- Summary

- Table Of Content

- Methodology

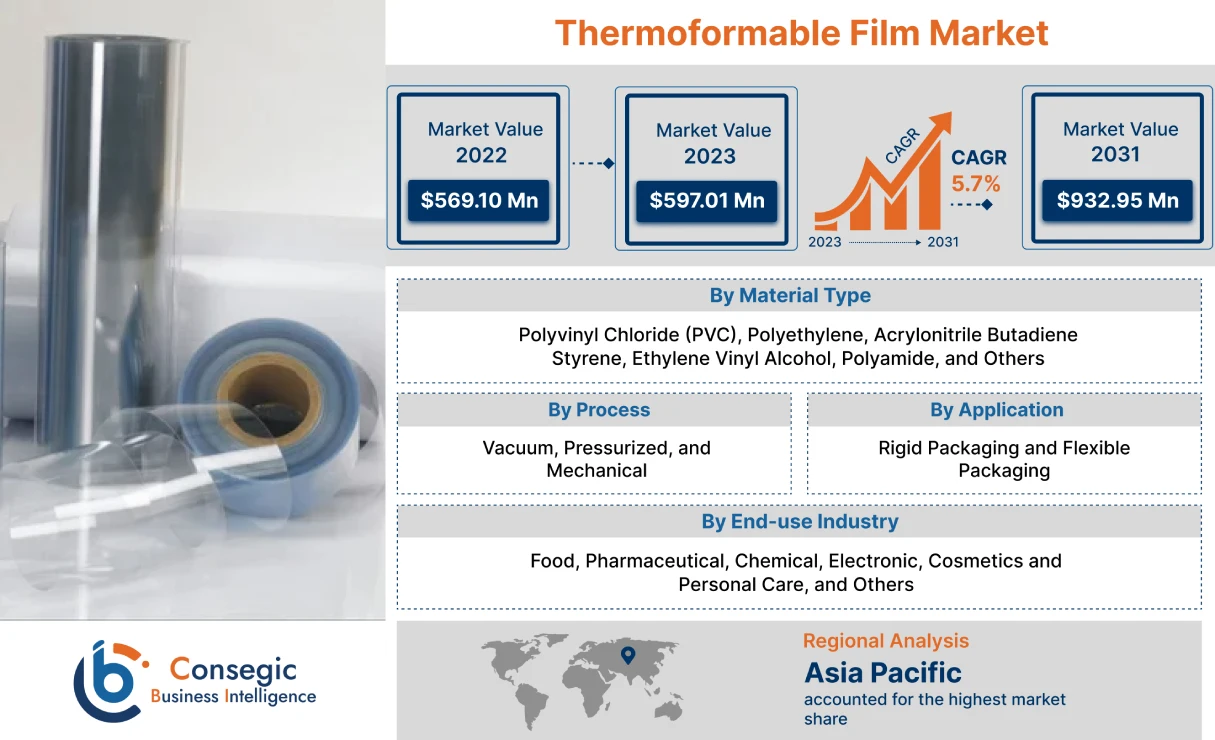

Thermoformable Film Market Size :

Consegic Business Intelligence analyzes that the thermoformable film market size is growing with a CAGR of 5.7% during the forecast period (2023-2031), and the market is projected to be valued at USD 932.95 Million by 2031 and USD 597.01 million in 2023 from USD 569.10 Million in 2022.

Thermoformable Film Market Scope & Overview:

Thermoformable film is a type of plastic film that can be heated and shaped into a variety of forms. It is used in a wide variety of applications. The films are made either through pressure molding or vacuum-forming technology. These films come in varying thicknesses, widths, base materials, and sealing layers. Thermoformable films possess moisture barrier properties, provide a clean and hygienic look, and offer puncture-resistant properties. The products are known as one of the best and most cost-effective options for packaging as they offer moisture-free and reliable packaging. The films can be used for fresh and frozen trays, packs, lids, and other similar usages. Thermoformable films are an affordable option and provide great flexibility. Thermoformable films based products are utilized in wide industries space namely food, pharmaceutical, chemical, electronic, and others.

