- Summary

- Table Of Content

- Methodology

Tire Curing Press Market Size:

Tire Curing Press Market size is estimated to reach over USD 1,717.56 Million by 2032 from a value of USD 1,230.25 Million in 2024 and is projected to grow by USD 1,260.74 Million in 2025, growing at a CAGR of 4.3% from 2025 to 2032.

Tire Curing Press Market Scope & Overview:

A tire curing press is specialized equipment used in the final stage of tire manufacturing to mold and vulcanize raw tires into their final shape and specifications. This process involves applying heat and pressure to cure the rubber, ensuring the tire achieves its desired durability, tread pattern, and performance characteristics. Tire curing presses are integral to the production of passenger, commercial, and specialty vehicle tires, offering precision and consistency in the curing process.

These presses are available in various configurations, including hydraulic, mechanical, and hybrid models, to meet the specific production needs of manufacturers. They are equipped with features such as automated controls, real-time monitoring systems, and advanced safety mechanisms to ensure efficient operation and high-quality output. Tire curing presses are designed for long-term reliability and optimized energy consumption, enhancing their operational efficiency in demanding manufacturing environments.

End-users of tire curing presses include tire manufacturers, automotive companies, and industrial production facilities, where consistency, precision, and efficiency are essential for meeting quality standards and production targets.

Key Drivers:

Growth in Aftermarket Tire Replacement Segment Drives the Market Progress

The expanding aftermarket for tire replacement is driving demand for efficient curing solutions. As vehicle ownership increases, the need for periodic tire replacement rises, particularly in commercial fleets and passenger vehicles. Tire manufacturers are increasingly investing in advanced curing equipment to meet the growing production requirements of replacement tires. The aftermarket segment also demands cost-effective solutions that ensure durability and performance, pushing manufacturers to adopt innovative curing technologies for consistent quality. Additionally, the rising preference for retreaded tires in the aftermarket, especially for heavy-duty and off-road vehicles, further amplifies the need for specialized curing systems. Thus, the aforementioned factors are driving the tire curing press market growth.

Key Restraints:

Environmental Concerns Related to Emissions Hampers the Market Growth

Traditional tire curing processes, particularly those relying on steam and hydraulic systems, contribute to harmful emissions, including volatile organic compounds (VOCs) and greenhouse gases. These emissions pose environmental risks and attract regulatory scrutiny, especially in regions with strict environmental policies such as Europe and North America. Governments are enforcing stringent emission control measures, compelling manufacturers to adopt cleaner and more sustainable curing technologies.

For many tire manufacturers, transitioning to eco-friendly processes presents restraints due to the significant capital investment required for upgrading existing infrastructure. Small and medium-sized enterprises, in particular, face financial constraints in meeting compliance standards. Additionally, VOCs and carbon emissions impact the workplace environment, increasing health risks for employees and adding pressure to adopt safer operational practices. The growing emphasis on reducing industrial emissions is pushing manufacturers to find a balance between regulatory compliance and cost-effective production, creating hurdles for the widespread adoption of traditional curing presses. Thus, the above mentioned factors limit the tire curing press market demand.

Future Opportunities :

Expansion in Retreaded Tire Production Creates New Growth Avenues

The increasing emphasis on sustainability and cost-efficiency is boosting the demand for tire retreading, particularly in commercial vehicles, where operational expenses are significant. Retreaded tires provide a cost-effective alternative to new tires, extending their life cycle while reducing waste and raw material consumption. Advanced curing presses specifically designed for retreading applications play a crucial role in achieving consistent quality, durability, and performance comparable to new tires.

These presses enable precise control over pressure and temperature during the curing process, ensuring the structural integrity of retreaded tires. The growing adoption of retreading is further supported by rising environmental regulations aimed at minimizing landfill waste and promoting circular economy practices. Emerging markets, where cost sensitivity is higher, are particularly witnessing increased demand for retreaded tires. This trend offers growth potential for manufacturers developing specialized curing presses that cater to the evolving needs of the retreading industry while aligning with global sustainability goals. Hence, the aforementioned factors are creating significant tire curing press market opportunities.

