- Summary

- Table Of Content

- Methodology

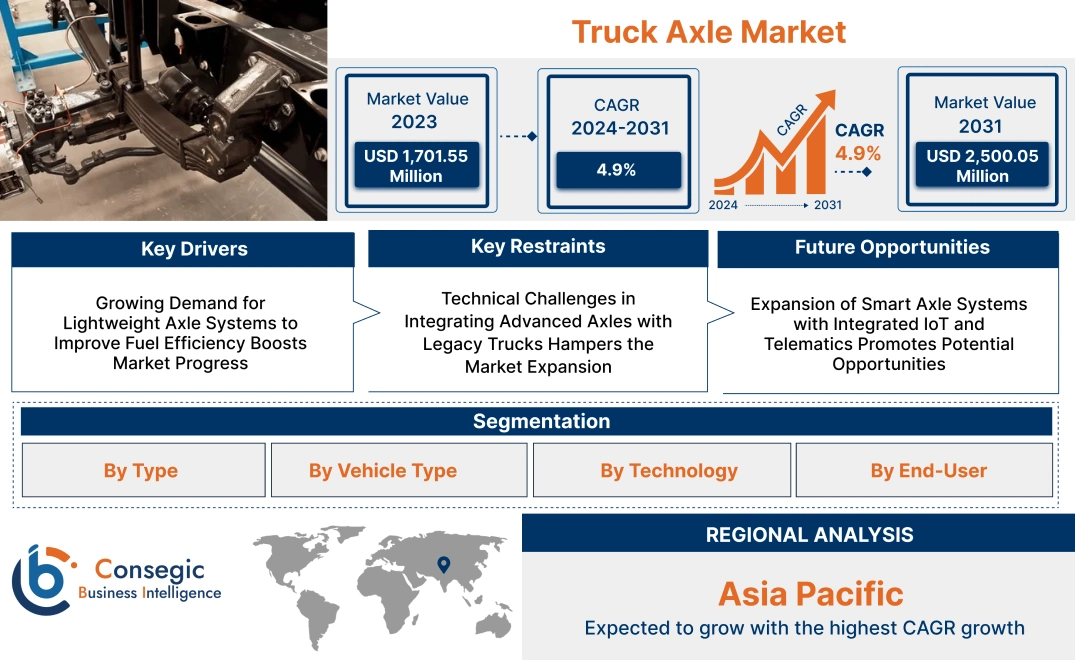

Truck Axle Market Size:

Truck Axle Market size is estimated to reach over USD 2,500.05 Million by 2031 from a value of USD 1,701.55 Million in 2023 and is projected to grow by USD 1,755.08 Million in 2024, growing at a CAGR of 4.9% from 2024 to 2031.

Truck Axle Market Scope & Overview:

A truck axle is a critical mechanical component that supports the weight of the vehicle and its load while facilitating power transmission to the wheels. These axles are designed to endure heavy loads and rough terrains, ensuring optimal vehicle performance and stability. Depending on their function, axles are categorized into drive axles, dead axles, and lift axles, each tailored to specific operational requirements in heavy-duty and commercial vehicles. Truck axles are engineered using high-strength materials to provide durability and efficiency under demanding conditions. Their design incorporates features such as differential mechanisms, axle shafts, and bearings to enhance vehicle performance and maintain balance during operation. Modern axles also integrate advanced technologies for improved load distribution and reduced wear and tear, contributing to extended vehicle lifespan. End-users of truck axles include original equipment manufacturers (OEMs), fleet operators, and aftermarket service providers, all of whom rely on robust axle systems to ensure reliable and efficient vehicle performance in logistics, construction, and other industrial applications.

