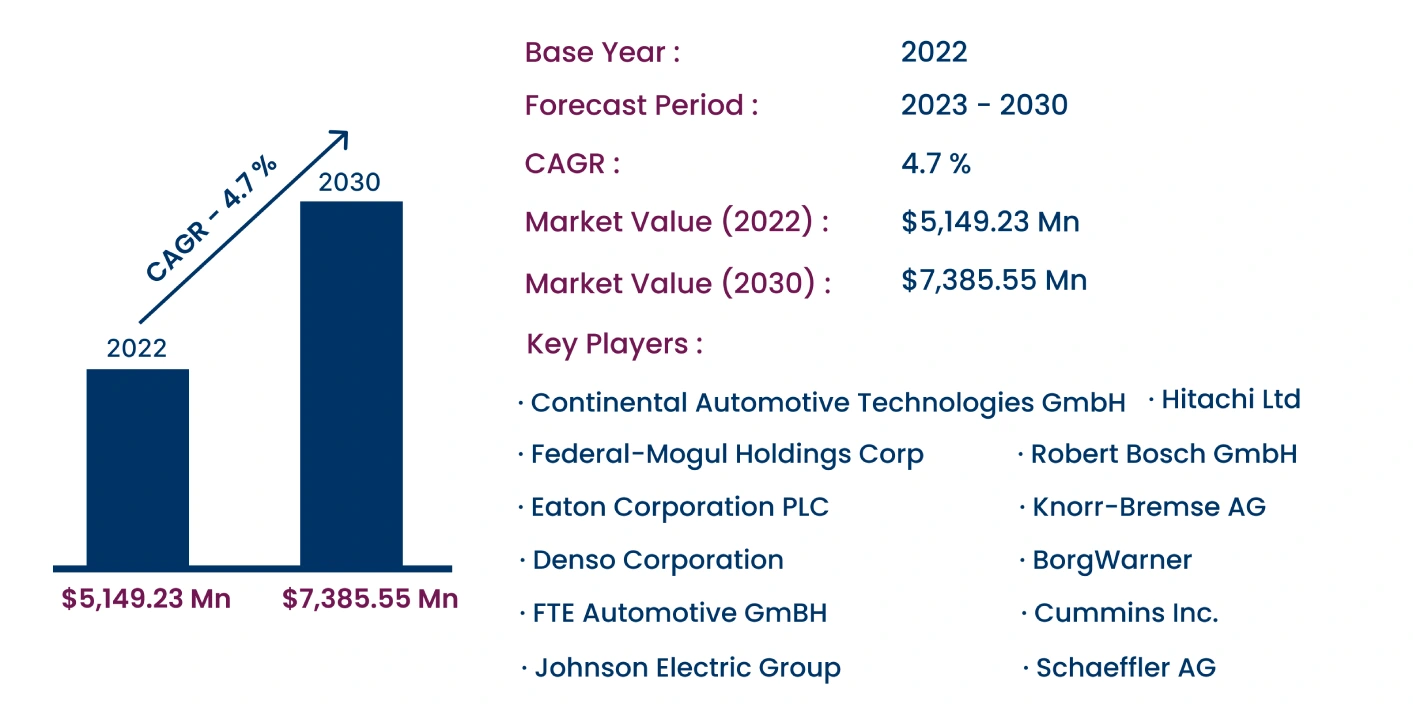

Global Automotive Engine Valve Market to Reach USD 7,385.55 Million by 2030 | CAGR of 4.7%

Category : Automotive Services | Published Date : Nov 2024 | Type : Press Release

Automotive Engine Valve Market Scope & Overview:

In the newly published report, Consegic Business Intelligence states that the Automotive Engine Valve Market size was valued at USD 5,149.23 Million in 2022 and is projected to reach USD 7,385.55 Million by 2030, growing at a CAGR of 4.7% from 2023 to 2030. Automotive engine valves are critical components in internal combustion engines, controlling the flow of air and fuel into the combustion chamber and allowing exhaust gases to exit the engine. These valves are manufactured from durable materials like steel and alloys to withstand high temperatures and pressures during engine operation.

The report comprises the Automotive Engine Valve Market Share, Size & Industry Analysis, By Product Type (Monometallic Valves, Bimetallic Valves, Hollow Valves), Vehicle Type (Compact Passenger Cars, Mid-Sized Passenger Cars, Premium Passenger Cars), Material Type (Steel, Titanium, Nickel Alloy), Fuel Type (Diesel, Gasoline), Sales Channel (OEM, Aftermarket), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East & Africa), and Forecast, 2023-2030.