Tire Curing Press Market Segmental Analysis :

By Type:

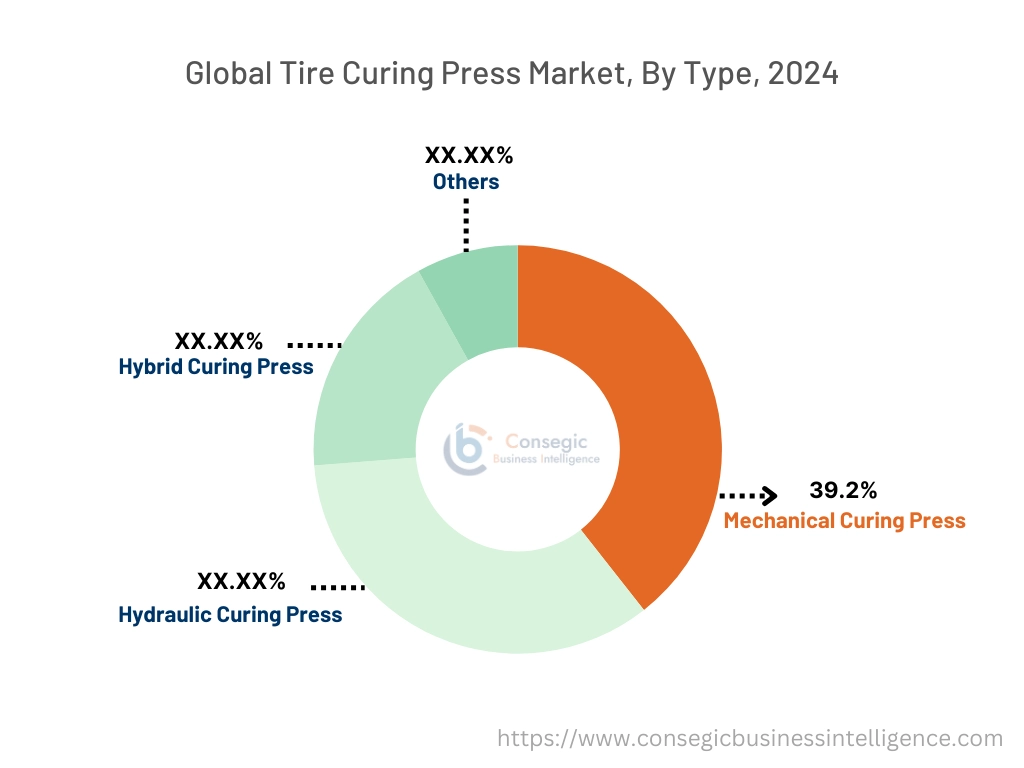

Based on type, the market is segmented into mechanical curing press, hydraulic curing press, hybrid curing press, and others.

The mechanical curing press segment accounted for the largest revenue of 39.2% of the total tire curing press market share in 2023.

- Mechanical curing presses are widely used for tire manufacturing due to their cost-effectiveness and ability to handle high-volume production processes.

- The dominance of this segment is driven by their long-standing presence and reliability in producing ordinary and radial tires across various industries.

- Many manufacturers prefer mechanical presses for their robust structure and ease of operation in tire curing applications.

- As per segmental trend analysis, the adoption of mechanical presses remains strong in developing regions where cost considerations and simplicity of maintenance play a crucial role, contributing to the tire curing press market expansion.

The hydraulic curing press segment is expected to register the fastest CAGR during the forecast period.

- Hydraulic curing presses are increasingly used for advanced tire manufacturing, particularly for radial tires, due to their precision and ability to ensure uniform pressure.

- These presses offer enhanced energy efficiency, higher flexibility, and reduced operating noise compared to mechanical alternatives.

- The segment’s growth is supported by rising requirement for premium tires in the automotive and specialty tire markets, where precision is critical.

- As per tire curing press market trends, technological advancements in hydraulic systems, such as smart controls and automated pressure regulation, further accelerate adoption in modern tire production facilities.

By Mold:

Based on mold, the market is segmented into two-piece mold and segmental mold.

The segmental mold segment held the largest revenue of the total tire curing press market share in 2023.

- Segmental molds are preferred for high-performance and radial tires due to their ability to provide superior precision and consistency in tire tread design.

- These molds enable manufacturers to produce complex tread patterns efficiently, meeting the evolving requirements of premium and performance tires.

- The segment’s prominence is attributed to increasing need for specialty tires in applications like sports cars, trucks, and industrial vehicles.

- As per tire curing press market analysis, leading tire manufacturers are investing in advanced segmental mold technologies to enhance production output and maintain product quality standards.