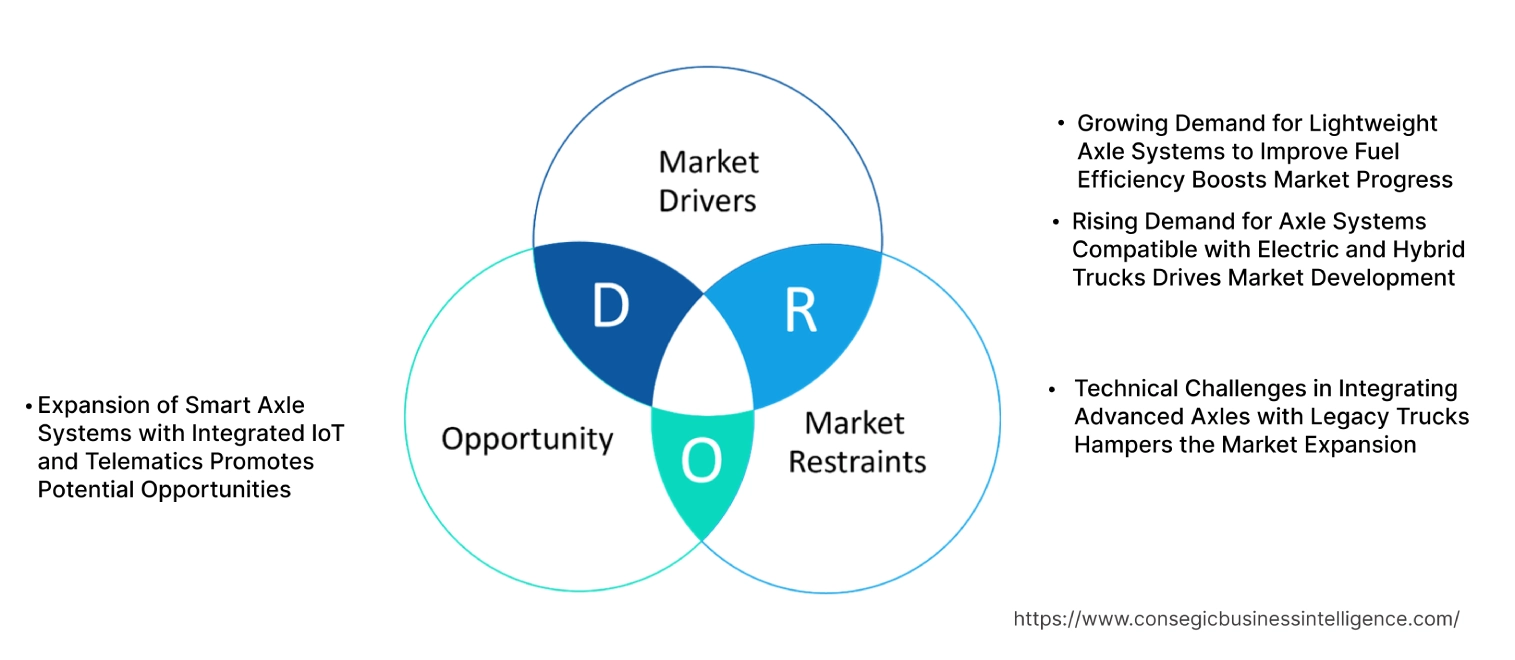

Truck Axle Market Dynamics - (DRO) :

Key Drivers:

Growing Demand for Lightweight Axle Systems to Improve Fuel Efficiency Boosts Market Progress

Regulations aimed at reducing vehicle emissions have prompted manufacturers to develop axles using advanced materials such as high-strength steel, aluminum alloys, and carbon composites. These materials help reduce the overall weight of trucks, improving fuel efficiency without compromising load capacity or structural integrity. Lightweight axles are particularly critical for long-haul trucks and heavy-duty vehicles, where fuel costs constitute a significant portion of operational expenses. This need is further amplified by the rise of electric and hybrid trucks, where reducing weight is essential to maximize battery efficiency and extend driving range, contributing to truck axle market growth.

Rising Demand for Axle Systems Compatible with Electric and Hybrid Trucks Drives Market Development

Electric trucks require axles capable of integrating with electric motors and advanced drivetrain components. E-axles, which combine electric motors, power electronics, and axles into a single compact unit, are gaining traction in the market. These systems improve efficiency, reduce drivetrain complexity, and offer enhanced performance for electric trucks. Governments' increasing push toward zero-emission vehicles and rising investments in electric truck infrastructure are accelerating the adoption of advanced axle systems specifically designed for electric and hybrid platforms, driving truck axle market demand as manufacturers focus on innovative and efficient designs.

