- Summary

- Table Of Content

- Methodology

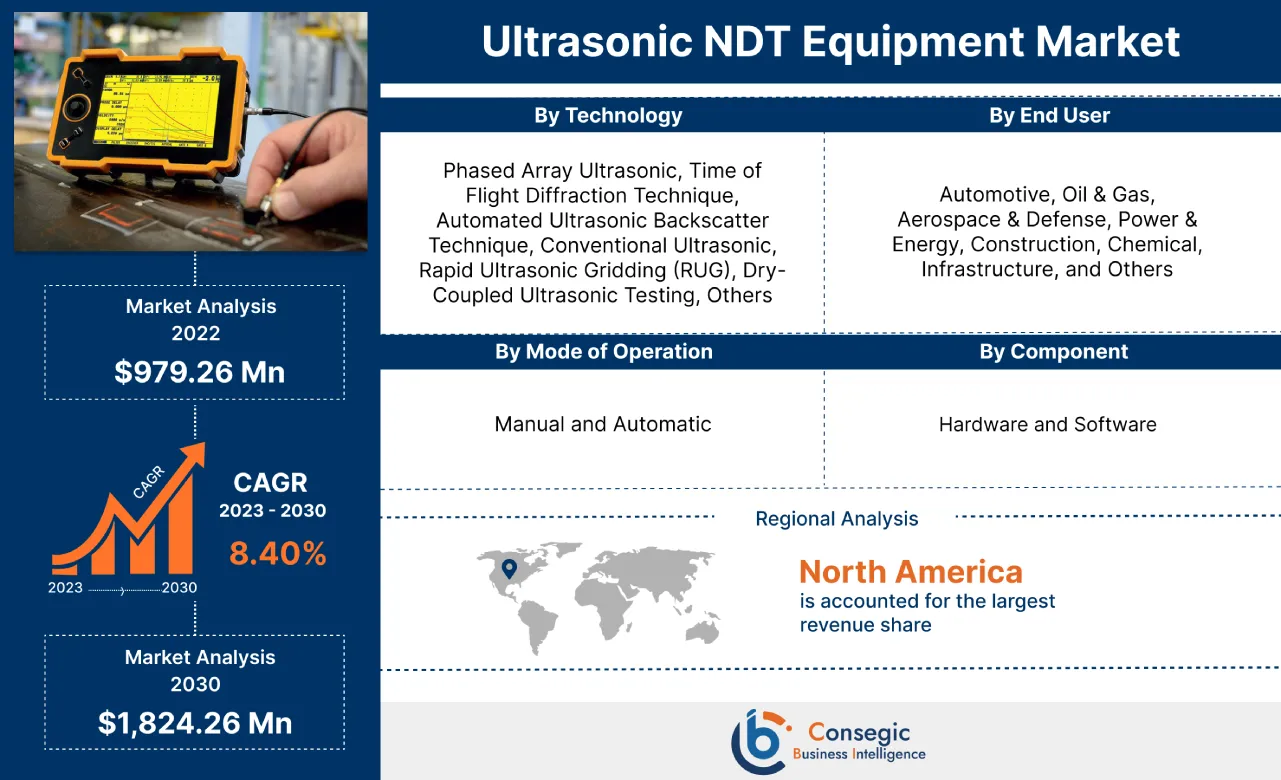

Ultrasonic NDT Equipment Market Size :

Ultrasonic NDT Equipment Market size is estimated to reach over USD 1,824.26 Million by 2030 from a value of USD 979.26 Million in 2022, growing at a CAGR of 8.40% from 2023 to 2030.

Ultrasonic NDT Equipment Market Scope & Overview:

NDT is known for nondestructive testing and is a technology used to identify defects and cracks in specimen including materials manufactured from plastic, metal, composite, and ceramic. Moreover, ultrasonic nondestructive testing is one of the NDT techniques employed by user through means of emitting pulse of ultrasonic on the object to detect flaw and identify it on a display. Ultrasonic NDT technology includes several technologies including phased array ultrasonic, time of flight diffraction technique, automated ultrasonic backscatter technique, among others. Among one of its types of technology, time of flight diffraction technique utilizes ultrasonic to transit pulse between the probe and flaw extremities to identify the defect by means of measuring the time. Furthermore, owing to accuracy, ultrasonic NDT equipment are popular testing devices being utilized in end use industries including oil and gas, energy and power, among others.

