- Summary

- Table Of Content

- Methodology

Speed Sensor Market Introduction :

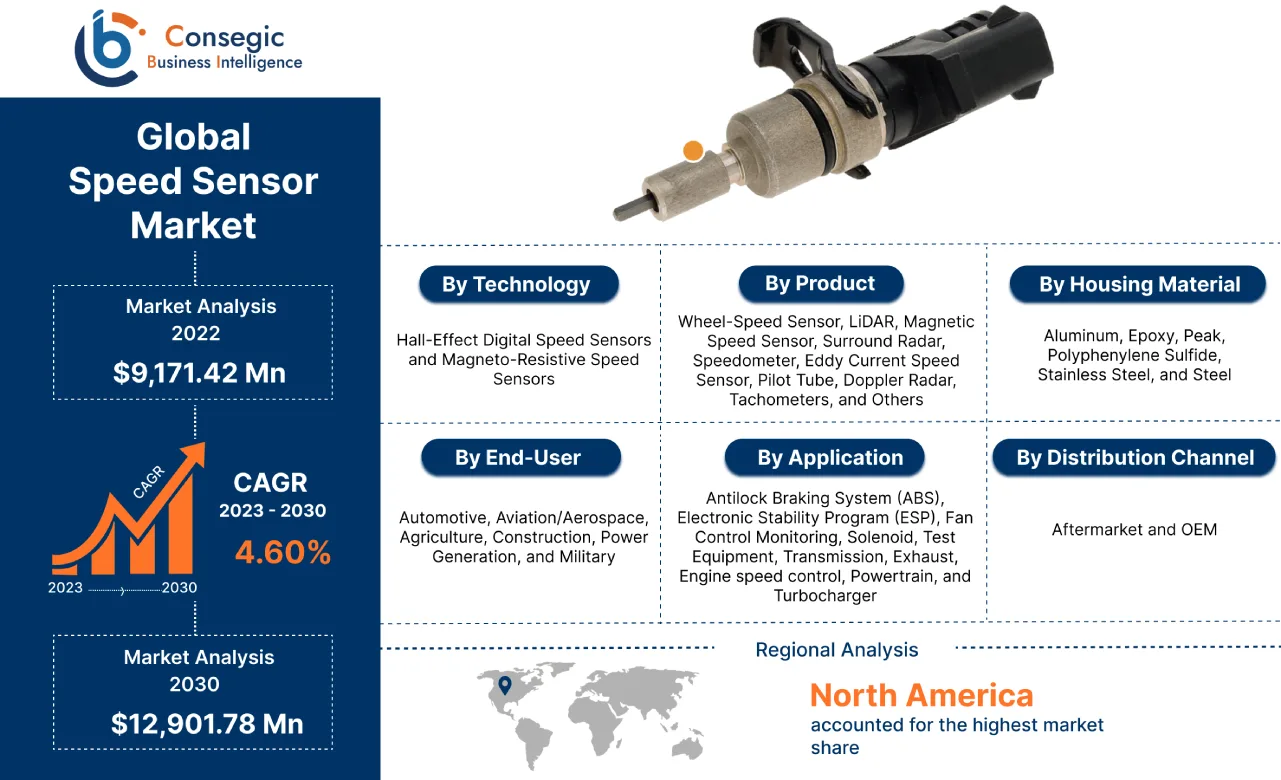

Speed Sensor Market is estimated to reach over USD 12,901.78 Million by 2030 from a value of USD 9,171.42 Million in 2022, growing at a CAGR of 4.60% from 2023 to 2030.

Speed Sensor Market Definition & Overview:

A speed sensor is a device used to measure and monitor the velocity and speed of an object, in terms of the object's linear and rotational movement. The sensor functions by detecting changes in position over time and calculating the rate of change, providing real-time data on the speed of the object's motion. Additionally, speed sensors are deployed in various industries including automotive, aerospace, manufacturing, and robotics. Furthermore, the sensors enable precise control, safety, and optimization of various processes and systems that rely on accurate speed information.