Key Restraints :

Technical Challenges in Integrating Advanced Axles with Legacy Trucks Hampers the Market Expansion

Integrating modern axle systems with legacy truck platforms presents significant technical hurdles. Many older trucks lack the necessary infrastructure, such as advanced electronics and compatible drivetrains, to support modern axle technologies. Retrofitting older vehicles with advanced axles often involves extensive modifications, including updates to suspension systems, braking systems, and onboard electronics. This process increases operational downtime and maintenance costs for fleet operators. The lack of standardization in axle designs further complicates integration, deterring companies from upgrading their fleets with advanced axle systems and posing a challenge to truck axle market expansion by limiting widespread adoption.

Future Opportunities :

Expansion of Smart Axle Systems with Integrated IoT and Telematics Promotes Potential Opportunities

The growing adoption of IoT and telematics in the commercial vehicle sector presents a significant opportunity for the development of smart axle systems. These axles are equipped with sensors and communication modules to monitor real-time data, such as axle load, temperature, and performance metrics. This data is transmitted to fleet management systems, enabling predictive maintenance, optimized load distribution, and enhanced safety. Smart axles also play a vital role in autonomous truck operations by providing accurate inputs for vehicle control systems. As fleet operators increasingly adopt telematics solutions to improve efficiency and reduce maintenance costs, the need for smart axle systems is expected to rise, presenting significant truck axle market opportunities in developed markets with advanced logistics infrastructure.

Truck Axle Market Segmental Analysis :

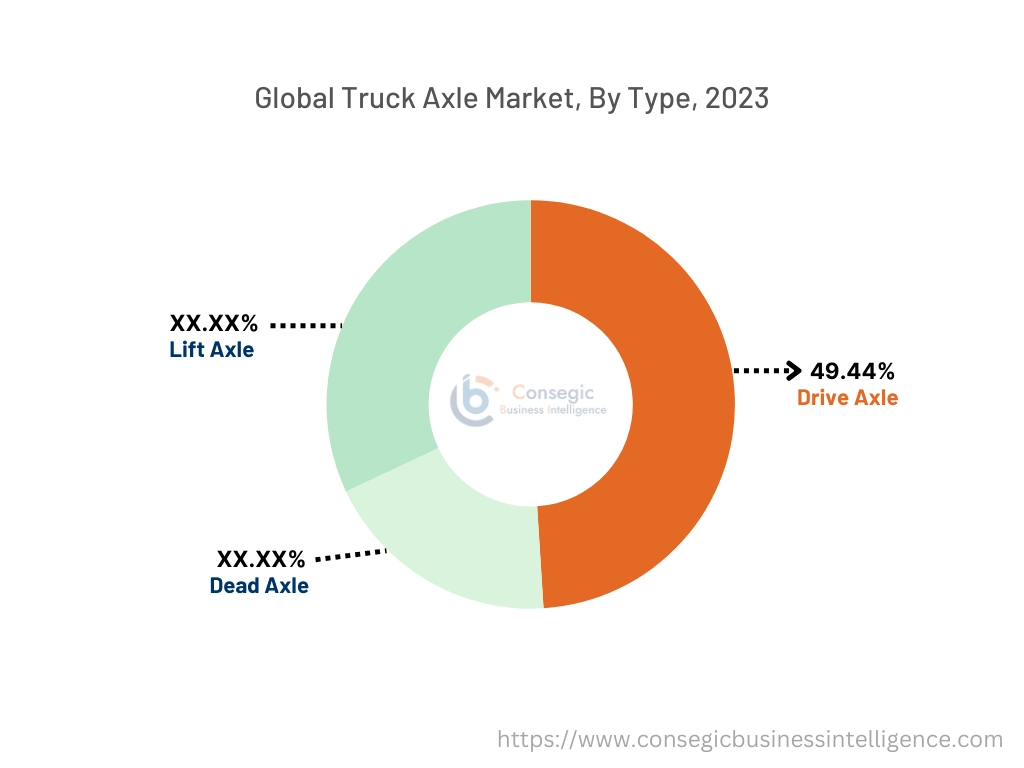

By Type:

The Drive Axle segment accounted for the largest revenue of 49.44% of the total truck axle market share in 2023.