Ultrasonic NDT Equipment Market Insights :

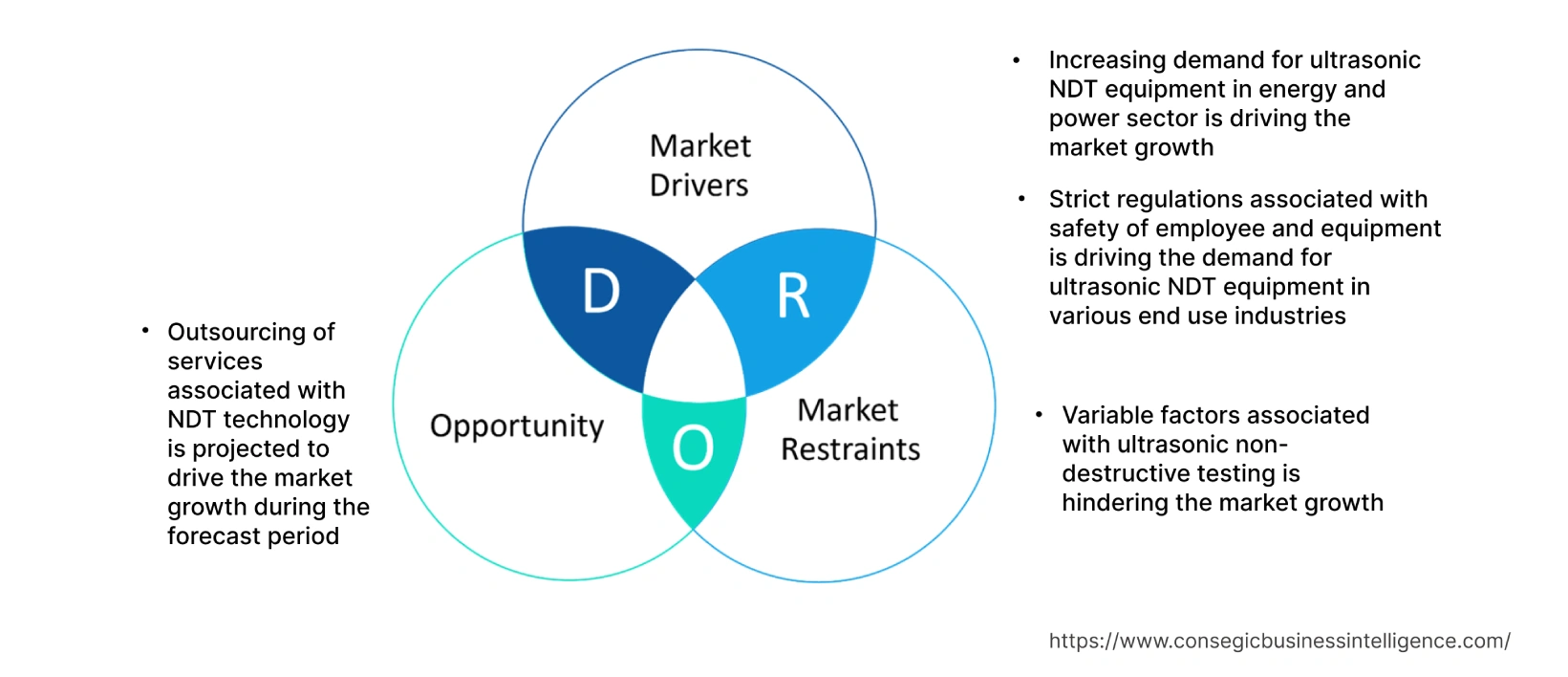

Key Drivers :

Increasing demand for ultrasonic NDT equipment in energy and power sector is driving the market

Ultrasonic NDT equipment's are increasingly employed in non-conventional energy sector including solar energy, hydroelectric, and wind energy. Non-conventional source of energy is mainly referred to generation of energy obtained from other than fossil fuels and nuclear source. The factors contributing towards the extensive application of non-conventional source of energy are due to depletion of natural resources and rise in carbon emission. Based on the analysis, non-destructive testing (NDT) method is mainly employed to analyze the nature of components and materials without compromising with the structure or installations.

