Refinery Process Additives Market Introduction :

Consegic Business Intelligence analyzes that the refinery process additives market size is growing with a healthy CAGR of 6.8% during the forecast period (2023-2030), and the market is projected to be valued at USD 3,305.73 Million by 2030 from USD 1,961.39 Million in 2022.

Refinery Process Additives Market Definition & Overview:

Refinery process additives are chemicals or compounds which are utilized to enhance performance in various refinery processes, including distillation, and reformer system, it is also used for making the end fuel products. The various types of additives include demulsifiers, antifoulants, corrosion inhibitors, hydrogen sulfide scavengers, stabilizers, biocides, and octane boosters, among others. Based on the analysis, these additives provide aid in optimizing the refinery processes to produce superior-quality fuels.

Moreover, based on the analysis, the above-mentioned types of additives ensure excellent flexibility in the field for fuel temperatures at the point of the addition of additives in the heavy fuel oil. As a result, these additives are an ideal solution for applications such as crude oil processing, fluid catalytic cracking, hydroprocessing, and others.

Refinery Process Additives Market Insights :

Refinery Process Additives Market Dynamics - (DRO) :

Key Drivers :

Booming technological innovations associated with refinery process additives

The key players dealing in the refinery process additives product range are substantially investing in the technological innovations of these additives, which are ideal for applications, including crude oil processing, and fluid catalytic cracking, among others. As a result of this, manufacturers are continuously leveraging their technological potential to develop new products with updated technological advancements. For instance, recently, Hindustan Petroleum Corporation Limited HPCL, a leading refinery process additive launched HP NICKTREAT. This additive is ideal for refinery applications such as Fluid Catalytic Cracking Units (FCCUs). Thus, the launch of new products with upgraded technology is accelerating the adoption of these additives to improve the refining process. This, in turn, is driving the market trends.

The increasing adoption of refinery process additives in crude oil processing

Refinery process additives are employed in crude oil processing to eliminate corrosion in the processing stage. The recent technological upgrades associated with crude oil processing plants are driven by the factors such as increasing government initiatives for the modernization of oil refineries, increasing investment in upgradation projects, and others. For instance, the commercial operation of the Al-Zour oil refinery plant was started in 2022. The location of the plant is in Southern Kuwait. The plant is carrying out crude oil processing. Thus, with the recent launch of oil processing refineries, the adoption of these additives in crude oil processing is increasing to improve fuel performance. This, in turn, is fostering market trends.

Key Restraints :

Stringent rules and regulations governing the utilization of refinery process additives is retraining the market

Refinery process additives are equipped with various beneficial properties such as superior protection from corrosion, improved final product quality, and others. However, on the flip slide, there are various regulations governing the utilization of these additives in oil refineries. They generally focus on environmental protection, safety, and product quality. Additionally, these regulations generally include restrictions on the type and amount of additives incorporated, and requirements for proper handling, disposal, and adherence to industry standards to minimize the risk to human health as well as the environment. For instance, the Petroleum and Natural Gas Regulatory Board of India has regulated the use of these additives in refineries. Hence, the stringent rules and regulations governing the utilization of these additives in oil refineries are posing a bottleneck for the market during the projected forecast period.

Future Opportunities :

Development of new oil refineries will foster the growth of the market

The additives are employed in the new oil refineries to ensure the superior quality of the final product. The future prospective projects for the oil & gas industry at the level will create lucrative refinery process additives market opportunities and trends for the market to ensure protection from corrosion. For instance, as of March 2022, the Wisting Central Oil Discovery project located in Norway, Europe is under the designing. The development of the Wisting Central Oil Discovery project will include 19 producer wells along with 15 water injection wells leading to a processing capacity of 150,000 b/d of oil. The operation of the project will commence in 2026. Hence, the development of new oil refineries in countries such as Norway, India, and the United States, among others is accelerating the refinery process additives market demand. This prime factor will proliferate the global refinery process additives market trends.