Speed Sensor Market Insights :

Key Drivers :

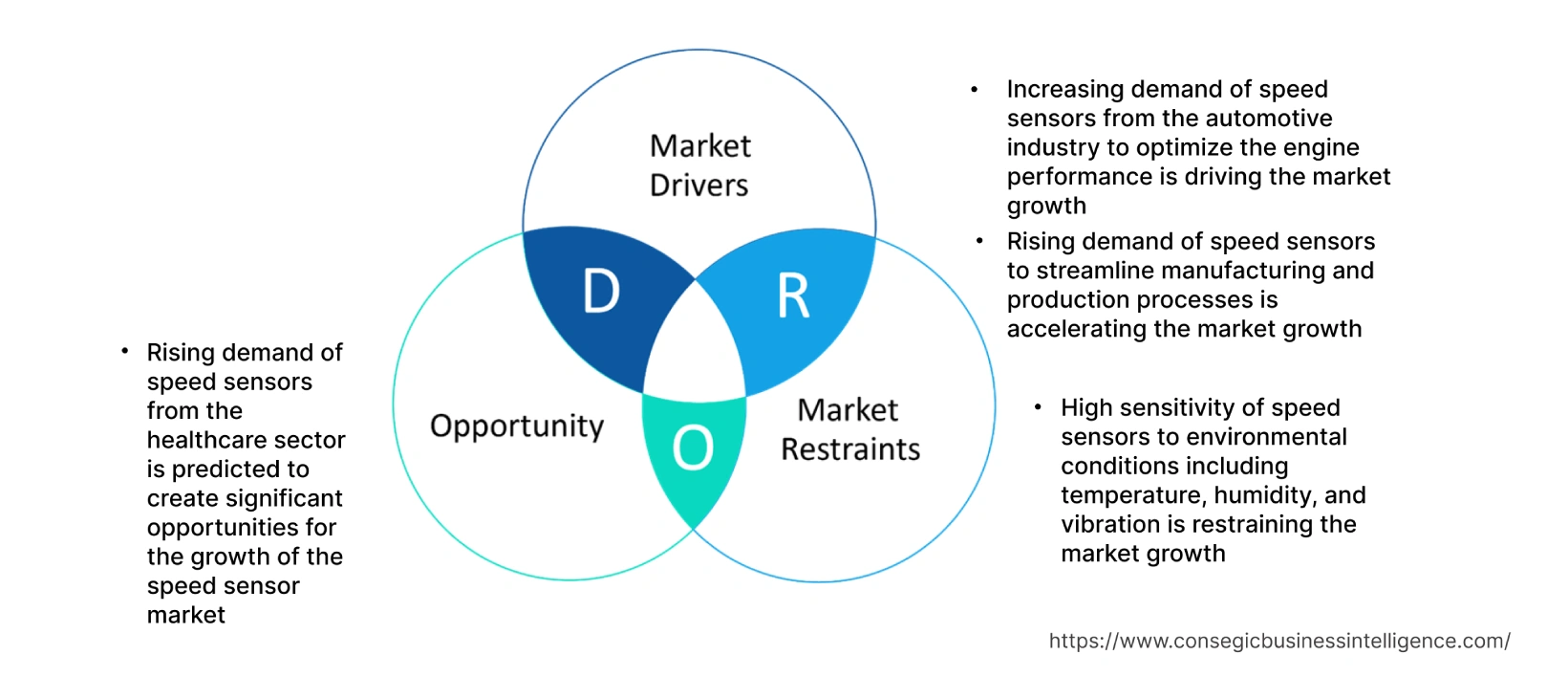

Increasing demand of speed sensors from the automotive industry to optimize the engine performance is driving the market growth

Speed sensors are employed to monitor and optimize engine performance and fuel efficiency by providing data to control systems that regulate engine speed and transmission shifting. Additionally, autonomous vehicles heavily relies on precise and continuous speed data to ensure safe navigation and coordination with other vehicles and the surrounding environment. Speed sensors are vital for controlling vehicle movements, calculating acceleration, and maintaining proper distances, thus contributing significantly in driving the growth of the market.

Moreover, the growing adoption of electric vehicles is also raising the demand for sophisticated speed sensors to accurately measure and monitor both the electric motor's rotational speed and the vehicle's speed. The sensors play a crucial role in maintaining efficient energy utilization and ensuring a seamless transition between electric and internal combustion modes. Consequently, the emergence of electric vehicles is contributing significantly in driving the adoption of speed sensors. For instance, according to International Energy Agency (IEA), electric car sales exceeded 10 million in 2022 and has more than tripled in last three years, from 4% in 2020 to 14% in 2022. Additionally, China accounted approximately 60% of electric cars registration in 2022 and the share of domestic electric cars in China increased from 16% in 2021 to 29% in 2022.