In the field of solar energy, certain equipment including solar panels, inverters, meter, electrical panels, and solar grids are playing an important role in energy generation. Accordingly, these installations need to be carefully maintained owing to their sensitive nature and require regular inspection which is generally performed by NDT technique.

In a similar instance, hydroelectric installations also require regular maintenance and operational lookout for their proper functioning. Ultrasonic NDT is mainly used in the inspection of critical infrastructure including blades of hydroelectric turbines. Ultrasonic testing method employes high frequency ultrasonic waves to identify any flaws and defects that could potentially harm the equipment. Moreover, ultrasonic NDT plays a crucial role in protecting the equipment from breakdown thus driving ultrasonic NDT equipment industry.

For instance, Doppler Electronic Technologies Co., Ltd. has been providing software through phased array ultrasonic detection technology in conjunction with chrysanthemum-ring array probe and special phased array detector for identification of flaws in turbine blades. Thus, the increasing demand of this equipment is driving the market trend.

Strict regulations associated with safety of employee and equipment is driving the demand for ultrasonic NDT equipment in various end use industries

Critical infrastructure is needed constant monitoring during their working conditions and requires proper maintenance. The environment in which these infrastructures are installed is hazardous in nature and poses risk of life and property. In addition, environmental hazards are dynamic in nature and the risks changes in varied locations. Moreover, NDT testing done for infrastructure poses risks including electrical, gaseous, among others. Therefore, as per the analysis, certain regulatory measures need to be taken care of during hazard analysis that would prevent any mishaps. For instance, code includes National Fire Protection Association 70, National Electrical Code regulates the safety standards for safe electrical design, installation, and inspection to protect risk to life and property.

Accordingly, in order to prevent any critical conditions which, account to impact the health and safety of employee leads to the rise in demand for NDT, ultimately propelling the demand for ultrasonic NDT equipment.

Key Restraints :

Variable factors associated with ultrasonic non-destructive testing is hindering the market

Ultrasonic non-destructive testing is one of testing technique employed by end use industry to prevent losses, however, is an expensive method of testing in comparison to other non-destructive testing types. There are variable factors that impact the testing efficiency of the equipment that include irregular shape of the material, inaccessible surface, thickness of the material, among others. Moreover, unavailability of skilled labor owing to extensive nature of testing is restraining the market trends.

Future Opportunities :

Outsourcing of services associated with NDT technology is projected to drive the market growth during the forecast period

Ultrasonic non-destructive technique is an expensive method and requires procurement of machinery and employing of employee. Apart from aforementioned factors, constant technological upgrades and skills improvement lead to an additional cost for the company thus increasing the operational cost. Therefore, sectors are increasingly moving towards adoption of outsourcing software for testing in order to avoid aforementioned costings.

Moreover, outsourcing software offered by service providers includes quality control, support to production process, plant maintenance, scheduled shutdown inspections, among others.

For instance, Intertek Group plc is offering software for non-destructive testing to end use industries including oil and gas, energy, construction, among others. The software offered by such firms includes material testing, welding software, specialist NDT software, and non-destructive consulting. Accordingly, owing to growing demand for regular maintenance at lower operational cost is projected to drive the ultrasonic NDT equipment market opportunities and trends in the coming years.

Ultrasonic NDT Equipment Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2017-2030 |

| Market Size in 2030 | USD 1,824.26 Million |

| CAGR (2023-2030) | 8.40% |

| By Component | Hardware and Software |

| By Mode of Operation | Manual and Automatic |

| By Technology | Phased Array Ultrasonic, Time of Flight Diffraction Technique, Automated Ultrasonic Backscatter Technique, Conventional Ultrasonic, Rapid Ultrasonic Gridding (RUG), Dry-Coupled Ultrasonic Testing, Others |

