- Summary

- Table Of Content

- Methodology

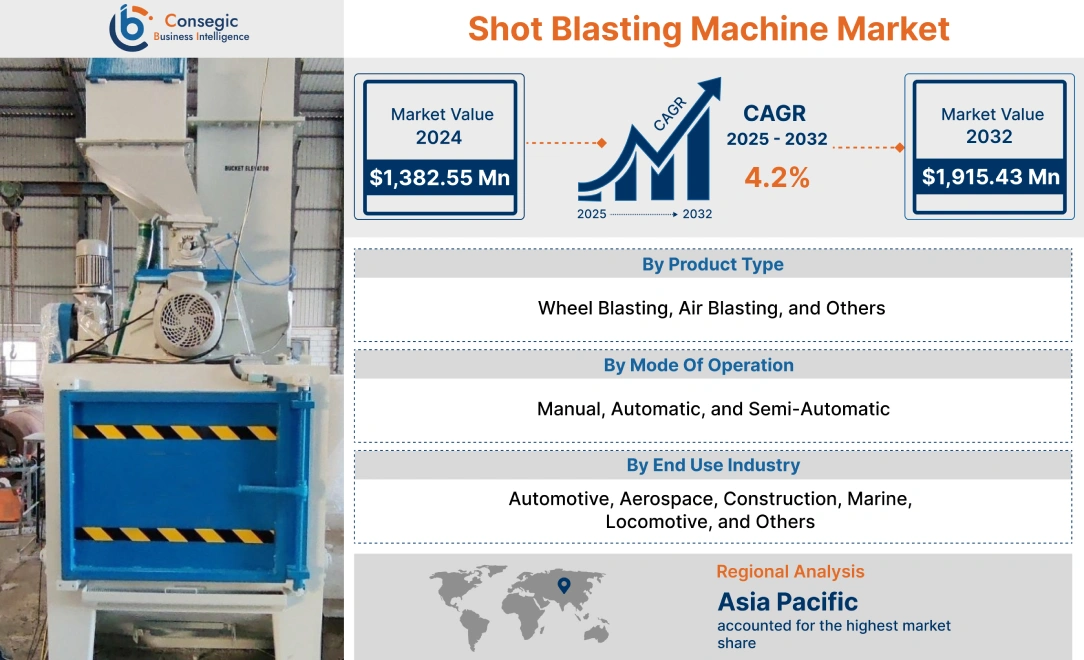

Shot Blasting Machine Market Size :

Consegic Business Intelligence analyzes that the Shot Blasting Machine Market size is estimated to reach over USD 1,915.43 Million by 2032 from a value of USD 1,382.55 Million in 2024 and is projected to grow by USD 1,415.43 Million in 2025, growing at a CAGR of 4.2 % from 2025 to 2032.

Shot Blasting Machine Market Scope & Overview :

The shot blasting machine is enclosed equipment manufactured for abrasive blasting for preparing & cleaning stone, metal, and other surfaces. Its is an equipment, utilized for shot peening & cleaning metal parts, including casting parts, forging, heavy metal structures, steel surfaces, and rusted metal parts, among others. Its major types include wheel blasting, air blasting, and others. These products exhibit various benefits such as corrosion resistance, being environment-friendly, faster operation, preparing the surface, showing up surface defects, and others. As a result, its an ideal solution for various end-use industries such as automotive, aerospace, construction, marine, locomotive, and others.

