Superalloys Market Size :

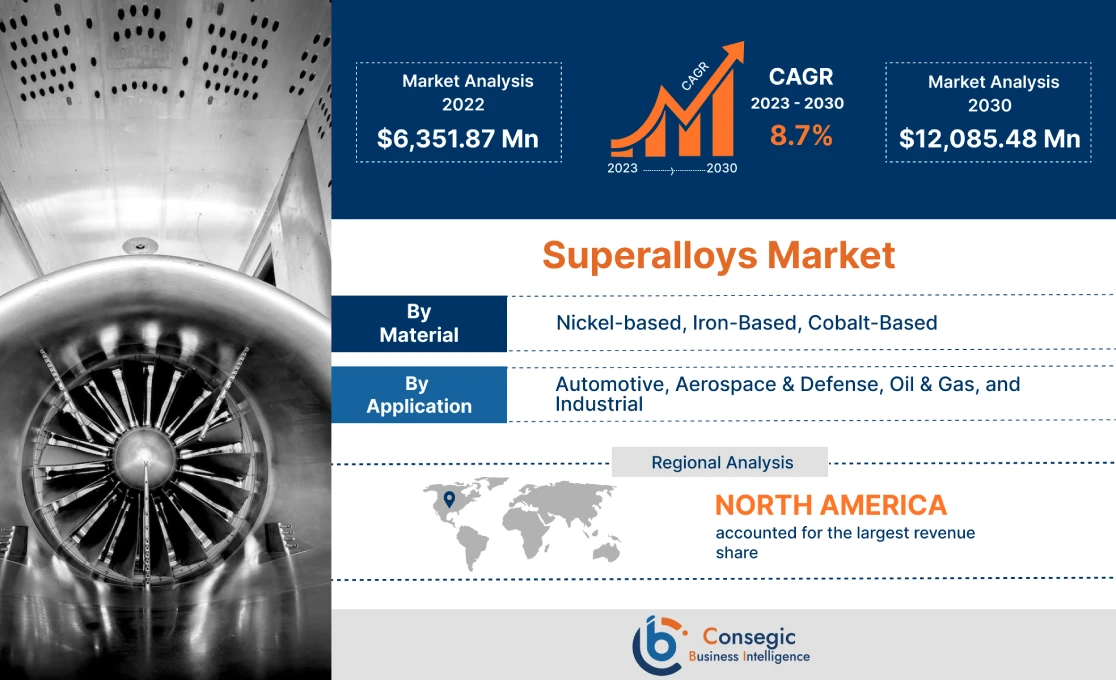

Superalloys Market size is estimated to reach over USD 12,085.48 Million by 2030 from a value of USD 6,351.87 Million in 2022, growing at a CAGR of 8.7% from 2023 to 2030.

Superalloys Market Scope & Overview :

Superalloys are a class of high-performance alloys that exhibit excellent mechanical strength, corrosion resistance, and thermal stability at high temperatures. They have the ability to maintain their structural integrity at temperatures above 540 °C (1000 °F). Moreover, based on the analysis, these materials possess oxidation and corrosion resistance properties due to the formation of a protective oxide layer that encapsulates the material, thereby providing protection to the devices. Consequently, they are extensively used in gas turbine engines, nuclear reactors, and chemical processing applications.

Superalloys Market Insights :

Superalloys Market Dynamics - (DRO) :

Key Drivers :

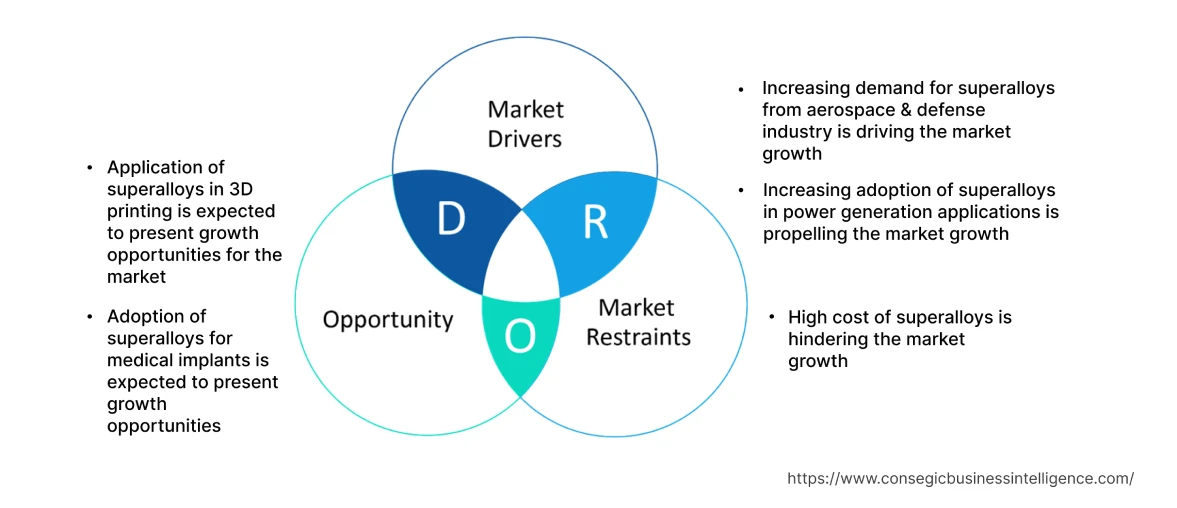

Increasing demand for superalloys from aerospace & defense industry is driving the market