| By End Use | Automotive, Oil & Gas, Aerospace & Defense, Power & Energy, Construction, Chemical, Infrastructure, and Others |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | Nanjing BKN Automation System Co., LTD., Magnetic Analysis Corporation, Unique Group, EVIDENT, Modsonic Instruments Mfg. Co. (P) Ltd., Instrumart, Honesdom International (HK) Limited, OKOndt GROUP, TWI Ltd., Baker Hughes Company, Sonatest, and Aimil Ltd. |

| Geographies Covered | |

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage | Revenue Forecast, Competitive Landscape, Growth Factors, Restraint or Challenges, Opportunities, Environment & Regulatory Landscape, PESTLE Analysis, PORTER Analysis, Key Technology Landscape, Value Chain Analysis, Cost Analysis, and Regional Trends & Forecast |

Ultrasonic NDT Equipment Market Segmental Analysis :

By Component :

Based on the component, the market is bifurcated into hardware and software. The hardware segment is accounted for the largest revenue share in the year 2022. Hardware ultrasonic NDT equipment mainly include ultrasonic pulser and receiver. Ultrasonic detectors are designed for efficient handling and are gradually decreasing in size thus providing efficient handling ability to the user. Moreover, handheld devices are available in small and portable size thus providing greater affordability and accessibility to the operator, which tends to be driving the hardware segment.

For instance, Waygate Technologies has launched Krautkrämer RotoArray compact, a manual operating based portable roller probe, employes manual phased array (PA) ultrasonic inspection technique for inspection of large-scale composite materials.

Moreover, software segment is also anticipated to grow at the fastest rate during the forecast period. Software is considered as key operating part of the instrument. Software installed in the ultrasonic NDT equipment is programmed to interpret the returning wave from specimen to generate image or wave signals in the oscilloscope. Therefore, based on the analysis, software reduces the effort to manually interpret the obtained data and allows the operator to easily understand the obtained data in a more efficient manner. For instance, Zetec, Inc. is offering software to end users by means of offering varied software, namely ULTRAVISION3 and ULTRAVISION TOUCH. Thus, the aforementioned factors are propelling the ultrasonic NDT equipment market trends.

By Mode of Operation :

Based on the mode of operation, the market is segmented into manual and automatic. Manual segment is accounted to generate largest market share in the year 2022. Manual mode of operation is important for the area where high precision and accuracy is required. Moreover, manual mode of operation is considered effective in detection of material integrity, volumetric flaws and component thickness. Aforementioned type of testing is preferred on forging, castings, welded components, and composite structure across various industries. The key attributable factors that drive the expansion of the segment include its application in flaw detection such as porosity, cracks, determining the thickness of test objects, among others. Moreover, the rising requirement for proficient testing methods for critical infrastructures is compelling the requirement for manual ultrasonic NDT equipment.

Furthermore, automatic segment is anticipated to grow at the fastest expansion rate during the forecast period. Owing to increasing requirement for automation involved with application of advanced software and robotics is promoting the expansion of automatic segment. Moreover, with rising complex nature of testing and requirement of non-destructive testing leveled at larger volume is expected to generate opportunities and trends for the segment during the forecast period.

By Technology :

Based on the mode of operation, the market is segregated into phased array ultrasonic, time of flight diffraction technique, automated ultrasonic backscatter technique, conventional ultrasonic, rapid ultrasonic gridding (RUG), dry-coupled ultrasonic testing, others. Phased array ultrasonic segment is accounted to generate largest market share in the year 2022. Factors contributing towards the expansion of the segment include precise control over the ultrasonic beam thus allowing better defect detection and characterization. Technology is commonly employed for applications including corrosion mapping, weld detection, and other critical applications where accurate defect sizing is important.

Rapid Ultrasonic Gridding (RUG) segment is anticipated to grow at the fastest growth rate during the forecast period. RUG inspection type is mainly performed by means of robot thus providing an enhanced image or thickness grid maps for better identification of area having wall thickness. In addition, based on the analysis, RUG is an updated technology, an alternative to hand-held gridding and traditional inspection methods. Furthermore, rise in requirement for inspection of large components is projected to drive the market ultrasonic NDT equipment market growth.

