- Summary

- Table Of Content

- Methodology

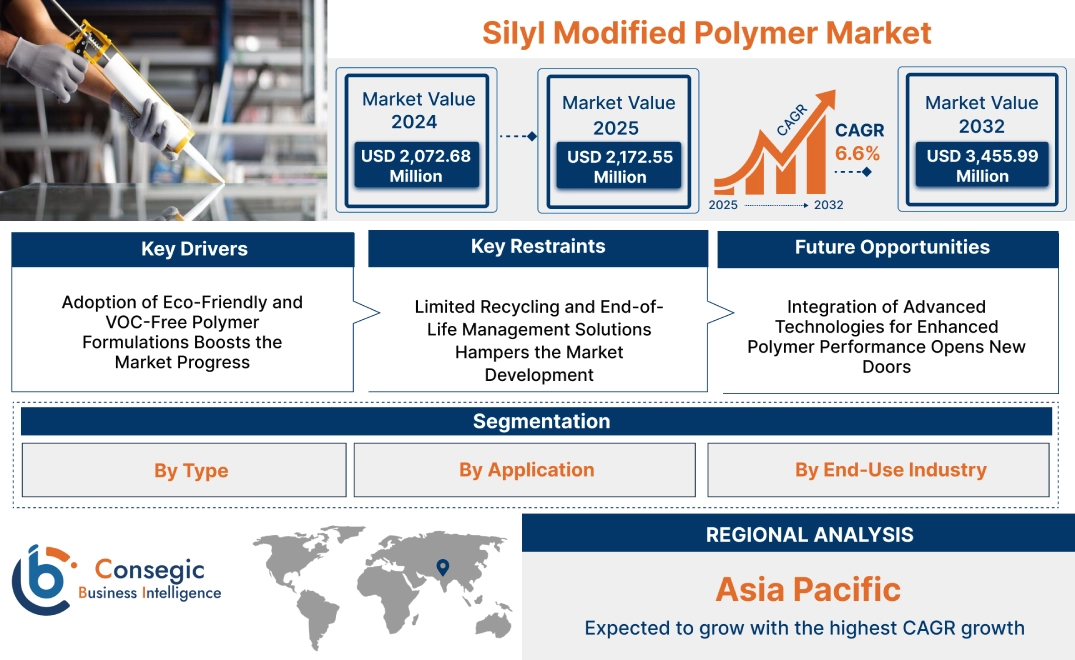

Silyl Modified Polymer Market Size:

Silyl Modified Polymer Market size is estimated to reach over USD 3,455.99 Million by 2032 from a value of USD 2,072.68 Million in 2024 and is projected to grow by USD 2,172.55 Million in 2025, growing at a CAGR of 6.6% from 2025 to 2032.

Silyl Modified Polymer Market Scope & Overview:

The silyl modified polymer or polymers that focuses on the production and application of hybrid polymers, also known as MS polymers or SMPs, which combine the properties of silicone and polyurethane. These polymers are widely used in sealants, adhesives, and coatings due to their superior bonding strength, flexibility, and durability. Key characteristics of polymers include excellent adhesion to diverse substrates, weather resistance, and low VOC (volatile organic compound) emissions, making them an environmentally friendly alternative to traditional materials. The benefits include enhanced performance in demanding conditions, ease of application, and compliance with stringent environmental regulations. Applications span construction, automotive, industrial manufacturing, and electronics for bonding, sealing, and waterproofing solutions. End-users include construction companies, automotive manufacturers, and industrial product developers, driven by the rising adoption of sustainable materials, increasing silyl modified polymer market demand for high-performance adhesives, and advancements in polymer technology.

Key Drivers:

Adoption of Eco-Friendly and VOC-Free Polymer Formulations Boosts the Market Progress

The rising focus on sustainable and eco-friendly solutions is shaping key silyl modified polymer market trends in the silyl modified polymer (SMP) market growth. As regulatory bodies enforce stricter environmental standards, particularly regarding volatile organic compound (VOC) emissions, industries are transitioning to low-emission alternatives. SMPs stand out as a VOC-free option, making them increasingly relevant in sectors such as construction and automotive, where environmental compliance is critical. Their isocyanate-free composition further enhances their appeal by reducing health risks associated with traditional polyurethane-based sealants.