Rising demand of speed sensors to streamline manufacturing and production processes is accelerating the market growth

Speed sensors are essential for maintaining precise control and monitoring of machinery and equipment in industrial settings. The sensors enable real-time measurement of rotational and linear speeds, to regulate processes with high levels of accuracy. Additionally, in manufacturing and production environments, speed sensors are utilized to optimize processes by ensuring consistent speeds in conveyor systems and robotic arms leading to improved productivity, reduced downtime, and higher efficiency. Moreover, the sensors also enable the users to make strategic decisions utilizing existing data from machines and processes, further contributing to market growth. For instance, in September 2022, Falkonry launched Falkonry Insight that operates on speed sensor time series data. The sensors permit high operational yield and reliability, enabling operations team to make smarter decisions, thus contributing significantly in driving the growth of speed sensor market.

Key Restraints :

High sensitivity of speed sensors to environmental conditions including temperature, humidity, and vibration is restraining the market growth

Environmental sensitivity restricts the operational range of speed sensors in extreme conditions namely due to high temperatures, high humidity, and strong vibrations, hampering the market growth. Additionally, in industries including automotive, aerospace, and manufacturing inaccurate speed readings due to environmental sensitivity leads to operational errors, reduced product quality, and safety concerns. Moreover, environmental sensitivity leads to the need for more frequent calibration and maintenance to ensure accuracy. The calibration of the sensors leads to additional upfront cost, hence impeding the growth of the global speed sensor market.

Future Opportunities :

Rising demand of speed sensors from the healthcare sector is predicted to create significant opportunities for the growth of the speed sensor market

Speed sensors are utilized in various medical devices namely centrifuges, blood analyzers, and diagnostic imaging equipment to ensure precise and efficient operation. Additionally, speed sensors are also employed in robotic arms and instruments to monitor the movement and ensure accuracy during surgical procedures. Moreover, the sensors are also deployed in patient monitoring systems to track the rotational speed of medical pumps, ventilators, and other equipment. Furthermore, medical laboratories rely on various equipment that requires accurate speed measurements including centrifuges for separating blood samples. In conclusion, the expanding healthcare sector is predicted to create potential opportunities for the growth of speed sensor market during the forecast period.

Speed Sensor Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2017-2030 |

| Market Size in 2030 | USD 12,901.78 Million |

| CAGR (2023-2030) | 4.60% |

| By Product | Wheel-Speed Sensor, LiDAR, Magnetic Speed Sensor, Surround Radar, Speedometer, Eddy Current Speed Sensor, Pilot Tube, Doppler Radar, Tachometers, and Others |

| By Technology | Hall-Effect Digital Speed Sensors and Magneto-Resistive Speed Sensors |

| By Housing Material | Aluminum, Epoxy, Peak, Polyphenylene Sulfide, Stainless Steel, and Steel |

| By Distribution Channel | Aftermarket and OEM |

| By Application | Antilock Braking System (ABS), Electronic Stability Program (ESP), Fan Control Monitoring, Solenoid, Test Equipment, Transmission, Exhaust, Engine speed control, Powertrain, and Turbocharger |

| By End-User | Automotive, Aviation/Aerospace, Agriculture, Construction, Power Generation, and Military |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | Robert Bosch GmbH, Honeywell International Inc., Continental AG, Infineon Technologies AG, Ford Motor Company, Electro Sensors Inc., Standard Motor Products, Inc., TE Connectivity, ABB, NXP Semiconductors, Siemens |

Speed Sensor Market Segmental Analysis :

Based on the Technology :

The technology segment is divided into hall-effect digital speed sensors and magneto-resistive speed sensors. Hall-effect digital speed sensors accounted for the largest market share in 2022 owing to the non-contact feature of the sensors that leads to minimal wear and tear, ensuring long-term reliability and reduced maintenance requirements. Additionally, hall-effect sensors accurately measure a wide range of speeds, from low to high, becoming versatile for various applications across different industries. Moreover, hall-effect sensors are solid-state devices and are highly durable and resistant to mechanical wear. Furthermore, the sensors offer fast response times, providing real-time speed data that is essential for applications that require quick adjustments and feedback. For instance, in July 2021, Honeywell International Inc. introduced LCZ Series of hall-effect digital speed sensors to provide a durable and cost-effective solution in harsh environments. The stainless sensor with hall-effect digital technology does not require rotational orientation and is easy to install, thus contributing significantly in fueling the growth of the market.

