- Summary

- Table Of Content

- Methodology

Precision Bearings Market Size :

Global Precision Bearings Market size is estimated to reach over USD 13,867.82 Million by 2030 from a value of USD 8,972.09 Million in 2022, growing at a CAGR of 5.9% from 2023 to 2030.

Precision Bearings Market Scope & Overview:

Precision bearings, also known as ball bearings and roller bearings are designed to perform specialized applications depending on the consumer demands. They offer a range of benefits including high running accuracy, higher system rigidity, lower noise, low friction, high-speed performance, and others. Their aforementioned benefits are key determinants for increasing its deployment in automotive, aerospace, medical, power generation, oil & gas, and others. Moreover, aforementioned bearings have higher standard precision level and are meant for utilization in applications that require high rigidity, high accuracy, and high speeds.

Precision Bearings Market Insights :

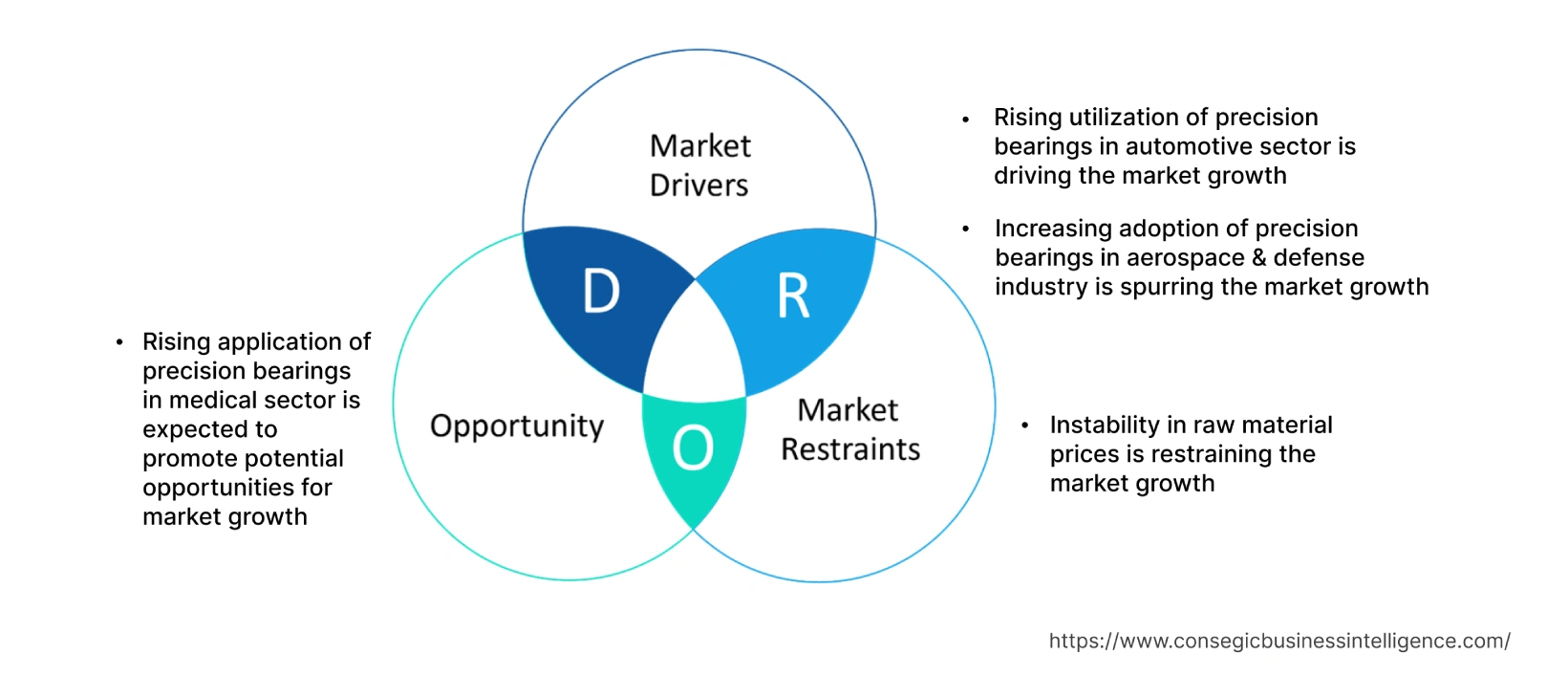

Key Drivers :

Rising utilization in automotive sector

Precision bearings are used in automotive sector, particularly in moving parts of automobiles. They are utilized in various automotive sub-systems including engines, transmissions, wheels, gearboxes, steering, electrical motors, and other related components. Analysis of market trends concludes that their ability to enhance the performance of vehicles, reduce friction, and bear heavy loads are prime aspects for increasing its utilization in automotive sector.