Refinery Process Additives Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2017-2030 |

| Market Size in 2030 | USD 3,305.73 Million |

| CAGR (2023-2030) | 6.8% |

| By Type | Demulsifier, Antifoulants, Corrosion Inhibitor, Hydrogen Sulfide Scavenger, Stabilizer, Biocides, Octane Booster, and Others |

| By Crude Oil Type | Light Crude Oil, Medium Crude Oil, and Heavy Crude Oil |

| By Application | Crude Oil Processing, Fluid Catalytic Cracking, Hydroprocessing, and Others |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | BASF SE, Chevron Corporation, Total, Westlake Chemical Corporation, Mitsubishi Chemical Corporation, SABIC, LG Chem, Dow, DuPont, and Eastman Chemical Company |

Refinery Process Additives Market Segmental Analysis :

Based on the Type :

The type segment is categorized into demulsifier, antifoulants, corrosion inhibitor, hydrogen sulfide scavenger, stabilizer, biocides, octane booster, and others. In 2022, the antifoulants segment accounted for the highest market share in the market. Antifoulants are deployed in oil refineries to reduce organic and inorganic material deposition on heat transfer surfaces, including polymers, sludge, corrosion productions, coke, and catalyst fines. The antifoulant additives enhance throughput and increase the production of crude oil. Moreover, antifoulants enhance product quality and overall equipment reliability. Based on the analysis, this results in minimizing the equipment cleaning and replacement costs. For instance, according to the recent statistics published by the U.S. Energy Information Administration, in 2021, the annual production of crude oil in OPEC countries was 31.66 million barrels per day, and in 2022, it was 34.17 million barrels per day. In 2022, the year-on-year growth of crude oil production at the global level was 7.91%. Thus, the increase in the production activities associated with crude oil in OPEC countries is favoring the expansion of antifoulant to minimize waste disposal costs, which, in turn, is benefiting the market growth and trends.

However, the corrosion inhibitor segment is expected to be the fastest-growing segment during the forecast period. This is due to the development of a new product range, which is leading to expansion of the segment trends.

Based on the Crude Oil Type :

The crude oil type segment is categorized into light crude oil, medium crude oil, and heavy crude oil. In 2022, the light crude oil segment accounted for the highest refinery process additives market share of 45.88% in the overall refinery process additives market. The light crude oil refineries utilize these additives to efficiently break water content from the oil. Furthermore, as per the analysis, the efficient deployment of these additives in light crude oil minimizes the crude oil viscosity and consequently. As per the analysis, this minimizes the pipeline pressure drop. For instance, according to the recent data published by the Alberta Energy Regulator, in 2021, the annual production of light crude oil in Alberta, Canada was 39.90 10³m³/day, and in 2022, it was 43.90 10³m³/day. In 2022, the year-on-year growth of crude oil production in Alberta, Canada was 10.02%. Thus, the increase in the production of light crude oil is fostering the demand for these additives to increase crude oil performance, thereby spurring market expansion and trends.

However, the medium crude oil segment is expected to be the fastest-growing segment during the forecast period because of the development of new medium crude oil refinery facilities.

Based on the Application :

The application segment is categorized into crude oil processing, fluid catalytic cracking, hydroprocessing, and others. In 2022, the crude oil processing segment accounted for the highest market share in the refinery process additives market. These additives are deployed in crude oil processing to facilitate the equal and continuous flow of the crude oil mass. This prevents clogging in the flow stream processes and production wells. In addition, as per the analysis, the use of these additives in crude oil processing prevents obtrusion of the manufacturing and flow stream delivery or renewed production of inactive wells. For instance, according to the recent statistics published by the U.S. Energy Information Administration, in 2021, the annual production of crude oil at the global level was 95.69 million barrels per day, and in 2022, it was 99.85 million barrels per day. In 2022, the year-on-year growth of crude oil production at the global level was 4.34%. Henceforth, the increase in the production of crude oil at the global level is accelerating the demand for refinery process additives to ensure efficient crude oil processing, thereby propelling the market trends.

However, the fluid catalytic cracking segment is expected to be the fastest-growing segment in the refinery process additives market during the forecast period. This expansion will be attributed due to factors such as new technological innovations, and increasing investment opportunities, among others.

Based on the Region :