Thermoformable Film Market Insights :

Key Drivers :

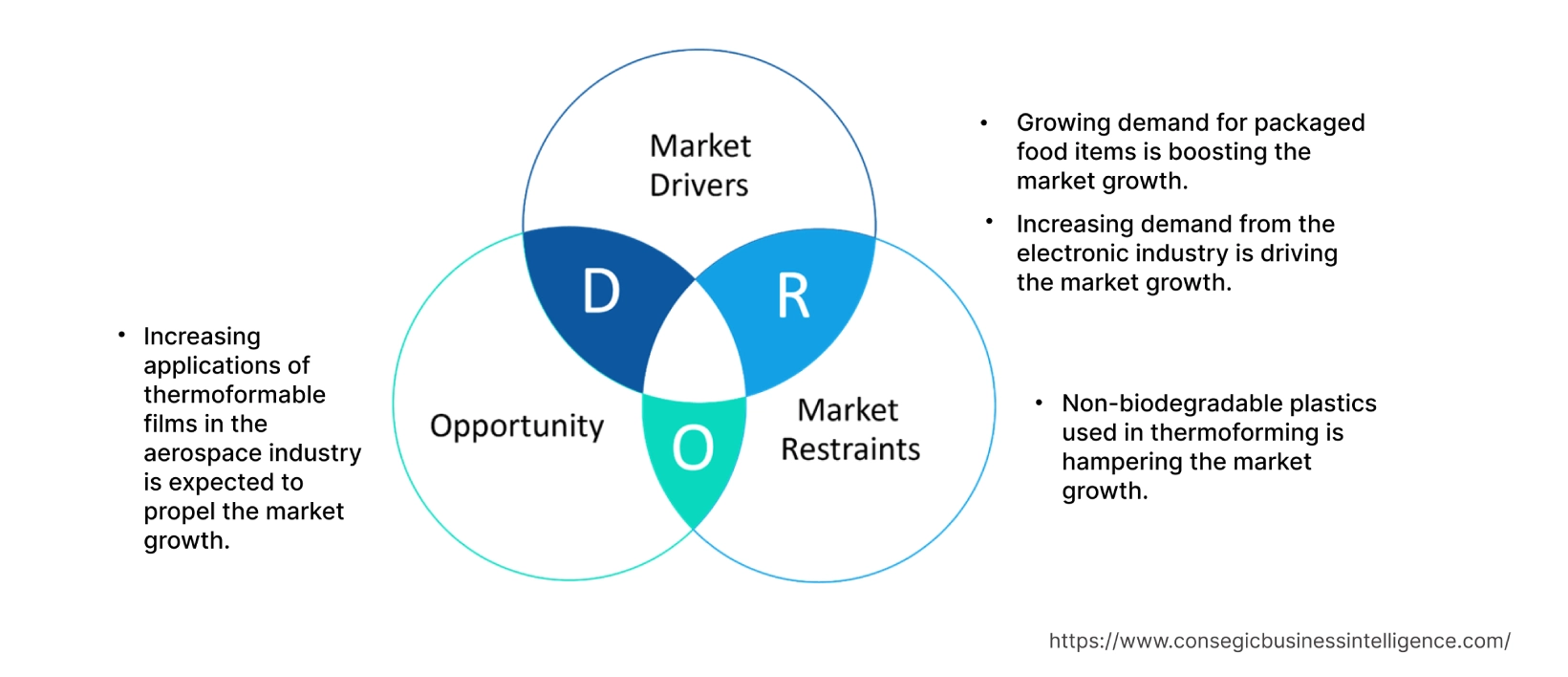

Growing demand for packaged food items is boosting the market growth

Thermoformable films are widely used in the packaging of different food items such as dry food, confections, baked food items, frozen food, soups, hot foods, and others. Owing to certain advantages of the product offering such as minimal leakage, and puncture resistance, thermoformable films are widely demanded for food packaging. The products are ideal for packaging specific items such as red meat and cheese, as they retain strength at freezing temperatures in refrigerators. Furthermore, the increasing food and beverage industry is leading to growing demand for packaged food items. For instance, according to a report by Invest India, in 2023, India's food processing sector is one of the largest in the world and its production output is expected to reach around USD 535 billion by 2025 to 2026. Also, production linked incentive schemes for the food processing industry are boosting domestic manufacturing in India. Hence, due to the growing food industry globally, there is a higher demand for thermoformable films for packaging purposes.

Increasing demand from the electronic industry is driving the market growth

Thermoformable films are used in a variety of applications in the electronic industry including packaging, displays, enclosures, and RF shielding, among others. Thermoformable films are largely demanded by the electronics industry due to the wide offerings of the product. Thin gauge and high-performance thermoforming films are widely utilized in small and portable electronics. These films are largely preferred by electronics OEMs for microelectronics, due to certain features of the product such as vapor barrier and electrical insulation. Furthermore, the products have anti-static, anti-dust, and anti-moisture properties which make their usage ideal in high-end electronic components for resisting lengthy delivery times. Also, the increasing electronics industry is fostering a significant impact on the growth of thermoformable film usage. For instance, according to a press release in 2022, by the Ministry of Electronics & IT, the domestic production of electronic goods has increased from USD 37 billion in 2015 to 2016 to USD 74.7 billion in 2020 to 2021, growing at a CAGR of 17.9%. This growth has been owing to different schemes and initiatives undertaken by the Government of India. Thus, the growing production of electronic goods globally impacts the thermoformable films market demand.

Key Restraints :

Non-biodegradable plastics used in thermoforming is hampering the market growth