Factors including increasing automobile production, advancement in autonomous driving, and rising investments in automobile manufacturing facilities are driving the expansion of the automotive sector.

According to OICA (International Organization of Motor Vehicle Manufacturers), the total production of passenger cars in the Asia-Pacific region reached 42,324,447 units in 2022, depicting a rise of nearly 11% in comparison to 38,188,956 units in 2021. Thus, the rise in automobile production is driving the adoption of the bearings for above applications, in turn driving precision bearings market demand.

Increasing adoption in aerospace & defense industry

Precision bearings utilized in the aerospace & defense sector in applications including aircraft shafts, landing gear struts, shock absorbers, and others. They offer excellent corrosion resistance, superior reliability, weight reduction, and high-temperature resistance, which are prime aspects increasing its adoption in the aerospace & defense sector.

Factors including rising commercial flight activities, increasing aircraft production, growing investments in the air defense system are primary determinants driving the expansion of the aerospace & defense sector.

For instance, Boeing, a U.S.-based airline company, delivered 99 commercial jets in the fourth quarter of 2021, witnessing a significant increase of 68% as compared to 59 deliveries in the fourth quarter of 2020. Analysis of market trends concludes that the growing aerospace & defense sector is driving the utilization of the bearings in aircraft shafts, landing gear struts, shock absorbers, and others, in turn proliferating the precision bearings market demand.

Key Restraints :

Instability in raw material prices

The overall cost of precision bearings is primarily dependent on the cost of production, followed by the cost of raw materials including steel, aluminum, ceramic, plastic, and others used in their manufacturing. Analysis of market trends concludes that the fluctuations in raw material prices impact their overall cost, which is a primary factor limiting the market proliferation.

For instance, according to MEPS International Ltd., the average price of steel in North America reached approximately USD 1,548 per ton in May 2022, witnessing an increase of 23.2% in comparison to February 2022. Additionally, steel prices declined to USD 848 per ton by October 2022. Further, the price of aluminum reached USD 2,830.32 per ton in May 2022, depicting an increase of 16.3% as compared to USD 2,433.53 per ton in May 2021. Hence, the instability in prices of raw materials including steel, aluminum, and others that are used in the production of the bearings is restraining the development of the market.

Future Opportunities :

Rising application in medical sector

The rising application of precision bearings in medical sector is expected to present potential opportunities for the growth of the precision bearings market. They are utilized in medical devices including surgical power tools, diagnostics & monitoring devices, ventilators, heart pumps, and other medical devices. Moreover, their ability to offer high precision and high-speed capabilities makes it ideal for utilization in medical devices.

Factors including the rising incidence of chronic diseases, surging number of diagnostic or surgical procedures, and increasing investments from medical companies for the development of advanced medical devices are key prospects driving the expansion of the medical sector.

According to the International Trade Administration, the medical device industry in Italy was valued at USD 8.95 billion in 2022, an increase of around 18.9% as compared to 2020. Analysis of market trends concludes that the proliferation of medical industry is anticipated to increase the application of the bearings in monitoring & diagnostic devices, surgical power tools, and others, in turn emerging as one of many precision bearings market opportunities that will drive market expansion during the forecast period.

Precision Bearings Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2017-2030 |

| Market Size in 2030 | USD 13,867.82 Million |

| CAGR (2023-2030) | 5.9% |

| By Type | Ball Bearings and Roller Bearings |

| By End-User | Automotive, Aerospace & Defense, Medical, Power Generation, Oil & Gas, and Others |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | SKF, Schaffler AG, Kaman Corporation, CW BEARING, AST Bearings, THE TIMKEN COMPANY, JTEKT Corporation, GMN Bearing USA, Pacamor Kubar Bearings (National Precision Bearing), NSK Ltd., and Schatz Bearing Corp. |

Precision Bearings Market Segmental Analysis :

By Type :

Based on the type, the market is bifurcated into ball bearings and roller bearings. In 2022, the ball bearings segment accounted for the highest precision bearings market share. Ball bearings refers to a kind of rolling-element bearing that utilizes balls for maintaining separation between the bearing races. The primary function of a ball bearing is to reduce rotational friction as well as support axial and radial loads. Moreover, ball bearing offer several benefits including optimum design, long shelf-life, high accuracy, high rotational speed, and others. The above benefits of ball bearings are increasing its application in aerospace, medical, automotive, and other industries.

