- Summary

- Table Of Content

- Methodology

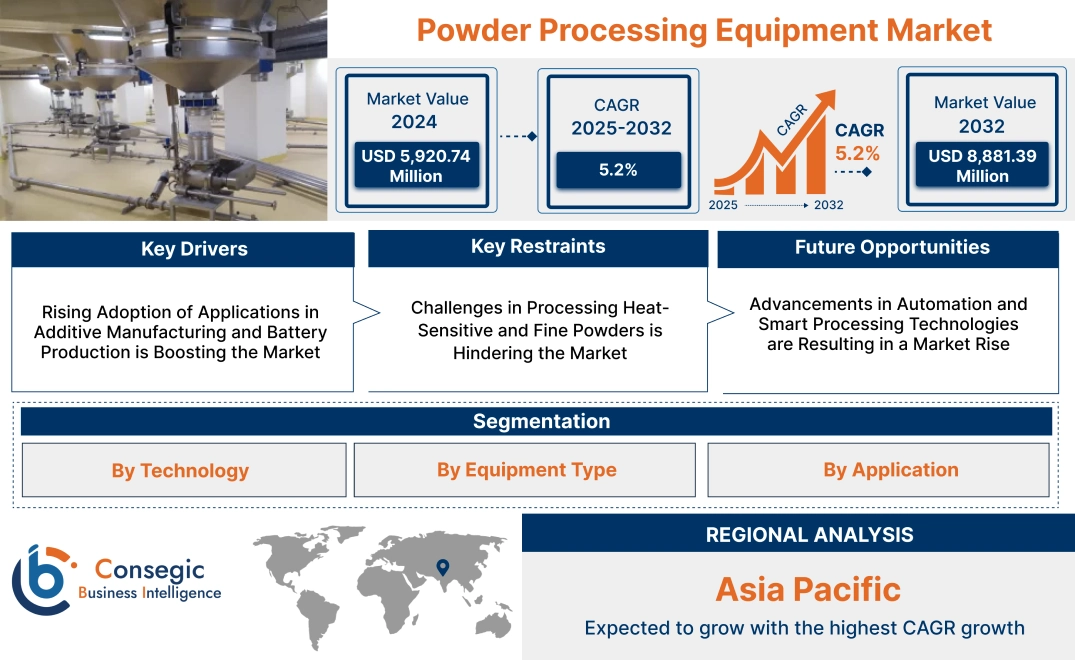

Powder Processing Equipment Market Size:

Powder Processing Equipment Market size is estimated to reach over USD 8,881.39 Million by 2032 from a value of USD 5,920.74 Million in 2024 and is projected to grow by USD 6,123.12 Million in 2025, growing at a CAGR of 5.2% from 2025 to 2032.

Powder Processing Equipment Market Scope & Overview:

The powder processing equipment machinery and systems used to handle, process, and refine powders in industries such as pharmaceuticals, chemicals, food and beverages, and mining. These machines, including mixers, mills, classifiers, dryers, and conveyors, enable precise particle size reduction, blending, and packaging for various powder-based materials. Key characteristics of powder processing equipment include high efficiency, precision control, and adaptability to a range of materials and production scales. The benefits include enhanced product quality, improved operational efficiency, and compliance with industry standards for hygiene and safety. Applications span pharmaceutical manufacturing, food processing, mineral refining, and chemical production, where powder uniformity and consistency are critical. End-users include pharmaceutical companies, food manufacturers, chemical producers, and metallurgy firms, driven by increasing demand for high-quality powders, advancements in process automation, and the rising need for efficient material handling solutions across industries.