- Drive axles are essential for transmitting torque from the vehicle’s engine to the wheels, enabling propulsion and efficient vehicle performance.

- These axles are extensively used in heavy-duty and medium-duty trucks, which require high torque transmission for long-distance and heavy-load transportation.

- The increasing need for fuel-efficient trucks and the adoption of advanced axle designs with integrated drivetrain components are driving the progress of this segment.

- Drive axles are often integrated with technologies like torque vectoring, enhancing vehicle stability and traction in challenging terrains.

- As per the truck axle market analysis, the dominance of the drive axle segment is attributed to its critical role in vehicle propulsion and its widespread use in heavy-duty transportation applications.

The Lift Axle segment is expected to register the fastest CAGR during the forecast period.

- Lift axles are designed to reduce tire wear and improve fuel efficiency by lifting non-driven wheels off the ground when not in use.

- These axles are widely adopted in trucks used for seasonal or fluctuating loads, such as dump trucks, tanker trucks, and heavy cargo transport vehicles.

- The growing emphasis on reducing operational costs and environmental impact is encouraging fleet operators to adopt lift axle-equipped trucks.

- As per truck axle market trends, the rapid progress of the lift axle segment is driven by advancements in automation technologies, enabling seamless axle lifting and lowering during operation.

By Vehicle Type:

Based on vehicle type, the market is segmented into Light-Duty Trucks, Medium-Duty Trucks, and Heavy-Duty Trucks.

The Heavy-Duty Trucks segment accounted for the largest revenue of the total truck axle market share in 2023.

- Heavy-duty trucks rely on robust axle systems to support high loads, ensure stability, and maintain performance in long-haul and off-road applications.

- These trucks are essential for industries such as construction, mining, and logistics, which require reliable and durable axles to handle extreme operating conditions.

- The growing need for heavy-duty trucks in emerging economies, coupled with infrastructure development, is fueling the development of this segment.

- The dominance of the heavy-duty trucks segment is driven by its extensive use in industrial applications and the need for high-performance axle systems contributes to the truck axle market growth.

The Light-Duty Trucks segment is expected to register the fastest CAGR during the forecast period.

- Light-duty trucks play a crucial role in urban logistics and short-distance transportation, emphasizing the need for lightweight and fuel-efficient axle systems.

- The surge in electric and hybrid truck adoption is significantly increasing the need for advanced axle technologies, including electric axles and independent suspension axles.

- The segment's rapid growth is closely tied to the expanding e-commerce sector, which is driving demand for efficient last-mile delivery vehicles.

- Innovations in lightweight axle materials and designs are further enhancing the performance and fuel efficiency of light-duty trucks, making them more attractive for urban applications.

- The rise in urban delivery services and increasing environmental concerns are key factors driving truck axle market demand in the light-duty trucks segment, as manufacturers prioritize sustainability and operational efficiency.

By Technology:

Based on technology, the market is segmented into Mechanical Axles, Electric Axles, Hybrid Axles, Air Suspension Axles, Independent Suspension Axles, Hotchkiss Drive Unit, and Central Drive.

The Mechanical Axles segment held the largest market share in 2023.

- Mechanical axles are renowned for their high durability and cost-effectiveness, making them the preferred choice for a wide range of truck applications across diverse industries.

- These axles are extensively adopted in regions such as North America and Europe, where conventional internal combustion engine (ICE) trucks dominate the market due to established infrastructure and industrial requirements.

- The reliability and adaptability of mechanical axles contribute to their widespread use in both heavy-duty trucks for industrial applications and light-duty trucks for urban transportation needs.

