- Summary

- Table Of Content

- Methodology

Telehandler Market Size:

Telehandler Market size is estimated to reach over USD 11.24 Billion by 2032 from a value of USD 7.10 Billion in 2024 and is projected to grow by USD 7.39 Billion in 2025, growing at a CAGR of 5.9% from 2025 to 2032.

Telehandler Market Scope & Overview:

A telehandler, or telescopic handler, is a multi-purpose lifting machine with an extendable boom that handles material vertically and horizontally. It is widely applied in construction, agriculture, logistics, and industry, and integrates the functions of a forklift, crane, and loader into one small machine.

Core components consist of a telescopic boom, hydraulic system, load stabilizers, as well as attachments such as forks, buckets, and lifting jibs. Advanced models provide all-wheel steering, operator cabins with built-in controls, and terrain-adapted drivetrains.

The telehandler enables accurate placement of loads, long reach performance, and productive material handling in tight or tough spaces. Its versatility to undertake various tasks and interchangeable attachments enhance site productivity while minimizing the use of multiple machines. For lifting pallets on construction sites or loading agricultural materials on farms, it remains a must-have equipment for operations requiring flexibility, reach, and load stability across different work conditions.

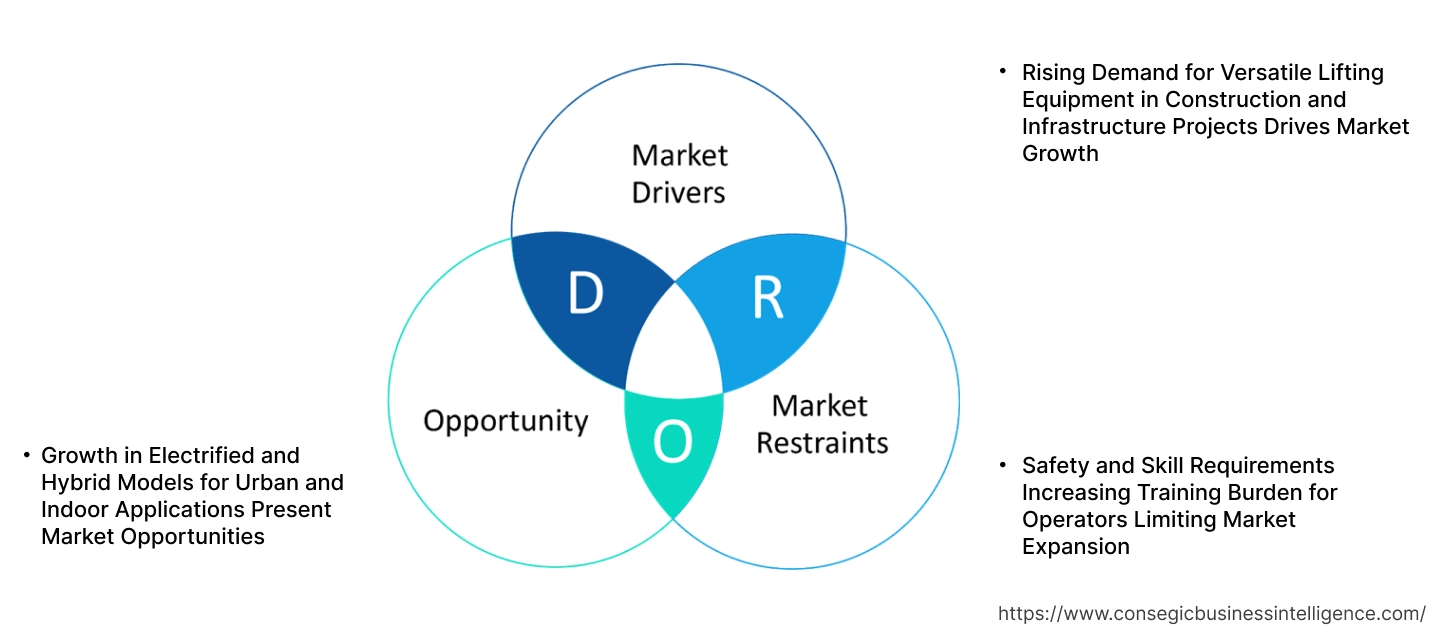

Key Drivers:

Rising Demand for Versatile Lifting Equipment in Construction and Infrastructure Projects Drives Market Growth

Construction companies are increasingly finding a place for telehandlers as a result of their versatility and performance in operating diverse site jobs. These machines consolidate the capacities of cranes, forklifts, and aerial lifts to serve excellently for moving material, taking personnel up to level heights, and positioning equipment on uneven or higher levels. Construction development projects of urban, industrial, and transportation sectors are the major drivers fueling equipment needs for offering reach, payload, and mobility in terrain. With attachments like buckets, winches, and pallet forks, they increase jobsite productivity and eliminate equipment redundancy. Their potential for working in limited spaces and on rough terrain positions them above conventional lifting equipment.

- For instance, in April 2025, Faresin unveiled the FS6.26 Telehandler at Bauma 2025. The upgraded model offers agility, maneuverability and cost efficiency for fuel, along with improved hydraulic system and control features.

As contractors focus on equipment versatility to maximize cost and time, uptake is steadily growing, propelling the telehandler market expansion.

Key Restraints:

Safety and Skill Requirements Increasing Training Burden for Operators Limiting Market Expansion

Telehandlers operation necessitates professional training to handle load balance, boom extension, and terrain stability. Regulatory requirements in countries such as North America and Europe impose certification and regular assessment on operators. Tip-over, load drop, and maneuvering risks highlight the need for experienced personnel. Small contractors and rental companies struggle to hire certified operators, particularly in high-turnover labor markets. In addition, employers also need to incur costs for refresher training and safety inspections, adding to operating expenses. Lacking formal training facilities in emerging markets, there are further limiting factors to deploying safe equipment in such markets. With increasing demand, these limitations on human capital hold back expanded access and safe use—thus curbing telehandler market growth in fragmented or under-equipped markets.

Future Opportunities :

Growth in Electrified and Hybrid Models for Urban and Indoor Applications Present Market Opportunities

Electrification of material handling is gathering pace as indoor operations and city construction require low-emission, noiseless machinery. Companies are launching battery-electric and hybrid telehandler versions that enable compliance with clean energy in zero-emission areas. These machines come with lower maintenance, less operating expense, and enhanced operator comfort. Small electric versions are widely applied in warehouses, city redevelopment projects, and tight-access maintenance applications. Demand is increasing in North America and Europe, where green building codes and environmental regulations focus on emission-free machinery. Increasing adoption of sustainable building and eco-industrial parks is widening the application base for electric models.

- For instance, in March 2025, LGMG launched its first electric telehandler, the H625E. The machine has a maximum lifting height of 5.94m, 3.41m outreach and a capacity of 2.75 tons (2500kg). Powered by an 80V lithium battery, the vehicle provides emission and noise-free operation at a low cost.

With operators requiring cleaner, quieter, and more efficient equipment, electrified product lines are opening high-value telehandler market opportunities based on both regulatory change and customer needs.

Telehandler Market Segmental Analysis :

By Max Lifting Height:

Based on max lifting height, the telehandler market is segmented into below 5m, 5–10m, and above 10m.

The 5–10m segment accounted for the largest revenue share in 2024.

- Machines with 5–10m lift height are versatile and suitable for both indoor and outdoor use across construction and agriculture.

- This range supports common tasks like pallet lifting, load placement on scaffolding, and material handling on farms.

- Medium-lift units strike a balance between cost-efficiency and functionality, making them a preferred choice across SMEs.

- As per telehandler market analysis, this height segment dominates due to widespread use across mid-rise construction and agricultural applications.

The above 10m segment is projected to witness the fastest CAGR during the forecast period.

- High-lift machines are essential for tall building construction, large-scale warehousing, and mining operations.

- These models offer greater outreach, advanced stability systems, and load sensors, enhancing worker safety at height.

- Their growing adoption is fueled by vertical expansion in urban infrastructure and need for high-reach machines.