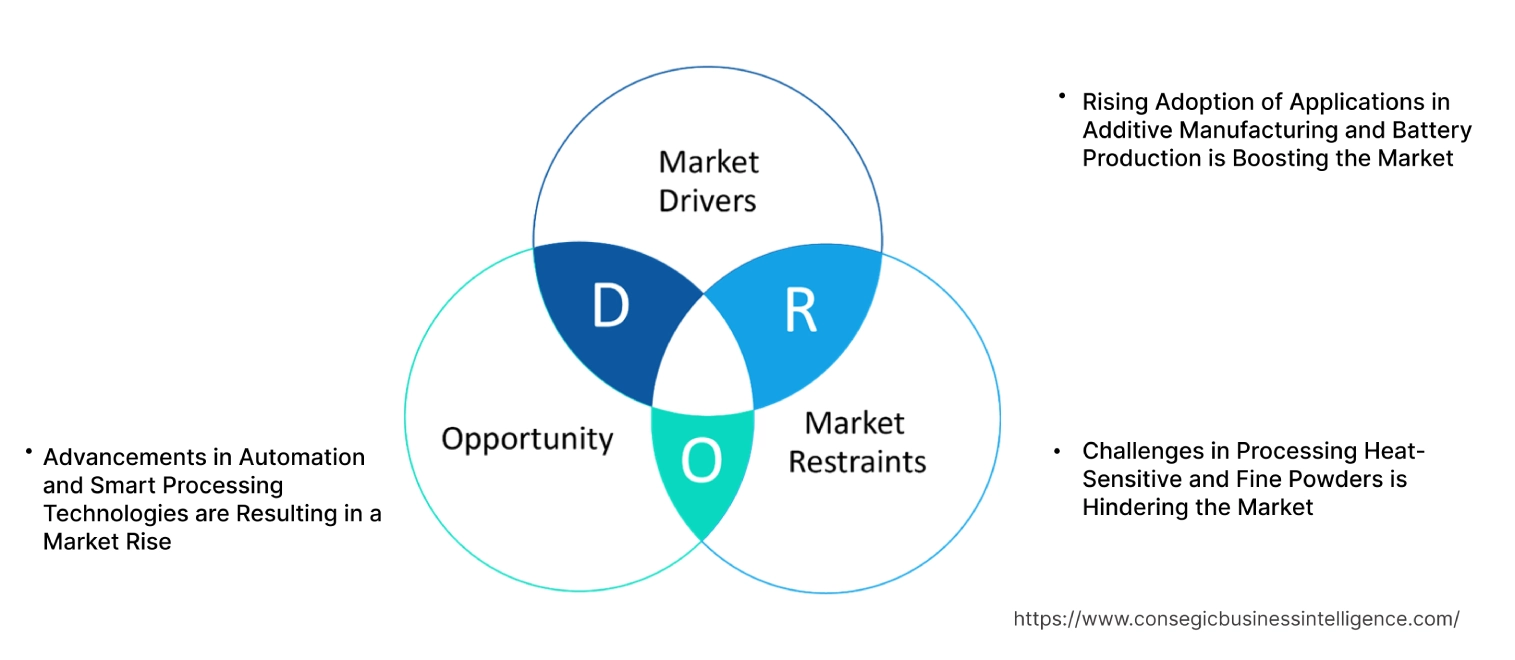

Key Drivers:

Rising Adoption of Applications in Additive Manufacturing and Battery Production is Boosting the Market

The increasing use of powder processing equipment in additive manufacturing and battery production is driving significant advancements in the market. In additive manufacturing (3D printing), high-quality metal and ceramic powders are critical for producing precision-engineered components across industries such as aerospace, healthcare, and automotive. Powder processing equipment ensures uniform particle size, consistency, and purity, which are essential for achieving the required material properties and performance standards.

Similarly, the production of battery materials, particularly for electric vehicles (EVs) and energy storage systems, relies on efficient powder processing for cathode and anode materials. Trends in sustainable transportation and the global push for clean energy solutions are accelerating investments in battery manufacturing, creating new opportunities for advanced powder handling, mixing, and granulation systems. Analysis suggests that as these industries continue to expand, the powder processing equipment market demand for specialized powder processing equipment capable of handling advanced materials will increase.

Key Restraints:

Challenges in Processing Heat-Sensitive and Fine Powders is Hindering the Market

The processing of heat-sensitive and fine powders poses significant challenges in industries such as pharmaceuticals, food, and chemicals. Heat-sensitive materials can degrade or lose their functional properties during high-temperature processing, which impacts product quality and consistency. To overcome this, manufacturers require specialized equipment with features like cooling systems, gentle handling mechanisms, and precision controls to maintain optimal processing conditions.

Additionally, fine powders are prone to issues such as dust formation, clogging, and agglomeration during handling and processing, resulting in operational inefficiencies and safety risks. These challenges necessitate advanced filtration systems, dust management technologies, and enhanced material flow solutions to ensure smooth operations. Trends in equipment innovation and the development of tailored systems are essential to address these constraints, enabling manufacturers to process complex materials efficiently while maintaining product integrity.