Moreover, SMPs align with the global shift toward green building certifications and eco-labeling, allowing manufacturers to market their products as environmentally responsible. This silyl modified polymer market analysis portrays the encouragement in the growth of advanced SMP formulations tailored for high-performance applications while maintaining a low ecological footprint. As industries prioritize sustainability, the role of SMPs in enabling eco-conscious manufacturing and construction practices is expected to solidify further.

Key Restraints:

Limited Recycling and End-of-Life Management Solutions Hampers the Market Development

Despite their eco-friendly benefits during use, the lack of effective recycling and end-of-life management solutions for silyl modified polymers market expansion presents a significant challenge. SMPs, like many advanced materials, are designed for durability and long-term performance, which complicates their recycling processes. Currently, there are limited systems in place to handle SMP waste, leading to concerns about their environmental impact once disposed of.

This limitation is particularly significant in regions with stringent waste management and circular economy policies, where industries are increasingly scrutinized for their contributions to landfill waste. The absence of clear guidelines or technologies for SMP recycling may discourage environmentally conscious manufacturers and users, creating a barrier to widespread adoption. Addressing these challenges through innovation in recycling technologies and partnerships with waste management industries could unlock new opportunities for SMP sustainability..

Future Opportunities :

Integration of Advanced Technologies for Enhanced Polymer Performance Opens New Doors

The integration of advanced technologies, such as nanotechnology and hybrid formulations, is driving innovation in the silyl modified polymer market expansion. By incorporating nanoparticles and other additives, manufacturers are enhancing the mechanical properties, adhesion strength, and curing speed of SMPs, making them suitable for more demanding applications. For instance, advanced formulations can provide improved resistance to extreme temperatures, UV radiation, and chemical exposure, expanding the applicability of SMPs across diverse industries.

Furthermore, smart SMPs with self-healing properties or responsiveness to environmental triggers are emerging as a potential breakthrough in the polymer sector. These innovations cater to the evolving needs of industries like aerospace, automotive, and renewable energy, where materials must perform under challenging conditions. The trends toward tailored solutions is fostering collaborations between material scientists and end-users, paving the way for new applications and setting the stage for the next generation of high-performance SMPs.

Silyl Modified Polymer Market Segmental Analysis :

By Type:

Based on type, the SMP market is segmented into silyl modified polyethers (MS polymers) and silyl modified polyurethanes (SPUR polymers).

The silyl modified polyethers (MS polymers) segment accounted for the largest revenue in silyl modified polymer market share in 2024.

- MS polymers are extensively used due to their high flexibility, durability, and excellent adhesion properties.

- These polymers are particularly favored in adhesives and sealants across industries like construction and automotive.

- The increasing trends of adopting eco-friendly, solvent-free materials in construction applications has driven the growth for MS polymers.

- Furthermore, their compatibility with various substrates, including metals, plastics, and glass, enhances silyl modified polymer market growth and their utility in diverse industrial applications.

- Thus, MS polymers dominate the market due to their versatility, durability, and analysis shows rising adoption in sustainable construction and automotive applications.

The silyl modified polyurethanes (SPUR polymers) segment is anticipated to register the fastest CAGR during the forecast period.

- SPUR polymers combine the benefits of polyurethane and silane chemistries, offering enhanced mechanical properties and weather resistance.

- The growing trends of utilizing high-performance sealants in aerospace and electronics industries has increased the growth for SPUR polymers.

- Additionally, their ability to provide superior bonding in extreme environmental conditions supports their adoption across critical applications.

- SPUR polymers are expected to grow rapidly, driven by their superior mechanical properties and increasing demand in high-performance applications such as aerospace and electronics.

By Application:

Based on application, the market is segmented into adhesives, sealants, coatings, construction materials, and fibers.

The adhesives segment accounted for the largest revenue share in 2024.

