Textile Chemicals Market Size:

Textile Chemicals Market size is estimated to reach over USD 38.04 Billion by 2031 from a value of USD 26.90 Billion in 2023 and is projected to grow by USD 27.61 Billion in 2024, growing at a CAGR of 4.4% from 2024 to 2031.

Textile Chemicals Market Scope & Overview:

The textile chemicals market focuses on chemicals used during various stages of textile production, including pre-treatment, dyeing, printing, and finishing processes. These chemicals, such as surfactants, softeners, bleaching agents, and colorants, enhance the performance, appearance, and durability of textile products. Key characteristics of textile chemicals include their ability to impart desired properties like water repellency, wrinkle resistance, flame retardancy, and colorfastness to fabrics. The benefits include improved textile quality, enhanced production efficiency, and adherence to environmental and safety standards. Applications cover a wide range of end products, including apparel, home textiles, industrial textiles, and technical fabrics. End-use industries include fashion and apparel, automotive interiors, home furnishings, and healthcare textiles, driven by advancements in textile manufacturing technologies, rising consumer demand for functional textiles, and growing awareness of sustainable production practices.

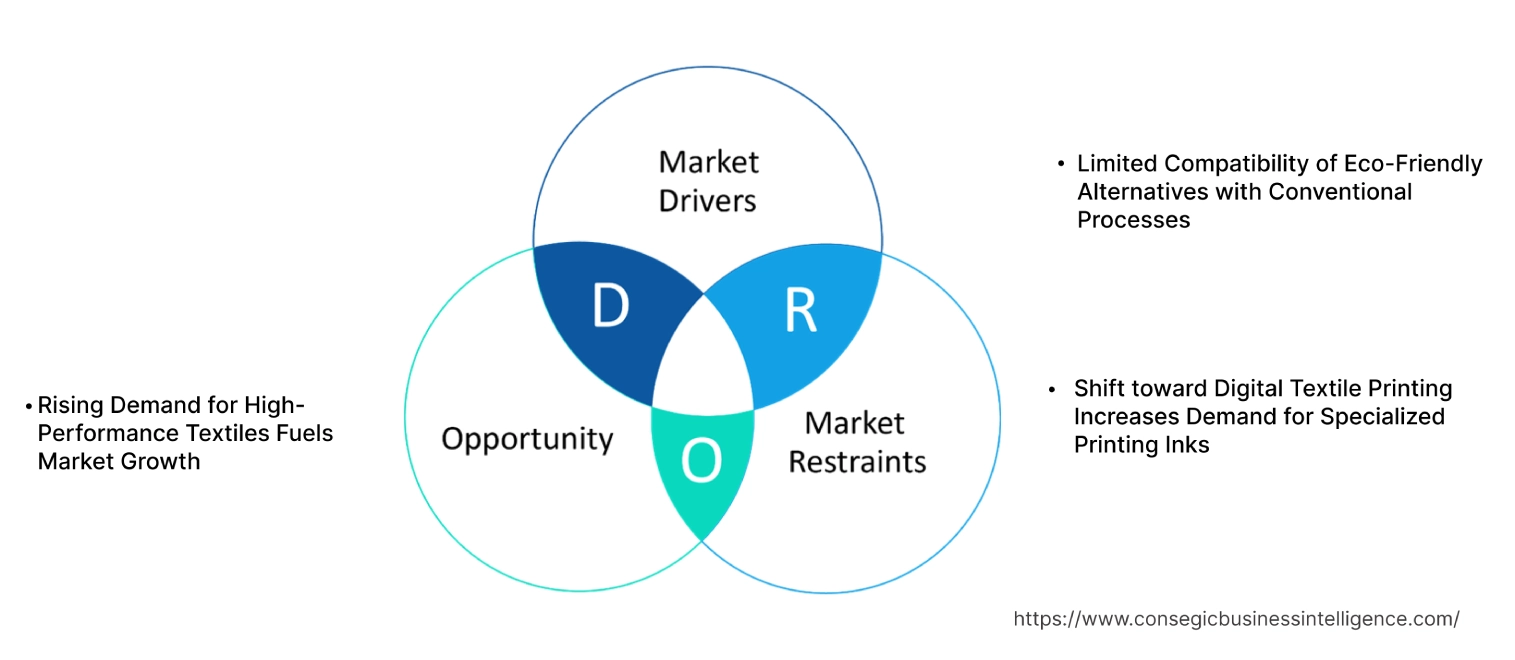

Textile Chemicals MarketDynamics - (DRO) :