The rising demand for these materials in aerospace & defense sector for the construction of aircraft engines, gas turbines, and other critical components is driving the market. The aforementioned components operate at extremely high temperatures and require materials that withstand thermal stress, oxidation, and corrosion. Thus, according to the analysis, these materials provide necessary mechanical strength, heat resistance, and durability to ensure reliable and efficient engine performance. For instance, in April 2023, NASA introduced 3D printable high-temperature superalloy called GRX-810 to build parts of aircraft and spacecraft to withstand high-temperature applications. Consequently, the increasing demand for high-performance engines in aerospace & defense sector is accelerating the market trend.

Increasing adoption of superalloys in power generation applications is propelling the market

The application of these materials in gas turbine power plants for power generation is propelling the market. These materials play a crucial role in turbine blades and vanes that operate at extremely high temperatures. Moreover, they are used for the construction of combustion chambers that are exposed to hot gases and chemical reactions. These materials including nickel-based alloys are essential in power generation applications due to their corrosion resistance and high temperature resistance properties. For instance, in February 2023, National Technology and Engineering Solutions of Sandia, LLC revealed a high-performance metal alloy using 3-D printer that enables power plants to generate more electricity with minimal carbon production. Therefore, the increasing requirement for electricity among consumers is driving the superalloys market growth.

Key Restraints :

High cost of superalloys is hindering the market

Superalloys are quite expensive in comparison to conventional alloys due to the complex composition and the use of rare and expensive alloying elements. These materials including cobalt-based alloys are expensive in comparison to the nickel-based alloys due to the limited availability of the base element. Moreover, the complex manufacturing processes of this alloys are further adding to the overall cost of these alloys, thereby restraining the development of the market.

Future Opportunities :

Application of superalloys in 3D printing is expected to present growth opportunities for the market

The application of these materials in advanced manufacturing techniques including 3D printing is expected to present potential superalloys market opportunities for the expansion of the market during the forecast period. 3D printing with these materials enables fabrication of complex geometries and the production of high-performance components for aerospace and industrial applications. Moreover, as per the analysis, 3D printing with this alloy is expected to reduce material waste during the production process. Consequently, the application of these materials in 3D printing is expected to drive market development and trend during the forecast period.

Adoption of superalloys for medical implants is expected to present growth opportunities

The application of these alloys for medical implants including orthopedic and dental implants is expected to create lucrative trends for the superalloys market during the forecast period. These alloys provide a combination of strength, ductility, durability, and biological safety that is well-suited for biomedical applications. Consequently, according to the analysis, the adoption of these alloys including nickel-based alloys for clinical applications is expected to drive the market trend during the forecast period.

Superalloys Market Report Insights:

| Report Attributes | Report Details |

| Study Timeline | 2017-2030 |

| Market Size in 2030 | USD 12,085.48 Million |

| CAGR (2023-2030) | 8.7% |

| Based on the Material | Nickel-based, Iron-Based, Cobalt-Based |

| Based on the Application | Automotive, Aerospace & Defense, Oil & Gas, and Industrial |

| Based on the Region | Asia-Pacific, Europe, North America, Latin America, Middle East & Africa |

| Key Players | Aubert & Duva, Precision Castparts Corp, VSMPO-AVISMA, Advanced Metallurgical Group, SuperAlloy Industrial Company, Doncasters, Haynes International, Special Metals Corporation, Aperam, Carpenter Technology, AMG Superalloys |

Superalloys Market Segmental Analysis :

By Material :

