- Summary

- Table Of Content

- Methodology

Resin Market Size:

Resin Market size is estimated to reach over USD 825.24 Billion by 2031 from a value of USD 567.38 Billion in 2023, growing at a CAGR of 4.9% from 2024 to 2031.

Resin Market Scope & Overview:

The resin market involves the production and application of synthetic and natural resins used across various industries for their adhesive, coating, and molding properties. Epoxy, polyester, polyethylene, and polyurethane, are valued for their durability, flexibility, and chemical resistance. These materials serve as critical components in the manufacturing, construction, automotive, and electronics sectors. Key features of it include its strong bonding capabilities, high-performance thermal and mechanical properties, and adaptability for different processes like injection molding, casting, and laminating. The benefits of using resins are enhanced product durability, superior finishing, and increased resistance to environmental stressors. Applications span coatings, adhesives, sealants, composites, and encapsulation materials. End-use industries include automotive, construction, electronics, aerospace, and packaging, driven by the rising demand for lightweight, durable, and versatile materials in advanced manufacturing processes.

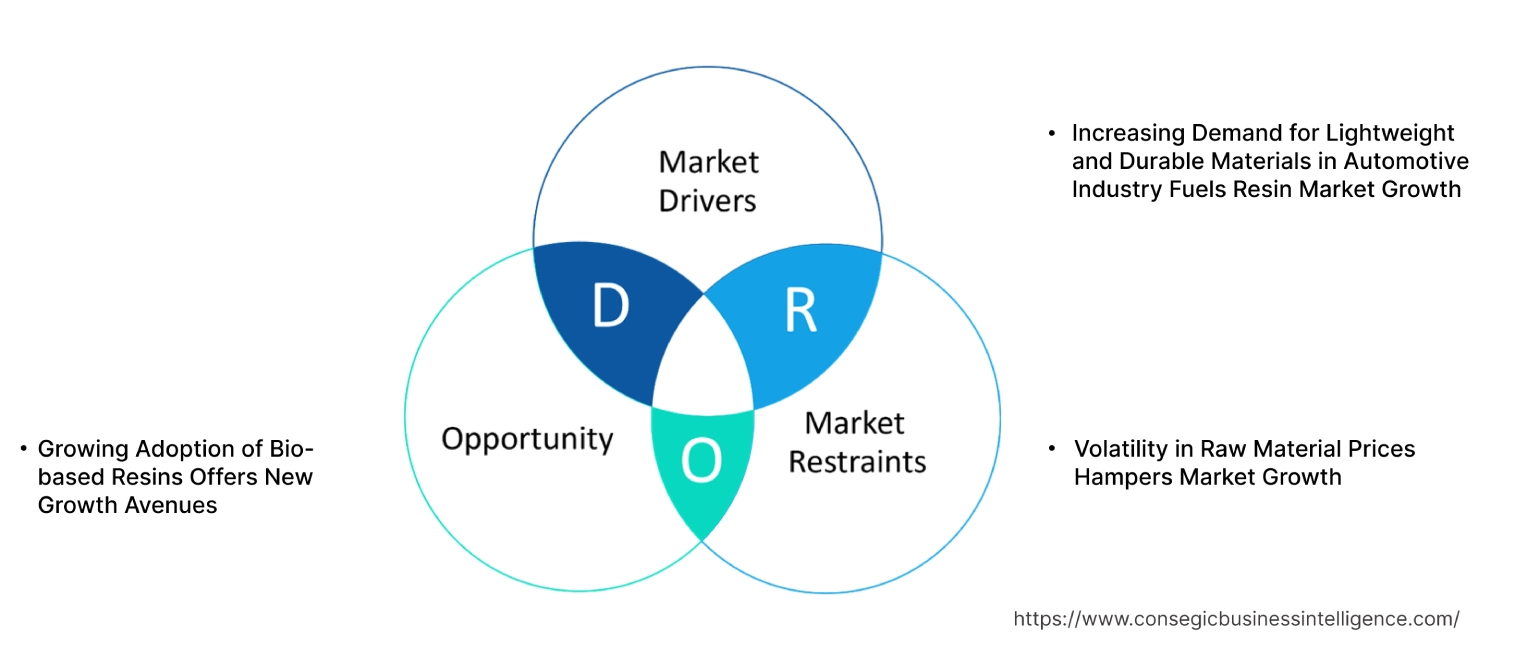

Resin Market Dynamics - (DRO) :

