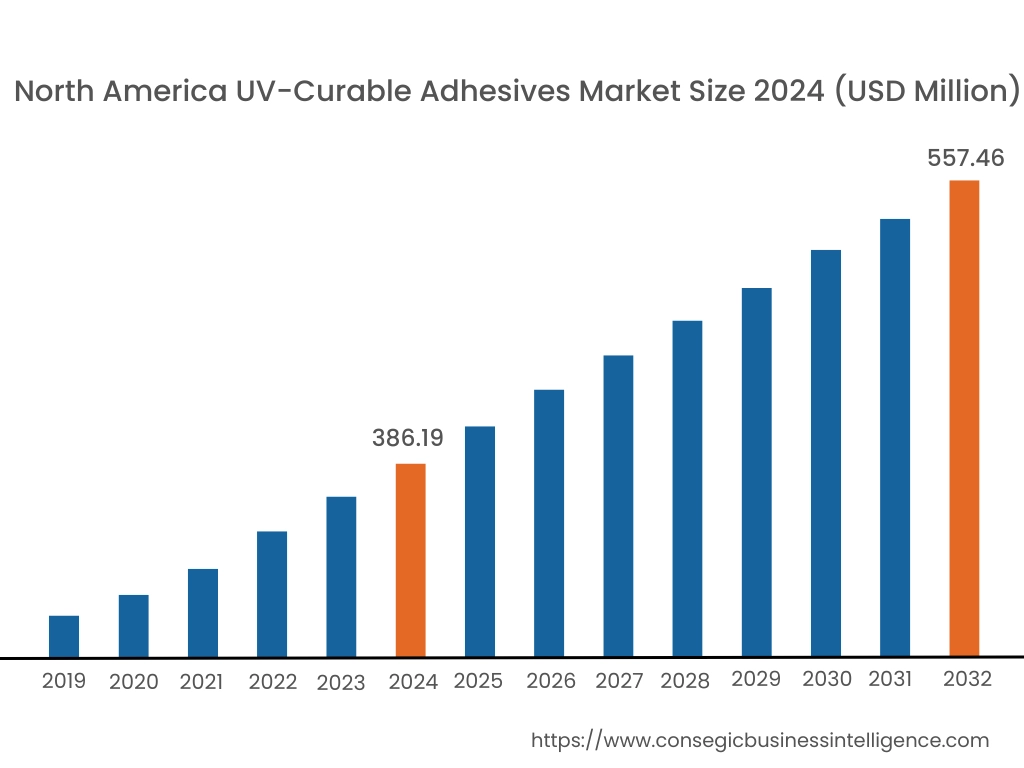

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, North America was valued at USD 386.19 Million and is expected to reach USD 557.46 Million in 2032. In North America, the U.S. accounted for the highest share of 71.60% during the base year of 2024.

North America dominates the UV-curable adhesives industry, driven by strong demand from the electronics, medical, and automotive sectors. The U.S. leads the region, with extensive adoption in electronic device assembly, where fast curing times and high precision are critical. Medical device companies also heavily utilizes these adhesives for bonding applications in disposable medical products. Canada’s market is growing steadily, driven by its expanding packaging and construction sectors. However, challenges such as the high cost of advanced UV-curable adhesives and stringent environmental regulations regarding VOC emissions remain significant.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 5.4% over the forecast period. As per the analysis, Asia-Pacific is the fastest-growing region, driven by rapid industrialization and increasing UV-curable adhesives market opportunities from electronics, automotive, and construction sectors in countries like China, Japan, and South Korea. China is the largest contributor, with its thriving electronics manufacturing sector and growing emphasis on environmentally friendly adhesive solutions. Japan’s advanced automotive and electronics industries are fueling UV-curable adhesives market demand for high-performance, particularly for precision bonding applications. In India, the market is expanding due to the rapid development of the packaging and construction industries. However, the region faces challenges related to limited awareness of advanced UV-curing technologies and higher initial investment costs.

The UV-curable adhesives market analysis of the European region shows a robust demand from industries such as automotive, packaging, and aerospace. Germany leads the region, leveraging its strong automotive manufacturing base, where they are extensively used for lightweight assembly and bonding. The UK and France are key contributors, driven by the growing use of adhesives in sustainable packaging solutions and electronics manufacturing. Additionally, the region’s focus on environmentally friendly adhesives, in compliance with stringent EU regulations, is fostering innovation in low-VOC and solvent-free UV-curable adhesives. However, high energy costs associated with UV curing systems pose challenges for wider adoption.

The Middle East & Africa region is witnessing steady advancement in UV-curable adhesives market opportunities, primarily driven by increasing investments in construction and infrastructure projects in the UAE and Saudi Arabia. The UV-curable adhesives market demand in the construction sector is growing due to their fast curing properties and strong bonding capabilities, making them ideal for architectural applications. In Africa, South Africa is a key market, with rising adoption in automotive repairs and maintenance applications. However, the region faces challenges such as limited local production capabilities and reliance on imported adhesives, which can affect cost competitiveness.

Latin America is an emerging market for UV-curable adhesives, with Brazil and Mexico leading the UV-curable adhesives market trends. The region’s demand is fueled by increasing adoption in the packaging and automotive sectors, particularly for lightweight bonding solutions. Brazil’s growing focus on sustainable packaging materials is driving its use in food and beverage packaging applications. Mexico’s expanding electronics manufacturing sector is also contributing to market growth. However, the region faces challenges such as economic instability and limited access to advanced curing technologies, which can hinder its broader adoption.

Top Key Players and Market Share Insights:

The UV-curable adhesives market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global UV-curable adhesives market. Key players in the UV-curable adhesives industry include -

- Henkel AG & Co. KGaA (Germany)

- B. Fuller Company (United States)

- 3M Company (United States)

- Sika AG (Switzerland)

- Dymax Corporation (United States)

- DELO Industrie Klebstoffe GmbH & Co. KGaA (Germany)

- Master Bond Inc. (United States)

- Permabond LLC (United States)

- Panacol-Elosol GmbH (Germany)

- Epoxy Technology (Meridian Adhesives Group LLC) (United States)

UV-Curable Adhesives Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | 1,720.02 Million |

| CAGR (2025-2032) | 5.0% |

| By Resin Type |

|

| By Substrate |

|

| By End-User Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the projected growth rate of the market? +

UV-Curable Adhesives Market size is estimated to reach over USD 1,720.02 Million by 2032 from a value of USD 1,164.24 Million in 2024 and is projected to grow by USD 1,201.70 Million in 2025, growing at a CAGR of 5.0% from 2025 to 2032.

How does the automotive industry use UV-curable adhesives? +

They are used in bonding sensors, displays, and other components, ensuring durability and reliability.

Which region dominates the UV-curable adhesives market? +

North America leads due to advancements in industrial applications and the adoption of green technologies.

What are the advantages of UV-curable adhesives? +

They offer fast curing, low environmental impact, and strong bonds on various substrates like glass, metal, and plastic.

What is driving the growth of the UV-curable adhesives market? +

Growing demand for eco-friendly adhesives and their application in advanced electronics and medical devices.