- Summary

- Table Of Content

- Methodology

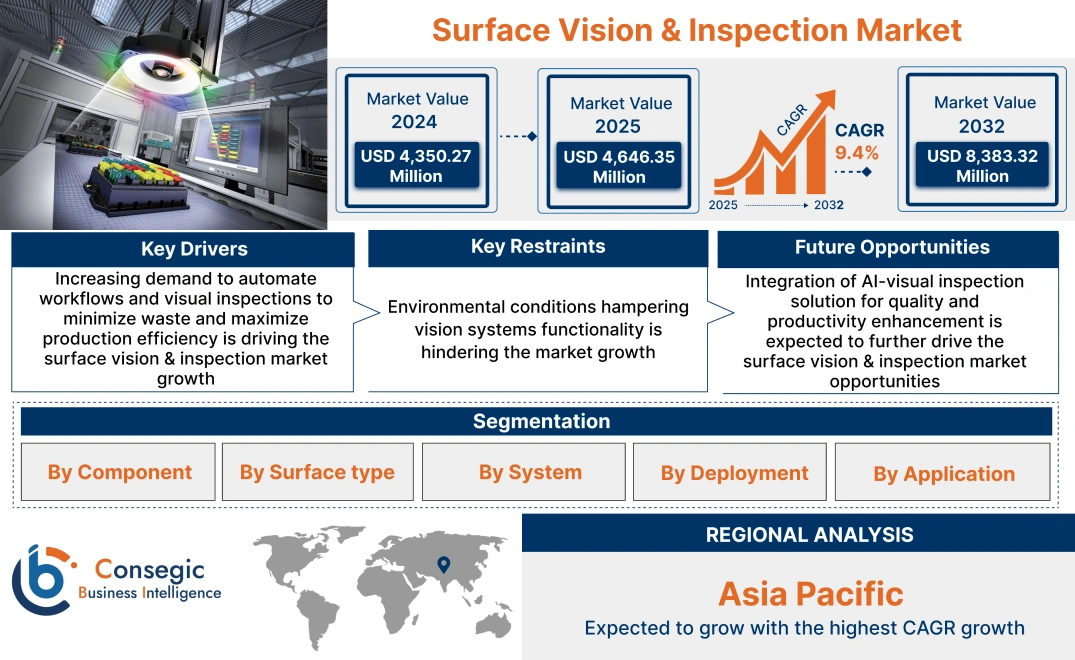

Surface Vision & Inspection Market Size:

Surface Vision & Inspection Market Size is estimated to reach over USD 8,383.32 Million by 2032 from a value of USD 4,350.27 Million in 2024 and is projected to grow by USD 4,646.35 Million in 2025, growing at a CAGR of 9.4% from 2025 to 2032.

Surface Vision & Inspection Market Scope & Overview:

Surface vision & inspection is used to monitor products through production lines for defect detection ensuring consistent and high-quality product manufacturing. Additionally, it is used for other applications such as product measurement, guiding robotic manufacturing, and sorting products by color or shape. Moreover, automated vision inspection systems help eliminate human error in production and manufacturing lines, using advanced camera technologies.