Magneto-resistive speed sensors is anticipated to witness the fastest CAGR in the speed sensor market during the forecast period. Magneto-resistive sensors offer high accuracy and precision in measuring speed and detect even small changes in magnetic fields, ideal for applications that require precise speed measurements. Additionally, magneto-resistive sensors provide a digital output signal, which is compatible with digital control systems, microcontrollers, and modern electronic devices. Moreover, the sensors are relatively less sensitive to environmental factors including temperature changes, humidity, and vibrations. Furthermore, magneto-resistive sensors consume low amounts of power, suitable for battery-operated devices and applications where energy efficiency is essential. Consequently, the aforementioned factors are collectively responsible in boosting the growth of magneto-resistive speed sensors in the upcoming years.

Based on the Product :

The product segment is classified into wheel-speed sensor, LiDAR , magnetic speed sensor, surround radar, speedometer, eddy current speed sensor, pilot tube, Doppler radar, tachometers, and others. Wheel-speed sensors accounted for the largest market share in 2022 owing to the rising demand from the automotive industry. Wheel speed sensors are a fundamental component in various automotive safety and control systems including anti-lock braking systems (ABS), electronic stability control (ESC), traction control systems (TCS), and adaptive cruise control (ACC). Additionally, wheel speed sensors are also used in industrial automation, robotics, aerospace, and consumer electronics. Moreover, the sensors are designed to survive in extreme challenging environmental conditions and are made up of advanced materials including polybutylene terephthalate (PBT) that offers improved protection to the sensors. For instance, in May 2022, BASF SE launched Ultradur B4335G3 HR HSP–all-rounder, a wheel speed sensor for automotive applications. The sensor has excellent hydrolysis resistance and is deployed in the ABS and ESP systems of vehicles to maintain vehicle stability. Furthermore, the polybutylene terephthalate (PBT) material of the sensor protects sensitive electronics from harsh environmental conditions, thus contributing notably in bolstering the growth of wheel speed sensors segment.

Magnetic speed sensors are anticipated to witness the fastest CAGR in the speed sensor market during the forecast period. The growth is attributed to the emergence of Industry 4.0 solutions and Internet of Things (IoT) in industrial settings that drive the demand for magnetic speed sensors. The sensors provide data for predictive maintenance, process optimization, and data-driven decision-making. In addition, magnetic speed sensors are utilized in industrial machinery and robotic systems to monitor the speed of rotating components, ensuring efficient and precise operation. Moreover, magnetic speed sensors are essential in renewable energy applications, namely wind turbines, to monitor the rotational speed of blades. Subsequently, the above-mentioned factors are predicted to drive the growth of magnetic speed sensors during the forecast period.