Key Drivers:

Limited Compatibility of Eco-Friendly Alternatives with Conventional Processes

The growing emphasis on sustainability has led to the development of eco-friendly textile chemicals, such as bio-based dyes, biodegradable finishes, and waterless processing agents. However, these alternatives often face compatibility challenges with conventional textile processing systems. Traditional dyeing and finishing setups are designed for synthetic, chemical-intensive formulations, and switching to eco-friendly chemicals may require modifications to machinery and processes. For example, waterless dyeing technologies using supercritical CO₂ require specialized equipment that many textile manufacturers do not possess.

Additionally, bio-based dyes and finishes can sometimes exhibit inconsistent performance, such as limited colorfastness or durability, across different fabric types. These issues increase production complexity and operational costs, making it challenging for manufacturers to transition fully to sustainable solutions. Such limitations restrict the adoption of eco-friendly alternatives, particularly in regions where cost efficiency and scalability are critical concerns.

Key Restraints :

Shift toward Digital Textile Printing Increases Demand for Specialized Printing Inks

The growing adoption of digital textile printing technologies is driving the textile chemicals market demand for advanced printing chemicals and inks tailored to this method. Unlike conventional screen printing, digital printing requires precision-engineered inks such as reactive dyes for cotton, sublimation inks for polyester, and pigment dispersions for versatile applications. These specialized inks offer enhanced color vibrancy, durability, and environmental benefits by reducing water and chemical waste.

Digital printing technology is gaining popularity in the fashion, home textiles, and signage industries due to its ability to produce intricate designs, reduce lead times, and offer customization at scale. For instance, pigment-based digital printing eliminates the need for post-treatment processes, saving energy and water. The growing applications for high-quality and sustainable printing solutions are driving innovations in digital textile chemicals, propelling the market forward as industries increasingly shift toward digital methods.

Future Opportunities :

Rising Demand for High-Performance Textiles Fuels Market Growth

The increasing high application for high-performance textiles with advanced functionalities is a significant driver for the textile chemicals market. Industries such as sportswear, healthcare, and defense are seeking textiles with enhanced properties like moisture management, UV protection, antimicrobial activity, and flame retardancy. Advanced textile chemicals, including durable water-repellent (DWR) coatings, phase-change materials (PCMs), and silver-based antimicrobial agents, are integral to achieving these functionalities.

For instance, flame-retardant finishes are crucial in protective clothing for firefighters and industrial workers, while moisture-wicking treatments are essential in performance sportswear. Innovations such as nanotechnology-based coatings and breathable waterproof membranes are expanding the applications of high-performance textiles. As consumer expectations for durability, comfort, and multifunctionality grow, the adoption of advanced textile chemicals is expected to rise, further driving the textile chemicals market.

Textile Chemicals Market Segmental Analysis :

By Product Type:

Based on product type, the textile chemicals market is segmented into coating & sizing agents, colorants & auxiliaries, finishing agents, surfactants, de-sizing agents, bleaching agents, and others.

The coating & sizing agents segment accounted for the largest revenue in textile chemicals market share in 2023.

- Coating and sizing agents play a critical role in improving the strength and smoothness of yarns during the weaving process.

- These chemicals enhance fiber performance, reduce breakage rates, and improve processing efficiency in textile production.

- The increasing applications for high-quality textiles, coupled with advancements in textile machinery requiring superior yarn performance, support the dominance of this segment.

- Additionally, the rising adoption of eco-friendly and biodegradable coating agents, driven by stringent environmental regulations, is further boosting development and creating new textile chemicals market opportunities.

- Coating & sizing agent’s analysis lead the textile chemicals market trends due to their essential role in yarn preparation and the growing appeal for sustainable solutions in textile manufacturing.

The finishing agents segment is anticipated to register the fastest CAGR during the forecast period.

- Finishing agents are increasingly used to impart desired properties to textiles, such as water repellency, flame resistance, antimicrobial effects, and softness.

- The applications for multifunctional textiles in sectors like healthcare, outdoor apparel, and home furnishings are driving the rapid adoption of advanced finishing chemicals.

- Innovations in nanotechnology-based finishes and sustainable formulations are further enhancing the rising potential of this segment.