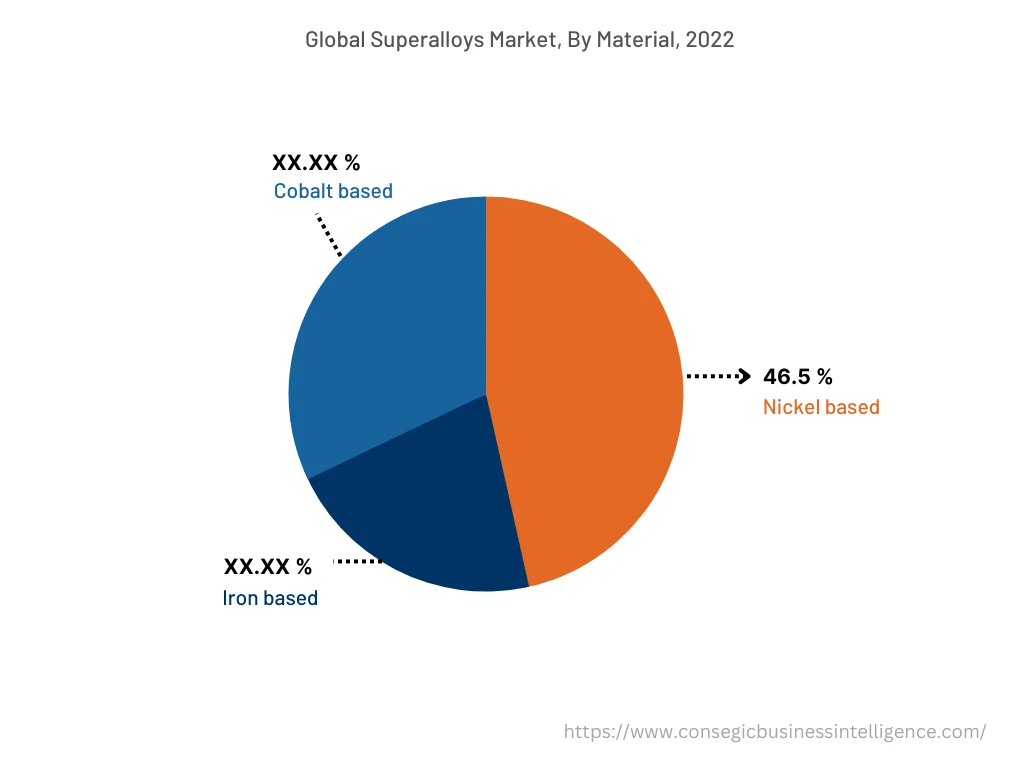

Based on the material, the market is trifurcated into nickel-based, iron-based, cobalt-based. Nickel-based segment accounted for the largest revenue share of 46.5% in the year 2022. The exceptionally high mechanical strength, corrosion resistance, and thermal stability of nickel-based superalloys is contributing to the superalloys market growth. Nickel-based superalloys consist of nickel as the primary element along with other elements such as chromium, molybdenum, and aluminum. For instance, in April 2023, Elementum 3D revealed new additive manufacturing parameters for enhanced nickel superalloy called IN625-RAM2 by developing 100 µm and 80 µm layer parameters to boost production capacity and reduce the build cost of components. Subsequently, the application of these alloys in turbine blades, exhaust fans, turbochargers and other components is driving the market.

The cobalt-based segment is anticipated to witness the fastest CAGR during the forecast period. These alloys based on cobalt are more stable and possess high mechanical strength. Moreover, cobalt-based superalloys exhibit high sulfidation resistance properties in comparison to nickel-based alloys. Consequently, the application of cobalt-based superalloys in rocket motors, nuclear reactors, and power plants is propelling the expansion and trend of the market.

By Application :

Based on the application, the market is separated into automotive, aerospace & defense, oil & gas, and industrial. The aerospace & defense sector accounted for the largest revenue share in the year 2022. These alloys play a crucial role in gas turbine engines in both commercial and military aircraft. These materials are employed in turbine blades, vanes, and combustors providing extremely high strength and corrosion resistance. Moreover, based on the superalloys market analysis, the ability of this material to enable engines to operate at high temperatures and withstand harsh environments is contributing to the development of the superalloys market trend.

The industrial sector is anticipated to emerge as the fastest-growing segment during the forecast period. The increasing demand for electricity among consumers is driving the superalloys market. These materials are utilized in electricity generation due to the excellent properties of these alloys. Moreover, the application of these alloys in chemical processing applications is propelling the superalloys market demand.

By Region :

The regional segment includes North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

North America accounted for the largest superalloys market share in the year 2022. The increasing adoption of these alloys for the generation of electricity is driving the growth of the market. These materials play a crucial role in wind turbines for efficient generation of electricity. Moreover, as per the analysis, government of United States is implementing significant investments in aerospace & defense industry for manufacturing for various parts using advanced technologies.