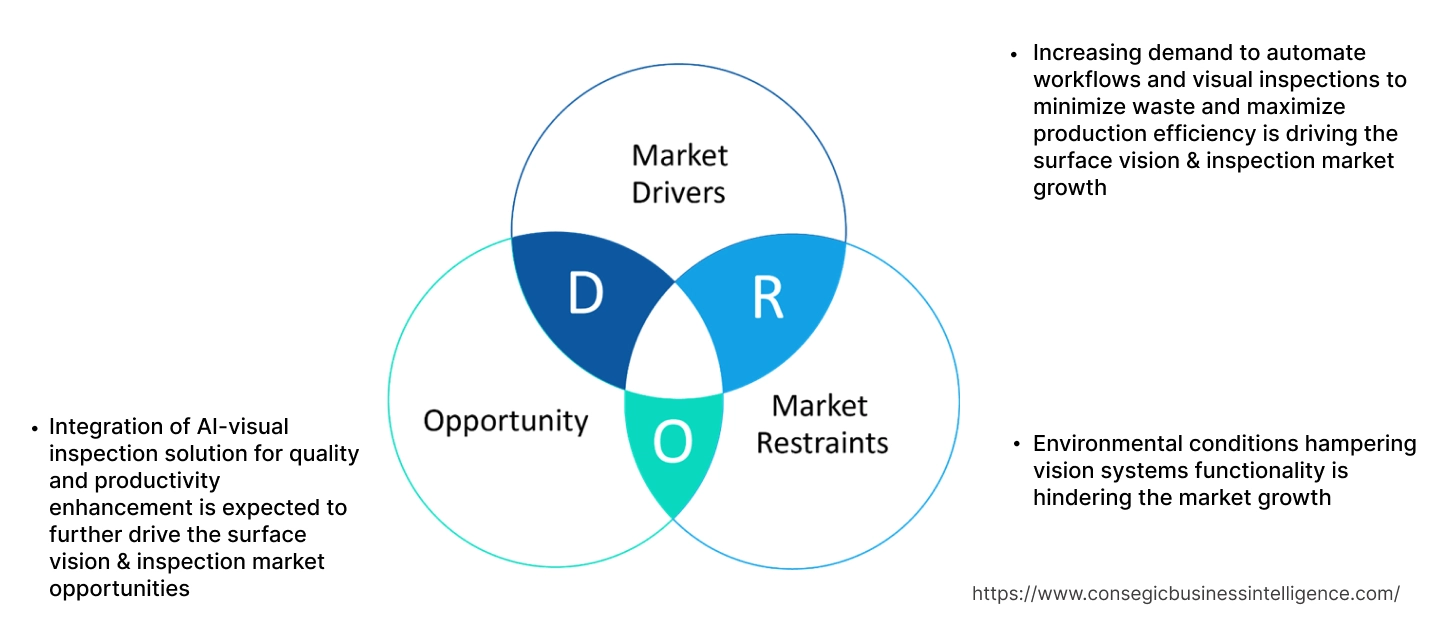

Key Drivers:

Increasing demand to automate workflows and visual inspections to minimize waste and maximize production efficiency is driving the surface vision & inspection market growth

Advanced surface vision inspection and automation tools play a crucial role in minimizing the scrap, costly rework, while improving productivity. The systems use high-definition cameras, advanced lighting, and a high-resolution touchscreen operator interface to precisely detect and classify defects in real-time. Moreover, surface inspection is widely applied in surface and print inspection applications, to identify defects such as insects, gels, carbons, color problems, streaks, drags, roller marks and more. Further, by detecting these issues early in the process and taking correct actions, it prevents costly rework and ensure high-quality output.

- For instance, in March 2022, Maxcess’s, VisionMax and VisionConnect new line of 100% vision inspection and workflow automation solutions. This new vision inspection system features high-definition cameras, advanced lighting, a high-resolution touchscreen operator interface, for wide-web applications.

Thus, automating workflow to reduce rework cost and material waste is driving the surface vision & inspection market expansion.

Key Restraints:

Environmental conditions hampering vision systems functionality is hindering the market growth

The major restraint for surface vision inspection system is their high sensitivity to environmental conditions, variation in lighting temperature and humidity. External interference significantly impacts their performance leading to inaccurate detection and inconsistent inspection result. Surface vision systems rely on controlled illumination for optimal image capture, poor lighting obscures fine details while excessive brightness causes glare, reflections and shadows. This sensitivity limits the use of machine vision systems in environments with fluctuating lighting conditions. Further, implementing solutions to mitigate these issues, such as controlled lighting environments, vibration dampening systems, and dust protection, is increasing both the setup and maintenance costs.

Thus, the poor functionality of vision systems due to environmental conditions hinders the surface vision & inspection market expansion.