The two-piece mold segment is expected to register the fastest CAGR during the forecast period.

- Two-piece molds are primarily used for producing standard tires, offering simplicity and cost efficiency in manufacturing processes.

- This segment benefits from its strong application in ordinary tire production, particularly in emerging markets with a focus on cost-effective solutions.

- Two-piece molds are widely used in the production of bias-ply tires, which continue to cater to specific automotive and industrial segments.

- Thus, the rapid need for two-piece molds reflects their suitability for producing tires with less complex tread patterns at a competitive cost, which further fuels the tire curing press market growth.

By Application:

Based on application, the market is categorized into radial and ordinary tires.

The radial tire segment accounted for the largest revenue share in 2023.

- Radial tires dominate the market due to their superior performance, durability, and fuel efficiency, making them the preferred choice for passenger and commercial vehicles.

- The segment benefits from increased global automotive production and rising requirement for premium and performance tires.

- Manufacturers are adopting advanced tire curing technologies to meet the stringent quality requirements of radial tires across different vehicle categories.

- Therefore, growing awareness about the advantages of radial tires, such as longer life span and reduced rolling resistance, further drives the segment’s dominance boosting the tire curing press market demand.

The ordinary tire segment is expected to register the fastest CAGR during the forecast period.

- Ordinary tires continue to hold a strong position in niche markets, including two-wheelers, agriculture, and light industrial vehicles, where cost efficiency is a key factor.

- The segment’s stability is supported by the significant need for bias-ply tires in regions with challenging terrains and infrastructure limitations.

- Ordinary tires remain an economical choice for applications requiring limited operational performance and shorter life cycles.

- As per the market analysis, manufacturers continue to focus on improving ordinary tire quality to maintain their relevance in price-sensitive markets globally, facilitating the tire curing press market expansion.

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

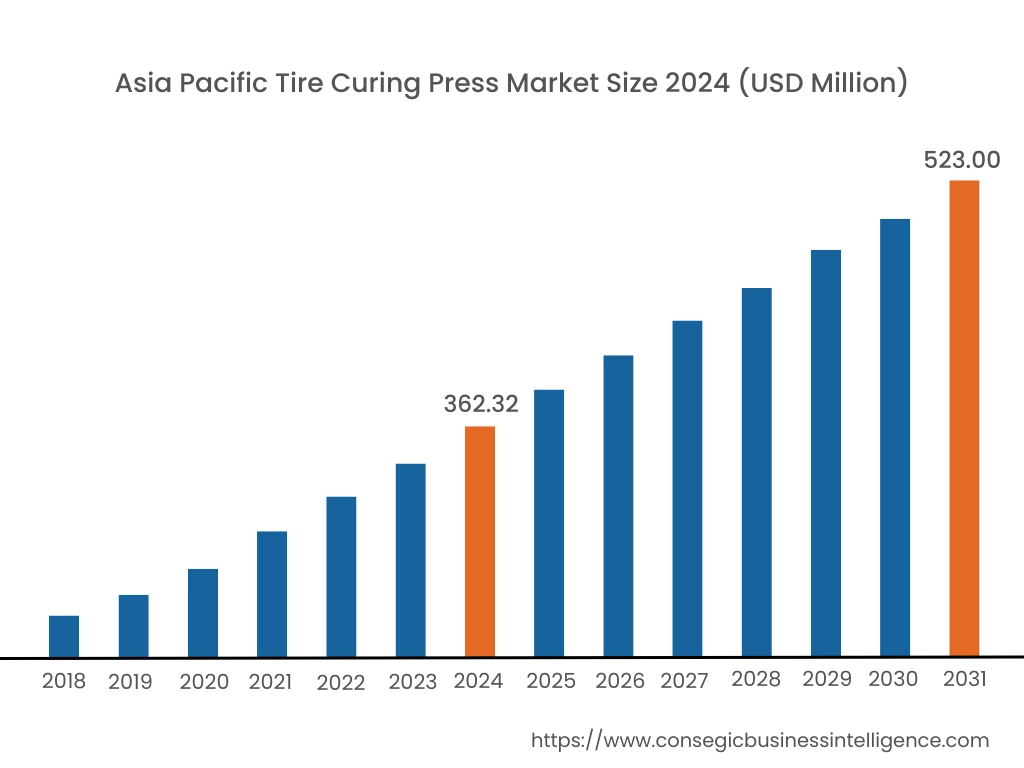

Asia Pacific region was valued at USD 362.32 Million in 2024. Moreover, it is projected to grow by USD 372.35 Million in 2025 and reach over USD 523.00 Million by 2032. Out of this, China accounted for the maximum revenue share of 29.8%. The Asia-Pacific region is experiencing rapid development in the tire curing press market, driven by industrialization and technological advancements in countries such as China, Japan, and India. The expansion of the automotive industry and the rising need for passenger vehicles have intensified the need for advanced tire manufacturing equipment. Government initiatives promoting industrial efficiency further influence tire curing press market opportunities.