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

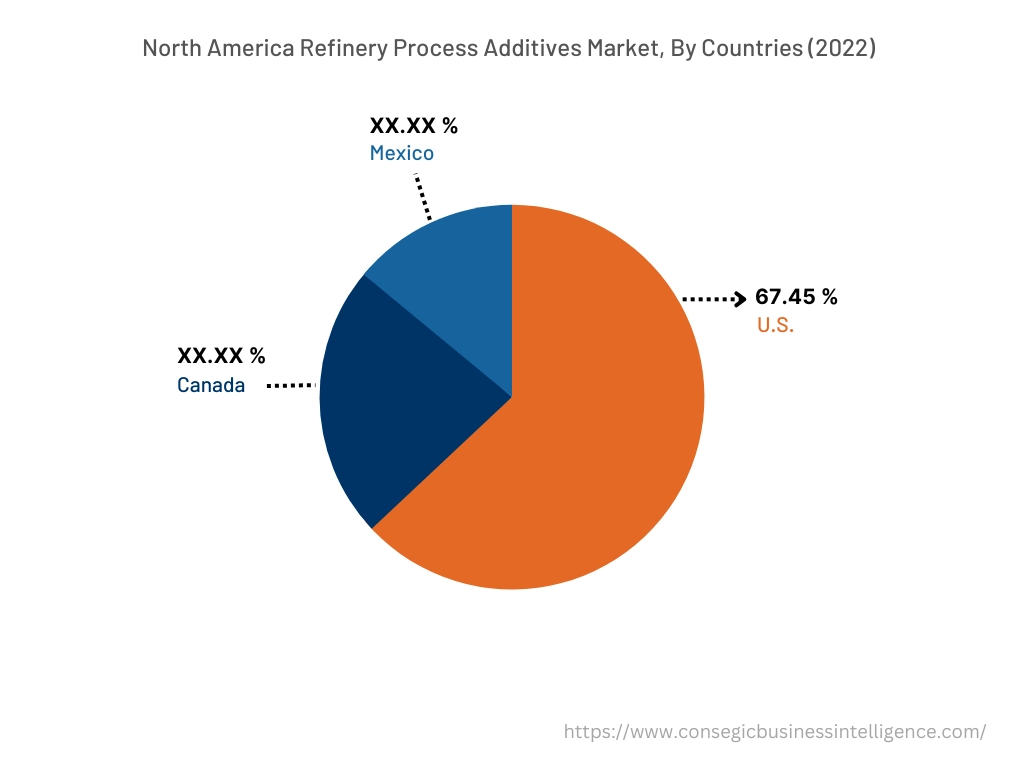

In 2022, North America accounted for the highest market share at 36.55% and was valued at USD 716.89 million, and is expected to reach USD 1,211.55 million in 2030. In North America, the U.S. accounted for the highest market share of 67.45% during the base year of 2022. Based on the refinery process additives market analysis, this is due to the increase in the production process of crude oil in the North American region. For instance, according to the recent statistics published by the U.S. Energy Information Administration, in 2021, the annual production of crude oil in North America was 26.44 million barrels per day, and in 2022, it was 27.82 million barrels per day. In 2022, the year-on-year growth of crude oil production in North America was 5.19%. Therefore, the expansion of crude oil production in North America is boosting the demand for refinery process additives industry to ensure a reduction in corrosion. This, in turn, is proliferating the market.

Furthermore, Asia Pacific is expected to witness significant refinery process additives market growth over the forecast period, growing at a CAGR of 7.1% during 2023-20230. This is attributed to the growing demand for refinery process additives market from various applications, including fluid catalytic cracking, crude oil processing, and hydroprocessing, among others.

Top Key Players & Market Share Insights :

The refinery process additives market is highly competitive, with several large players and numerous small and medium-sized enterprises. These companies have strong research and development capabilities and a strong presence in the market through their extensive product portfolios and distribution networks. The market is characterized by intense competition, with companies focusing on expanding their product offerings and increasing their market revenue through mergers, acquisitions, and partnerships. The key players in the market include-

- BASF SE

- Chevron Corporation

- Dow

- DuPont

- Eastman Chemical Company

- Total

- Westlake Chemical Corporation

- Mitsubishi Chemical Corporation

- SABIC

- LG Chem

Recent Industry Developments :

- In October 2021, BASF SE, a leading chemical manufacturer in Germany launched Enable FCC additive. The product is an advanced refinery additive. Enable ensures excellent performance in regenerator afterburn control and emissions. The introduction of a new range of products is benefiting the market growth.

Key Questions Answered in the Report

What was the market size of the refinery process additives industry in 2022? +

In 2022, the market size of refinery process additives was USD 1,961.39 million

What will be the potential market valuation for the refinery process additives industry by 2030? +

In 2030, the market size of refinery process additives will be expected to reach USD 3,305.73 million.

What are the key factors driving the growth of the refinery process additives market? +

The increasing adoption of refinery process additives in crude oil processing is driving the growth of the market.

What is the dominating segment in the refinery process additives market by crude oil type? +

In 2022, the light crude oil segment accounted for the highest market share of 45.88% in the overall refinery process additives market.

Based on current market trends and future predictions, which geographical region is the dominating region in the refinery process additives market? +

North America accounted for the highest market share in the overall refinery process additives market.