Key Drivers:

Increasing Demand for Lightweight and Durable Materials in Automotive Industry Fuels Resin Market Growth

The rising application for lightweight and durable materials in the automotive industry is a key driver for the market. With the increasing emphasis on reducing vehicle weight to enhance fuel efficiency and meet stringent emission regulations, automotive manufacturers are shifting towards high-performance resin-based composites. Such as epoxy, polyurethane, and polypropylene are widely used in automotive components, including bumpers, interior panels, and engine covers, due to their superior mechanical properties, chemical resistance, and moldability. The growing trend towards electric vehicles (EVs) is further boosting the resin market demand for advanced resin materials, as manufacturers seek to optimize performance while reducing overall vehicle weight.

Key Restraints :

Volatility in Raw Material Prices Hampers Market Growth

The resin market faces significant challenges due to the volatility of raw material prices, particularly petrochemical derivatives. Most resins, including polyethylene, polypropylene, and epoxy, are derived from crude oil and natural gas, making their production costs highly sensitive to fluctuations in global oil prices. Political instability, supply chain disruptions, and changes in crude oil production levels can lead to unpredictable price swings, affecting the profitability of manufacturers. Additionally, rising environmental concerns and regulations on petrochemical production have led to increased scrutiny, further impacting raw material availability and pricing. These factors pose a constraint on resin market growth, especially for small and mid-sized manufacturers struggling with cost pressures.

Future Opportunities :

Growing Adoption of Bio-based Resins Offers New Growth Avenues

The increasing focus on sustainability and eco-friendly products presents a significant resin market opportunity, particularly in the adoption of bio-based resins. As industries aim to reduce their carbon footprint and comply with stricter environmental regulations, the advancement for resins derived from renewable sources, such as corn starch, soy protein, and cellulose, is rising. Bio-based offers comparable performance to conventional petrochemical-based while providing environmental benefits, including reduced greenhouse gas emissions and lower toxicity. Innovations in biopolymer technology and increased investment opportunities in research and development are expected to drive the market's transition towards sustainable solutions, opening new resin market opportunities for manufacturers.

Resin Market Segmental Analysis :

By Type:

Based on type, the market is segmented into thermoplastic (polyethylene, polypropylene, polyvinyl chloride, polystyrene, polyethylene terephthalate, acrylonitrile butadiene styrene, others) and thermosetting (epoxy, phenolic, polyurethane, unsaturated polyester resin (UPR), melamine, and alkyd).

The thermoplastic resins segment accounted for the largest revenue in resin market share in 2023.

- Thermoplastic resins, including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), polyethylene terephthalate (PET), and acrylonitrile butadiene styrene (ABS), dominate the market due to their versatility, ease of processing, and recyclability.

- PE and PP are extensively used in packaging applications due to their lightweight properties and durability, while PVC is popular in construction for pipes and fittings.

- PET is a key material in beverage manufacturing companies for manufacturing bottles due to its excellent clarity and strength.

- The rising resin market trends for sustainable and recyclable materials have further boosted the adoption of thermoplastics, especially in the packaging and consumer goods industries.

- Thermoplastic analysis shows the market, driven by their extensive application in packaging, construction, and consumer goods, along with increasing appeal for recyclable materials.

The thermosetting resins segment is anticipated to register the fastest CAGR during the forecast period.

- Thermosetting resins, such as epoxy, phenolic, polyurethane, unsaturated polyester resin (UPR), melamine, and alkyd, are widely used for their superior mechanical strength, thermal stability, and chemical resistance.