Future Opportunities :

Advancements in Automation and Smart Processing Technologies are Resulting in a Market Rise

The integration of automation and smart technologies is transforming the powder processing equipment market by enhancing precision, efficiency, and real-time control. Advanced equipment now incorporates IoT-enabled sensors, AI-driven monitoring systems, and automated process controls that enable manufacturers to optimize operations, ensure consistent product quality, and minimize downtime. These technologies allow real-time data collection and analysis, helping operators identify inefficiencies and improve decision-making processes during powder handling, mixing, and granulation.

Trends in Industry 4.0 and smart manufacturing are driving this shift, as industries like pharmaceuticals, chemicals, and food processing prioritize intelligent systems to meet stringent quality standards. For example, automated systems can adjust critical parameters like temperature, humidity, and particle size in real time, ensuring uniformity and reducing waste. The analysis highlights that as industries adopt digital transformation strategies, the powder processing equipment market demand for automated and intelligent powder processing equipment will rise, offering new opportunities for innovation and productivity enhancements.

Additionally, advancements in robotics and machine learning further streamline operations, allowing for seamless integration with existing production lines. These innovations not only improve efficiency but also reduce labor dependency, making powder processing solutions more sustainable and cost-effective for manufacturers operating in competitive markets.

Powder Processing Equipment Market Segmental Analysis :

By Technology:

Based on technology, the market is segmented into dry processing and wet processing.

The dry processing segment accounted for the largest revenue of powder processing equipment market share in 2024.

- Dry processing technology is widely adopted across industries such as food & beverage, chemicals, and pharmaceuticals due to its efficiency in handling materials without the use of water or solvents.

- This method is preferred for producing powders, granules, and other dry products, ensuring minimal resource usage and waste generation.

- Its advantages, such as energy efficiency, cost-effectiveness, and compatibility with bulk material handling, have strengthened its adoption.

- The increasing usage of dry processing in food manufacturing, particularly for snacks, cereals, and powdered products, has solidified its position as the dominant segment.

The wet processing segment is anticipated to register the fastest CAGR during the forecast period.

- Wet processing technology involves the use of liquids or solvents to handle and process materials, making it ideal for applications such as chemical formulations, cosmetics, and liquid food products.

- Its growing use in pharmaceuticals for tablet coatings, suspensions, and emulsions is a key factor driving its growth.

- Additionally, the increasing opportunities for premium cosmetic products and advanced chemical formulations are further fueling the adoption of wet processing technologies.

- Advances in water recycling and solvent recovery techniques are expected to enhance the efficiency and sustainability of wet processing, driving its rapid growth.

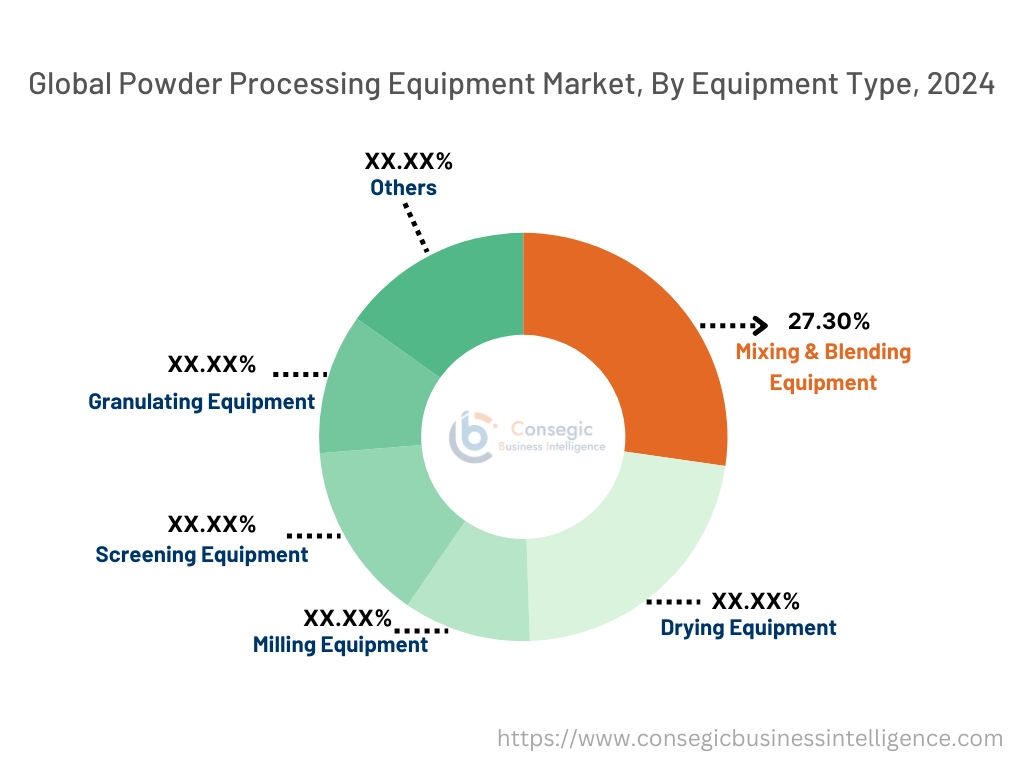

By Equipment Type:

Based on equipment type, the market is segmented into mixing & blending equipment, drying equipment, milling equipment, screening equipment, granulating equipment, and others.

The mixing & blending equipment segment accounted for the largest revenue of 27.30% in powder processing equipment market share in 2024.

- Mixing and blending equipment are essential for ensuring uniform distribution of ingredients and consistency in end products across industries such as food & beverage, pharmaceuticals, and chemicals.

- These machines are widely used in applications like food product preparation, pharmaceutical powder blending, and chemical formulation.

- The growing demand for precision and automation in production processes has boosted the adoption of advanced mixing and blending equipment.

- Additionally, technological advancements, such as the integration of programmable controls and real-time monitoring systems, have further driven the growth of this segment.

The drying equipment segment is anticipated to register the fastest CAGR during the forecast period.

- Drying equipment is critical for removing moisture from materials to enhance their shelf life, stability, and usability.

- Its application spans industries such as food & beverage, pharmaceuticals, and chemicals, where moisture control is essential for product quality.

- The rising advancement for dried food products, pharmaceuticals, and chemical powders has driven the powder processing equipment market trends of this segment.

- Innovations in energy-efficient drying technologies, including freeze-drying and vacuum drying, are further boosting the adoption of drying equipment.

- Moreover, its ability to enhance productivity while minimizing energy consumption is expected to fuel segment analysis.

By Application:

Based on application, the market is segmented into food & beverage, pharmaceuticals, chemicals, cosmetics, minerals & mining, construction materials, and others.

The food & beverage segment accounted for the largest revenue share in 2024.

- The food & beverage sector is a major consumer of processing equipment, including mixing, drying, and granulating machines, to ensure product quality, safety, and consistency.

- These machines are used in applications such as dairy processing, bakery production, beverage preparation, and snack manufacturing.

- The rising development of processed and packaged food products, coupled with advancements in automated food processing technologies, has driven the dominance of this segment.

- Additionally, the growing trends of health-conscious and ready-to-eat food products are further boosting the adoption of processing equipment in this sector.

The pharmaceuticals segment is anticipated to register the fastest CAGR during the forecast period.

- Processing equipment plays a critical role in pharmaceutical manufacturing, including mixing of drug formulations, granulation of powders, and drying of active pharmaceutical ingredients (APIs).

- The increasing powder processing equipment market opportunities for generic and specialty drugs, coupled with the expansion of pharmaceutical manufacturing facilities globally, is driving the powder processing equipment market growth in this segment.

- Additionally, advancements in clean-in-place (CIP) and sterilization-in-place (SIP) technologies have enhanced the efficiency and hygiene of pharmaceutical processing equipment.

- The rising focus on precision, consistency, and regulatory compliance in pharmaceutical manufacturing is expected to fuel the segment's rapid trends.