- The segment's dominance is further supported by its proven performance in challenging conditions and cost-efficiency, driving truck axle market expansion across both developed and emerging markets.

The Electric Axles segment is expected to register the fastest CAGR during the forecast period.

- Electric axles integrate electric motors and drivetrain components, enabling efficient propulsion in electric and hybrid trucks.

- The increasing shift toward electrification in the automotive industry, driven by stringent emission regulations and growing environmental awareness, is fueling the adoption of electric axles.

- Leading manufacturers are investing in R&D to develop lightweight, high-performance electric axles to improve the range and efficiency of electric trucks.

- The rapid development of the electric axles segment is attributed to the rising need for electric vehicles (EVs) and advancements in axle electrification technologies, highlighting significant truck axle market opportunities.

By End-Use:

Based on end-user, the market is segmented into OEMs (Original Equipment Manufacturers) and Aftermarket.

The OEMs segment accounted for the largest revenue share in 2023.

- OEMs are the primary buyers of truck axles, integrating them into new vehicles during the manufacturing process to meet specific performance and regulatory requirements.

- The increasing production of advanced trucks with lightweight and efficient axle systems is driving need in the OEM segment.

- Collaboration between axle manufacturers and OEMs to develop customized solutions is further boosting progress in this segment.

- As per the truck axle market analysis, the dominance of the OEMs segment is attributed to the growing production of commercial vehicles and the rising adoption of advanced axle technologies.

The Aftermarket segment is expected to register the fastest CAGR during the forecast period.

- The aftermarket segment caters to customers requiring replacement or upgraded axle systems, often driven by factors such as wear and tear, performance improvement needs, or compliance with evolving regulations.

- The expanding fleet sizes in industries such as logistics and transportation, along with the high maintenance needs of heavy-duty and long-haul trucks, are significant contributors to the segment's progress.

- Fleet operators are increasingly prioritizing regular maintenance to ensure vehicle performance and reduce downtime, further driving demand for aftermarket axle systems.

- As per truck axle market trends, the availability of cost-effective replacement parts, combined with advancements in axle technologies, supports the progress of this segment as operators seek efficient solutions to enhance vehicle longevity and operational efficiency.