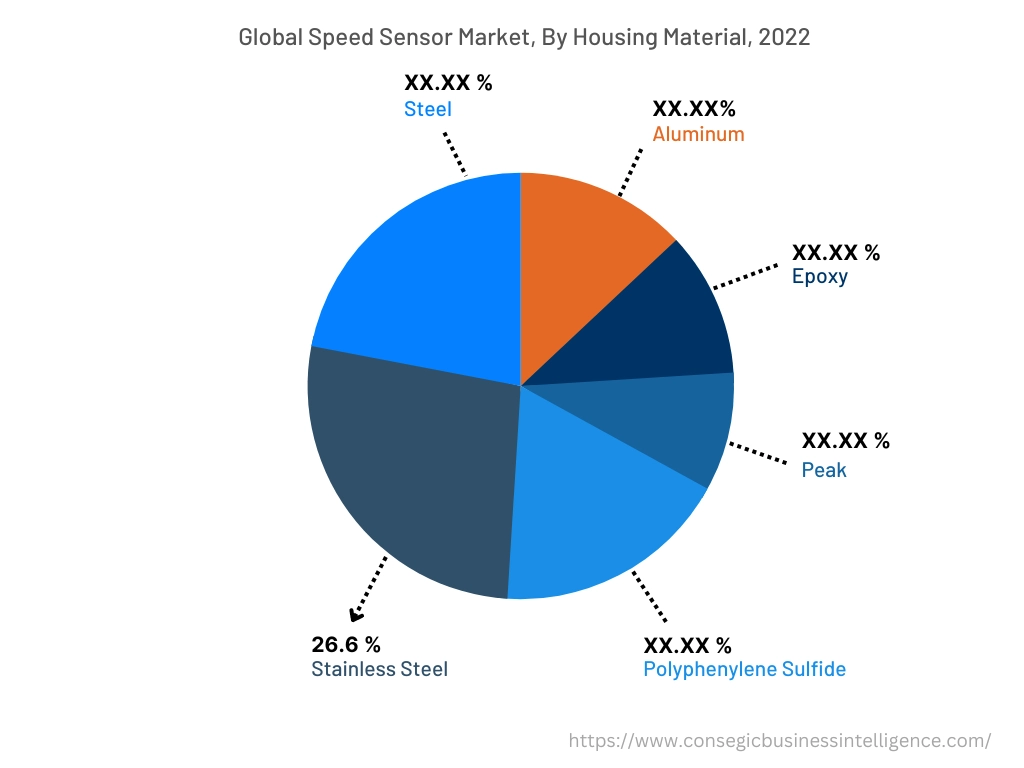

Based on the Housing Material :

The housing material segment is divided into aluminum, epoxy, peak, polyphenylene sulfide, stainless steel, and steel. Stainless steel accounted for the largest market share of 26.6% in 2022 owing to the exceptional corrosion resistance nature of stainless steel, ideal for applications in various environments, including moisture, chemicals, and harsh weather conditions. Corrosion resistance property ensures the durability and longevity of speed sensors, especially in industries namely automotive, aerospace, marine, and industrial automation. Additionally, stainless steel is a robust and strong material, capable of withstanding mechanical stress, impacts, and vibrations. The durability is crucial for speed sensors used in rugged environments that are subjected to physical stresses. Moreover, stainless steel maintains its structural integrity at high temperatures, suitable for applications that involve elevated operating temperatures to heat sources. For instance, Rheintacho Messtechnik GmbH introduced 1-Channel Hall M18, IP67 and IP69K degree of protection, stainless steel speed sensors for automotive applications. The sensors are capable of operating at a vast temperature range from -40°C to +125 °C and are also corrosion resistant, thus contributing significantly in bolstering the growth of stainless steel speed sensors segment.

Polyphenylene sulfide (PPS) is projected to register the fastest CAGR in the speed sensor market during the forecast period. PPS exhibits excellent resistance to a wide range of chemicals, including acids, bases, and solvents. The chemical resistance property is advantageous in applications in which the sensor housing is exposed to aggressive chemical environments. Additionally, PPS is an electrically insulating material, suitable for preventing interference of the sensor with sensitive electronic components. Moreover, PPS has low thermal expansion and minimal moisture absorption, resulting in excellent dimensional stability over a wide temperature range, essential for maintaining accurate sensor measurements. Furthermore, PPS is a lightweight material and contributes to overall weight reduction in applications including automotive and aerospace, leading to improved fuel efficiency and performance. In conclusion, the aforementioned benefits offered by polyphenylene sulfide speed sensors is expected to drive the market growth in the upcoming years.

Based on the Distribution Channel :

The distribution channel is classified into aftermarket and OEM. OEMs accounted for the largest market share in 2022 as OEMs are the manufacturers of products that incorporate speed sensors as integral components. OEMs require large quantities of speed sensors to meet the production demands of the end-products in numerous sectors including automobiles, industrial machinery, and consumer electronics. Additionally, OEMs have established supply chain relationships with speed sensor manufacturers and work closely with suppliers to ensure the timely availability of components and consistent quality to maintain efficient production processes. Moreover, OEMs require customized speed sensors tailored to the specific product designs and requirements and collaborate with suppliers to ensure that the sensors meet the exact specifications, performance needs, and compatibility standards. Consequently, the vast network of OEMs is contributing remarkably in propelling the growth of the segment.

