- Summary

- Table Of Content

- Methodology

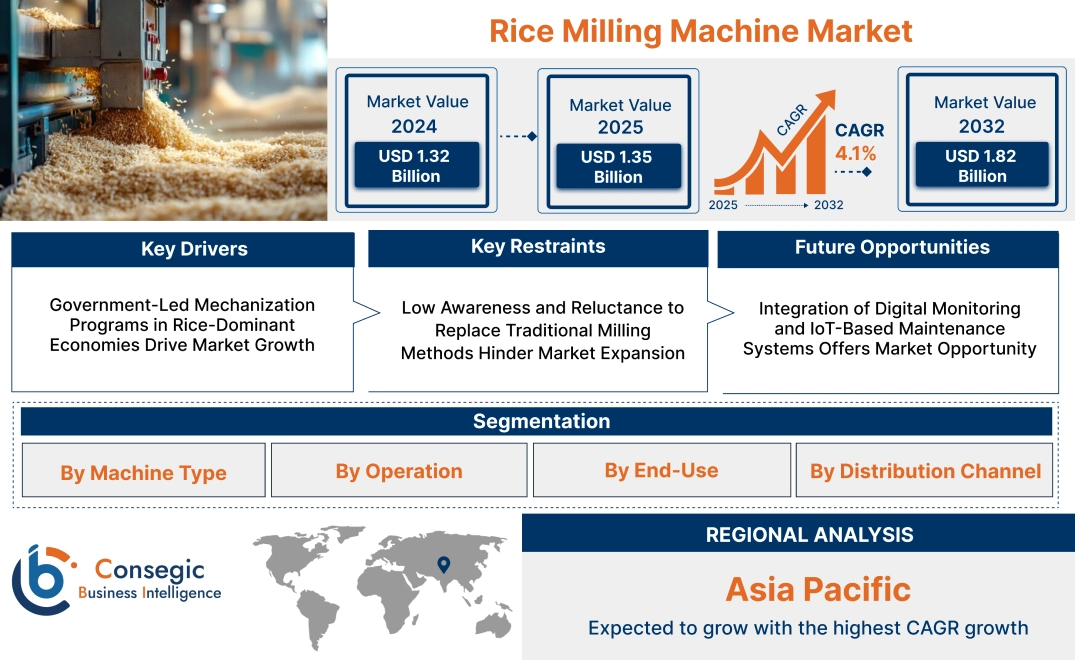

Rice Milling Machine Market Size:

Rice Milling Machine Market size is estimated to reach over USD 1.82 Billion by 2032 from a value of USD 1.32 Billion in 2024 and is projected to grow by USD 1.35 Billion in 2025, growing at a CAGR of 4.1% from 2025 to 2032.

Rice Milling Machine Market Scope & Overview:

Rice milling machine refers to a dedicated farm processing system used to strip husk, bran layers, and impurities from paddy in order to deliver polished, consumable rice. It is highly applied in smallholder farms, commercial mills, and integrated rice processing units to enhance milling effectiveness as well as ultimate grain quality.

The machine is made up of modules like pre-cleaners, dehuskers, separators, polishers, and grading units that play specific roles in particular phases of the milling process. It has adjustable output levels, heavy-duty material build, and automatic control components to accommodate different production capacities.

The major advantages are increased grain recovery rate, low breakage, and uniform output quality. Rice milling machine facilitates hygienic processing, low man-handling, and efficient workflows, thus being fit for single as well as integrated operations. Its application across varied rice types and processing levels ensures value in multiple diverse agricultural zones, enabling effective post-harvest handling and marketability of rice.