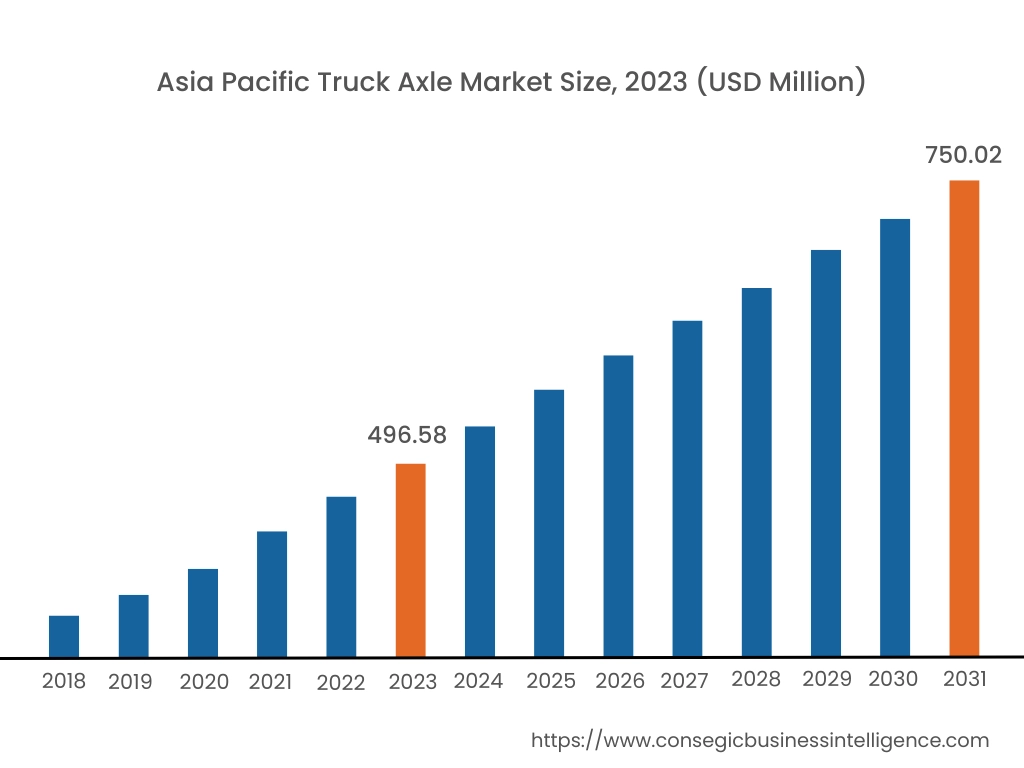

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

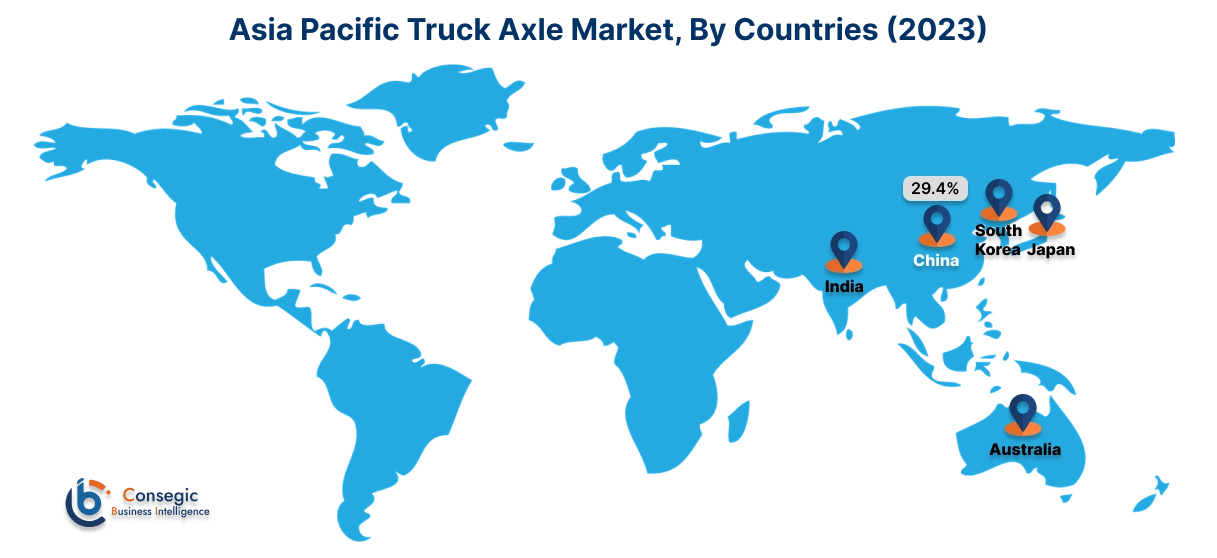

Asia Pacific region was valued at USD 496.58 Million in 2023. Moreover, it is projected to grow by USD 513.40 Million in 2024 and reach over USD 750.02 Million by 2031. Out of these, China accounted for the largest share of 29.4% in 2023. Asia-Pacific is witnessing the fastest growth in the market, driven by rapid industrialization and urbanization in countries like China, India, and Japan. The region has become a global hub for automotive production, with a strong emphasis on commercial vehicles to support infrastructure development. The growing e-commerce sector and the need for efficient logistics are further propelling market growth.

North America is estimated to reach over USD 817.52 Million by 2031 from a value of USD 562.49 Million in 2023 and is projected to grow by USD 579.66 Million in 2024. North America holds a substantial share of the market, primarily due to the robust automotive industry and the presence of major truck manufacturers. The United States, in particular, leads the market with a strong need for heavy-duty trucks used in the logistics and construction sectors. The focus on enhancing fuel efficiency and load capacity has led to the adoption of advanced axle technologies.