The non-biodegradable plastics used in thermoforming films is harmful to the environment and are proving to be a restraint for hampering the demand of the market. The majority of the materials used in thermoforming such as polyvinyl chloride (PVC), polyethylene (PE), acrylonitrile butadiene, styrene (ABS), ethylene vinyl Alcohol (EVOH), polyamide, and others are not biodegradable. Moreover, increasing regulations by governments globally to monitor the reduction of plastic waste, particularly in packaging is hampering the market growth. Hence, due to increasing actions for climate change and sustainability, the growth of thermoformable films is being challenged. Thus, due to the aforementioned factors, the non-biodegradable plastics used in thermoforming films are proving to be a restraint for thermoformable film market growth.

Future Opportunities :

Increasing applications of thermoformable films in the aerospace industry is expected to propel the market growth

Thermoformable film products have major usage in the aerospace industry in airplane interior panels, overhead luggage storage, and galley components. Owing to the product's lightweight, it is widely used to produce seatbacks, armrests, footwell trays, window shrouds, shades, and others. Also, the product offers flexibility and simple and modern design in aircraft interiors. Hence, due to the wide application of thermoformable films in the aerospace industry, the market is expected to flourish further in the forecast years. Furthermore, the increasing aerospace industry is bringing in more demand for thermoformable film products. Hence, due to the increasing aerospace industry, the thermoformable film market is expected to flourish significantly in the forecast period.

Thermoformable Film Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2017-2031 |

| Market Size in 2031 | USD 932.95 Million |

| CAGR (2023-2031) | 5.7% |

| By Material Type | Polyvinyl Chloride (PVC), Polyethylene, Acrylonitrile Butadiene Styrene, Ethylene Vinyl Alcohol, Polyamide, and Others |

| By Process | Vacuum, Pressurized, and Mechanical |

| By Application | Rigid Packaging and Flexible Packaging |

| By End-use Industry | Food, Pharmaceutical, Chemical, Electronic, Cosmetics and Personal Care, and Others |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | Klockner Pentaplast, UFlex Limited, Vecom Group, Vishakha Polyfab Pvt Ltd, DuPont Specialty Products India Pvt. Ltd., Hypac Packaging Pte. Ltd., Clifton Packaging Group Ltd., Synpac, RapidMade, and A&M Packaging |

| Geographies Covered | |

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage | Revenue Forecast, Competitive Landscape, Growth Factors, Restraint or Challenges, Opportunities, Environment & Regulatory Landscape, PESTLE Analysis, PORTER Analysis, Key Technology Landscape, Value Chain Analysis, Cost Analysis, and Regional Trends & Forecast |