Shot Blasting Machine Market Insights :

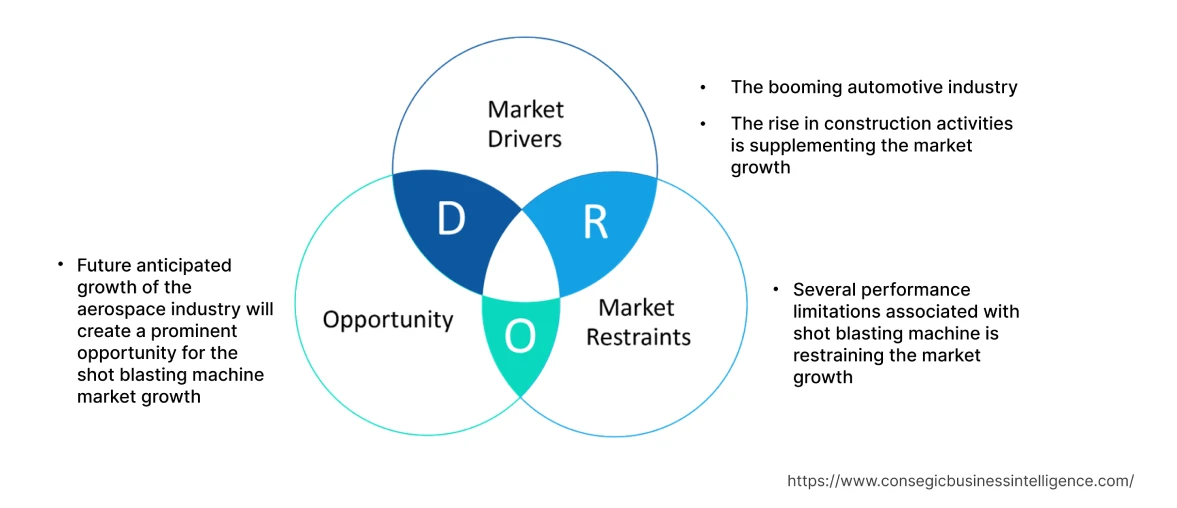

Key Drivers :

The booming automotive industry brings high market demand

The shot blasting machine is widely deployed in the automotive sector to eliminate the stress on the metal plate. The metal plates are utilized in automotive vehicles such as passenger cars, light commercial vehicles, and heavy commercial vehicles. The rising adoption of electric vehicles, the increasing purchasing power of people, and others are some of the key trends proliferating the development of the automotive sector at the global level. For instance, according to the Organisation Internationale des Constructeurs d'Automobiles (OICA), the global automobile vehicles production was 80,205,102 units in 2021, and in 2022, it was 85,016,728 units, a year-on-year growth rate of 6%. Analysis of market trends concludes that the expansion of the automotive sector is a prime factor boosting the requirement for these machines at the global level to ensure efficient anti-rust treatment. This factor is driving the shot blasting machine market demand at the global level.

The rise in construction activities spurs market growth

Shot blasting machines are employed in construction applications, including angle steel, steel structures, metal sheets, welded parts, beams, pipes, section bars, and others. Their adoption in the above applications ensures the elimination of burrs, de-rusted, oxides, and others. Vital factors such as increasing investments in new construction projects, the rising necessity for increased floor area for commercial spaces, and others are driving the expansion of global building & construction activities. For instance, according to the European Construction Industry Federation (FIEC), in 2020, the total investments in new building & construction projects across the European Union region was valued at Euro 1,402 billion (USD 1,598.6 billion), and in 2021, it was Euro 1,602 billion (USD 1,893.6 billion). The year-on-year growth rate of the new building & construction investment in the European Union region was 14.3% in 2021. Therefore, the bolstering of building & construction activities at the global level is fueling the need for these machines to meet the structural requirements, which, in turn, is fostering shot blasting machine market demand.

Key Restraints :

Several performance limitations bring doom to the market

Shot blasting machines have several performance limitations such as limited cleaning impact of the machine, noise constraints, low dust removal efficiency, and others. For instance, their frequent utilization can often lead to fatigue, aging, and others. This can impact the performance features of these machines such as wear and corrosion protection. Hence, their timely maintenance is recommended to ensure smoother functioning of equipment without compromising performance. Analysis of market trends concludes that the above performance limitations associated with shot blasting machines are posing a major bottleneck for the global market expansion during the projected forecast period.

