- Summary

- Table Of Content

- Methodology

Rotary Lobe Pump Market Introduction :

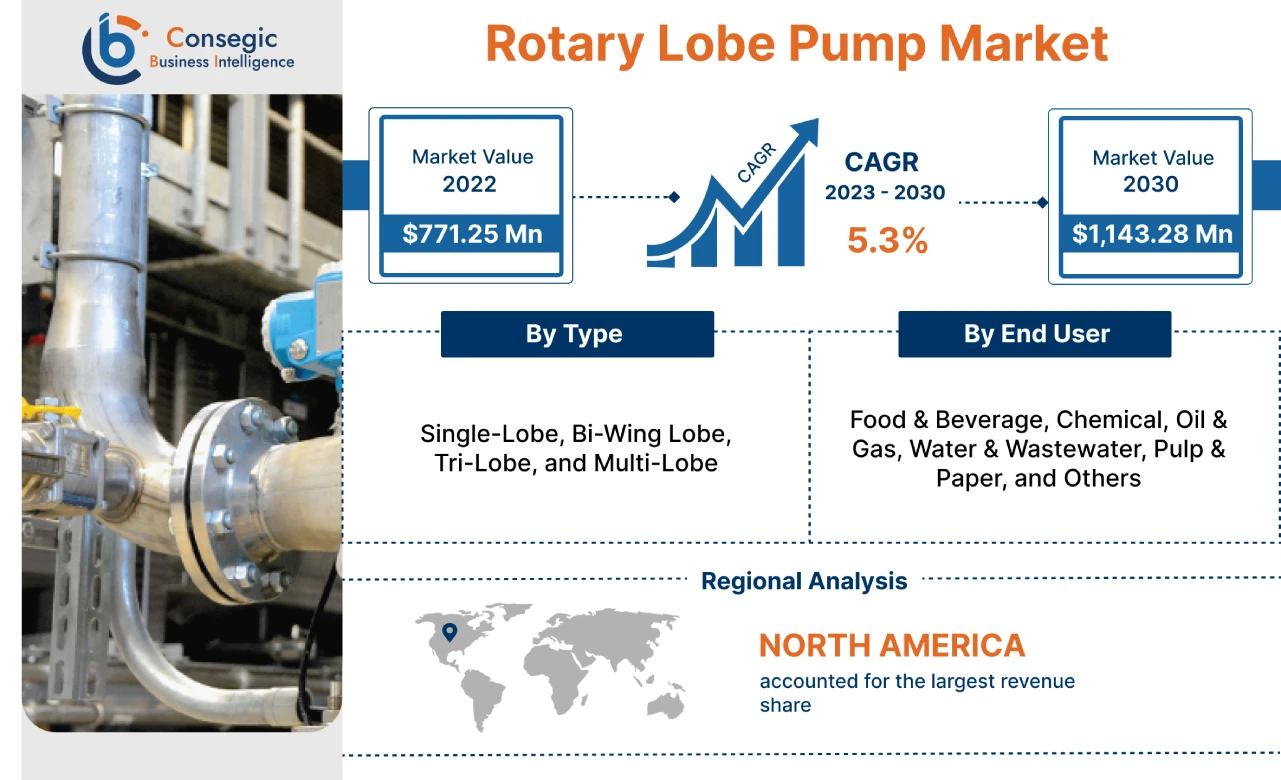

Rotary Lobe Pump Market is estimated to reach over USD 1,143.28 Million by 2030 from a value of USD 771.25 Million in 2022, growing at a CAGR of 5.3% from 2023 to 2030.

Rotary Lobe Pump Market Definition & Overview:

Rotary lobe pumps are a type of positive-displacement pump that are used in various industrial applications for transferring of viscous and non-viscous fluids. Rotary lobe pumps offer a range of benefits including gentle handling of fluids, high flexibility, self-priming capabilities, compact design, ease of maintenance, high efficiency, and low life cycle costs among others. The aforementioned benefits of rotary lobe pumps are key determinants for increasing its deployment in food & beverage, chemical, oil & gas, wastewater, pulp & paper, and other industries.