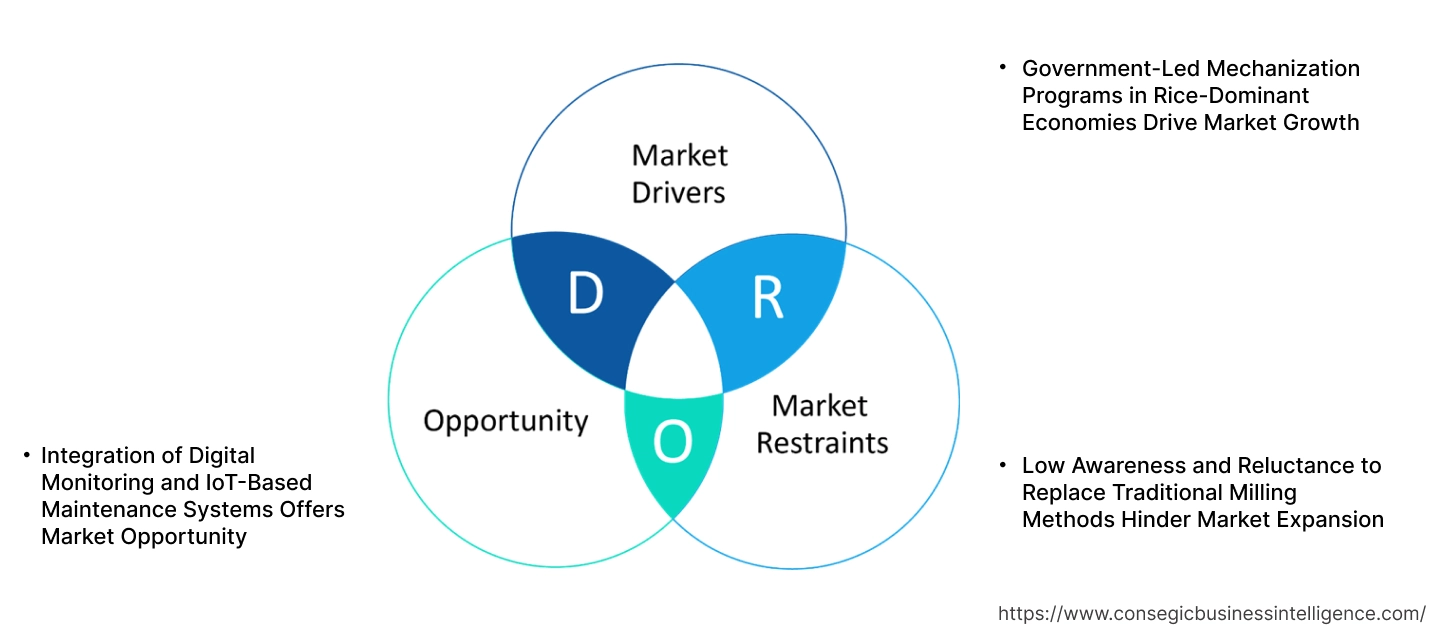

Key Drivers:

Government-Led Mechanization Programs in Rice-Dominant Economies Drive Market Growth

A number of rice-producing countries are undertaking national mechanization programs to upgrade post-harvest processing and enhance food security. National programs in India, Bangladesh, Nigeria, and Vietnam involve subsidies, concessionary loans, and rural infrastructure support to promote the use of modern milling machinery. The programs are designed to minimize grain losses, increase milling yield, and grade rice production for domestic and export consumption. Public-private collaborations and agricultural development organizations in most areas are setting up model rice mills to highlight the advantages of multi-stage automated mills. Demonstrations are enhancing millers' and cooperatives' awareness and acceptance.

- For instance, in December 2024, several farmer cooperatives and associations, and local government units (LGUs) in Nueva Ecija received agricultural machines free of cost under the Rice Competitiveness Enhancement Fund (RCEF)-Mechanization Program in the Philippines. The program is operated by the Department of Agriculture, led by the Philippine Center for Postharvest Development and Mechanization (PHilMech), in partnership with DA-RFOs and local governments. Farm machines worth a total of P19 million were distributed.

With governments focusing on rural industrialization and grain quality improvement, demand for advanced equipment is gradually rising, ultimately leading to rice milling machine market expansion.

Key Restraints:

Low Awareness and Reluctance to Replace Traditional Milling Methods Hinder Market Expansion

In most rice-producing areas, conventional single-stage or huller-based milling remains prevalent, even though superior technologies are available. Most small-scale millers are reluctant to change because of inadequate technical know-how, lack of on-farm demonstrations, and perceived risk of using sophisticated systems. This is further aggravated by irregular extension services and poor access to training or after-sales assistance in rural areas. As such, the promise of better grain quality, increased yield, and lowered operating losses is not maximized. Even in areas with financing incentives, inertia based on operating familiarity with existing equipment restrains modernization. This unwillingness to change is a major inhibitor of technology penetration and retards rice milling machine market growth despite rising demand for improved output quality.