Future Opportunities :

Integration of AI-visual inspection solution for quality and productivity enhancement is expected to further drive the surface vision & inspection market opportunities

The integration of AI- driven visual inspection solution is transforming surface vision & inspection market by significantly enhancing quality and productivity. AI-powered systems leverage machine learning algorithms and computer vision techniques to identify the smallest defect with high precision and speed. By automating defect detection, classification and predictive maintenance reduces errors, minimizes material wastage, and improves overall efficiency. Integrating AI visual inspection aims to ease reliance on scarce human capital while upholding rigorous quality standards.

- For instance, in 2024, Mitsubishi Electric Corporation and HACARUS Corporation collaborated to develop AI-based visual-inspection applications for manufacturing to improve manufacturing quality and overall productivity.

Thus, the AI driven solution in surface vision & inspection to create quality products further drives the surface vision & inspection market opportunities.

Surface Vision & Inspection Market Segmental Analysis :

By Component:

Based on the component, the market is segmented into hardware and software

Trends in the Component:

- Increasing trend of lens using spiral-shaped surface to maintain a clear focus at different distances in varying light conditions.

- LED lighting is increasingly being used in automotive lighting applications. Everything from small interior accent lights, high tech instrument panels

Hardware segment accounted for the largest revenue share in 2024

- The surface inspection system is consist of a single-board microcomputer for gathering data by operating multiple cameras simultaneously and transferring it to an external processing device.

- Line scan cameras are specifically utilized to capture high-resolution images of products as they move continuously through a production line.

- Area scan cameras captures wider area image in a single exposure, making them ideal for applications where the entire surface of an object needs to be inspected at once.

- For instance, Keyence, new 64 megapixel camera significantly improves accuracy in conventional inspections, covers a wider area in clear detail for increased inspection stability.

- Thus, based on the analysis, the capability of inspecting wider area at once is driving the surface vision & inspection market size.

Software segment is registered as the fastest CAGR in forecast period.

- In vision system, software plays a crucial role in detecting defects, predictive maintenance, cloud-based vision solutions, and advanced processing of images.

- Additionally, they also help with rapid development and deployment of machine vision inspection systems. Hundreds of algorithms and inspection steps are used for image processing to generate high-quality output.

- For instance, NI Vision Builder’s vision builder for automated inspection is a software for development and deployment purpose. It helps with object classification, detection and inspection of parts.

- Thus, the advancement in software technologies further drives the market growth.

By Surface Type:

Based on the surface type, the market is segmented into 2D and 3D.

Trends in Surface Type:

- The ability of 2D systems to quickly capture and analyse images allows for real-time quality control.

- 3D machine vision is widely used for precise measurements, shape analysis, and volumetric inspections.

3D segment accounted for the largest revenue share in 2024 as well as the fastest CAGR in forecast period.

- 3D inspection is able to detect minor flaws, such as surface imperfections, irregularities, deviations from design specifications, by capturing detailed 3D data of metal parts.

- Moreover, the speed and efficiency of 3D vision inspection systems reduce production downtime. Its rapid inspection and defect detection processes prevents production line stoppages while maintaining a smooth workflow.

- For instance, Mabri Vision’s new MV.EYE CR1 uses a 3D chromatic confocal line sensor. With 192 measuring points in a line and a measuring frequency of up to 6,000 Hz, even larger test areas with a very high point density.

- Thus, based on the analysis, the speed and efficiency of 3D inspection system is driving the surface vision & inspection market demand.

By System:

Based on the system, the surface vision & inspection market is segmented into camera-based system, and computer-based system.

Trends in System:

- Camera vision systems inspect products without physically touching them, making them ideal for delicate or sensitive items.

- Computer based system are increasingly being adopted to improve production, increase uptime and reduce expenses.

Camera based system accounted for the largest revenue share in the year 2024

- Camera vision inspection systems capture images and videos of items which is being inspected and analyzes them in real-time.

- Additionally, it reduces the need for manual labor, leading to faster and more efficient production lines, resulting in higher output while maintaining product quality.