Future Opportunities :

Future anticipated growth of the aerospace industry bring multiple opportunities

In the aerospace sector, metal parts and components are designed with exact and even finishes to meet highly specialised specifications and tolerances. Hence, shot blasting machines are ideal for the aerospace sector for the manufacturing of new components, repair of existing components, overhaul, and others to provide a uniform, rough or matte surface. For instance, according to the Airbus 2023-2042 forecast, the demand for new passengers and freighter aircraft will reach 40,850 in the coming 20 years. Thus, it is evident from the above data that the aerospace sector will register a favorable growth outlook in the long run. Analysis of market trends suggest that the expansion of the aerospace sector will boost the demand for these machines for the production of new components. This, in turn is emerging as one of many shot blasting machine market opportunities that drive market expansion during the projected forecast period.

Shot Blasting Machine Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 1,915.43 Million |

| CAGR (2025-2032) | 4.2% |

| Based on the Product Type | Wheel Blasting, Air Blasting, and Others |

| Based on the Mode of Operation | Manual, Automatic, and Semi-Automatic |

| Based on the End-use Industry | Automotive, Aerospace, Construction, Marine, Locomotive, and Others |

| Based on the Region | North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

| Key Players | Rosler Oberflachentechnik GmbH, AGTOS GmbH, Goff Inc, Shandong Kaitai Shot-blasting Machinery Co.Ltd, Pangborn Group, SIAPRO, Sintokogio Ltd., Norican Group, MEC SHOT, and Surface Finishing Equipment Company |

Shot Blasting Machine Market Segmental Analysis :