Thermoformable Film Market Segmental Analysis :

By Material Type :

The material type segment is categorized into polyvinyl chloride (PVC), polyethylene, acrylonitrile butadiene styrene, ethylene vinyl alcohol, polyamide, and others. In 2022, the polyethylene segment accounted for the highest market share and is expected to grow at the fastest CAGR over the forecast period in the thermoformable film market. This is due to the reduction in the weight of packaging, being offered by polyethylene thermoformable films. Also, these products save the hidden costs of pre-labeled products and branding and limit the usage of adhesives. Hence, increasing demand for low-cost packaging options coupled with good shelf appeal is increasing the usage of polyethylene in the thermoformable film market. Furthermore, new product launches by the key players in the polyethylene thermoformable films segment are driving the segment growth. For instance, in February 2023, UFlex Limited launched a new product, co-extruded transparent biaxially oriented polyethylene terephthalate or BOPET film. The product has different properties including high tensile strength, chemical stability, dimensional integrity, and transparency. Hence, increasing product innovations and launches are driving the segment growth in the thermoformable film market.

By Process :

The process segment is categorized into vacuum, pressurized, and mechanical. In 2022, the vacuum segment accounted for the highest market and is expected to grow at the fastest CAGR over the forecast period in the thermoformable film market. The vacuum enabled packages allow a longer shelf life and are durable. Also, the product is not harmed by any mechanical influences, as the product is fixed by the presence of a vacuum in the package. Moreover, the removal of microbial spoilage by this process ensures enhanced taste and freshness in the products. Hence, certain key advantages of the vacuum process such as protection against moisture, corrosion, mechanical damage, scratches, dust, and other contamination lead to greater usage of the product. Furthermore, increasing innovative product launches in this segment by the leading players in the market are driving the segment growth. For instance, in 2023, Klockner Pentaplast launched a new product, kp Flexivac, in collaboration with Dow. The product is a multi-layer recyclable vacuum film and is termed one of the most sustainable products in its portfolio. Hence, innovative product launches by the key players are driving the segment growth in the thermoformable film market.

By Application :

The application segment is categorized into rigid packaging and flexible packaging. In 2022, the rigid packaging segment accounted for the highest market share in the thermoformable film market. Rigid films are polymeric sheets that are widely used to make containers, boxes, trays, and other food packaging products. The rigid films are used largely for mechanical purposes such as protective headgear, pipe systems, musical instruments, recorders, and others. Certain advantages of the thermoformable film include excellent barrier properties against oxygen, moisture, and light. Such properties help to boost its demand in the food industry. Hence, the increasing adoption of rigid films in the food industry is increasing the segment growth in the thermoformable film market.

However, the flexible packaging segment is expected to grow at the fastest CAGR over the forecast period in the potassium sulfate. The flexible segment is growing at a significant rate due to certain advantages of the product such as barrier resistance, cost efficiency, and lightweight nature. Furthermore, the product is widely demanded for different applications such as labeling and printing on various products. Hence, due to the aforementioned factors, the flexible packaging segment is foreseeing significant thermoformable film market trend in the forecast years.