Future Opportunities :

Integration of Digital Monitoring and IoT-Based Maintenance Systems Offers Market Opportunity

The implementation of digital monitoring and IoT-based technologies is redefining the operational effectiveness of contemporary rice milling equipment. Online monitoring of factors like motor load, belt vibration, husk recovery percentage, and machine temperature facilitates predictive maintenance and process optimization. Such functionalities minimize unscheduled downtime, maximize throughput, and increase equipment longevity. Sophisticated control systems also facilitate remote diagnostics and performance benchmarking across multi-location milling operations. The need for intelligent infrastructure in agri-processing is growing, particularly in large-scale commercial mills and cooperatives with high processing capacities. These technologies are part of wider digital agriculture trends and building a competitive advantage for technology providers.

- For instance, in January 2025, Browns Agriculture unveiled two groundbreaking additions to its portfolio: the new TAFE tractor model, Dynatrack and the Browns Sumo Rice Mill. The Browns Sumo Rice Mill is an IoT-integrated, automated milling machine that enables real-time performance monitoring, maintenance scheduling, and receiving of remote alerts through an advanced equipment management system accessible through laptops or mobile devices. The TAFE tractor model, Dynatrack, equipped with a powerful Simpson engine, provides exceptional fuel efficiency and unmatched profitability.

With digitization becoming a part of operational strategy, the transition towards smart milling platforms is building long-term rice milling machine market opportunities based on growth in automation and data-driven maintenance.

Rice Milling Machine Market Segmental Analysis :

By Machine Type:

Based on machine type, the rice milling machine market is segmented into rice whitening machines, paddy separators, rice huskers, destoner machines, and others.

The rice whitening machine segment accounted for the largest revenue share in 2024.

- Rice whitening machines are essential in producing high-quality polished rice, contributing directly to consumer preference in global rice-exporting markets.

- These machines enhance the appearance and shelf life of milled rice, making them indispensable in commercial and industrial milling plants.

- Their dominance is supported by the adoption of multi-pass whitening systems that reduce breakage and improve efficiency.

- For instance, in February 2024, Satake launched a new model of rice milling machine, the SSW60A/100A (SATAKE SPIRAL WHITENER), to mill rice more gently. The new model utilizes an internal resistance system that ensures pressure is evenly distributed throughout the chamber. This lowers the occurrence of broken rice while maintaining a low grain temperature, resulting in an overall high-quality mill.

- As per rice milling machine market analysis, increasing installation of integrated rice mills with whitening units is driving segment performance.

The paddy separator segment is projected to witness the fastest CAGR during the forecast period.

- Paddy separators play a critical role in separating unhusked paddy from brown rice, optimizing the efficiency of subsequent milling operations.

- Advanced gravity-based and reciprocating paddy separators are increasingly adopted to reduce reprocessing cycles and improve throughput.

- The segment benefits from rising emphasis on minimal loss and better segregation in automated processing lines.

- According to rice milling machine market trends, improvements in separator design and material handling capacity are accelerating adoption in mid- and high-capacity mills.