- Finishing agents are expected to grow rapidly as per the textile chemicals market analysis, driven by the applications for high-performance textile trends with specialized functionalities across various industries.

By Fiber Type:

Based on fiber type, the market is segmented into natural fibers and synthetic fibers.

The synthetic fibers segment accounted for the largest revenue in the textile chemicals market share in 2023.

- Synthetic fibers, such as polyester, nylon, and acrylic, dominate the textile sector's expansion due to their durability, affordability, and versatility.

- These fibers require significant chemical treatment during processing, including dyeing, finishing, and coating, contributing to the high textile chemicals market demand.

- The growing preference for synthetic fibers in industrial and technical textiles, combined with advancements in recycling technologies, supports the segment’s dominance.

- Additionally, the market rise for performance fabrics in sportswear and outdoor apparel further drives the consumption of chemicals for synthetic fibers.

- Synthetic fibers lead the market analysis, supported by their widespread application in cost-effective and high-performance textiles across multiple industries resulting in rapid market trends.

The natural fibers segment is anticipated to register the fastest CAGR during the forecast period.

- Natural fibers, including cotton, wool, and silk, are experiencing renewed interest due to the rising application for sustainable and eco-friendly textiles.

- The processing of natural fibers involves various chemicals, such as desizing agents and bleaching agents, to enhance fiber quality and dye uptake.

- The growing consumer preference for organic and ethically sourced textiles, along with increasing regulatory support for natural fiber production, is boosting advancement in this segment.

- Natural fibers are expected to grow rapidly, driven by the rising applications for sustainable textiles and advancements in chemical treatments to enhance fiber quality and performance.

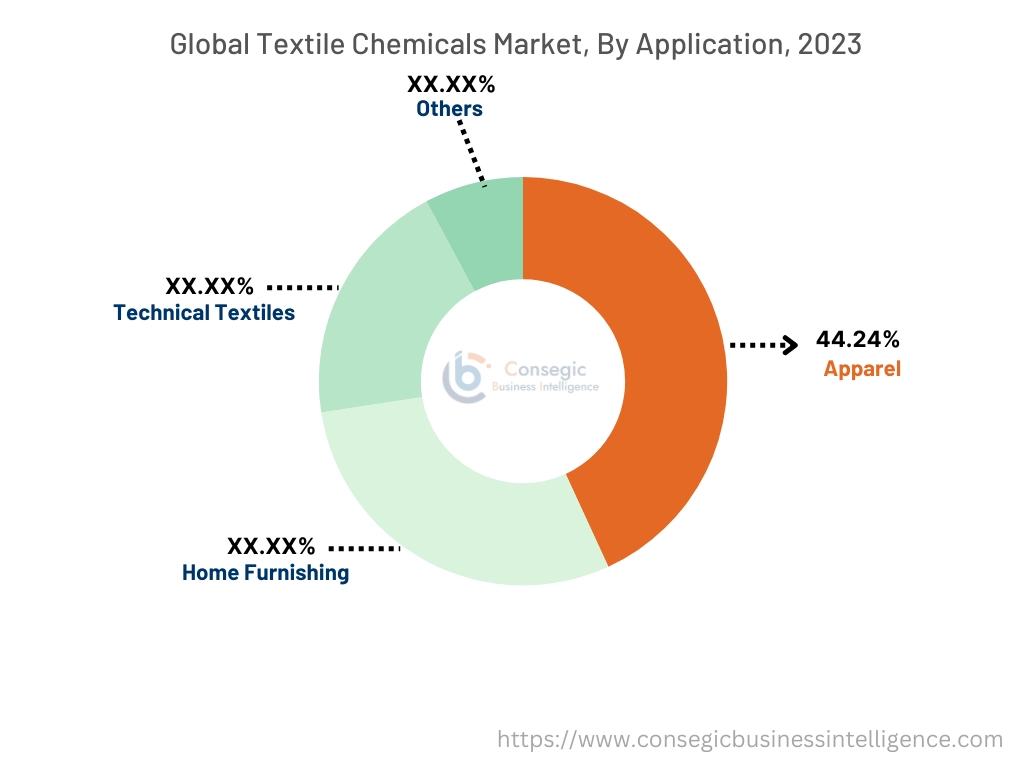

By Application:

Based on application, the market is segmented into apparel, home furnishing, technical textiles, and others.

The apparel segment accounted for the largest revenue share of 44.24% in 2023.