- According to the telehandler market trends, infrastructure megaprojects in developing regions are accelerating adoption in this category.

By Lift Capacity:

Based on lift capacity, the market is segmented into below 3 tons, 3–10 tons, and above 10 tons.

The 3–10 tons segment accounted for the largest telehandler market share in 2024.

- Mid-capacity models are the industry standard for general material handling in construction and farming.

- Their ability to handle heavy loads while remaining maneuverable supports broad utility across job sites.

- These models are widely available from global OEMs and rental firms, ensuring easy access and serviceability.

- According to the telehandler market analysis, the segment’s flexibility and cost-performance ratio maintain its dominance.

The above 10 tons segment is projected to grow at the fastest CAGR during the forecast period.

- Heavy-duty machines are gaining traction in mining and industrial sectors where oversized materials need lifting and transporting.

- These machines feature reinforced frames, extended booms, and high-powered drivetrains to handle extreme loads.

- Increasing mechanization of large-scale logistics yards and port operations is boosting this segment.

- As per telehandler market trends, rising industrialization and off-highway handling requirements support this segment's strong momentum.

By Propulsion Type:

Based on propulsion type, the telehandler market is segmented into fossil fuel, electric, and hybrid.

The fossil fuel segment held the largest revenue share in 2024.

- Diesel-powered vehicles remain the most commonly used due to their high torque, extended run times, and proven performance in outdoor conditions.

- These machines are ideal for rugged terrains, making them a mainstay on construction and mining sites.

- Widespread service infrastructure and fuel availability continue to favor fossil fuel-driven models.

- Despite emission regulations, fossil fuel units retain dominance due to their unmatched performance in heavy-duty applications to support the telehandler market demand.

The electric segment is anticipated to witness the fastest CAGR during the forecast period.

- Electric models are gaining popularity in indoor environments and low-emission zones due to zero exhaust output.

- OEMs are investing in lithium-ion battery systems and compact electric drivetrains to boost performance and reduce charge times.

- Regulatory support and environmental mandates are pushing commercial operators toward clean energy alternatives.

- For instance, in January 2025, JLG Industries launched its first electric telehandler, the E313, developed for all-terrain and off-road use. Powered by 48V lithium-ion batteries, which provide up to 4h of continuous operation, the E313 ensures zero emissions and low-noise operation. The model also comes with charging adapters for users to independently charge their vehicles using a 110-volt or 220-volt power source.

- Thus, electrification is key to long-term telehandler market expansion across industrial and urban sectors.