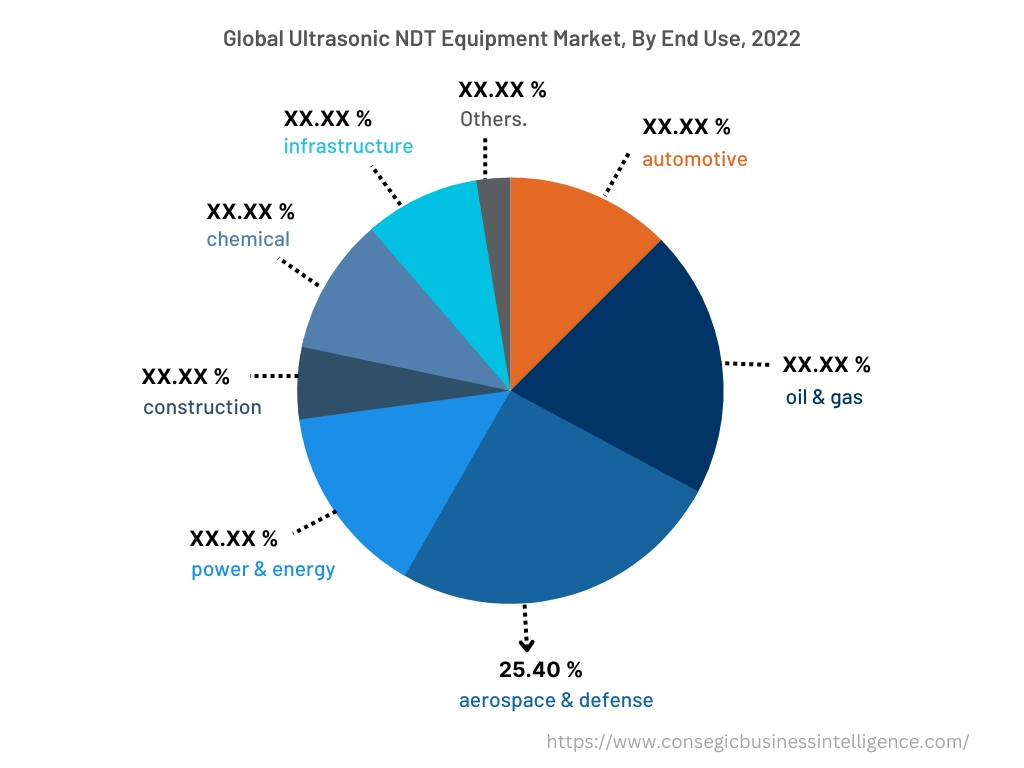

By End-Use :

Based on the end use, the market is segmented into automotive, oil & gas, aerospace & defense, power & energy, construction, chemical, infrastructure, and others. Aerospace & defense segment is accounted to generate largest ultrasonic NDT equipment market share of 25.40% in the year 2022. The key factors attributed to the expansion of the segment owing to increasing importance to manufacture defect free components of aircraft are driving the market. Moreover, the industry is constantly using ultrasonic NDT technology to identify the strength and wear and tear present in the airframe of aircrafts to avoid any accident is further promoting the ultrasonic NDT equipment market demand and trends.

For instance, Raytheon Technologies was accounted to have garnered highest revenue of USD 67.1 billion in the year 2022. Moreover, Airbus has delivered highest numbers of aircrafts that is 611 jets, in the year 2021. Furthermore, the rising requirement for aircrafts at commercial and military level is promoting the market.

Power & energy segment is anticipated to grow at the fastest growth rate during the forecast period. Owing to factors including rising requirement for renewable source of energy and installation of large number of infrastructures including solar, hydro, and wind energy is projected to drive the market. For instance, according to IRENA (International Renewable Energy Agency), the global generation of electricity from PV cells has reached to 179 TWh in 2021, accounting for China with the highest energy generation of 430 GW during the period. Moreover, according to Global Energy Monitor (GEM), China has ambition of generating 1,200 GW of solar capacity by the end of the year 2030 which will propel the want for solar panels in near future. Also, owing to the growing requirement of energy, the demand for testing equipment will also rise for maintenance purposes and will ultimately fuel the trend during the forecast period.