- For instance, Trident's Vision Intelligence Systems using advanced technology to analyze the appearance of products, damaged packaging, broken seal, incorrect information, and misleading labels on the products to meet the required quality standards.

- Thus, as per the surface vision & inspection market analysis, the high dependency on cameras for increasing efficiency while reducing manual labour is driving the surface vision & inspection market demand.

Computer based system is registered as the fastest CAGR in forecast period.

- Computer based systems are used to advanced quality control technology which uses high-resolution cameras and lightning systems.

- Additionally, these systems capture detailed image of an objects and perform analysis on them using computer vision techniques.

- For instance, Mettler Toledo launched its Vision Inspection System, V35 PC-based reading device, with six-camera configuration, gives 360° view of each product for 100% inspection of label design and packages up to 230 mm in diameter.

- Thus, as per the surface vision & inspection market analysis, the capability of computer based systems to give 360◦ view is driving the market surface vision & inspection

By Deployment:

Based on the deployment, the Surface Vision & Inspection market is segmented into traditional surface deployment and robotic cells.

Trends in Deployment:

- Traditional surface deployment is widely used for 2D inspection.

- Robotic cells are ideal for inspecting items such as car bodies, large panels, or manufacturing rolls.

Robotic cells accounted for the largest revenue in the year 2024 as well as the fastest CAGR in forecast period.

- Robotic vision inspection systems have become increasingly powerful and flexible, allowing inspection tasks to be integrated into robotic work cells.

- Innovative robotic vision inspection technology also offers the advantage of increasing productivity through optimized process uptime, elimination of quality slips, and reduced rework.

- Quality in manufacturing improves with robotic vision inspection because robots can inspect every part produced

- For instance, Remtec’s Machine vision systems used in a broad range of applications for machine vision inspection and quality control. Machine vision inspection capabilities are well suited for defect detection, functional, flaws, manufacturing irregularities, and product and package matching

- Thus, the rising adoption of robotic cells deployment for product quality control is driving the surface vision & inspection market trends.