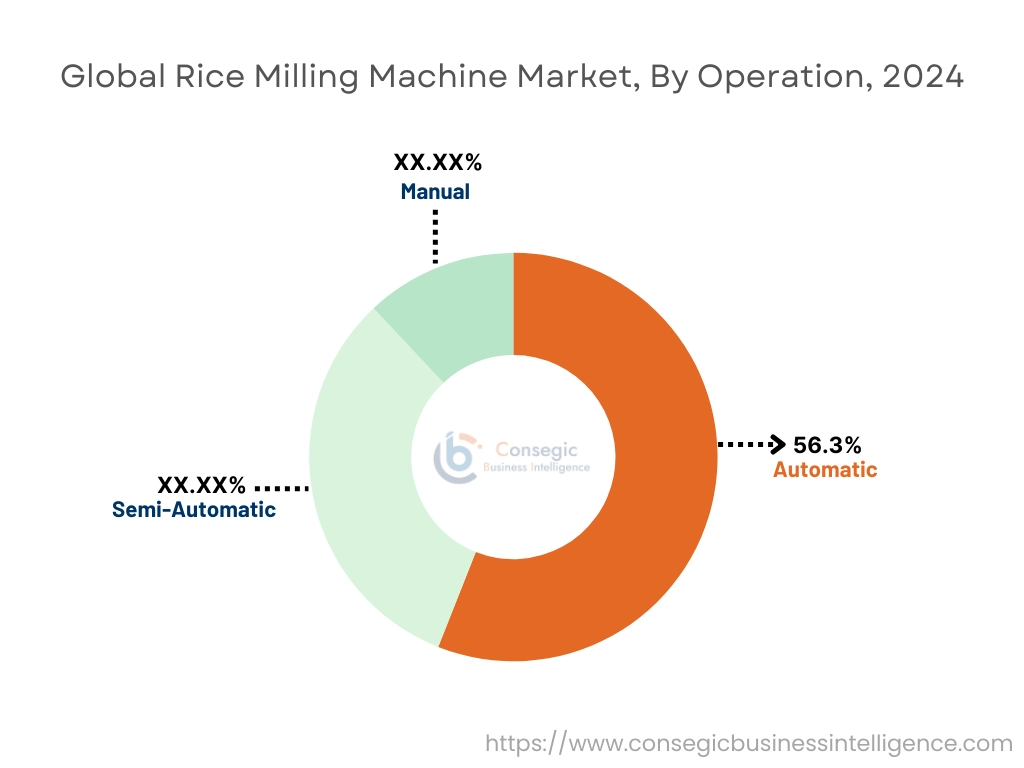

By Operation:

Based on operation, the market is segmented into automatic, semi-automatic, and manual.

The automatic segment held the largest rice milling machine market share of 56.3% in 2024.

- Automatic rice milling systems offer complete integration of husking, whitening, grading, and polishing, reducing labor and improving consistency.

- These machines are in high demand across industrial facilities focusing on bulk production and stringent quality control.

- Technological advancements like PLC-based systems, real-time process monitoring, and intelligent diagnostics are fueling adoption.

- Thus, automation is a critical pillar for rice milling machine market expansion across developed and modernizing regions.

The semi-automatic segment is anticipated to grow at the fastest CAGR during the forecast period.

- Semi-automatic machines are preferred for their balance between operational control and mechanical efficiency, especially in medium-scale mills.

- These systems offer flexibility in adjusting process parameters, enabling better adaptation to varied rice qualities and moisture levels.

- The widespread deployment in Asia-Pacific’s rural and peri-urban milling centers supports steady rice milling machine market demand.

- Hence, segmental trends highlight the continued dominance of semi-automatic machines due to their favorable cost-to-performance ratio.

By End-Use:

Based on end-use, the rice milling machine market is divided into commercial milling, industrial milling, and community/cooperative milling.

The industrial milling segment accounted for the largest revenue share in 2024.

- Industrial mills handle large volumes of paddy and are typically equipped with high-capacity, fully automated processing lines.

- These facilities cater to export markets and retail packaging, where uniformity and throughput are key performance criteria.

- Investments in automated quality assurance, packaging integration, and energy efficiency further support this segment.

- As per rice milling machine market trends, the industrial segment leads due to its scale, product consistency, and value-added service offerings.

The community/cooperative milling segment is expected to grow at the fastest CAGR during the forecast period.

- Community-based mills are expanding in low-income and developing regions to improve food security and rural incomes.

- These setups often benefit from public sector support, NGO funding, or cooperative farming models.

- Simple, robust machines like huskers and polishers are favored in this segment, providing affordable post-harvest solutions.

- This segment’s rapid adoption aligns with sustainability-focused rural development initiatives, driving rice milling machine market growth and inclusion.

By Distribution Channel:

Based on distribution channel, the market is segmented into direct sales, distributors & dealers, and online retail.

The distributors & dealers segment held the largest rice milling machine market share in 2024.

- Distributors and dealers form the primary sales and support channel for rice milling machines across both urban and rural markets.

- Their role in installation, training, and aftersales service adds considerable value to buyers with limited technical knowledge.

- The well-established dealer networks in India, China, Vietnam, and Bangladesh ensure strong market penetration.

- As per rice milling machine market analysis, this channel continues to thrive due to its local accessibility and reliability.