Rotary Lobe Pump Market Insights :

Key Drivers :

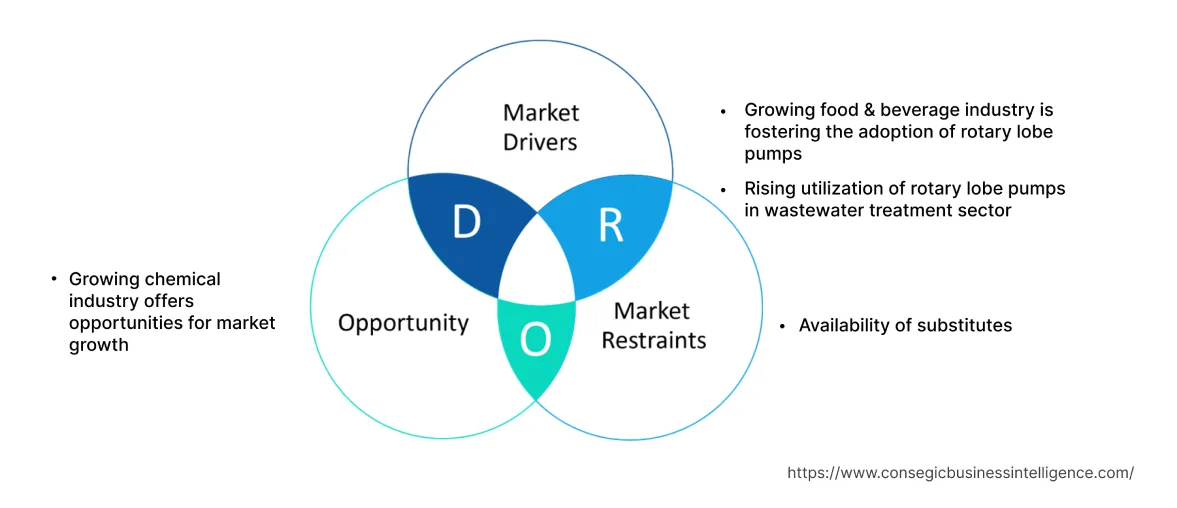

Growing food & beverage industry is fostering the adoption of rotary lobe pumps

Rotary lobe pumps are primarily utilized in food & beverage facilities for sanitary and processing applications. Rotary lobe pumps offer gentle processing of food products without causing any damage. Moreover, rotary lobe pumps are often installed in food processing plants for applications involving transferring, mash & peel, waste, centrifuge feed & thickening, and other related processes. Factors such as the significant investments in the food & beverage sector, increasing consumer demand for packaged and processed food products, along with rising hygiene standards in the food industry are major factors driving the growth of the food & beverage industry.

For instance, according to Food Drink Europe, a European Union confederation for the food industry, the European Union food and beverage industry was valued at USD 1,292.0 billion in 2022, representing an increase of 2.6% in comparison to USD 1,177.8 billion in 2021. Thus, the growing food & beverage industry is driving the demand for rotary lobe pumps during the forecast market.

Rising utilization of rotary lobe pumps in wastewater treatment sector

Rotary lobe pumps are mainly used in wastewater treatment plants for pumping sludge to and from thickeners, digesters, separators, and clarifiers installed in wastewater treatment facilities. Rotary lobe pumps offer an even, pulsation-free flow of liquid, which are prime aspects increasing its utilization for transferring sludge and feeding dewatering equipment in wastewater treatment plants. Factors including the increasing need for clean water, rising development of wastewater treatment plants, and the growing demand for efficient water treatment and processing solutions are among the key factors driving the adoption of rotary lobe pumps.

In September 2022, Lanxess AG launched a new wastewater treatment plant in Belgium with an initial investment of around USD 11.68 million. The plant has a treatment capacity of approximately 260,000 liters of wastewater per hour. Additionally, in April 2021, Sewerages Systems Ghana Limited expanded its wastewater treatment plant located in Accra, Ghana. The expansion increased the wastewater treatment plant's capacity from 2,000 cubic meters to 3,500 cubic meters per day. Hence, the rising development of wastewater treatment plants is increasing the adoption of rotary lobe pumps for transferring sludge and feeding dewatering equipment, thereby, proliferating the growth of the market.