The report contains detailed information on Automotive Engine Valve Market Trends, Opportunities, Value, Growth Rate, Segmentation, Geographical Coverage, Company Profile, In-depth Expert Analysis, Revenue Forecast, Competitive Landscape, Growth Factors, Restraints or Challenges, Environment & Regulatory Landscape, PESTLE Analysis, PORTER Analysis, Key Technology Landscape, Value Chain Analysis, and Cost Analysis.

Increasing vehicle production and advancements in engine technology are driving the market growth, while rising adoption of electric vehicles (EVs) is expected to limit market expansion.

Segmental Analysis :

Based on product type, the market is trifurcated into monometallic valves, bimetallic valves, and hollow valves.

- Monometallic valves held the largest market share in 2022, driven by their durability, high-temperature resistance, and reliability in light and heavy-duty vehicles.

- Bimetallic valves are projected to register the fastest CAGR during the forecast period, attributed to their enhanced performance under high-stress conditions, making them ideal for modern engine systems.

Based on vehicle type, the market is divided into compact passenger cars, mid-sized passenger cars, and premium passenger cars.

- Mid-sized passenger cars dominated the market in 2022, driven by the increasing production of engine valves for gasoline and diesel engines to meet emission standards.

- Premium passenger cars are expected to grow at the fastest rate, fueled by the demand for advanced materials and high-performance engine valves to ensure durability and optimal performance.

Based on material type, the market is segmented into steel, titanium, and nickel alloy.

- Steel accounted for the largest revenue share of 41.15% in 2022, due to its extensive use in manufacturing valves for both commercial and passenger vehicles.

- Nickel alloy is anticipated to register the fastest growth, driven by its malleability and corrosion resistance, making it ideal for high-power diesel engines.

Based on fuel type, the market is bifurcated into diesel and gasoline.

- Gasoline held the largest market share in 2022, driven by its application in spark-ignited engines that require high-performance engine valves for efficient fuel transmission.

- Diesel is expected to grow at the fastest CAGR due to the increasing focus on reducing carbon emissions and improving fuel efficiency in diesel vehicles.

Based on sales channel, the market is divided into OEM and aftermarket.

- OEM held the largest revenue share in 2022, as manufacturers prefer purchasing automotive engine valves from established brands for quality assurance.

- Aftermarket is projected to witness the fastest growth, driven by the demand for replacement and upgradation of engine valves after the OEM warranty period expires.

Based on regions, the global market is segmented into North America, Europe, Asia-Pacific, Middle East & Africa, and Latin America.

- Asia-Pacific led the market in 2022 with a market share of USD 1,763.61 million, driven by the increasing demand for automobiles and investments in the automotive sector in countries like China, Japan, and India.

- North America is expected to witness significant growth, driven by advancements in automotive engines such as Variable Valve Timing (VVT) and direct injection systems.

| Report Attributes | Report Details |

| Study Timeline | 2017-2030 |

| Market Size in 2030 | USD 7,385.55 Million |

| CAGR (2023-2030) | 4.7% |

| By Product Type | Monometallic Valves, Bimetallic Valves, Hollow Valves |

| By Vehicle Type | Compact Passenger Cars, Mid-Sized Passenger Cars, Premium Passenger Cars |

| By Material Type | Steel, Titanium, Nickel Alloy |

| By Fuel Type | Diesel, Gasoline |

| By Sales Channel | OEM, Aftermarket |

| By Region | North America(U.S., Canada, Mexico) Europe(U.K., Germany, France, Spain, Italy, Russia, Benelux, Rest of Europe) APAC(China, South Korea, Japan, India, Australia, ASEAN, Rest of Asia-Pacific) Middle East & Africa(GCC, Turkey, South Africa, Rest of MEA) LATAM(Brazil, Argentina, Chile, Rest of LATAM) |

Top Key Players & Competitive Landscape :

The competitive landscape includes major global manufacturers known for innovation and technological advancements in automotive engine valve production.

List of prominent players in the Automotive Engine Valve Industry:

- Continental Automotive Technologies GmbH

- BorgWarner

- Denso Corporation

- Eaton Corporation PLC

- Federal-Mogul Holdings Corp

- Hitachi Ltd

- Johnson Electric Group

- Robert Bosch GmbH

- Schaeffler AG

- Cummins Inc.

Recent Industry Developments :

- In December 2022, BorgWarner introduced several new products for fuel systems, including fuel pump hanger and fuel pump check valves, which have applications in engine valve systems.

- In February 2023, Eaton Corporation launched new valve actuation technologies aimed at reducing emissions, supporting efforts to improve fuel efficiency in gasoline and diesel engines.