- Epoxy is preferred in electronics and automotive applications for coatings and adhesives due to its strong bonding properties.

- UPR is a key material in the construction industry for composite applications, including reinforced plastic components.

- The trends of thermosetting are driven by their increasing use in high-performance applications, particularly in the automotive, electronics, and aerospace sectors, where durability and heat resistance are critical.

- Thermosetting is expected to grow rapidly, supported by its high-performance properties and increasing adoption in industries requiring enhanced mechanical and thermal stability.

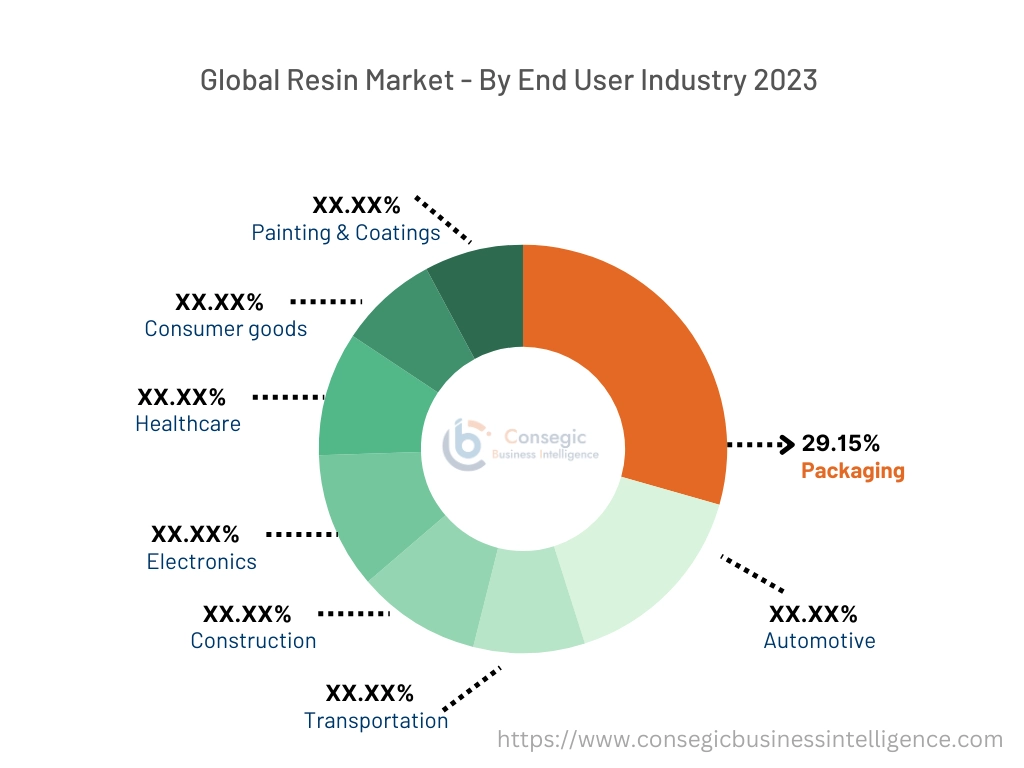

By End-User Industry:

Based on the end-user sector, the market is segmented into packaging, automotive, transportation, construction, electronics, healthcare, consumer goods, paints & coatings, and others.

The packaging segment accounted for the largest revenue share of 29.15% in 2023.

- The packaging sector is the largest consumer of resins, particularly thermoplastics like PE, PP, and PET, due to their lightweight, durable, and flexible properties.

- These are essential in manufacturing flexible and rigid packaging solutions for food, beverages, and consumer goods.

- The increasing applications for sustainable packaging materials and innovations in bioplastics are further driving the resin market trends for applications in this sector.

- The shift towards recyclable and environmentally friendly packaging solutions aligns with global sustainability trends, enhancing the trends for resins in the packaging sector.