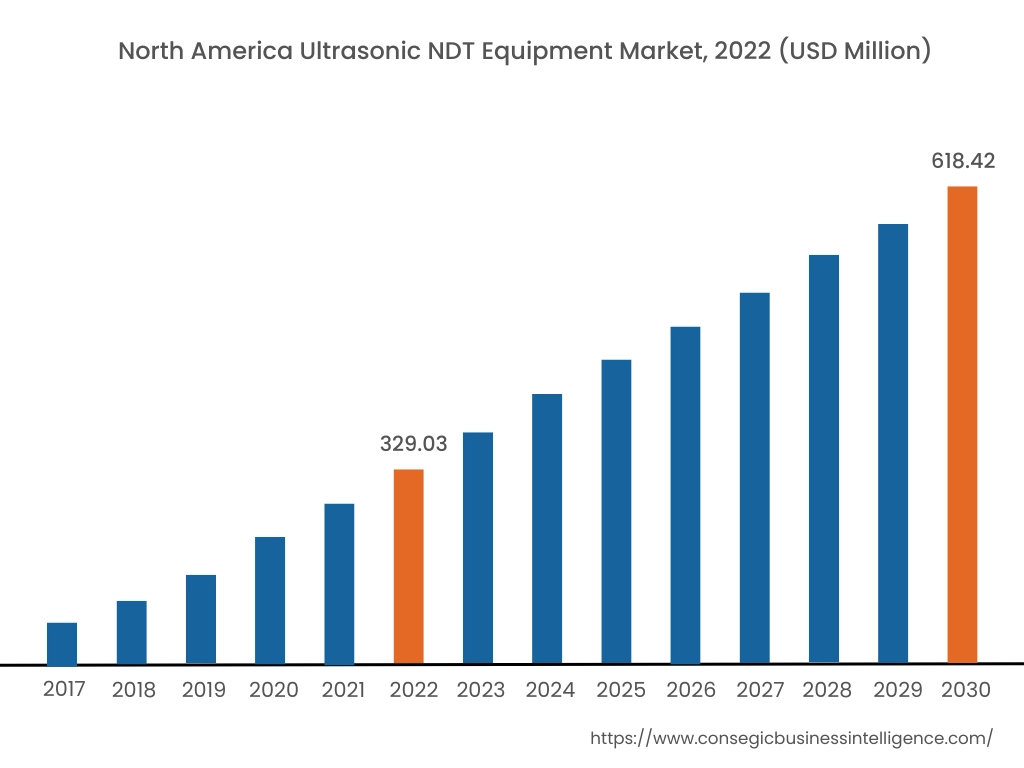

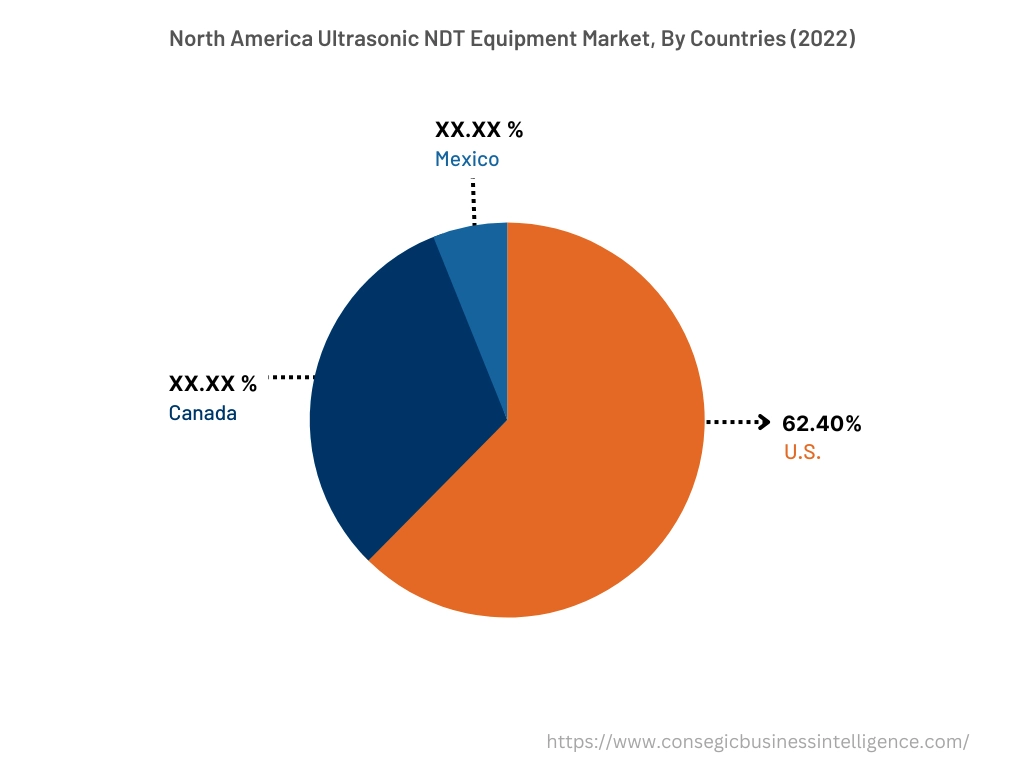

By Region :

The regional segment includes North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

North America is accounted for the largest revenue share of USD 329.03 Million in 2022 and is expected to reach USD 618.42 Million by 2030. In addition, in the region, the U.S. accounted for the maximum revenue share of 62.40% in the same year. As per the ultrasonic NDT equipment market analysis, the adoption of this equipment in North American region is primarily driven by factors including increased requirement for predictive maintenance and flourished oil and gas sector. According to EIA (Energy Information Agency), U.S. had total petroleum consumption of 20.28 million barrels per day in 2021. Moreover, U.S. held largest petroleum consumer ranking of 20.4% globally during same year. Thus, the aforementioned factors are propelling the trends in the coming years.

Moreover, Asia-Pacific is expected to register fastest CAGR growth of 8.8% during the forecast period. Factors attributable to the development of the region during the forecast period are due to faster rate of growth among sectors including energy, oil and gas, construction, among others. Moreover, with the motive of improving industrial infrastructure among Asian countries including India, Vietnam, Malaysia, China, among others will promote the development of the market. Furthermore, growth of renewable energy sector in Asia to empower need of energy for varied sectors will promote the trend of the market.

Top Key Players & Market Share Insights:

The global ultrasonic NDT equipment market is highly competitive with major players providing this equipment to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end use launches to hold a strong position in ultrasonic NDT equipment market. Key players in the ultrasonic NDT equipment market include-

- Nanjing BKN Automation System Co., LTD.