Key Restraints :

Availability of substitutes

Rotary lobe pumps have various substitutes such as eccentric disc pumps, external gear pumps, and others. Comparatively, the substitutes have similar properties, performance, and applications, with respect to rotary lobe pumps, which is a significant factor restricting the market growth. For instance, eccentric disc pumps act as an ideal alternative to rotary lobe pumps for food processing applications. Therefore, the availability of various substitutes for rotary lobe pumps is limiting the growth of the market.

Future Opportunities :

Growing chemical industry offers opportunities for market growth

The application of rotary lobe pumps in the chemical sector is expected to present potential opportunities for the growth of the rotary lobe pump market. Rotary lobe pumps are often utilized in the chemical sector for applications involving maintenance-friendly pumping processes, owing to its high flexibility and performance. Moreover, rotary lobe pumps are used for the pumping of highly viscous and abrasive media as the pumps are capable of moving a variety of fluids quickly and safely without pulsation. The rising investments in the chemical sector, expansion of chemical manufacturing units, and increasing production of industrial chemicals are key factors driving the growth of the chemical industry. For instance, according to the American Chemistry Council, the overall production of industrial chemicals increased by 5.9% in 2021 in comparison to 2020. Additionally, the production from the chemical industry in the U.S. has increased up to 4.3% in 2022.

Therefore, the growth of chemical sector will increase the application of rotary lobe pumps in chemical facilities, further promoting opportunities for market growth during the forecast period.

Rotary Lobe Pump Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2017-2030 |

| Market Size in 2030 | USD 1,143.28 Million |

| CAGR (2023-2030) | 5.3% |

| By Type | Single-Lobe, Bi-Wing Lobe, Tri-Lobe, and Multi-Lobe |

| By End-User | Food & Beverage, Chemical, Oil & Gas, Water & Wastewater, Pulp & Paper, and Others |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | Borger GmbH, Alfa Laval AB, NETZSCH Group, GEA Group, Vogelsang GmbH & Co. KG, SPXELOW Inc., LobePro, Verder Liquids BV, INOXPA Group, ZEILFELDER Pumps, Fristam Pumpen GmbH |

Rotary Lobe Pump Market Segmental Analysis :

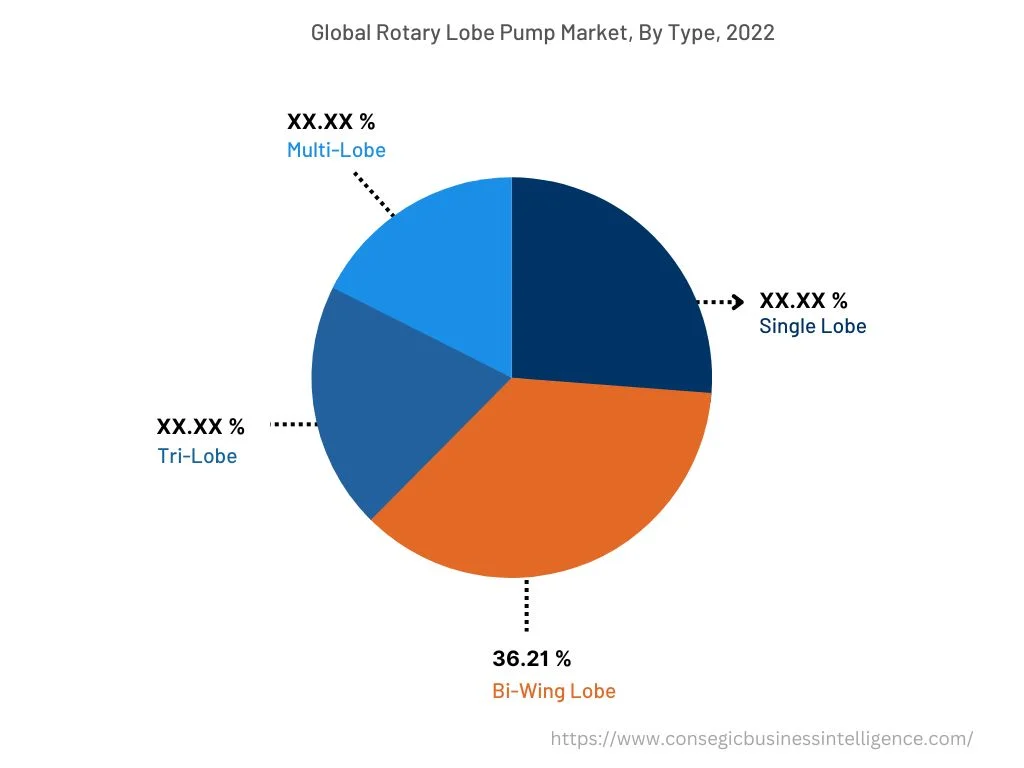

Based on the Type :