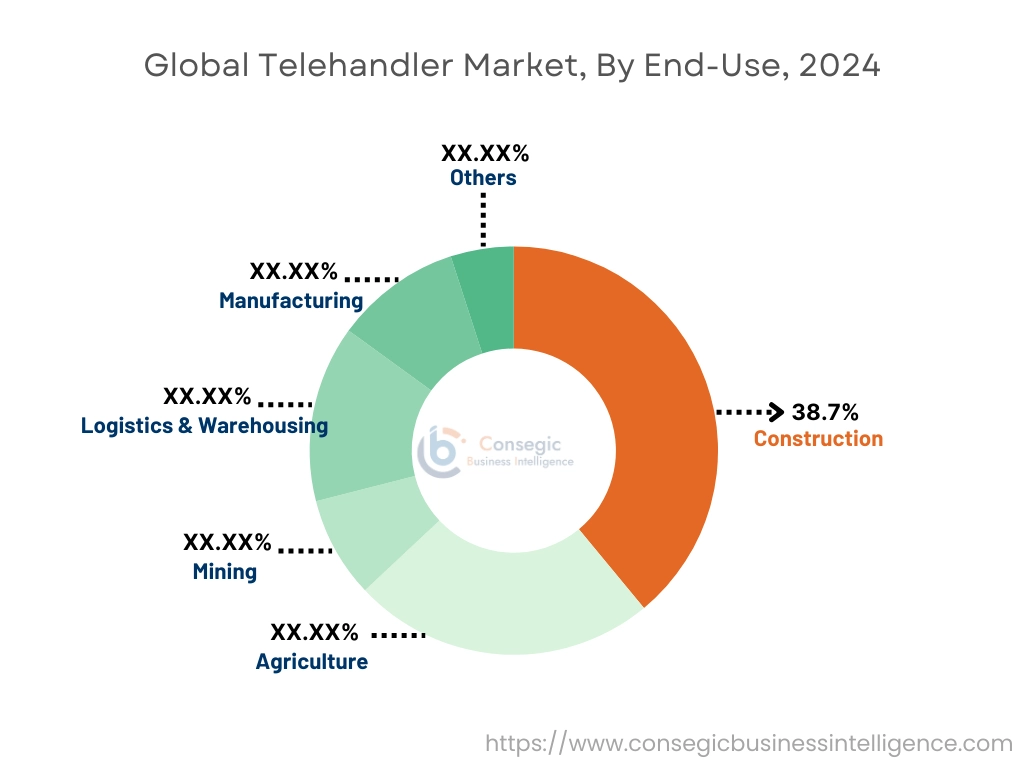

By End-Use:

Based on end-use, the telehandler industry is segmented into construction, agriculture, mining, logistics & warehousing, manufacturing, and others.

The construction segment accounted for the largest telehandler market share of 38.7% in 2024.

- They are critical to material placement, block stacking, and site cleanup in mid- to high-rise construction projects.

- The segment benefits from rising global infrastructure investment, urbanization, and smart city development.

- Rotating telehandlers and high-reach boom models are necessary in congested job sites.

- Hence, strong construction activity across Asia-Pacific and North America drives the telehandler market growth.

The logistics & warehousing segment is projected to grow at the fastest CAGR during the forecast period.

- They offer flexibility in loading/unloading containers, stacking pallets, and moving bulk loads in large distribution centers.

- E-commerce expansion and automated warehouse development are fueling machinery upgrades across the sector.

- Electric and low-profile models are being deployed for indoor use with minimal floor impact.

- Telehandler market demand is surging in logistics hubs globally due to the rapid scaling of supply chain networks.