The aftermarket segment is expected to experience growth in the future due to the growing trend towards extending the lifespan of products and maximizing the value of the investments. Aftermarket products offer cost-effective alternatives to original equipment manufacturer (OEM) products and includes repairing, upgrading, and replacing components, leading to increased demand for aftermarket parts and services. Additionally, the aftermarket offers a wide range of products, from replacement parts to performance enhancements, customization options, and accessories, hence attracting a broader customer base. Moreover, consumers increasingly seek to personalize and customize the products to reflect the individual preferences and styles. The aftermarket offers a variety of options for customizing vehicles, electronics, and appliances, further contributing to the growth of the segment. For instance, in January 2022, NTN Global expanded its range of wheel speed sensors in the automotive aftermarket. The company's aftermarket portfolio comprises 324 products for approximately 7,000 vehicles, thus contributing remarkably to the growth of the segment.

Based on the Application :

The application segment is categorized into Antilock Braking System (ABS), Electronic Stability Program (ESP), fan control monitoring, solenoid, test equipment, transmission, exhaust, engine speed control, powertrain, and turbocharger. Powertrain accounted for the largest market share in 2022 and is also projected to register the fastest CAGR during the forecast period. The powertrain encompasses the components that generate and transmit power to the wheels, including the engine, transmission, and drivetrain. Speed sensors provide critical data that help monitor and control the components for optimal performance, efficiency, and safety.

Additionally, speed sensors monitor the rotational speed (RPM) of the engine's crankshaft and camshaft. The data is essential for precise fuel injection, ignition timing, and valve timing, ensuring optimal combustion efficiency and performance. Moreover, in automatic and manual transmissions, speed sensors provide input to control units that manage gear shifting. The input helps to shift gears based on vehicle speed and engine load, contributing to smooth and efficient gear changes. In conclusion, the growing adoption of speed sensors to enable the efficient functioning of powertrains is contributing significantly in boosting the growth of the powertrain segment.

Based on the End-User :

The end-user segment is categorized into automotive, aviation/aerospace, agriculture, construction, power generation, and military. Automotive industry accounted for the largest market share in 2022 as speed sensors play a crucial role in various applications across the automotive industry, enabling safety, performance, and efficiency enhancements. The sensors measure the speed of moving components and provide essential data for various systems and functions. Additionally, speed sensors are also employed in Emergency Braking System (EBS) to monitor the individual rotational speed of each wheel. The data allows the EBS system to prevent wheel lock-up during braking, maintaining vehicle stability and control. Moreover, the implementation of stringent regulations by the government is also contributing notably in driving the adoption of speed sensors in vehicles. For instance, in May 2023, the U.S. Department of Transportation mandate automatic emergency braking and pedestrian AEB systems in light trucks and passenger cars. The regulation is expected to save approximately 360 lives per year and reduce injuries by at least 24,000 annually, further contributing to the growth of the automotive segment.

Aviation/aerospace segment is predicted to witness the fastest CAGR as speed sensors play a vital role in aviation by providing essential data for safe and efficient flight operations. The sensors measure the speed of an aircraft relative to the surroundings, helping pilots to make informed decisions during various flight phases. Additionally, pitot-static systems utilize airspeed sensors to measure the aircraft's speed through the air. The data is crucial for determining safe takeoff and landing speeds, as well as maintaining appropriate airspeeds during flight for optimal performance and stability. Moreover, ground speed sensors, combined with navigation data, provide pilots with the aircraft's speed relative to the ground. The information is utilized for navigation, fuel efficiency calculations, and flight planning. Moreover, speed sensors also provide data for flight control systems, aiding in the management of control surfaces and flight stability. The sensors help maintain safe operating speeds during maneuvers and prevent excessive speeds that lead to structural stress, further accelerating the growth of the segment.

Based on the Region :