Based on the type, the market is bifurcated into single-lobe, bi-wing lobe, tri-lobe, and multi-lobe. The bi-wing lobe segment accounted for the largest revenue share of 36.21% in the year 2022. Bi-wing rotary lobe pumps consist of two seals around the edge that ensure enhanced performance and makes the lobe ideal for handling medium to high-viscosity liquids. Moreover, bi-wing rotary lobe pumps offer multiple benefits including superior hygiene, gentle product handling, integrated shaft and gear design, and ease of cleaning and maintenance among others. The above benefits of bi-wing rotary lobe pumps are increasing its utilization in food & beverage, pharmaceutical, wastewater treatment plants, and other related applications. According to the European Federation of Pharmaceutical Industries and Associations, the total production of the pharmaceutical industry in Europe was valued at USD 339.7 billion in 2021, witnessing an increase of 4.6% in comparison to USD 324.7 billion in 2020. Hence, the growth of pharmaceutical industry is among the key factors driving the application of bi-wing rotary lobe pumps in pharmaceutical manufacturing facilities, in turn contributing to the growth of the market.

The tri-lobe segment is anticipated to register the fastest CAGR growth during the forecast period. Tri-lobe pumps consist of three lobes that rotate in a circular motion. Tri-lobe pumps are optimized for handling viscous liquids with high solids content. The pumps offer several benefits including ease of maintenance, large selection of shaft seals, simple, clean, and robust construction, and others. Tri-lobe pumps are utilized for a wide range of processing applications in oil and gas, food and beverage, and chemical industries among others. According to Invest India, the oil and gas sector in India witnessed a growth of around 5% in FY 2021-22 as compared to the previous year. Additionally, India ranks second in terms of oil and gas refineries in Asia. The total refining capacity of India is equivalent to 251 MMTPA as of October 2022, comprising of 23 refineries. Therefore, the growth of oil and gas industry is driving the adoption of tri-lobe pumps, owing to the aforementioned benefits and usage, thereby driving the market growth during the forecast period.

Based on the End-use Industry :

Based on the end-user, the market is segregated into food & beverage, chemical, oil & gas, water & wastewater, pulp & paper, and others. Factors such as the significant investments in food & beverage facilities, rising hygiene standards in the food industry, and increasing utilization of rotary lobe pumps for food processing applications are major factors driving the growth of the food & beverage segment.

For instance, in July 2021, Interroll commenced the expansion of its food processing and logistics facility in Baal, Germany. The food processing facility became fully operational in 2022. Thus, considering the rising development of investment in food processing facilities the adoption of rotary lobe is expected to grow. Further, the pumps for food processing applications are used for processes involving transferring, mashing & peeling, centrifuge feed & thickening, and other related processes. The above factors are anticipated to drive the growth of the market.

Water & wastewater segment is expected to witness fastest CAGR growth during the forecast period. The growth of the water & wastewater segment is attributed to several factors including the rising need for clean water, increasing development of wastewater treatment plants, and the growing demand for efficient water treatment and processing solutions. Further the growing environmental concerns also plays an important role in driving the market growth. Thus, the increasing development of wastewater treatment plants is driving the adoption of rotary lobe pumps for transferring sludge and feeding dewatering equipment, in turn fostering market growth during the forecast period.