- The apparel industry is the largest consumer of textile chemicals, using them extensively for dyeing, finishing, and printing to achieve desired aesthetics and performance characteristics.

- The growing applications for fast fashion, coupled with the increasing need for functional clothing like sportswear and outdoor gear, drive the consumption of chemicals in this segment.

- Additionally, the rising focus on sustainable fashion and the adoption of eco-friendly dyes and finishes are reshaping the appeal of textile chemicals in the apparel sectors.

- The apparel segment dominates the market, driven by the extensive use of chemicals in dyeing and finishing processes and the rising hike for functional and sustainable clothing.

The technical textiles segment is anticipated to register the fastest CAGR during the forecast period.

- Technical textiles are engineered products designed for specific functional applications in industries such as automotive, construction, and healthcare.

- These textiles require advanced chemical treatments for properties like flame resistance, UV protection, and antimicrobial effects.

- The increasing adoption of technical textiles in infrastructure projects, protective clothing, and medical applications is driving the hike for specialized textile chemicals.

- Advancements in nanotechnology and smart textiles are further accelerating development in this segmental trend.

- Technical textiles analysis is expected to grow rapidly, supported by their expanding applications in industrial and medical sectors and the surge for high-performance chemical treatments.

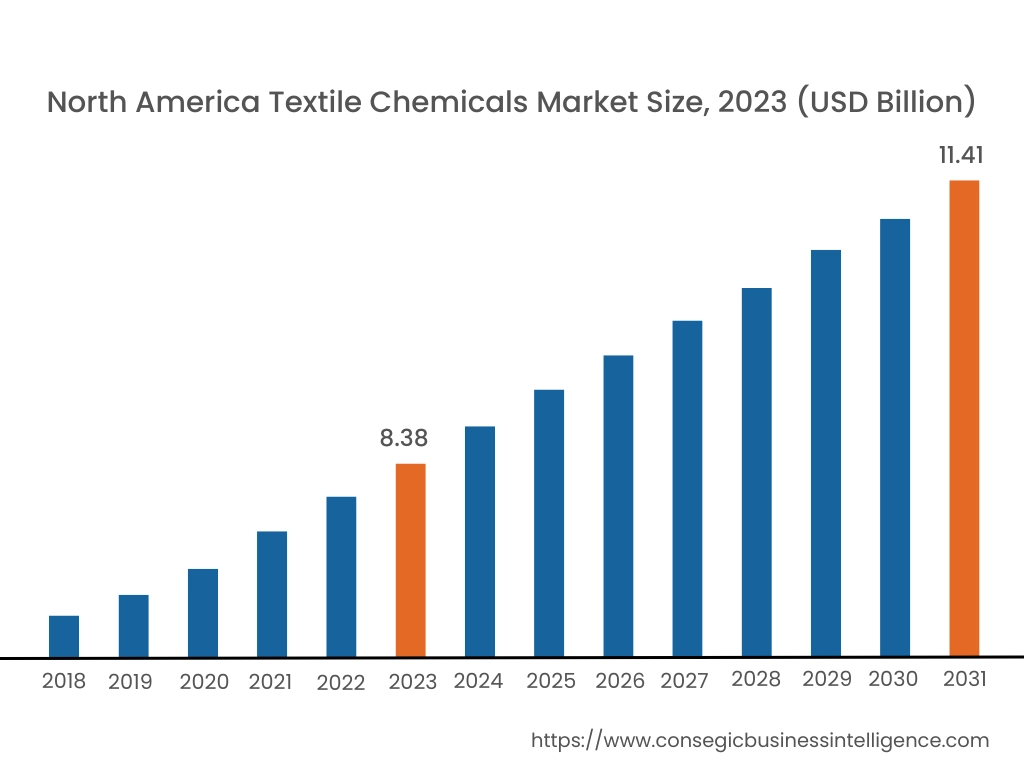

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2023, North America accounted for a significant market share at 31.27% and was valued at USD 8.38 Billion and is expected to reach USD 11.41 Billion in 2031. In North America, the U.S. accounted for the highest share of 78.14% during the base year of 2023. North America is a significant market for textile chemicals, driven by the rise of the region’s growing technical textiles and home furnishing industries. The U.S. dominates the region due to its advanced manufacturing capabilities and increasing adoption of functional textiles in sectors such as healthcare, automotive, and construction. Textile finishing chemicals, including stain repellents and flame retardants, are widely used in technical textiles, boosting market trends. Canada is contributing to the surge through its increasing focus on sustainable textiles and environmentally friendly processing chemicals. However, strict environmental regulations regarding chemical usage and disposal present challenges to manufacturers.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 4.7% over the forecast period. Asia-Pacific is the largest and fastest-growing region in the textile chemicals market expansion, fueled by the region's dominance in textile manufacturing and exports. China leads the market trends, driven by its massive textile production capacity and increasing adoption of advanced processing chemicals to enhance fabric quality. India is seeing a strong surge due to rising investments in textile parks and export-oriented textile production. Bangladesh and Vietnam are emerging as key players in the global textile chemicals market supply chain, increasing demand for pre-treatment and dyeing chemicals. However, environmental concerns related to wastewater treatment and stricter regulations on chemical usage in textile processing are challenges for the region.

Europe’s textile chemicals market analysis is supported by a strong emphasis on sustainable and eco-friendly solutions, driven by regulatory frameworks such as the EU REACH Regulation. Germany, Italy, and France lead the region, with robust advancement for specialty chemicals in fashion textiles and home furnishings trends. Germany’s focus on technical textiles for automotive and industrial applications is driving the use of finishing and coating chemicals. Italy’s textile industry is investing in eco-friendly dyeing and finishing chemicals to meet consumer needs for sustainable fashion. However, the high cost of compliance with stringent environmental standards can be a barrier for smaller manufacturers.