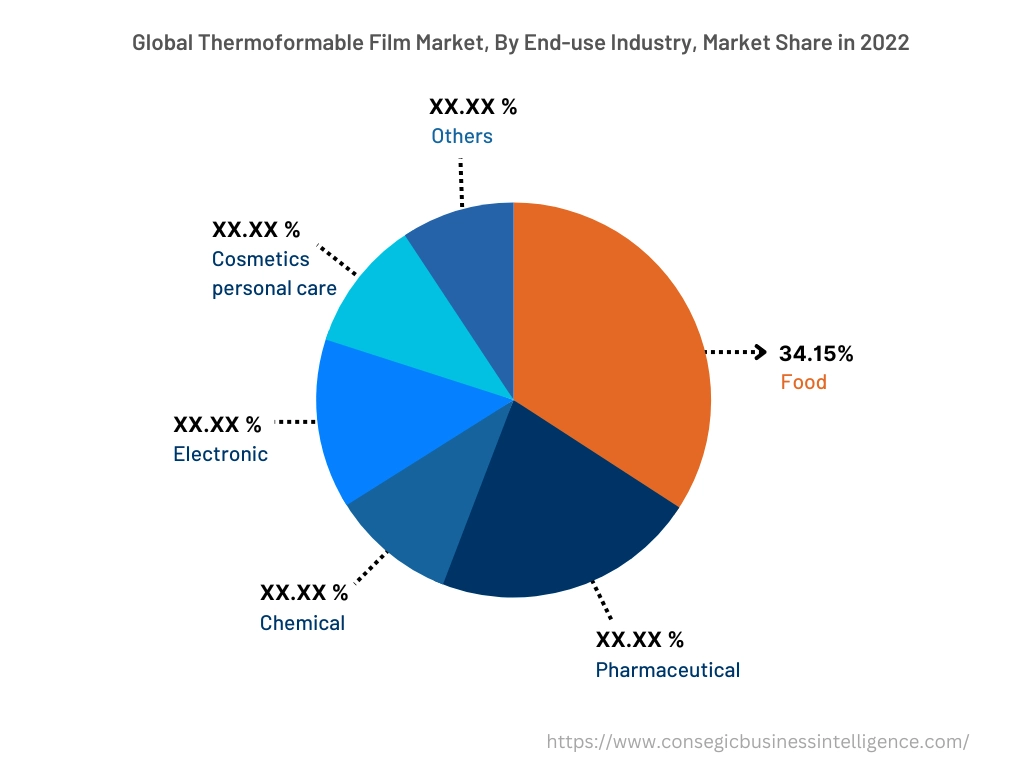

By End-Use-Industry :

The end-use industry segment is categorized into food, pharmaceutical, chemical, electronic, cosmetics personal care, and others. In 2022, the food segment accounted for the highest market share of 34.15% in the thermoformable film market. Due to the large demand for thermoformable films from the food packaging industry, the segment is experiencing significant growth. The films are widely used in packaging solutions for different food items such as frozen food, cheese, yogurt, ice cream, and other contaminants. The increasing demand for dairy and healthy products by consumers is leading to the growing demand for packaging solutions that can protect food products from spoilage. Hence, due to the aforementioned factors, the segment food is witnessing significant growth in the thermoformable film market.

However, the pharmaceutical segment is expected to grow at the fastest CAGR over the forecast period in the thermoformable film market. This is due to the large application of the product in medical devices such as stents and implants. Hence, due to the increased usage of stents and implants in different surgeries and operations, there has been a greater demand for thermoformable films. For instance, according to a report by the National Institutes of Health, in 2022, a staggering 310 million major surgeries are performed approximately every year, out of which around 40 to 50 million are performed in the USA and 20 million in Europe. Hence, increasing medical practices and surgical procedures is leading to high segment growth in the thermoformable film market.