Based on the Region :

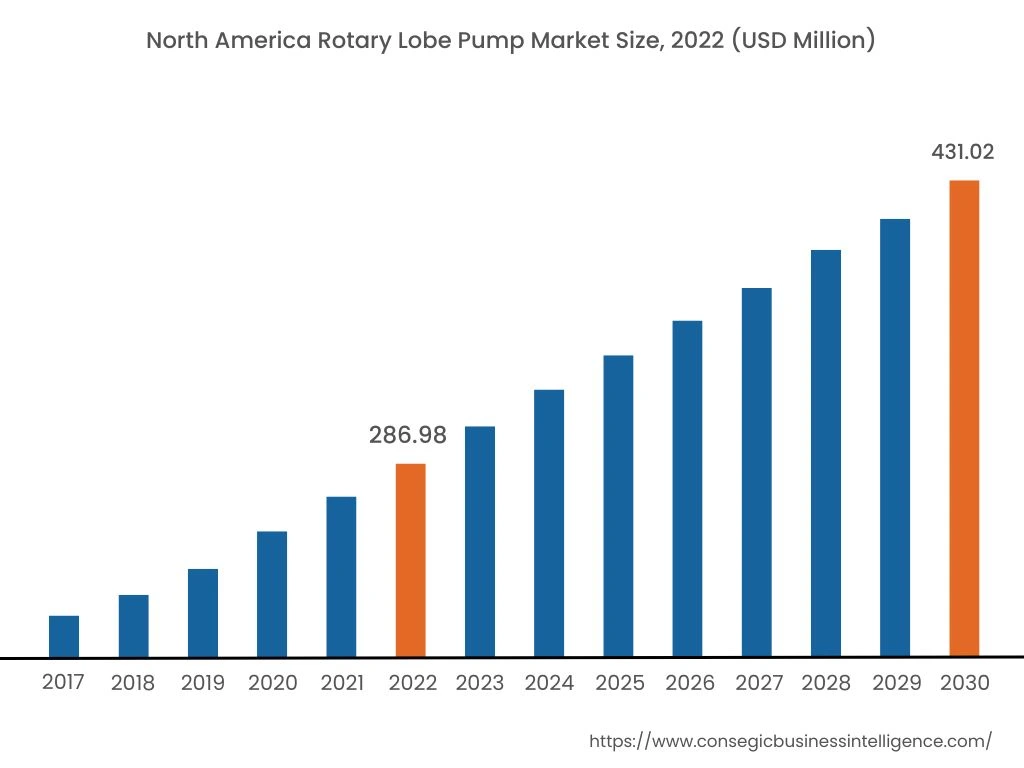

The regional segment includes North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

North America accounted for the largest revenue share of USD 286.98 Million in 2022 and is expected to reach USD 431.02 Million by 2030, registering a CAGR of 5.5% during the forecast period. The adoption of rotary lobe pumps in the North American region is primarily driven by its usage in food & beverage, pharmaceutical, wastewater treatment, and other sectors. Moreover, North America has been a major hub for the companies associated with pharmaceutical and food & beverage manufacturing among others. The increasing application of rotary lobe pumps in food & beverage plants for sanitary and processing applications is among the significant factors driving the market growth in the region. For instance, in March 2022, Kerry Group, a food and beverage company, launched its new food manufacturing facility worth USD 137 million in Georgia, United States. The above factors are further propelling the growth of the rotary lobe pump market in the North American region.