- SMP-based adhesives are widely used due to their strong bonding capabilities and resistance to weathering.

- The trends of adopting advanced adhesives for lightweight material bonding in the automotive and aerospace industries has significantly driven this segment.

- Additionally, the increasing use of adhesives in modular construction and prefabricated structures highlights their importance in modern construction techniques.

- Therefore, adhesives SMP analysis lead the market due to their critical role in lightweight bonding applications and their growing adoption in modern construction and manufacturing processes.

The coatings segment is anticipated to register the fastest CAGR during the forecast period.

- SMP-based coatings are gaining traction for their superior durability and environmental compliance.

- The rising trends of using low-VOC and solvent-free coatings in industrial and residential applications has fueled the demand for SMP coatings.

- Their excellent resistance to UV radiation and moisture makes them ideal for exterior applications in construction and marine sectors.

- Therefore, as per the analysis, coatings are expected to grow rapidly, supported by the analysis toward eco-friendly solutions and their extensive use in durable exterior applications.

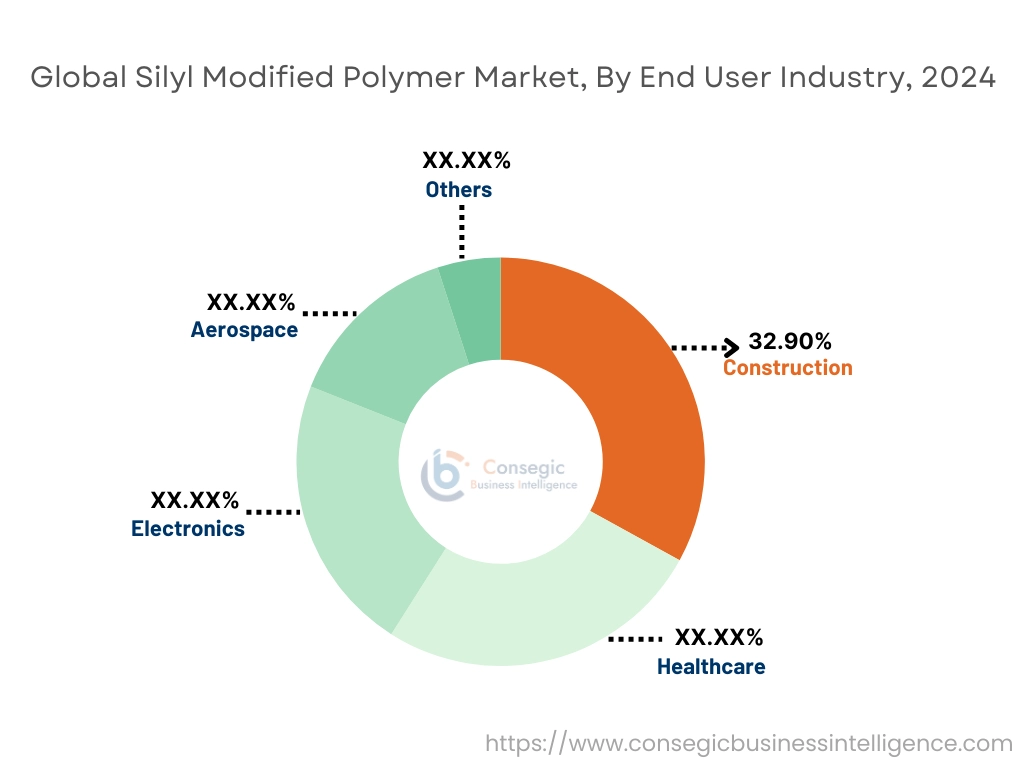

By End-Use Industry:

Based on end-use industry, the market is segmented into construction, healthcare, electronics, aerospace, and others.

The construction segment accounted for the largest revenue of 32.90% of the total silyl modified polymer market share in 2024.

- The construction sectors is the primary consumer of SMPs, using them in adhesives, sealants, and coatings.

- The trends of adopting green building materials and sustainable construction practices has driven the demand for SMP-based products.