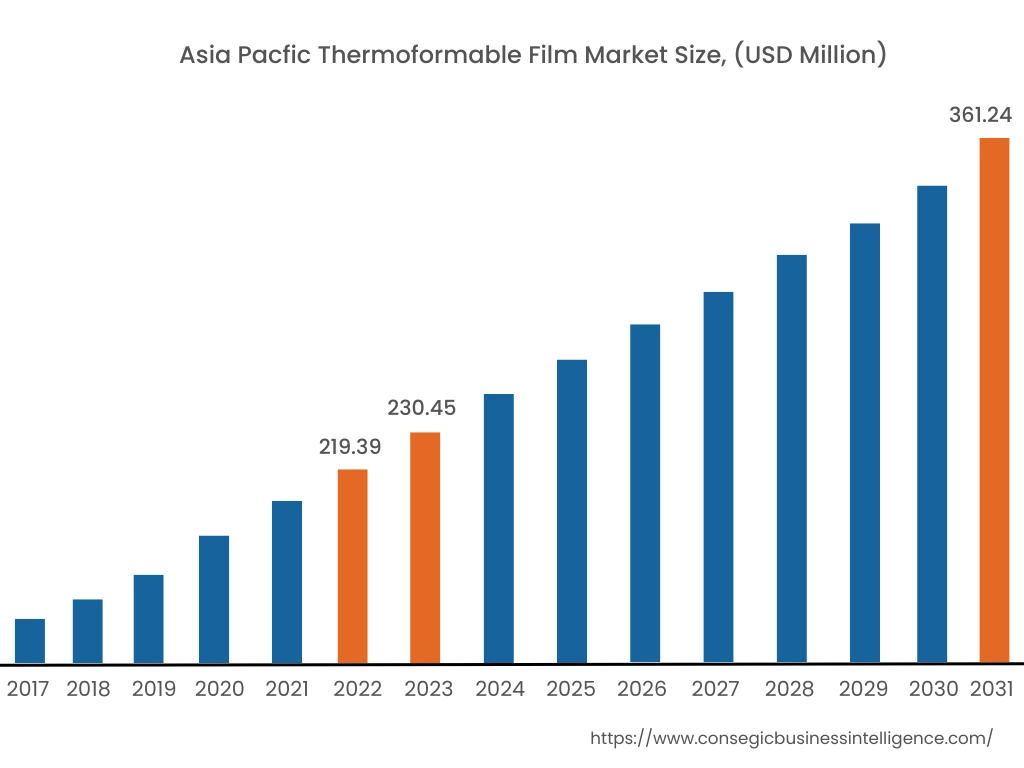

By Region :

The regional segment includes North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