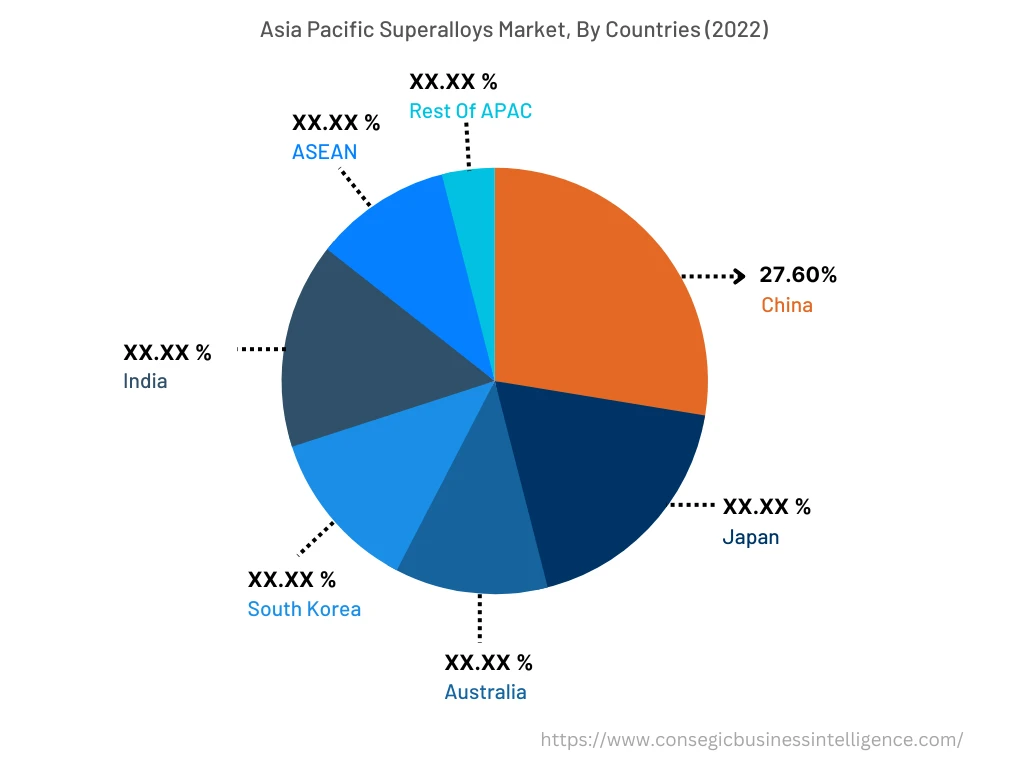

Asia-Pacific accounted for the largest revenue share of USD 2,007.19 million in 2022 and is expected to reach USD 3,889.11 million in 2030, registering a CAGR of 9.0% during the forecast period. Additionally, in the region, China accounted for the largest revenue share of 27.60% in the year 2022. The wide availability of raw materials including nickel, cobalt, and iron in Asia-Pacific region is driving the growth of the market. For instance, in January 2023, China accounted for 2,100,000 metric tons of nickel reserves in manganese crusts and nodules on the ocean floor. Moreover, the growing manufacturing sector in countries such as India, China, and Japan are driving the demand for high-performance alloys for the production of automotive parts, aircraft components, and industrial power plants. For instance, in April 2021, Defence Research and Development Organization (DRDO) developed single crystal blades using a nickel-based super alloy as a part of helicopter development program. Furthermore, the high rate of energy consumption in Asia-Pacific region is driving the demand for efficient alloys, resulting in the market growth.

Top Key Players & Market Share Insights :

The Superalloys market is characterized by the presence of major players offering high performance these alloys with excellent properties. Key players are adopting various business strategies such as product innovation, research, and development (R&D), and application launches to accelerate the growth of the superalloys industry. Key players in the market include-

- Aubert & Duva

- VSMPO-AVISMA

- Precision Castparts Corp.

- Aperam

- Carpenter Technology

- AMG Superalloys

- Advanced Metallurgical Group

- SuperAlloy Industrial Company

- Doncasters

- Haynes International

- Special Metals Corporation

Recent Industry Developments :

- In June 2020, Protolabs launched new cobalt chrome superalloy 3D printing material for its metal laser sintering process in oil & gas sector due to its heat, wear, and corrosion resistant properties.

- In October 2021, BEAMIT group developed printing process for new René 80-RAM1 featuring high melting point and excellent oxidation resistance at high temperatures.

Key Questions Answered in the Report

What are Superalloys? +

Superalloys are the high-performance alloys that possess high mechanical properties at high temperatures. Superalloys are widely used in aerospace & defense and industrial applications.

What specific segmentation details are covered in the superalloys report, and how is the dominating segment impacting the market growth? +

By material segment has witnessed nickel-based as the dominating segment in the year 2022, due to the high mechanical strength, corrosion resistance, and thermal stability of nickel-based superalloys.

What specific segmentation details are covered in the superalloys market report, and how is the fastest segment anticipated to impact the market growth? +

By application segment has witnessed aerospace & defense as the fastest-growing segment during the forecast period due to its ability to operate at high temperaturess and withstand harsh environments.

Which region/country is anticipated to witness the highest CAGR during the forecast period, 2023-2030? +

Asia-Pacific is expected to register fastest CAGR growth during the forecast period due to the large manufacturing base in Asia-Pacific region.