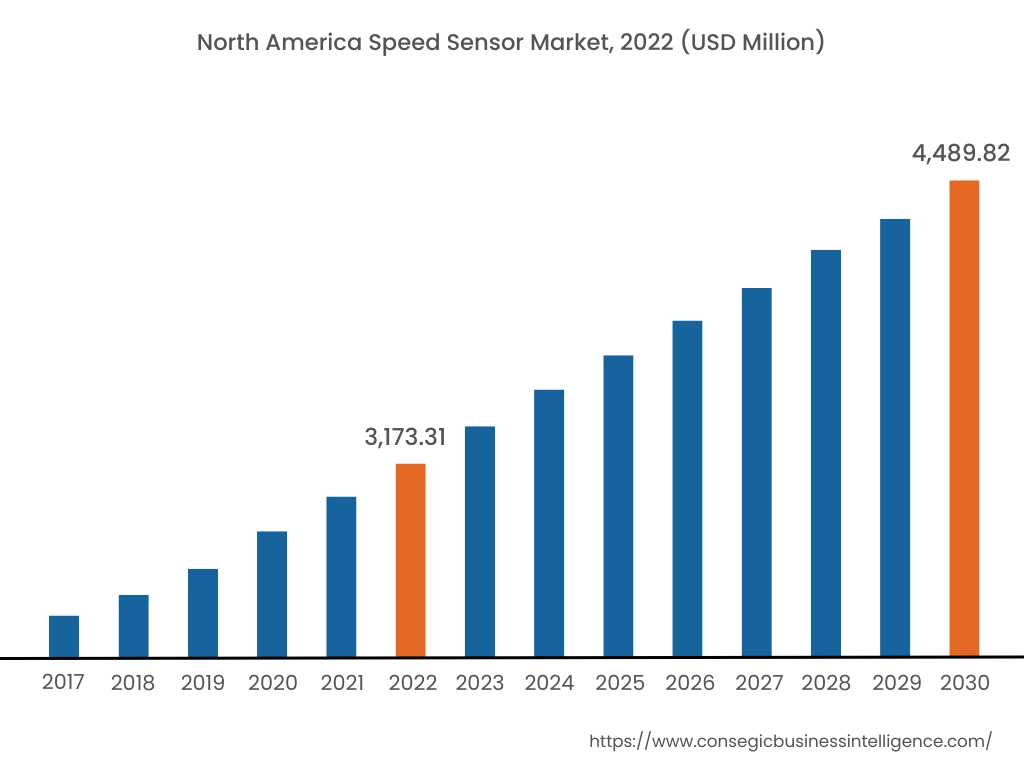

The regional segment includes North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