The Middle East & Africa region analysis is witnessing steady growth in the textile chemicals market expansion, driven by increasing trends in investments in textile manufacturing in countries like Turkey, Egypt, and South Africa. Turkey, as a major textile exporter, is focusing on enhancing fabric quality through advanced finishing and dyeing chemicals. In South Africa, the hike for technical textiles is driving the use of specialty chemicals in industrial applications. However, the region faces challenges such as limited local production capabilities for specialty chemicals and dependency on imports, which can increase costs for textile manufacturers.

Latin America is emerging for textile chemicals market opportunities, with Brazil and Mexico leading the region. Brazil’s growing home textile and apparel industries are driving instant hikes for pre-treatment, dyeing, and finishing chemicals. Mexico’s strong position in the textile supply chain for the U.S. market is boosting the adoption of textile processing chemicals to meet export quality standards. Additionally, the increasing focus on sustainable textile production in the region is creating opportunities for eco-friendly chemicals. However, economic instability and limited R&D capabilities for advanced chemicals can hinder the market's growth.

Top Key Players & Market Share Insights:

The textile chemicals market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global textile chemicals market. Key players in the textile chemicals industry include -

Recent Industry Developments :

Mergers and Acquisitions:

- In November 2024, John Hogg Technical Solutions acquired Avocet Dye and Chemical Company, adding Avocet's flame retardants, dyes, and CETAFLAM® brand to its portfolio. The move expands John Hogg's market reach and strengthens its specialty chemicals business.

- In February 2024, Fibre2Fashion acquired AlchemPro, a cloud-based platform for chemical market intelligence. This move diversifies its offerings beyond the textile sector, complementing its TexPro tool and expanding its reach to the chemicals industry.

Investments and Funding:

- In November 2024, Green Theme Technologies (GTT) closed a $6 million Series C funding round led by Pangaea Ventures and Cottonwood Technology Ventures. The funds will scale GTT’s sustainable EMPEL® technology, a PFAS-free, waterless textile treatment, catering to footwear, apparel, and military markets. This investment supports R&D, expansion, and growing demand for eco-friendly solutions.

Textile Chemicals Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 38.04 Billion |

| CAGR (2024-2031) | 4.4% |

| By Product Type |

|

| By Fiber Type |

|

| By Application |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the current size of the textile chemicals market? +

Textile Chemicals Market size is estimated to reach over USD 38.04 Billion by 2031 from a value of USD 26.90 Billion in 2023.

What is the projected growth rate of the market? +

The projected growth rate of the market is 4.4% during the forecasted period.

Which region dominates the textile chemicals market? +

Asia-Pacific leads the market, driven by large-scale textile production in countries like China, India, and Bangladesh.

What factors are driving the growth of the textile chemicals market? +

Rising demand for technical textiles and eco-friendly processing chemicals are major growth drivers.

What are the key developments in the market? +

Innovations include sustainable dyeing processes, biodegradable finishing agents, and advancements in performance-enhancing chemicals.