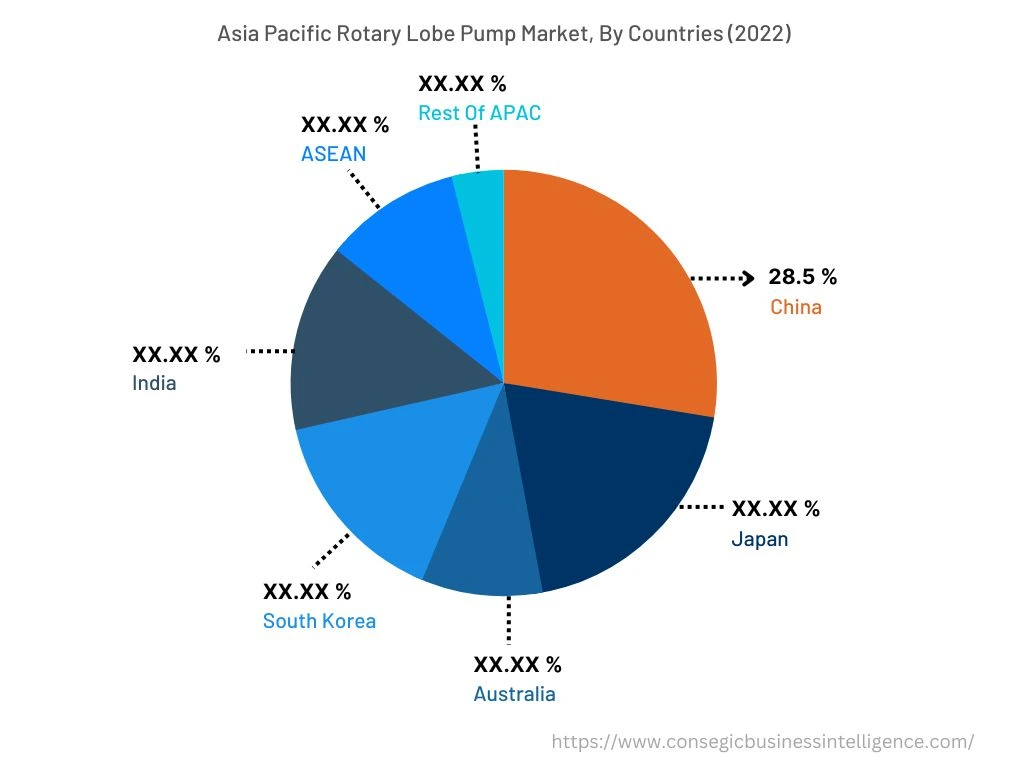

Asia-Pacific is expected to register the fastest CAGR growth of 5.7% during the forecast period. The rapid pace of industrialization and development is creating lucrative opportunities for market growth in the region. Moreover, the growth of multiple industries such as pharmaceutical, food & beverage, oil & gas, and others is fostering the market growth for rotary lube pumps in the Asia-Pacific region.

For instance, according to the India Brand Equity Foundation (IBEF), India ranked third in terms of pharmaceutical production by volume in 2021. According to IBEF, the local pharmaceutical industry in India consists of approximately 10,500 pharmaceutical manufacturing units and 3,000 drug companies. Therefore, the growing pharmaceutical facilities in the region are driving the deployment of rotary lobe pumps, thereby proliferating the market growth in the Asia-Pacific region.

Top Key Players & Market Share Insights:

The rotary lobe pump market is highly competitive with major players providing Rotary Lobe Pump to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and application launches to hold a strong position in Rotary Lobe Pump market. Key players in the Rotary Lobe Pump market include -

- Borger GmbH

- Alfa Laval AB

- NETZSCH Group

- GEA Group

- Vogelsang GmbH & Co. KG

- SPXELOW Inc.

- LobePro

- Verder Liquids BV

- INOXPA Group

- ZEILFELDER Pumps

- Fristam Pumpen GmbH

Recent Industry Developments :

- In July 2022, Vogelsang launched its new rotary lobe pumps that are optimized to meet the high demands of industrial applications. The new rotary lobe pumps offer enhanced efficiency and additional seal versatility.

- In July 2021, Borger introduced its new series of rotary lobe pumps, BLUELine Nova. The new series of rotary lobe pumps provide high levels of volumetric efficiency.

Key Questions Answered in the Report

What is rotary lobe pump? +

Rotary lobe pumps are a type of positive-displacement pumps that utilizes two or more lobes that rotate around parallel shafts in the pump’s body in order to move liquid.

What specific segmentation details are covered in the rotary lobe pump report, and how is the dominating segment impacting the market growth? +

The report consists of segments including type and end-user. Each segment has key dominating sub-segment being driven by the industry trends and market dynamics. For instance, by type segment has witnessed bi-wing lobe as the dominating segment in the year 2022, owing to its increasing utilization in food & beverage, pharmaceutical, wastewater treatment plants, and other related applications.

What specific segmentation details are covered in the rotary lobe pump market report, and how is the fastest segment anticipated to impact the market growth? +

The report consists of segments including type and end-user. Each segment is projected to have the fastest-growing sub-segment being fuelled by industry trends and drivers. For instance, by end-user segment has witnessed water & wastewater treatment as the fastest-growing segment during the forecast period due to the rising adoption of rotary lobe pumps for transferring sludge and feeding dewatering equipment in wastewater treatment plants.

Which region/country is anticipated to witness the highest CAGR during the forecast period, 2023-2030? +

Asia-Pacific is anticipated to register fastest CAGR growth during the forecast period due to rapid pace of industrialization and growth of multiple industries such as pharmaceutical, food & beverage, oil & gas, and others.