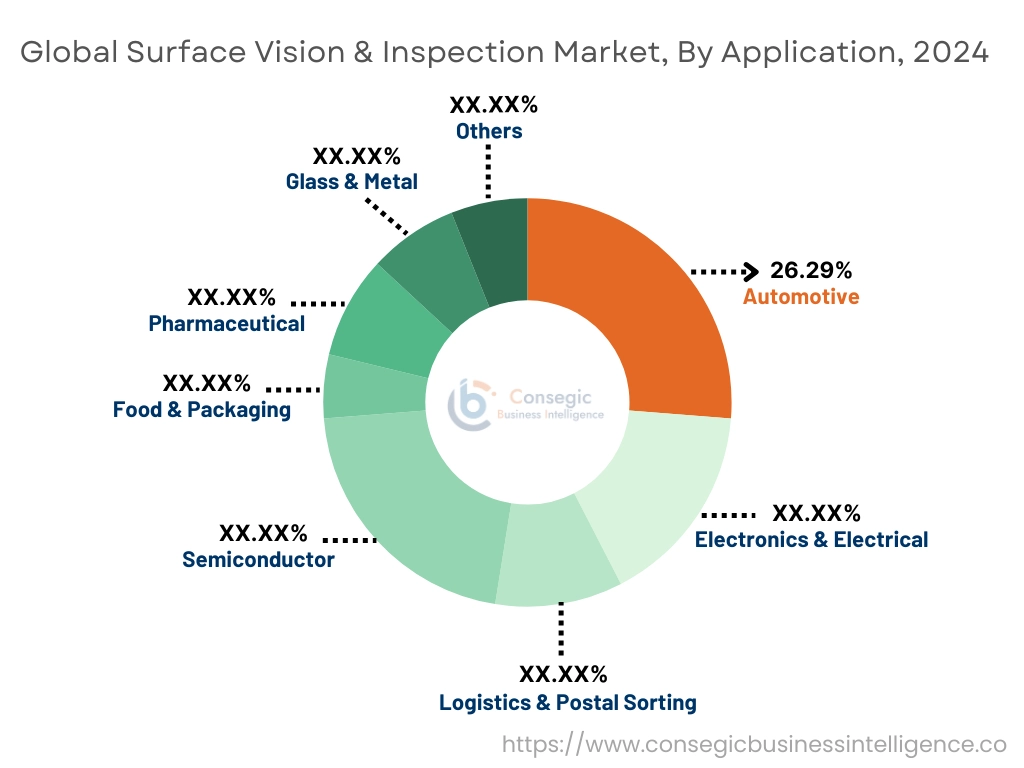

By Application:

Based on the application, the Surface Vision & Inspection market is segmented into automotive, electronics & electrical, semiconductor, food & packaging, pharmaceutical, glass & metal, and others.

Trends in Application:

- In food & packaging industry vision inspection system quickly identifies the issue such as product mix-ups, packaging damage, and contamination.

- Vision system is widely used in pharmaceutical industry to ensure product safety and integrity.

Automotive accounted for the largest revenue share of 26.29% in the year 2024

- Vision inspection systems employ cameras, sensors, and sophisticated software to analyze and interpret images of automotive components and assemblies.

- Surface vision inspection used to detect defects such as surface blemishes, cracks, and dimensional inaccuracies with incredible accuracy, ensuring that only flawless components make their way into the final assembly.

- For instance, Vitronic’s surface inspection for powertrain inspect powertrain components for defects such as cavities, pores and excess material, or processing errors such as scratches and dents—with micrometre precision.

- Thus, based on the analysis, manufacturing of high quality products is driving the surface vision & inspection market size.

Semiconductor segment is expected to register the fastest CAGR in forecast period.

- Vision systems for semiconductor manufacturing allows high-speed and accurate inspections, leading to increased production line yield and improved quality control.

- The vision systems in semiconductor industries include 3D vision, line scan cameras, dimensional semiconductor inspection, and quality inspection systems.

- For instance, Keyence XT series for 2D and 3D vision system used to perform advanced in-line inspections captures high-quality image of a semiconductor in 0.6 seconds. The XT series with 2 camera models and field of view up to 60x60mm to inspect and measure parts across various manufacturing industries.

- Thus, based on the analysis, the rising manufacturing and adoption of high-quality semi-conductors is driving the surface vision & inspection market share.