- Additionally, the increasing focus on enhancing the durability and weather resistance of construction materials has further propelled their use in this sector.

- Construction dominates the market due to the rising adoption of sustainable building materials and the increasing silyl modified polymer market demand for durable adhesives and sealants.

The aerospace segment is anticipated to register the fastest CAGR during the forecast period.

- SMPs are increasingly being used in aerospace applications due to their lightweight and high-strength bonding properties.

- The aim of replacing traditional fasteners with advanced adhesives and sealants to reduce aircraft weight and improve fuel efficiency has driven this segment.

- Additionally, their resistance to extreme temperatures and vibrations makes SMPs ideal for aerospace applications.

- The aerospace segment is expected to grow rapidly, driven by the silyl modified polymer market trends of lightweight bonding solutions and the increasing focus on fuel efficiency in the aerospace industries.

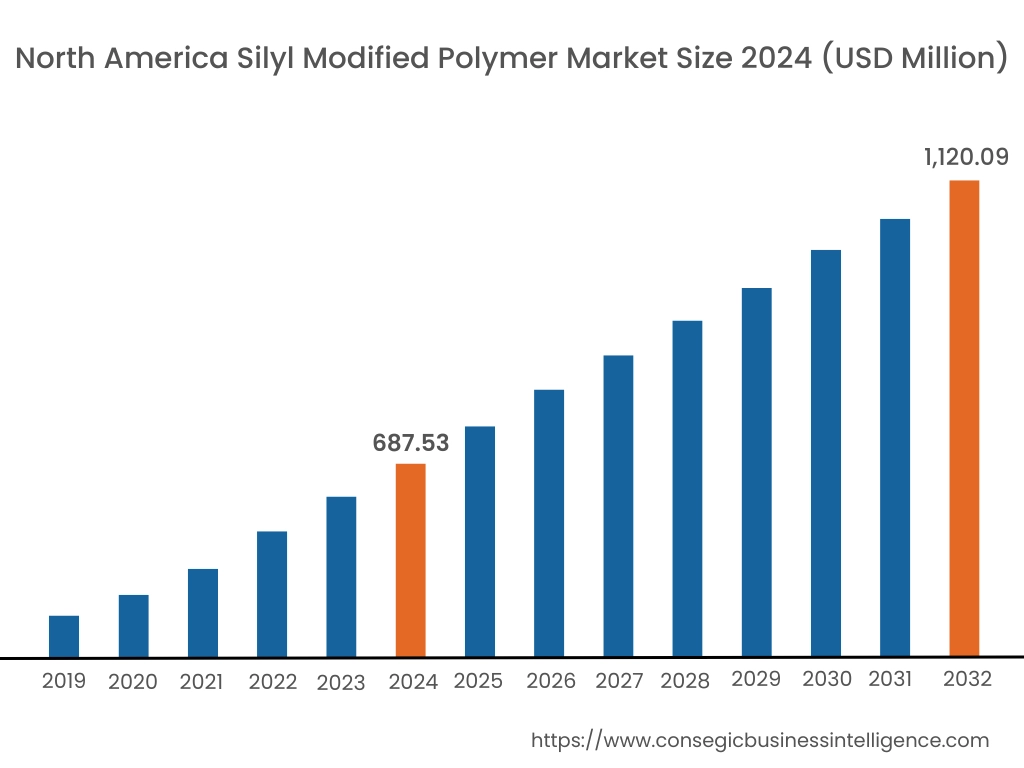

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, North America accounted for the highest market share and was valued at USD 687.53 Million and is expected to reach USD 1,120.09 Million in 2032. In North America, the U.S. accounted for the highest share of 71.80% during the base year of 2024. North America holds a significant position in the silyl modified polymer market analysis depicts, driven by its well-established construction and automotive industries. The U.S. leads the region, with increasing utilization of these polymers in sealants and adhesives for infrastructure projects and vehicle manufacturing. The region also benefits from advancements in polymer technologies and the push for environmentally friendly construction materials. Canada contributes with rising adoption in commercial construction and renovation projects. However, stringent environmental regulations and the high cost of raw materials are key challenges for market participants.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 7.0% over the forecast period. Asia-Pacific is the fastest-developing region in the silyl modified polymer market, supported by rapid urbanization, industrialization, and infrastructure projects in China, India, and Japan. China is leading the market with its large-scale construction projects and growing automotive manufacturing sector, where these polymers are widely used in adhesives and coatings. India’s expanding real estate sector and increased emphasis on sustainable construction materials are boosting polymer adoption. Japan focuses on advanced applications in electronics and specialty coatings, where SMP offer enhanced performance. However, cost-sensitive markets and lack of awareness about advanced polymers in some areas remain challenges.

Europe remains a key region for the silyl modified polymer market due to its focus on sustainable construction practices and stringent environmental regulations. Countries like Germany, France, and the UK lead the region, with growth in applications in waterproofing, industrial adhesives, and flexible sealants. Germany’s advanced manufacturing sector, especially in automotive and construction materials, is a major driver for SMP. France is seeing increased use in eco-friendly building projects, aligning with the European Union’s push for reduced emissions in construction materials. The region’s regulatory complexity can pose challenges for newer entrants.