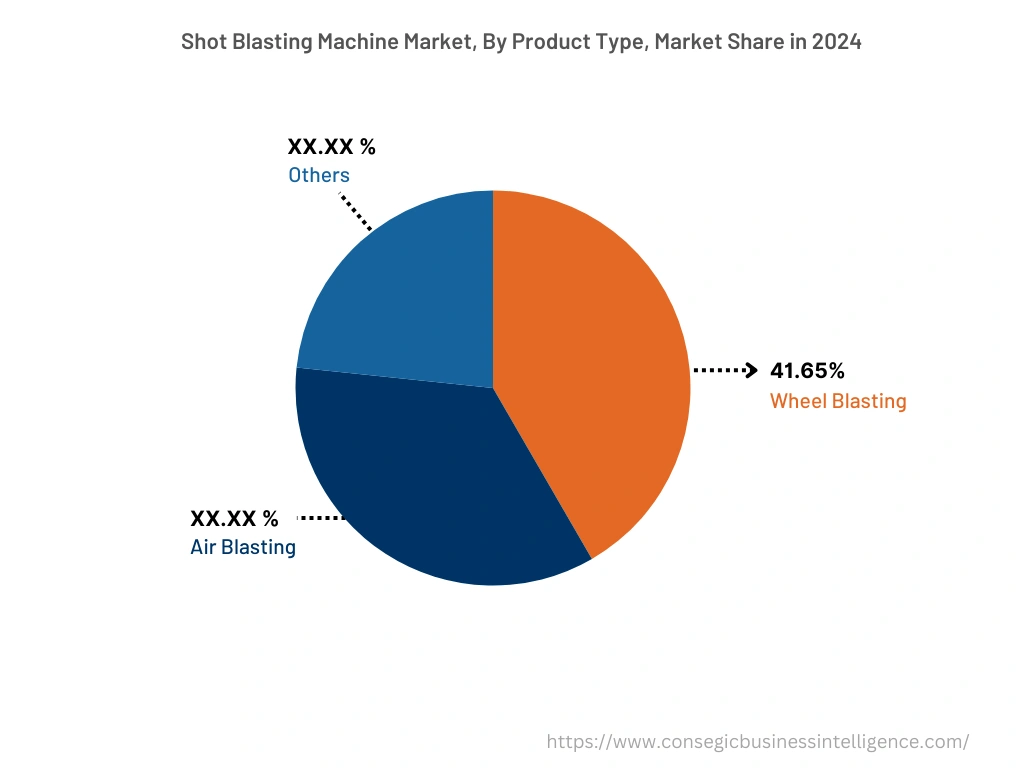

By Product Type

The product type segment is categorized into wheel blasting, air blasting, and others. In 2024, the wheel blasting segment accounted for the highest market share of 41.65% in the overall market. The prime benefits associated with wheel blasting include superior speed, excellent efficiency, and the ability to blast larger objects. Moreover, the deployment of wheel blasting ensures minimum dirt remains at the end of the cleaning process. Thus, wheel blasting is an ideal product for various end-use industries such as automotive, mining, industrial, and others. For instance, in August 2021, ActOn Finishing, a metal finishing manufacturer in India formed a partnership with Cogeim Europe, an Italy-based manufacturer. ActOn Finishing is supplying wheel blasting to the manufacturing sector in the United Kingdom as part of the partnership. The wheel blasting is designed by Cogeim Europe. Hence, the increasing product offering for wheel blasting at the global level ensures superior speed. This vital determinant is seen as one of the prominent opportunities that propells shot blasting machine market growth.

However, the air blasting segment is projected to be the fastest-growing segment during the forecast period. Evaluation of market trends suggest that the increasing construction activities at the global level are fostering segmental proliferation.

By Mode of Operation:

The mode of operation segment is categorized into manual, automatic, and semi-automatic. In 2024, the automatic segment accounted for the highest market share in the market and is expected to be the fastest-growing segment during the forecast period. The key benefits related to these automatic machines include reduced labor costs and increased productivity. In addition, they have superior performance features such as extended work life, optimal blast pattern, user-friendly, automatic abrasion refill, and others. As a result of the above features, automatic shot machines are frequently utilized in locomotives, marine, automotive, and other industries. For instance, in May 2021, Additive Manufacturing Technologies Ltd. launched PostProDP MAX, a new range of fully automated shot blasting systems. The key benefits of the product include minimizing the machine footprint and maintenance costs. Examination of market trends concludes that the development of a new range of automatic shot blasting machines will accelerate the market expansion in the forecast years.

By End-use Industry :

The end-use industry segment is categorized into automotive, aerospace, construction, marine, locomotive, and others. In 2024, the automotive segment accounted for the highest shot blasting machine market share. This machine ensures anti-rust treatment. This eliminates the stress of the steel plate and removes the welding slag. Thus, the shot blast machine is utilized in automotive chassis, steel frames, and others. These products are employed in passenger cars, electric vehicles, trucks, buses, and others. The development of infrastructure projects, public transportation, and others are key variables propelling the demand for commercial vehicles. These factors are contributing to the development of automotive production. For instance, according to the Organisation Internationale des Constructeurs d'Automobiles (OICA), the production of commercial vehicles at the global level was 21,787,126 units in 2020, and in 2021, it was 23,091,693 units. In 2021, the year-on-year growth rate for commercial vehicle production was 5.9%. The shot blasting machine market analysis concluded that the expansion of the automotive sector is favoring the demand for shot blast machines to remove the rust layer in automobiles. This, in turn, is fostering shot blasting machine market growth.

However, the aerospace segment is expected to be the fastest-growing segment during the forecast period. Analysis of shot blasting machine market trends concludes that this phenomenon is attributed to factors such as increasing investment in new aerospace manufacturing facilities, government initiatives for new aircraft model development, and others.