In August 2022, SKF launched its new ball bearing with enhanced flexibility in the design choices. The ball bearing operates more quietly and enables high power density, which further generates more power output from the same from factor electric motor. Assessment of market trends indicates that rising innovation associated with ball bearings is among the key factors contributing to the precision bearings market growth.

The roller bearings segment is anticipated to register the fastest CAGR growth during the forecast period. A roller bearing is a type of bearing in which a shaft runs on steel rollers held in a cage. Rolling bearings are capable of supporting and guiding oscillating or rotating machine elements including axles, shafts, or wheels and transferring loads between machine components. Roller bearings offer high precision, low friction, and high rotational speeds while reducing heat, energy consumption, noise, and wear. The above features of roller bearings make it ideal for deployment in the automotive, power generation, and oil & gas industries among others.

In June 2022, Schaeffler launched a new cylindrical roller bearing that offers high performance and features along with ease of mounting and dismounting on a shaft. Analysis of market trends concludes that the rising development of roller bearings for its utilization in high-speed industrial applications is anticipated to drive market proliferation during the forecast period.

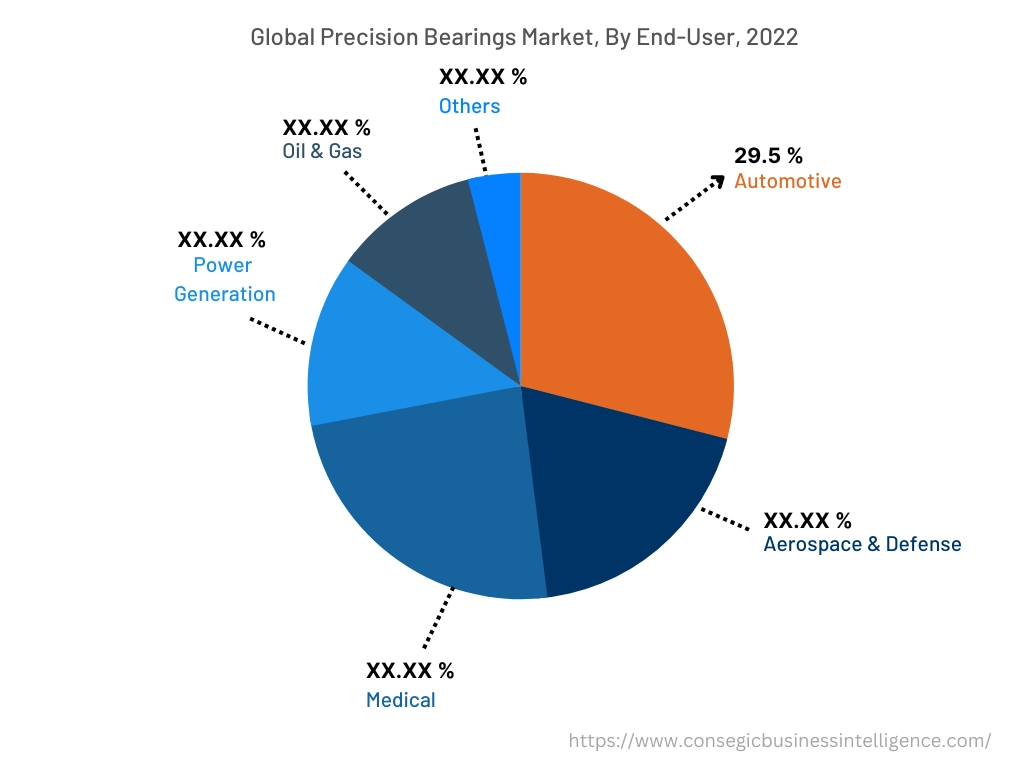

By End-User :

Based on the end-user, the market is segregated into automotive, aerospace & defense, medical, power generation, oil & gas, and others. The automotive segment accounted for the largest revenue share of 29.5% in the year 2022. Factors including rising automobile production, growing adoption of electric vehicles, and increasing investments in automobile manufacturing facilities are driving the expansion of the automotive segment.

For instance, according to the International Energy Agency, the adoption of electric cars in the United Kingdom reached 312 thousand units in 2021, depicting a substantial rise of 78.3% in comparison to 175 thousand units in 2020. Analysis of precision bearings market trends concludes that the expansion of automotive sector is driving the adoption of the bearings for its utilization in electrical motors, transmissions, gearboxes, wheels, steering, and other related components, in turn fostering market proliferation during the forecast period.

Aerospace & defense segment is expected to witness fastest CAGR growth during the forecast period. The precision bearings market analysis concluded that the proliferation of aerospace & defense segment is attributed to several factors including growing commercial flight activities, increasing aircraft production, and rising investments in air defense systems.