- The packaging segment analysis portrays the resin market expansion, driven by the extensive use of resins in flexible and rigid packaging applications, supported by the growth of sustainable packaging solutions.

The automotive segment is anticipated to register the fastest CAGR during the forecast period.

- The automotive sector increasingly uses advanced resins, particularly thermosetting types like epoxy and polyurethane, in the production of lightweight components to improve fuel efficiency and reduce emissions.

- Thermoplastics such as ABS and PP are also extensively used for interior parts, bumpers, and dashboards due to their impact resistance and ease of molding.

- The rising trend towards electric vehicles (EVs) and the need for lightweight, durable materials in battery casings and structural components are driving the appeal for high-performance resins in automotive applications.

- The automotive segment is expected to grow rapidly, driven by the increasing use of lightweight and durable to enhance vehicle performance and support the transition to electric vehicles.

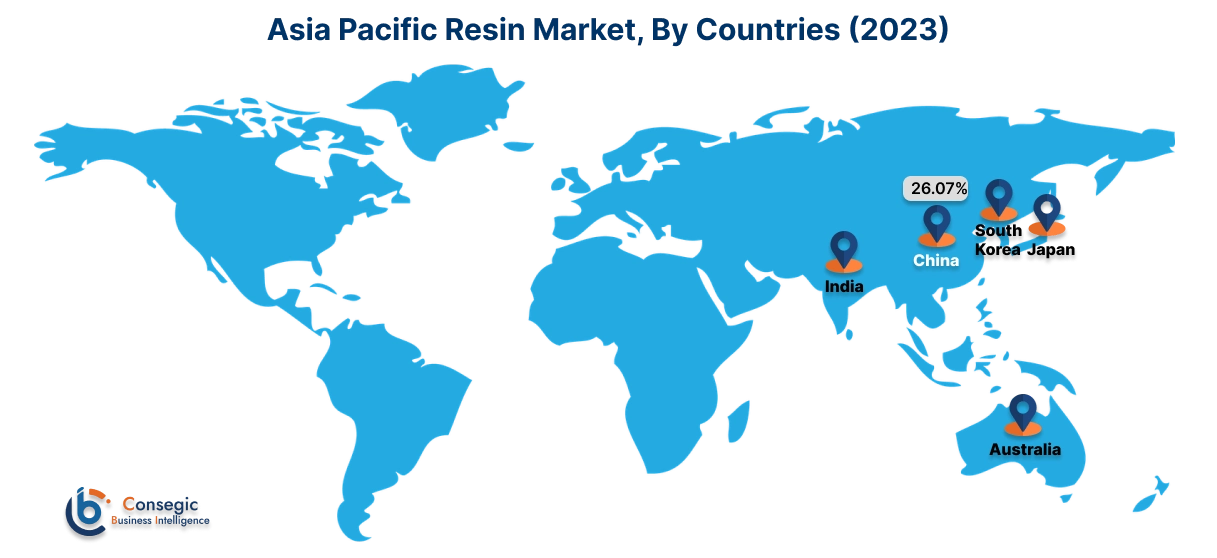

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2023, Asia Pacific accounted for the highest market share at 39.65% and was valued at USD 224.97 Billion and is expected to reach USD 329.93 Billion in 2031. In Asia Pacific, China accounted for the highest share of 26.07% during the base year of 2023. Asia-Pacific is the fastest-growing region in the resin market expansion, driven by rapid industrialization, urbanization, and increasing construction activities in countries like China, India, and Japan. China is the largest consumer of resins, particularly in the construction and electronics industries, where epoxy and polyester resins are widely used for laminates and coatings. India's booming packaging sector, driven by e-commerce and retail growth, is fueling demand for polyethylene and polypropylene resins. Japan's focus on advanced automotive manufacturing and electronics has led to a surge in advancement for specialty resins like polycarbonates and nylons. However, environmental regulations and concerns over plastic waste management pose challenges to market growth in the region.