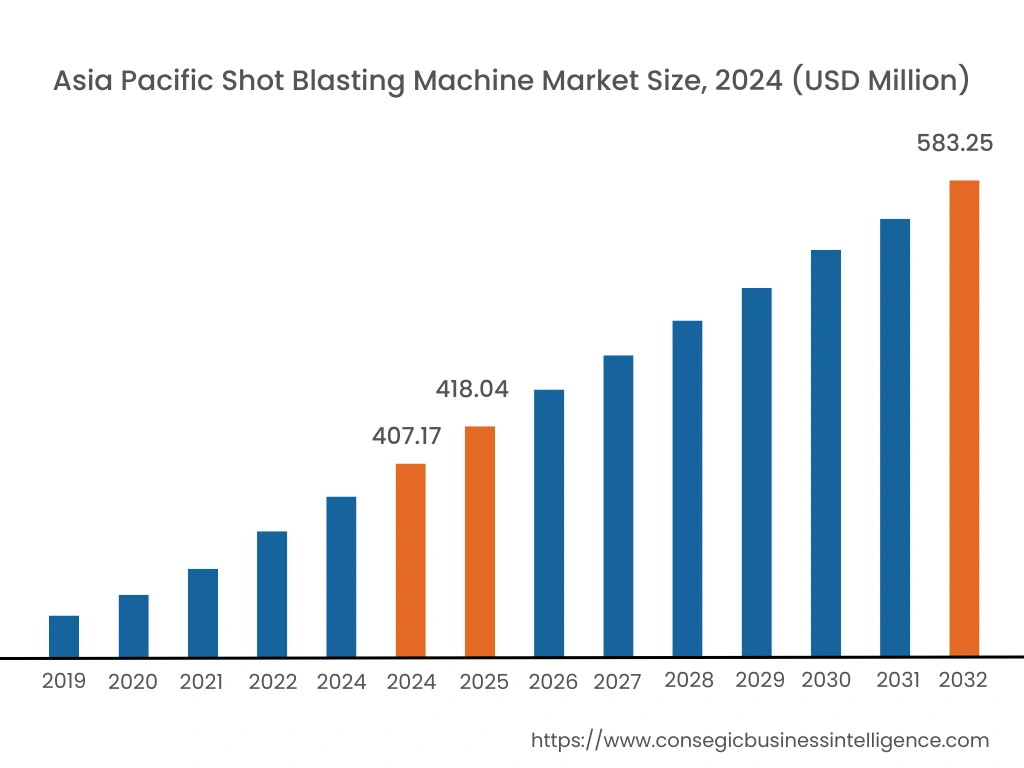

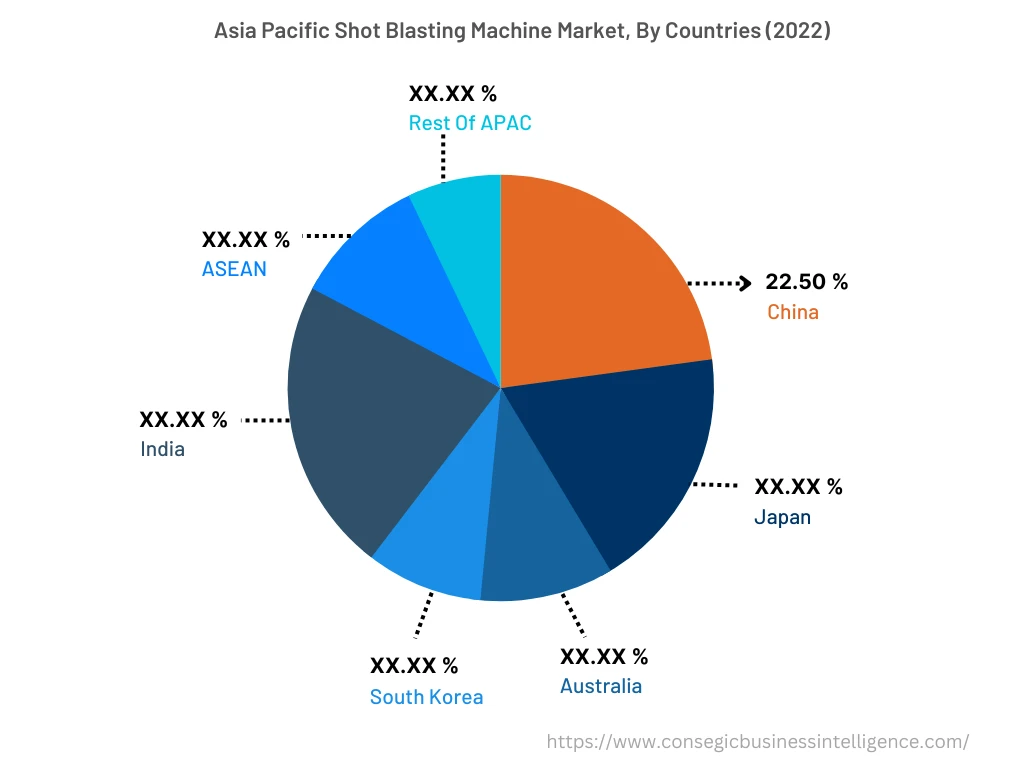

By Region :

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, Asia Pacific accounted for the highest market share at 38.35% and was valued at USD 407.17 million, and is expected to reach USD 583.25 million in 2032. In Asia Pacific, China accounted for the highest market share of 22.50% during the base year of 2024. Analysis of shot blasting machine market trends concludes that the the advancement of the sectors such as automotive, aerospace, construction, and others are boosting the shot blast machine market expansion in the Asia Pacific region. For instance, according to the Organisation Internationale des Constructeurs d'Automobiles (OICA), in 2022, the Asia Pacific region manufactured the highest number of total automotive vehicles at the global level, holding a share of 58.84%. In 2021, the total production of automotive vehicles in the Asia Pacific was 46,768,800 units, and in 2022, it was 50,020,793 units, an increase of 7% over 2021. Henceforth, the revenue expansion of the above end-use industries in the Asia Pacific region is driving the shot blast machine market expansion in the region.

Furthermore, Europe is expected to witness significant growth over the forecast period, growing at a CAGR of 4.9% during 2025-2032. The shot blasting machine market analysis concluded that this is due to the presence of various machine manufacturers, the development of new electric vehicle manufacturing facilities, and others.

Top Key Players & Market Share Insights :

The shot blasting machine market is highly competitive, with several large players and numerous small and mid-ranged enterprises. The companies operating in shot blasting machine industry have strong research and development capabilities and a strong presence in the market through their extensive product portfolios and distribution networks. The market is characterized by intense competition, with companies focusing on expanding their product offerings and increasing their product revenue through mergers, acquisitions, and partnerships. The key players in the market include-