For instance, Boeing delivered 340 commercial aircraft in 2021, depicting a significant rise of over 100% as compared to 157 aircraft deliverables in 2020. Assessment of market trends indicates that the rising aircraft production is driving the adoption of the bearings for application in aircraft shafts, landing gear struts, and other related components. The above factors are anticipated to drive the expansion of the market during the forecast period.

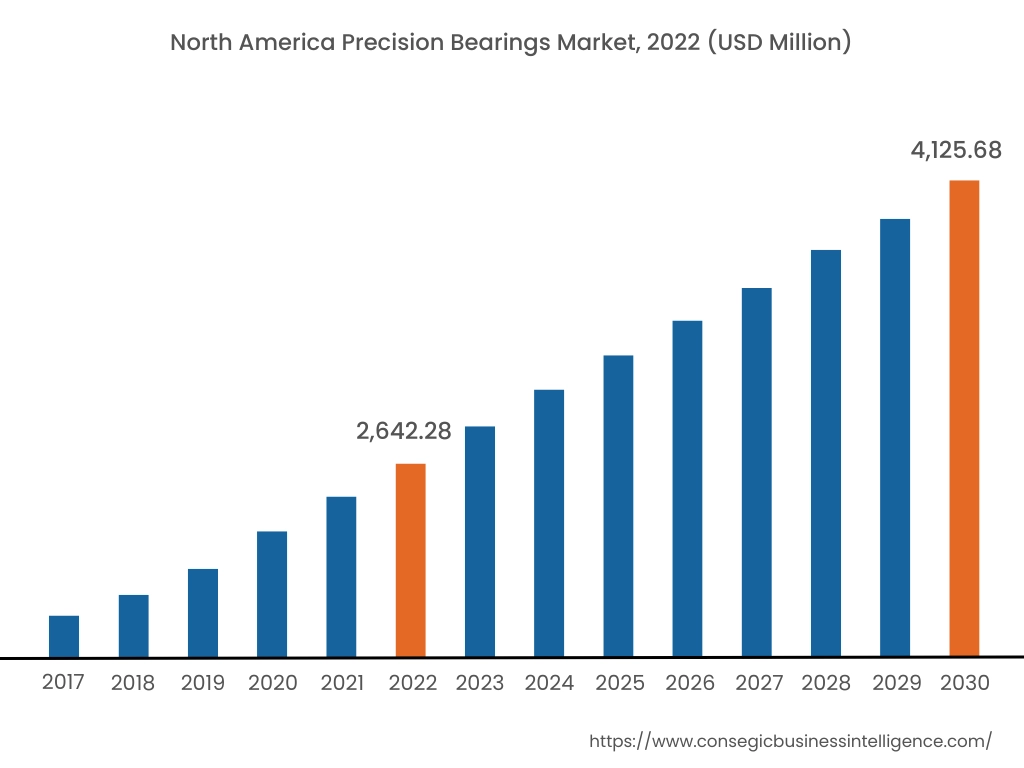

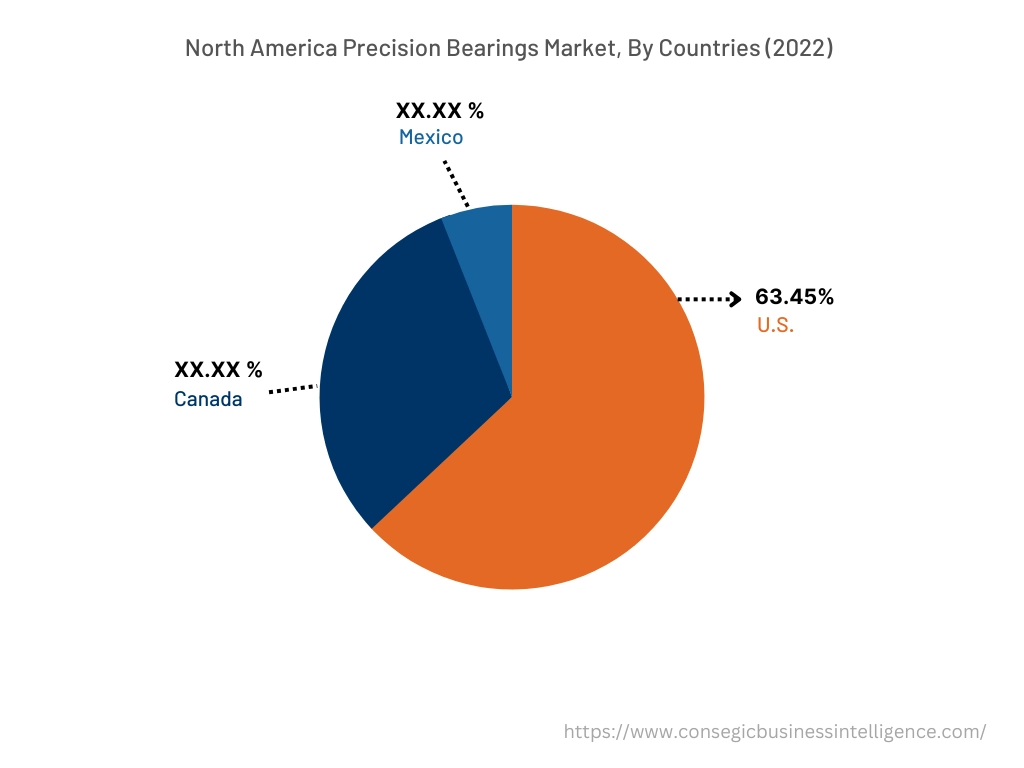

By Region :

The regional segment includes North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

North America accounted for the largest revenue share of USD 2,642.28 Million in 2022 and is expected to reach USD 4,125.68 Million by 2030, registering a CAGR of 6.1% during the forecast period. In addition, in the region, the U.S. accounted for the maximum revenue share of 63.45% in the same year. The adoption of precision bearings in the North American region is primarily driven by its usage in automotive, aerospace & defense, medical, and other sectors. Their increasing application in various automotive components including engines, wheels, gearboxes, steering, and others is among the significant factors driving the market growth in the region. For instance, according to the International Organization of Motor Vehicle Manufacturers, the overall production of automobile in the U.S. reached 10.06 million in 2022, witnessing an increase of 9.7% as compared to 2021. The above factors are propelling the proliferation of the precision bearings market in the North American region. Additionally, the growing adoption of electric vehicles and rising investments in medical and aerospace & defense sectors are anticipated to provide lucrative proliferation aspects for the market in North America during the forecast period.

Asia-Pacific is expected to register the fastest CAGR growth of 6.3% during the forecast period. The rapid pace of industrialization and development is creating lucrative opportunities for market proliferation in the region. Moreover, factors including the development of multiple industries including automotive, aerospace & defense, power generation, and others are fostering the market expansion in the Asia-Pacific region.