North America is estimated to reach over USD 556.66 Million by 2032 from a value of USD 408.08 Million in 2024 and is projected to grow by USD 417.40 Million in 2025. In North America, the tire curing press market is characterized by a rapid demand, primarily driven by the well-established automotive industry. The United States, being a significant player, showcases a consistent need for advanced tire manufacturing equipment. A notable trend in this region is the shift towards automation and the integration of IoT technologies in tire curing presses to enhance efficiency and reduce production times. The tire curing press market analysis indicate that manufacturers are investing in modernizing their machinery to meet stringent environmental regulations and to cater to the evolving preferences for high-performance tires.

Europe represents a substantial share of the global tire curing press market, with countries like Germany, France, and Italy leading in adoption and innovation. The region's emphasis on sustainability and energy efficiency has propelled the utilization of eco-friendly tire curing solutions. Analysis indicates a growing trend towards the deployment of hybrid curing presses that combine mechanical and hydraulic systems, offering flexibility across various tire types.

The Middle East & Africa region shows a growing interest in advanced tire manufacturing solutions, particularly in the construction and industrial sectors. Countries like Saudi Arabia and South Africa are investing in modern manufacturing technologies to enhance production efficiency. Analysis suggests an increasing trend towards adopting high-precision tire curing presses to meet international quality standards.

Latin America is an emerging market for tire curing presses, with Brazil and Mexico being key contributors. The region's growing focus on industrial modernization and the automotive sector has spurred the adoption of advanced tire manufacturing solutions. As per tire curing press market trends, government policies aimed at enhancing manufacturing capabilities influence market trends.

Top Key Players and Market Share Insights:

The Tire Curing Press market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global Tire Curing Press market. Key players in the Tire Curing Press industry include –

- HF TireTech Group (Germany)

- Uzer Makina (Turkey)

- HERBERT Maschinenbau GmbH & Co. KG (Germany)

- Alfred Herbert (India) Ltd. (India)

- Guilin Rubber Machinery Factory (China)

- CIMA Impianti (Italy)

- Rogers Industrial Products Inc. (USA)

- Kobe Steel, Ltd. (Japan)

- Larsen & Toubro Limited (India)

Tire Curing Press Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 1,717.56 Million |

| CAGR (2025-2032) | 4.3% |

| By Type |

|

| By Mold |

|

| By Application |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the size of the Tire Curing Press Market? +

Tire Curing Press Market size is estimated to reach over USD 1,717.56 Million by 2032 from a value of USD 1,230.25 Million in 2024 and is projected to grow by USD 1,260.74 Million in 2025, growing at a CAGR of 4.3% from 2025 to 2032.

What are the segments and subsegments covered in the Tire Curing Press Market report? +

The market is segmented into Type (Mechanical Curing Press, Hydraulic Curing Press, Hybrid Curing Press, Others), Mold (Two-Piece Mold, Segmental Mold), Application (Radial, Ordinary Tire), Region (Asia-Pacific, Europe, North America, Latin America, Middle East & Africa)

Which segment is expected to grow the fastest in the Tire Curing Press Market? +

The hydraulic curing press segment is expected to register the fastest CAGR during the forecast period, driven by the increasing demand for precision and flexibility in tire manufacturing, particularly for radial tires.

Who are the key players in the Tire Curing Press Market? +

Key players in the Tire Curing Press Market include HF TireTech Group (Germany), Uzer Makina (Turkey), CIMA Impianti (Italy), Rogers Industrial Products Inc. (USA), Kobe Steel, Ltd. (Japan), Larsen & Toubro Limited (India), HERBERT Maschinenbau GmbH & Co. KG (Germany), Alfred Herbert (India) Ltd. (India), and Guilin Rubber Machinery Factory (China).