- Magnetic Analysis Corporation

- TWI Ltd.

- Baker Hughes Company

- Sonatest

- Aimil Ltd.

- Unique Group

- EVIDENT

- Modsonic Instruments Mfg. Co. (P) Ltd.

- Instrumart

- Honesdom International (HK) Limited

- OKOndt GROUP

Recent Industry Developments :

- In July 2023, SONOTEC has conducted Ultrasonic testing in nuclear power plants at NDE in Sheffield.

- In April 2022, Honesdom International (HK) Limited launched NDT-KITS.

Key Questions Answered in the Report

What is Ultrasonic NDT Equipment? +

Ultrasonic non-destructive testing is one of the NDT techniques employed by user through means of emitting pulse of ultrasonic on the object to detect flaw and identify it on a display. Ultrasonic NDT technology includes several technologies including phased array ultrasonic, time of flight diffraction technique, automated ultrasonic backscatter technique, among others.

What specific segmentation details are covered in the ultrasonic NDT equipment report, and how is the dominating segment impacting the market growth? +

For instance, by component segment has witnessed hardware as the dominating segment in the year 2022, owing to its increasing demand of testing from industries including energy, oil and gas, and others.

What specific segmentation details are covered in the ultrasonic NDT equipment market report, and how is the fastest segment anticipated to impact the market growth? +

For instance, by end use segment has power and energy segment to grow at the fastest growth rate during the forecast period. The rising demand for renewable source of energy is expected to boost the market growth during the forecast period.

Which region/country is anticipated to witness the highest CAGR during the forecast period, 2023-2030? +

Asia-Pacific is anticipated to register fastest CAGR growth of 8.8% during the forecast period due to rapid pace of industrialization and demand for improved economic infrastructure.