The online retail segment is expected to witness the fastest CAGR during the forecast period.

- E-commerce platforms are gaining traction as farmers and mill operators increasingly explore digital procurement options.

- Online channels facilitate price comparison, wider machine selection, and access to customer reviews, influencing purchase decisions.

- Platforms catering specifically to agri-machinery and B2B procurement have emerged in both developed and emerging economies.

- Increasing digital literacy and infrastructure in rural areas is further strengthening the rice milling machine market demand through online channels.

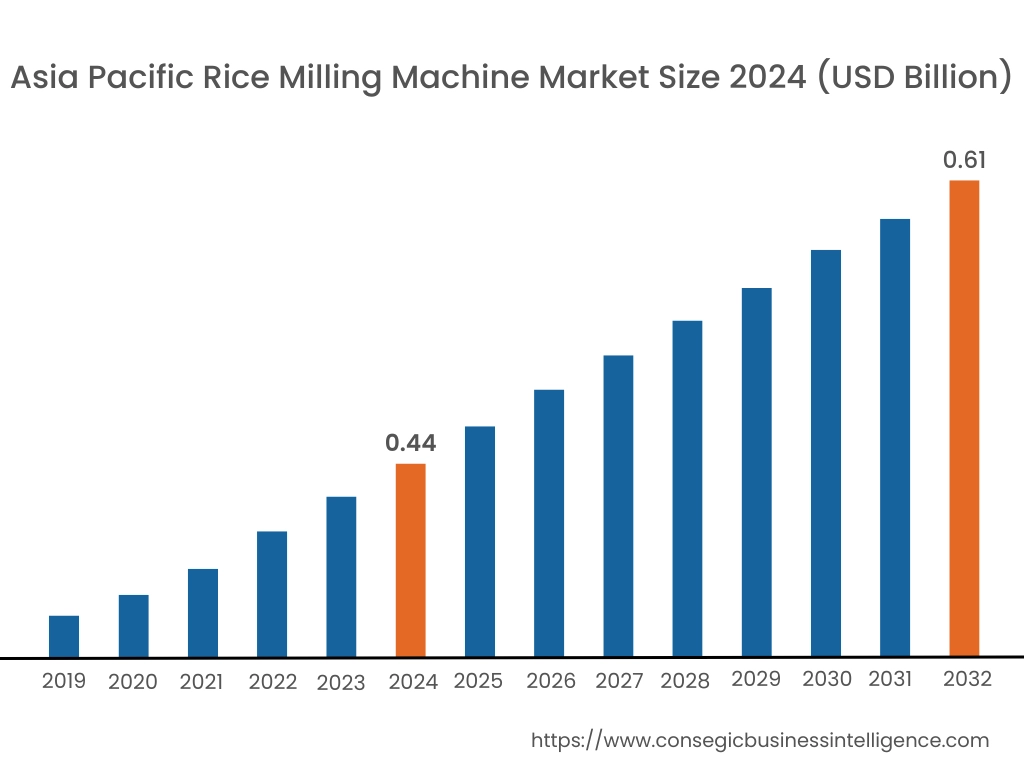

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

Asia Pacific region was valued at USD 0.44 Billion in 2024. Moreover, it is projected to grow by USD 0.45 Billion in 2025 and reach over USD 0.61 Billion by 2032. Out of this, China accounted for the maximum revenue share of 38.5%. Asia-Pacific is witnessing rapid expansion in the rice milling machine market, driven by the region's leading contribution to world rice production and consumption. Countries like China, India, Vietnam, Thailand, and the Philippines have strong equipment need both at industrial and rural levels. Regional analysis points towards major investment in automation of milling to enhance yield recovery, minimize grain breakage, and satisfy export quality standards. Transition from old village mills to modern, high-capacity processing centers is gaining pace due to government mechanization schemes, increasing labor costs, and new food safety requirements. Furthermore, localized manufacturing and low-cost innovation are augmenting regional competitiveness both in export and domestic markets.