Europe represents a significant portion of the global market, with countries like Germany, France, and the United Kingdom leading in terms of adoption and innovation. The region benefits from a well-established automotive sector and a strong emphasis on sustainability. The requirement for lightweight and fuel-efficient axles is increasing, driven by stringent emission norms and the push towards electric vehicles.

The Middle East & Africa region shows promising potential in the truck axle market, particularly in countries like Saudi Arabia, the United Arab Emirates, and South Africa. Increasing investments in infrastructure projects and the enlargement of the construction industry are driving the need for heavy-duty trucks and, consequently, truck axles. The focus on diversifying economies and reducing dependence on oil revenues has led to growth in the logistics and transportation sectors.

Latin America is an emerging market for truck axles, with Brazil and Mexico being the primary growth drivers. The rising adoption of commercial vehicles, improving road infrastructure, and increasing focus on enhancing logistics efficiency contribute to the market’s development. Government initiatives aimed at modernizing transportation networks and promoting trade are supporting market growth.

Top Key Players & Market Share Insights:

The Truck Axle market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global Truck Axle market. Key players in the Truck Axle industry include –

- Meritor, Inc. (USA)

- Dana Incorporated (USA)

- Eaton Corporation (Ireland)

- Sisu Axles (Finland)

- American Axle & Manufacturing, Inc. (USA)

- Hendrickson International Corporation (USA)

- Rockwell American (USA)

- Link Manufacturing, Ltd. (USA)

- Dexter Axle Company (USA)

- Axle Inc. (USA)

Recent Industry Developments :

Product Launches:

- In September 2024, AVL introduced a new e-axle designed for 40-ton trucks, enhancing efficiency and driving performance in electric commercial vehicles. This new technology focuses on improving energy management, reducing weight, and increasing power density, ultimately enabling better performance in the growing market for electric trucks. The e-axle offers a significant step forward in making electric transportation more viable for heavy-duty applications.

- In July 2023, ZF introduced a new eAxle technology that integrates electric motors, power electronics, and transmission into a single unit for electric vehicles (EVs). This innovation is designed to improve the efficiency and performance of electric drivetrains, offering automakers a scalable, modular solution for various EV models. The eAxle technology also contributes to reducing vehicle weight, boosting driving range, and optimizing space.

Partnerships & Collaborations:

- In December 2023, Great Dane and STEMCO entered into a strategic agreement to introduce the Auto-Torq Axle Fastener, an innovative solution designed to enhance axle assembly efficiency. This new fastener aims to improve performance and durability while simplifying the assembly process, providing benefits such as reducing installation time and improving reliability in commercial vehicles.

Truck Axle Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 2,500.05 Million |

| CAGR (2024-2031) | 4.9% |

| By Type |

|

| By Vehicle Type |

|

| By Technology |

|

| By End-User |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Truck Axle market? +

Truck Axle Market size is estimated to reach over USD 2,500.05 Million by 2031 from a value of USD 1,701.55 Million in 2023 and is projected to grow by USD 1,755.08 Million in 2024, growing at a CAGR of 4.9% from 2024 to 2031.

What specific segmentation details are covered in the Truck Axle Market report? +

The Truck Axle market report includes segmentation details for type (drive axle, dead axle, lift axle), vehicle type (light-duty trucks, medium-duty trucks, heavy-duty trucks), technology (mechanical axles, electric axles, hybrid axles, air suspension axles, independent suspension axles, Hotchkiss drive unit, central drive), end-user (OEMs, aftermarket), and region.

Which is the fastest-growing type in the Truck Axle market? +

The Lift Axle segment is expected to register the fastest CAGR during the forecast period, driven by advancements in automation technologies and the growing emphasis on reducing operational costs and environmental impact.

Who are the major players in the Truck Axle market? +

The major players in the Truck Axle market include Meritor, Inc. (USA), Dana Incorporated (USA), Eaton Corporation (Ireland), Sisu Axles (Finland), American Axle & Manufacturing, Inc. (USA), Hendrickson International Corporation (USA), Rockwell American (USA), Link Manufacturing, Ltd. (USA), Dexter Axle Company (USA), and Axle Inc. (USA).