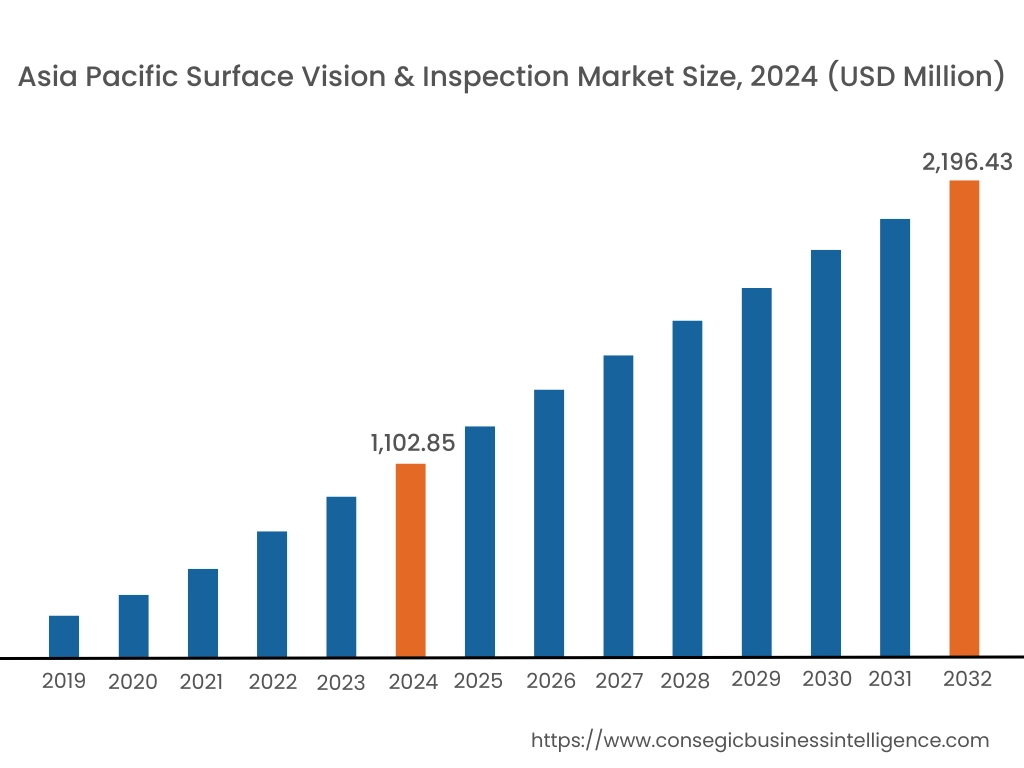

Regional Analysis:

The global market has been classified by region into North America, Europe, Asia-Pacific, MEA, and Latin America.

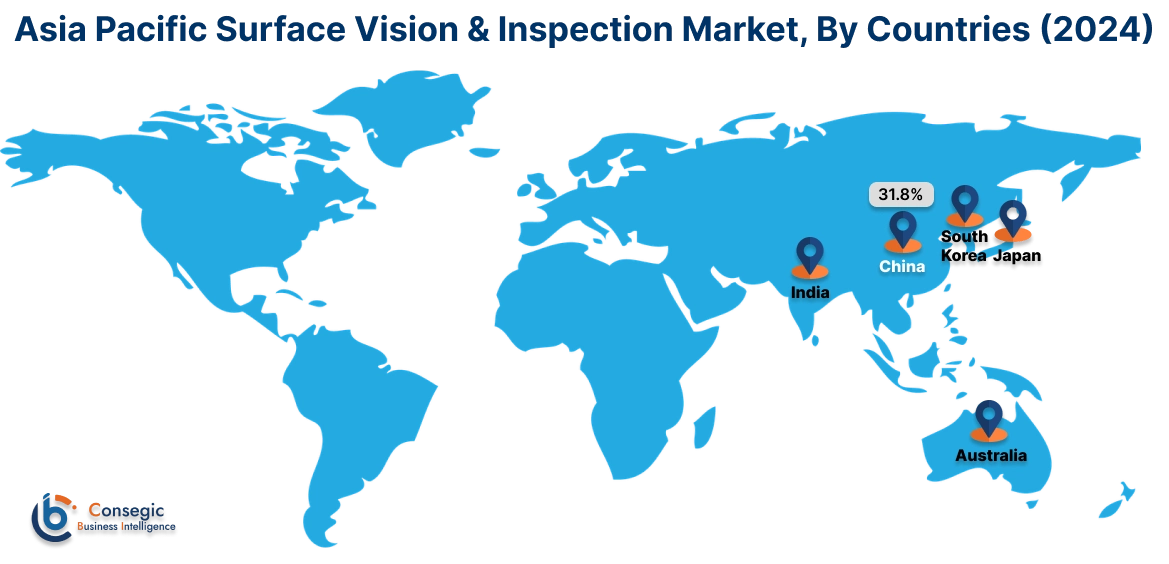

Asia Pacific region was valued at USD 1,102.85 Million in 2024. Moreover, it is projected to grow by USD 1,181.20 Million in 2025 and reach over USD 2,196.43 Million by 2032. Out of these, China accounted for the largest segment of 31.8% in 2024.

The Asia-Pacific surface vision & inspection market is witnessing substantial growth driven by the application of innovative technologies. The demand for advanced solutions is rising as industries seek to enhance their performance and operational efficiency. Companies are investing in new technologies to maintain a competitive edge and address evolving market demands. Additionally, increase in infrastructure development investments is also boosting market growth. Infrastructure projects require high-quality materials to ensure durability and safety. Surface vision and inspection systems are used to detect defects in materials like concrete, steel, and asphalt, ensuring that they meet the required standards.