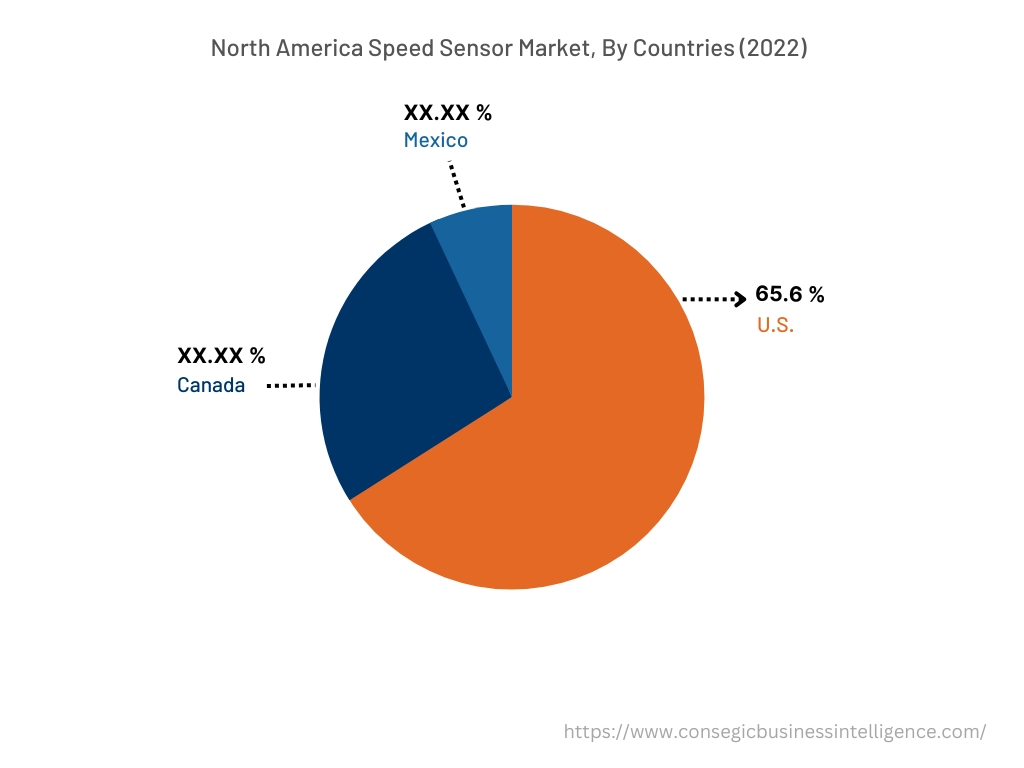

North America holds the largest market share accounting to USD 3,173.31 Million in 2022 and is expected to reach USD 4,489.82 Million in 2030 in the speed sensor market. In addition, in the region, the U.S. accounted for the maximum revenue share of 65.6% in the year 2022. The growth is attributed to the region's emphasis on industrial automation and the adoption of Industry 4.0 principles drive the demand for speed sensors in manufacturing processes, robotics, and machinery control. Additionally, North America is headquartered to worlds' largest and most advanced automotive manufacturers including Tesla, Inc., Ford Motor Company, and General Motors. The region's strong automotive industry drives significant demand for speed sensors, as the sensors are integral components in vehicles' safety, performance, and control systems. Moreover, North America has a high rate of vehicle ownership, leading to continuous demand for vehicles and components, including speed sensors. For instance, in September 2021, according to International Council on Clean Transportation, the electric share of new vehicle sales in 2020 in U.S. was 2.4%, an increase from about 2% in 2019. Additionally, Tesla Model 3 was the highest-selling model with 96,000 new sales in 2020, followed by the Tesla Model Y with 75,000 sales, and the Chevrolet Bolt with approximately 21,000 sales.

Asia Pacific is anticipated to witness the fastest CAGR of 4.9% in the speed sensor market during the forecast period. The growth is attributed to the presence of two densely populated countries including India and China that creates a large customer base, driving demand for goods, services, infrastructure, and technology. Additionally, countries including China, Japan, South Korea, and India are investing heavily in research and development, leading to technological advancements in various sectors including speed sensors. Moreover, the expansion of the manufacturing sector in Asia Pacific countries is also contributing notably in bolstering the growth of the market. The sensors enable real-time measurement of rotational and linear speeds, to regulate processes with high levels of accuracy. Additionally, in manufacturing and production environments, speed sensors are utilized to optimize processes by ensuring consistent speeds in conveyor systems and robotic arms leading to improved productivity, reduced downtime, and higher efficiency. Consequently, the expanding manufacturing sector is contributing remarkably in propelling the growth of speed sensor market in the upcoming years.

Top Key Players & Market Share Insights:

The landscape of the speed sensor market is highly competitive and has been examined in the report, along with complete profiles of the key players operating in the industry. In addition, the surge in innovations, acquisitions, mergers, and partnerships has further accelerated the growth of the speed sensor market. Major players in the market include-

- Robert Bosch GmbH

- Honeywell International Inc.

- TE Connectivity

- ABB

- NXP Semiconductors

- Siemens

- Continental AG

- Infineon Technologies AG

- Ford Motor Company

- Electro Sensors Inc.

- Standard Motor Products, Inc.

Recent Industry Developments :

- In March 2023, Standard Motor Products, Inc. expanded its line of ABS speed sensors for domestic and import vehicles to gather accurate data at low speeds and monitor the directional rotation of each wheel.

- In June 2022, Electro Sensors Inc., manufacturer of speed sensors and industrial monitoring systems entered into a definitive agreement with Mobile X Global, Inc. to merge and re-name the combined company as Mobile X Global, Inc.

Key Questions Answered in the Report

What is a speed sensor? +

A speed sensor is a device used to measure and monitor the velocity and speed of an object, in terms of the object’s linear and rotational movement.

What specific segmentation details are covered in the speed sensor market report, and how is the dominating segment impacting the market growth? +

o Hall-effect digital speed sensors dominates the market owing to the non-contact feature of the sensors that leads to minimal wear and tear, ensuring long-term reliability and reduced maintenance requirements.

What specific segmentation details are covered in the speed sensor market report, and how is the fastest segment anticipated to impact the market growth? +

Magneto-resistive sensors will witness the fastest CAGR as the sensors offer high accuracy and precision in measuring speed and detect even small changes in magnetic fields, ideal for applications that require precise speed measurements.

Which region is anticipated to witness the highest CAGR during the forecast period, 2023-2030? +

Asia Pacific is anticipated to witness the fastest CAGR during the forecast period due to the expanding manufacturing sector and the advancements in technology.