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

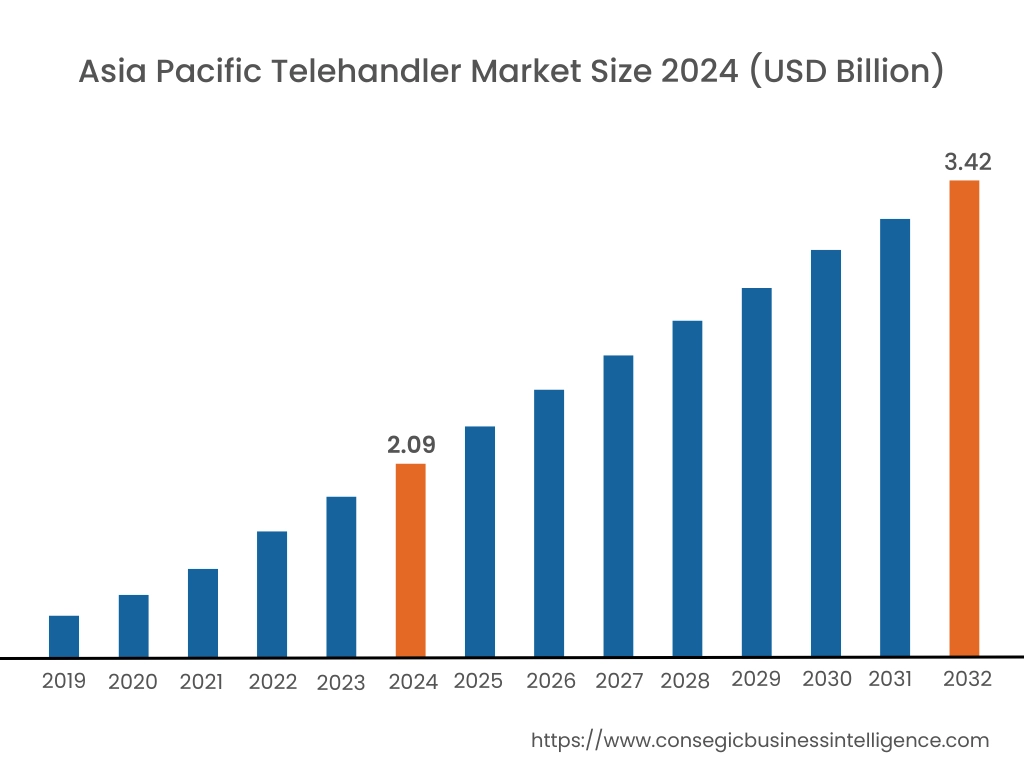

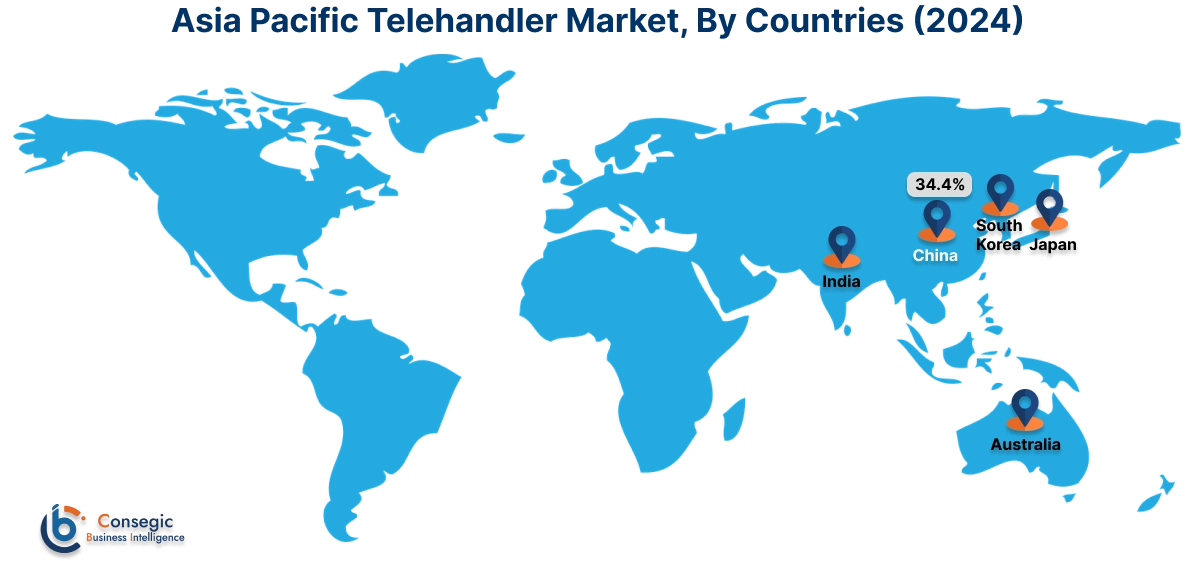

Asia Pacific region was valued at USD 2.09 Billion in 2024. Moreover, it is projected to grow by USD 2.18 Billion in 2025 and reach over USD 3.42 Billion by 2032. Out of this, China accounted for the maximum revenue share of 34.4%. Asia-Pacific emerges as the most dynamic region, driven by mega-infrastructure projects, growing agricultural mechanization, and rising warehousing requirements. In China and India, fast-paced urbanization and government-supported smart city projects are key drivers for equipment purchases. Market analysis reveals a growing trend towards compact and mid-range telehandlers for deployment in dense job sites and logistical centers. Japan and South Korea prioritize advanced automation and operator safety features, demonstrating mature construction habits. Southeast Asia's agricultural industry is slowly embracing them to efficiently handle crops, increasing equipment utilization outside traditional construction environments.