- For instance, according to the India Brand Equity Foundation (IBEF), automobile sector received a total foreign direct investment of USD 35.40 Billion from April 2000 - September 2023. This is further driving vision system sales, which in turn driving the surface vision & inspection market in Asia Pacific region.

North America region was valued at USD 1.494.89 Million in 2024. Moreover, it is projected to grow by USD 1,598.32 Million in 2025 and reach over USD 2,917.40 Million by 2032.

North America accounted for significant market share due to the early adoption of innovative technologies in automotive industry such as AI- based defect detection. These systems streamline the verification and quantity checks of assembled car parts, a process that was previously inefficient and susceptible to errors.

- For instance, in 2024, Cognex Corporation expanded the capabilities of its In-Sight SnAPP vision sensor with the launch of an AI-enabled counting tool. This AI technology provides accuracy during counting parts of the product including objects of similar size, reflective and distorted parts, and objects with varying contrasts and shapes.

The European countries lead the market, driven by advanced industrial sectors, high consumer awareness, and favorable regulations supporting the adoption of Surface Inspection Machine Vision Systems. Additionally, their robust manufacturing and automotive industries heavily rely on surface vision inspection system products for efficiency and innovation. In Latin America region the rising investments in infrastructure and manufacturing facilities contribute to the region’s increasing demand for surface inspection systems. The growth of surface vision and inspection in MEA region is driven by increasing industrial automation, advancement in AI-driven quality control and rising demand for high-quality manufacturing processes.

Top Key Players and Market Share Insights:

The market is highly competitive with major players providing surface vision & inspection systems to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the market. Key players in the Surface Vision & Inspection industry include-

- Omron Corporation (Japan)

- Cognex Corporation (US)

- AMETEK Surface Vision (U.S.)

- Shenzhen Sipotek Technology (China)

- Isra Vision AG (Germany)

- Keyence Corporation Daitron Inc. (Canada)

- Panasonic Corporation (Japan)

- Edmund Scientific Corporation (U.S.)

- Matrox Imaging Ltd. (Canada)

Recent Industry Developments :

Partnerships & Collaborations:

- In 2024, ASCONA and D-CUBE announced strategic partnership and launched a comprehensive inline surface inspection solution for the aluminium market.

- In 2022, AMETEK surface vision joined sensory analytics, the source for innovative SpecMetrix Systems, in a strategic partnership to provide customers an inspection system with significant cost savings as well as improved quality and production.

Surface Vision & Inspection Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 8,383.32 Million |

| CAGR (2025-2032) | 9.4% |

| By Component |

|

| By Surface type |

|

| By System |

|

| By Deployment |

|

| By Application |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Surface Vision & Inspection Market? +

Surface vision & inspection market size is estimated to reach over USD 8,383.32 Million by 2032 from a value of USD 4,350.27 Million in 2024 and is projected to grow by USD 4,646.35 Million in 2025, growing at a CAGR of 9.4% from 2025 to 2032.

What specific segmentation details are covered in the Surface Vision & Inspection report? +

The Surface Vision & Inspection report includes specific segmentation details for component, surface type, system, deployment, application and regions.

Which is the fastest segment anticipated to impact the market growth? +

In the Surface Vision & Inspection market, the robotic cells segment is the fastest-growing segment during the forecast period.

Who are the major players in the Surface Vision & Inspection Market? +

The key participants in the Surface Vision & Inspection Market are, Omron Corporation (Japan), Cognex Corporation (US), AMETEK Surface Vision (U.S.), Isra Vision AG (Germany), Keyence Corporation Daitron Inc. (Canada), Panasonic Corporation (Japan), Edmund Scientific Corporation (U.S.), Matrox Imaging Ltd. (Canada), Shenzhen Sipotek Technology (China), and others.