- Rosler Oberflachentechnik GmbH

- AGTOS GmbH

- Norican Group

- MEC SHOT

- Surface Finishing Equipment Company

- Goff Inc

- Shandong Kaitai Shot-blasting Machinery Co.Ltd

- Pangborn Group

- SIAPRO

- Sintokogio Ltd.

Recent Industry Developments :

- In December 2022, Norican Group, a Denmark-based manufacturer of shot blasting machines formed a strategic collaboration with Wuxi Xinan Technology Co., Ltd., a manufacturer in China.

- In June 2022, AGTOS Gesellschaft Fur Technische Oberflachensysteme GmbH, a leading manufacturer in Germany that offers shot blasting machines expanded its product offerings in France.

- In July 2021, Gienanth GmbH, a leading supplier of iron casting formed a partnership with Rösler Oberflächentechnik GmbH to install a Rösler wire mesh belt blast machine named RDGE 1250/300-8.

Key Questions Answered in the Report

What was the market size of the shot blasting machine industry in 2024? +

In 2024, the market size of shot blasting machine was USD 1,382.55 million.

What will be the potential market valuation for the shot blasting machine industry by 2030? +

In 2030, the market size of shot blasting machine will be expected to reach USD 1,715.30 million.

What are the key factors driving the growth of the shot blasting machine market? +

What are the key factors driving the growth of the shot blasting machine market?

What is the dominating segment in the shot blasting machine market by product type? +

In 2024, the wheel blasting segment accounted for the highest market share of 41.65% in the overall shot blasting machine market.

Based on current market trends and future predictions, which geographical region is the dominating region in the shot blasting machine market? +

Asia Pacific accounted for the highest market share in the overall shot blasting machine market.