For instance, the Government of India invested around USD 2.7 billion in transport aircraft manufacturing facility located in Gujarat, India. The facility is responsible for manufacturing C-295 aircraft for the Indian Air Force through partnership between Airbus Defense and Space S.A. and Tata Advanced Systems Limited. Therefore, the rising investment in aircraft production is driving the deployment of precision bearings for application in aircraft shafts, landing gear struts, shock absorbers, and others, thereby, proliferating the market growth in the Asia-Pacific region.

Top Key Players & Market Share Insights :

The precision bearings market is highly competitive with major players providing products to the national and international markets. The major companies operating in the precision bearings industry are adopting several strategies in research and development (R&D), product innovation, and application launches to hold a strong position in precision bearings market. Key players in the precision bearings market include-

- SKF

- Schaffler AG

- Pacamor Kubar Bearings (National Precision Bearing)

- NSK Ltd.

- Schatz Bearing Corp.

- Kaman Corporation

- CW BEARING

- AST Bearings

- THE TIMKEN COMPANY

- JTEKT Corporation

- GMN Bearing USA

Recent Industry Developments :

- In February 2022, Schaeffler AG strengthened its bearings business with the launch of two ball bearings for electric vehicles. The ball bearing offer high-efficiency and long service life for all types of powertrain.

Key Questions Answered in the Report

What is precision bearings? +

Precision bearings have a higher standard precision level and are designed for utilization in applications that require high rigidity, high accuracy, and high speeds.

What specific segmentation details are covered in the precision bearings report, and how is the dominating segment impacting the market growth? +

For instance, by type segment has witnessed ball bearings as the dominating segment in the year 2022, owing to its increasing utilization in aerospace, medical, automotive, and other industries.

What specific segmentation details are covered in the precision bearings market report, and how is the fastest segment anticipated to impact the market growth? +

For instance, by end-user segment has witnessed aerospace & defence as the fastest-growing segment during the forecast period due to the rising adoption of precision bearings for various aircraft components including shafts, landing gear struts, and others.

Which region/country is anticipated to witness the highest CAGR during the forecast period, 2023-2030? +

Asia-Pacific is anticipated to register fastest CAGR growth during the forecast period due to rapid pace of industrialization and growth of multiple industries including automotive, aerospace & defence, power generation, and others.