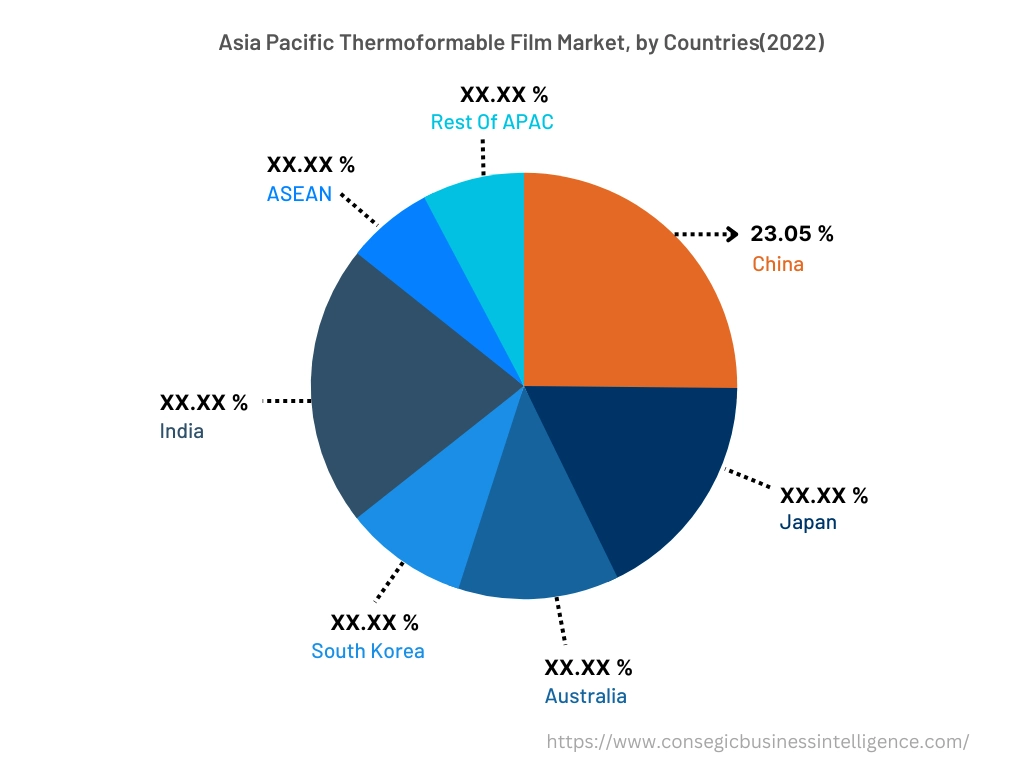

In 2022, Asia Pacific accounted for the highest market share at 38.55%, was valued at USD 219.39 million in 2022 and USD 230.45 million in 2023, and it is expected to reach USD 361.24 million in 2031. In Asia Pacific, China accounted for the highest market share of 23.05% during the base year of 2022. This is due to the high demand for ready-to-eat food items in this region. Large consumption of alcoholic beverages and ready to drink fruit juices by consumers in the region is driving the market growth. Furthermore, the increasing usage of materials such as PVC and PE in the food packaging industry is fostering regional growth. Also, the increasing population and rising disposable income is acting as a catalyst for growth in the usage of packaged food and consumer goods in this region. Thus, due to the aforementioned factors, the thermoformable film market is witnessing positive growth in the region.

Moreover, North America is expected to witness significant growth over the forecast period, growing at a CAGR of 6.4% during 2023-2031. The rising food & beverage industry in the US coupled with increasing electronic goods sales is driving the growth of the thermoformable film market.

Top Key Players & Market Share Insights:

The Thermoformable Film market is highly competitive, with several large players and numerous small and medium-sized enterprises. These companies have strong research and development capabilities and a strong presence in the market through their extensive product portfolios and distribution networks. The market is characterized by intense competition, with companies focusing on expanding their product offerings and increasing their market share through mergers, acquisitions, and partnerships. The key players in the market include-

- Klockner Pentaplast

- UFlex Limited

- Synpac

- RapidMade

- A&M Packaging

- Vecom Group

- Vishakha Polyfab Pvt Ltd

- DuPont Specialty Products India Pvt. Ltd.

- Hypac Packaging Pte. Ltd.

- Clifton Packaging Group Ltd.

Recent Industry Developments :

- In November 2020, Vishakha Polyfab Pvt Ltd acquired AcquaFrost, a leading water quenched blown film technology. This acquisition is expected to drive Vishakha's leadership position in the high barrier packaging in India and abroad.

- In February 2023, UFlex Limited, India's one of the largest multinational flexible packaging and solutions company, launched a new product which is co-extruded transparent biaxially-oriented polyethylene terephthalate or BOPET film. The product is known for its high tensile strength, chemical stability, dimensional integrity, and transparency.

Key Questions Answered in the Report

What was the market size of the thermoformable film industry in 2022? +

In 2022, the market size of thermoformable film was USD 569.10 million.

What will be the potential market valuation for the thermoformable film industry by 2031? +

In 2031, the market size of thermoformable film will be expected to reach USD 932.95 million.

What are the key factors driving the growth of the thermoformable film market? +

Growing demand for packaged food items is fueling market growth at the global level.

What is the dominating segment in the thermoformable film market by end-use industry? +

In 2022, the food segment accounted for the highest market share of 34.15% in the overall thermoformable film market.

Based on current market trends and future predictions, which geographical region is the dominating region in the thermoformable film market? +

Asia Pacific accounted for the highest market share in the overall thermoformable film market.