The Middle East & Africa region is showing steady advancements in the silyl modified polymer market, particularly in the UAE and Saudi Arabia. These countries are increasingly using these polymers in waterproofing and industrial adhesive applications to support ongoing large-scale construction projects. In Africa, South Africa is emerging as a key market, utilizing these polymers in both infrastructure development and automotive repairs. Limited local production capabilities and reliance on imports for advanced materials can create cost-related constraints in certain parts of the region.

Latin America is an emerging market for SMP, with Brazil and Mexico being primary contributors. Brazil’s growing focus on modernizing infrastructure and sustainable construction projects is driving polymer adoption in adhesives and sealants. Mexico’s expanding manufacturing base, particularly in the automotive sector, is fostering the use of these polymers for industrial applications. However, economic instability and inconsistent regulatory standards across the region may limit broader silyl modified polymer market opportunities.

Top Key Players & Market Share Insights:

The Silyl Modified Polymer market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global Silyl Modified Polymer market. Key players in the Silyl Modified Polymer industry include -

- Kaneka Corporation (Japan)

- Risun Polymer International Co., Ltd. (China)

- 3M Company (United States)

- DowDuPont Inc. (United States)

- B. Fuller Company (United States)

- PCC Group (Poland)

- Wacker Chemie AG (Germany)

- Evonik Industries AG (Germany)

- Henkel AG & Co. KGaA (Germany)

- Bostik SA (France)

Silyl Modified Polymer Market Report Insights:

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 3,455.99 Million |

| CAGR (2025-2032) | 6.6% |

| By Type |

|

| By Application |

|

| By End-Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the expected size of the Silyl Modified Polymer Market by 2032? +

The market is projected to reach over USD 3,455.99 Million by 2032.

What are Silyl Modified Polymers (SMPs)? +

SMPs are hybrid polymers combining silicone and polyurethane properties, widely used in adhesives, sealants, and coatings.

Why are SMPs gaining popularity? +

They offer excellent adhesion, flexibility, weather resistance, and low VOC emissions, making them eco-friendly and high-performance solutions.

What industries utilize SMPs the most? +

Major industries include construction, automotive, aerospace, and electronics.

What challenges does the SMP market face? +

Limited recycling options and competition from alternative materials pose significant challenges.

What is the expected size of the Silyl Modified Polymer Market by 2032? +

The market is projected to reach over USD 3,455.99 Million by 2032.

What are Silyl Modified Polymers (SMPs)? +

SMPs are hybrid polymers combining silicone and polyurethane properties, widely used in adhesives, sealants, and coatings.

Why are SMPs gaining popularity? +

They offer excellent adhesion, flexibility, weather resistance, and low VOC emissions, making them eco-friendly and high-performance solutions.

What industries utilize SMPs the most? +

Major industries include construction, automotive, aerospace, and electronics.

What challenges does the SMP market face? +

Limited recycling options and competition from alternative materials pose significant challenges.