North America is estimated to reach over USD 3.64 Billion by 2032 from a value of USD 2.36 Billion in 2024 and is projected to grow by USD 2.45 Billion in 2025. In North America, the market for telescopic handlers continues to be strong because of strong infrastructure investment and continued activity in residential and commercial building. The United States dominates the region with wide adoption in utility operations, industrial warehousing, and agricultural use. Market research shows that end-users are increasingly seeking models equipped with sophisticated load management, four-wheel drive, and hybrid powertrains to meet environmental and performance requirements. Development within the region is being fueled by rental fleet growth and replacement cycles of fleets, especially as dirty diesel-powered machines are being replaced with cleaner, more efficient equipment.

Europe is an established market in which product sophistication and regulatory issues influence equipment choice. Germany, the UK, France, and Italy are all investing in high-performance machines designed for compact urban construction and renewable energy installation. Market trends indicate increased incorporation of telematics, remote diagnostics, and safety automation in order to conform to EU operational safety and emission regulations. Increasing need for electric and hybrid options is observed because the region seeks to minimize the environmental footprint of construction activities. The European market opportunity involves multi-functional attachments for municipal and utility uses that are in heavy demand within the public and private sectors.

Latin America is seeing steady uptake, most notably in Brazil, Mexico, and Chile, as growth in the construction, agricultural, and mining industries generates a demand for flexible material-handling solutions. Market research emphasizes cost-effectiveness, durability, and low maintenance as major buying considerations. They are increasingly popular in agriculture for their capability to lift, move, and place items such as hay bales, feed, and other items over varied terrain. The telehandler market opportunity within the country exists in providing economical, tough machines that satisfy domestic job site specifications, with the availability of aftermarket service and spare parts.

The Middle East and Africa offer growth potential, particularly in the UAE, Saudi Arabia, and South Africa, where construction megaprojects and mining activities lead equipment needs. Market analysis indicates that there is strong demand for high-capacity models to be used in oil & gas plants, large-scale residential estates, and desert logistics. Moreover, the increasing focus on infrastructure resilience and agriculture farming practices' modernization in rural areas is generating growth opportunities. The difficulties posed by extreme weather conditions and lack of easy access to qualified maintenance assistance highlight the requirement for resilient, simple-to-maintain equipment.

Top Key Players and Market Share Insights:

The telehandler market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global telehandler market. Key players in the telehandler industry include -

- C. Bamford Excavators Ltd. (JCB) (United Kingdom)

- Manitou Group (France)

- Caterpillar Inc. (USA)

- Terex Corporation (USA)

- Komatsu Ltd. (Japan)

- Merlo S.p.A. (Italy)

- Liebherr-International Deutschland GmbH (Germany)

- Haulotte Group (France)

- Dieci S.r.l. (Italy)

- Bobcat Company (USA)

Recent Industry Developments :

Acquisitions:

- In September 2024, Oshkosh completed the acquisition of AUSACORP S.L., adding its compact all-terrain machines for transportation and material handling to Oshkosh’s subsidiary, JLG’s equipment portfolio.

Telehandler Market Report Insights:

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 11.24 Billion |

| CAGR (2025-2032) | 5.9% |

| By Max Lifting Height |

|

| By Lift Capacity |

|

| By Propulsion Type |

|

| By End-Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Telehandler Market? +

Telehandler Market size is estimated to reach over USD 11.24 Billion by 2032 from a value of USD 7.10 Billion in 2024 and is projected to grow by USD 7.39 Billion in 2025, growing at a CAGR of 5.9% from 2025 to 2032.

What specific segmentation details are covered in the Telehandler Market report? +

The Telehandler market report includes specific segmentation details for max lifting height, lifting capacity, propulsion type and end-use.

What are the end-use industries of the Telehandler Market? +

The end-use industries of the Telehandler Market are construction, agriculture, mining, logistics & warehousing, manufacturing, and others.

Who are the major players in the Telehandler Market? +

The key participants in the Telehandler market are J.C. Bamford Excavators Ltd. (JCB) (United Kingdom), Manitou Group (France), Merlo S.p.A. (Italy), Liebherr-International Deutschland GmbH (Germany), Haulotte Group (France), Dieci S.r.l. (Italy), Bobcat Company (USA), Caterpillar Inc. (USA), Terex Corporation (USA) and Komatsu Ltd. (Japan).