In North America, the market is experiencing the fastest growth with a CAGR of 5.5% over the forecast period. North America is a major market for resins, driven by strong trends from the automotive, construction, and packaging industries. The U.S. leads the region, particularly in the production and application of high-performance resins like epoxy, acrylic, and polyurethane, used extensively in automotive coatings, adhesives, and composites. The growing trend towards lightweight and durable materials in the automotive sector is fueling demand for advanced formulations. Canada also contributes to resin market analysis, with increasing utilization of resins in building materials and insulation products. However, fluctuations in raw material prices and regulatory constraints on chemical usage are challenges for the market expansion in the region.

Europe is a significant resins market analysis, supported by a strong focus on sustainability and stringent environmental regulations. Germany, Italy, and France are leading countries, driven by the rise of the automotive, aerospace, and packaging sectors. Germany's automotive industry is a key consumer of specialty like polyurethanes and epoxy, particularly for lightweight composite parts and advanced coatings. The UK and France are seeing increasing applications for bio-based resins, as part of the EU's push towards reducing carbon emissions and enhancing sustainability in manufacturing. However, the market faces challenges related to stringent regulations on volatile organic compounds (VOCs) and increasing raw material costs.

The analysis from the Middle East & Africa region is experiencing steady development in the market, driven by increasing demand from the construction, automotive, and packaging industries. The UAE and Saudi Arabia are key markets, with significant investments in infrastructure projects and a focus on expanding their petrochemical industries, which are crucial for production. The use of resins in construction materials like adhesives, sealants, and coatings is on the rise due to ongoing infrastructure development. In Africa, South Africa's manufacturing sector is utilizing resins for automotive parts and consumer goods. However, limited local production capabilities and dependency on imports are challenges for the region.

Latin America's analysis depicts market is growing, led by Brazil and Mexico, with demand primarily from the packaging, automotive, and construction industries. Brazil's expanding automotive manufacturing sector is a major consumer of resins like polypropylene and polyurethane, used for lightweight and durable automotive components. Mexico's growing packaging sectors, driven by consumer goods and food & beverage sectors, are increasing the trends for polyethylene resins. The region is also exploring bio-based and recycled resins to meet sustainability goals. However, economic volatility and limited local production capacity can impact resin availability and market stability in certain countries.

Top Key Players & Market Share Insights:

The resin market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global resin market. Key players in the Resin industry include -

- Dow Chemical Company (USA)

- BASF SE (Germany)

- ExxonMobil Corporation (USA)

- SABIC (Saudi Arabia)

- LyondellBasell Industries N.V. (Netherlands)

- Chevron Phillips Chemical Company (USA)

- INEOS Group (UK)

- Eastman Chemical Company (USA)

- Mitsui Chemicals, Inc. (Japan)

- Sumitomo Chemical Co., Ltd. (Japan)

Recent Industry Developments :

Mergers and Acquisitions:

- In 2021, Arkema completed the $1.65 billion acquisition of Ashland's Performance Adhesives business, reinforcing its position as a global leader in adhesives. This move expanded Arkema's portfolio with advanced pressure-sensitive adhesive technologies, catering to industries such as packaging, labeling, and woodworking. Additionally, the acquisition strengthened Arkema's footprint in North America while aligning with the industry's shift toward sustainable, eco-friendly adhesive solutions.

Resin Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 825.24 Billion |

| CAGR (2024-2031) | 4.9% |

| By Type |

|

| By End-User Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What are the main types of resins in the market? +

The main types are thermoplastic resins (PE, PP, PVC, PET) and thermosetting resins (epoxy, polyurethane, phenolic).

What industries use resins the most? +

Key industries include packaging, automotive, construction, electronics, and healthcare.

What factors are driving the growth of the resin market? +

Increasing demand from the automotive, packaging, and construction sectors due to their high-performance characteristics.

How is the resin market responding to sustainability trends? +

There is a growing focus on bio-based resins and improved recycling technologies to reduce environmental impact.