North America is estimated to reach over USD 0.54 Billion by 2032 from a value of USD 0.39 Billion in 2024 and is projected to grow by USD 0.40 Billion in 2025. North America has a niche but technologically advanced segment in the rice milling machine industry. The United States, mostly in southern states, has highly automated rice processing systems in line with export-quality standards. Market analysis shows that continued modernization in milling plants and emphasis on operational efficiency are sustaining equipment demand. This value-added rice and specialty grain trends are also facilitating upgrades to high-precision whitening, grading, and polishing machines. As much as market size is moderate, focus on food safety, traceability, and low-energy consumption guarantees repeated investment in top-end solutions.

Europe has specialized but limited demand for rice milling technology, in the form of Italy and Spain where small, niche rice varieties are grown. Market analysis finds that requirement is generally around artisanal and organic production needing equipment to mill varied grain types without sacrificing nutritional value. Concern with sustainability and minimal waste milling operations has prompted increased interest in energy-efficient, compact machines. Moreover, the growth of plant-based food processing in northern Europe offers an indirect challenge for hybrid machines employed for milling alternative grains in addition to rice, value creation through multi-functional systems.

Latin America is experiencing incremental uptake of rice milling machinery, with Brazil, Colombia, and Peru being strong growth areas. Market research indicates that increasing local rice consumption combined with the pressure to enhance the consistency of processing is propelling the shift away from simple hulling systems toward more comprehensive milling lines. The rise in small and medium-scale rice processing cooperatives offer new rice milling machine market opportunity, particularly to modular and energy-efficient machines. Further, international trade potential and demand for export-oriented premium rice are making regional players invest in higher-grade polishing and grading technology.

Middle East and African countries constitute a developing market with an increasing need for rice milling equipment as rice intake and food security programs develop. Nigeria, Egypt, and Iran are some countries experiencing a reduction of dependence on rice imports toward local manufacturing and processing. Analysis indicates that there is high potential for small, affordable machines appropriate for smallholder farmer cooperatives and rural processors. Infrastructure limitations and fluctuating power availability call for low-maintenance, rugged solutions with off-grid capability. With development agency and public-private partnership support, long-term growth opportunities remain promising for market participants aiming at grassroots agricultural change.

Top Key Players and Market Share Insights:

The rice milling machine market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global rice milling machine market. Key players in the rice milling machine industry include -

- Bühler Group (Switzerland)

- Satake Corporation (Japan)

- Mill Master Machinery Pvt. Ltd. (India)

- Yamamoto Co., Ltd. (Japan)

- Alvan Blanch Development Company (United Kingdom)

- AG Growth International (AGI) (Canada)

- Fowler Westrup (India)

- Hubei Bishan Machinery Co., Ltd. (China)

- Hubei Fotma Machinery Co., Ltd. (China)

- Zhejiang QiLi Machinery Co., Ltd. (China)

Recent Industry Developments :

Partnerships:

- In December 2022, AGI partnered with Ada Manufacturing Corporation (ADAMCO) In the Philippines. This partnership enables ADAMCO to distribute AGI products.

Rice Milling Machine Market Report Insights:

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 1.82 Billion |

| CAGR (2025-2032) | 4.1% |

| By Machine Type |

|

| By Operation |

|

| By End-Use |

|

| By Distribution Channel |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Rice Milling Machine Market? +

Rice Milling Machine Market size is estimated to reach over USD 1.82 Billion by 2032 from a value of USD 1.32 Billion in 2024 and is projected to grow by USD 1.35 Billion in 2025, growing at a CAGR of 4.1% from 2025 to 2032.

What specific segmentation details are covered in the Rice Milling Machine Market report? +

The Rice Milling Machine market report includes specific segmentation details for machine type, operation, end-use and distribution channel.

What are the end-uses of the Rice Milling Machine Market? +

The end-use of the Rice Milling Machine Market is commercial milling, industrial milling and community/cooperative milling.

Who are the major players in the Rice Milling Machine Market? +

The key participants in the Rice Milling Machine market are Bühler Group (Switzerland), Satake Corporation (Japan), AG Growth International (AGI) (Canada), Fowler Westrup (India), Hubei Bishan Machinery Co., Ltd. (China), Hubei Fotma Machinery Co., Ltd. (China), Zhejiang QiLi Machinery Co., Ltd. (China), Mill Master Machinery Pvt. Ltd. (India), Yamamoto Co., Ltd. (Japan) and Alvan Blanch Development Company (United Kingdom).