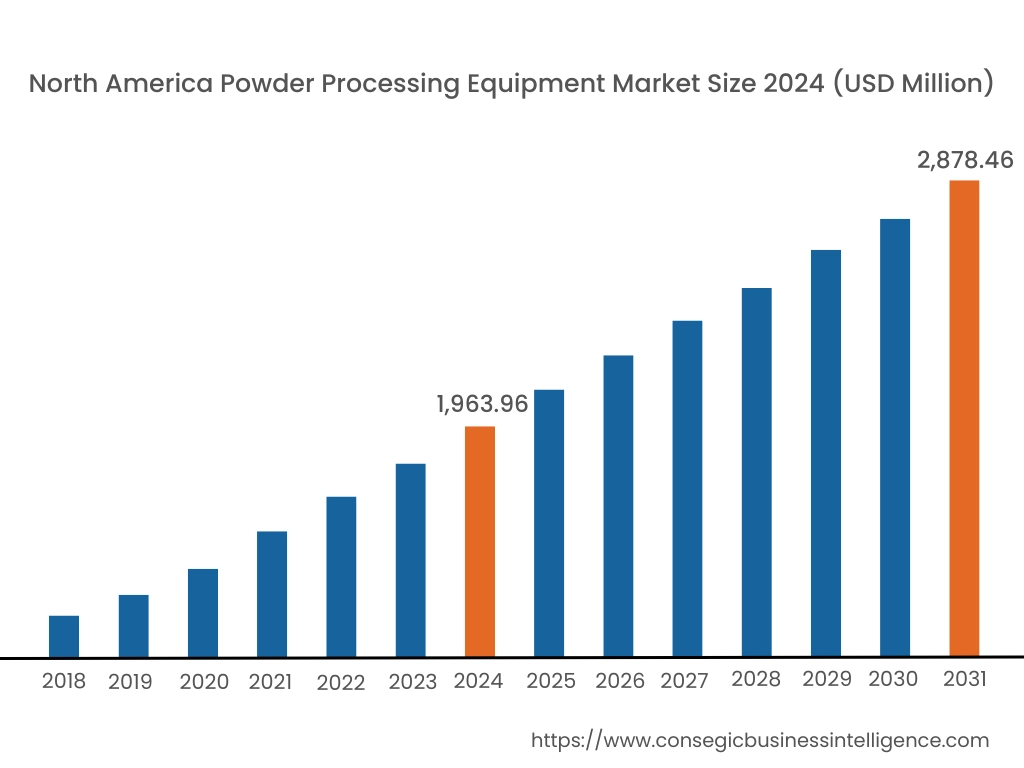

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, North America was valued at USD 1,963.96 Million and is expected to reach USD 2,878.46 Million in 2032. In North America, the U.S. accounted for the highest share of 72.20% during the base year of 2024. North America holds a significant share in the powder processing equipment market analysis, driven by advanced manufacturing industries such as pharmaceuticals, food & beverages, and chemicals. The U.S. leads the regional trends with high demand for precision powder processing equipment, particularly in the pharmaceutical sectors for tablet production and powder formulations. The food sector further drives adoption with increasing requirements for grinding, mixing, and drying equipment. Canada contributes through growing investments in food processing and industrial manufacturing sectors. However, the high costs associated with advanced equipment and maintenance may pose challenges for small-scale manufacturers.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 5.6% over the forecast period. Asia-Pacific is the fastest-growing region in the powder processing equipment market analysis, fueled by rapid industrialization, urbanization, and increasing opportunities across industries in China, India, and Japan. China dominates the market with its expanding food processing, pharmaceutical, and chemical manufacturing industries, which require advanced milling, mixing, and drying equipment. India’s growing pharmaceutical and food sectors, driven by exports and domestic demand, boost the adoption of powder processing equipment. Japan focuses on high-precision equipment for the electronics and healthcare industries, supporting its role as a leader in advanced powder processing technologies. However, challenges such as fluctuating raw material costs and low awareness of advanced technologies in rural areas may hinder powder processing equipment market expansion.

Europe is a prominent market for powder processing equipment, supported by strong industrial and regulatory frameworks. Countries like Germany, the UK, and France are key contributors. Germany leads with its well-established pharmaceutical and chemical industries, driving dominance for high-precision powder processing solutions. The UK emphasizes the use of advanced equipment in food and cosmetics production, particularly for clean-label and sustainable products. France focuses on powder processing equipment for the energy and construction sectors, particularly in cement and material manufacturing. However, strict EU regulations on machinery safety and energy efficiency can increase production costs for manufacturers.

The Middle East & Africa region is witnessing a steady rise in the powder processing equipment market trends, driven by increasing industrialization and infrastructure development. Countries like Saudi Arabia and the UAE are adopting powder-processing technologies for cement, construction, and chemical applications. In Africa, South Africa is an emerging market, with growing adoption in mining, agriculture, and food processing industries to improve production efficiency. However, limited access to advanced equipment and reliance on imported machinery may restrict market expansion in certain areas of the region.

Latin America is an emerging market, with Brazil and Mexico leading the region. Brazil’s expanding food and beverage sectors drive trends for grinding, blending, and drying equipment to meet growing domestic and export requirements. Mexico’s pharmaceutical and industrial manufacturing sectors are increasingly adopting advanced powder processing technologies to improve product quality and production efficiency. The region is also focusing on modernizing its mining and construction sectors, further supporting powder processing equipment market growth. However, economic instability and inconsistent regulatory frameworks may pose challenges to broader adoption in some parts of the region.

Top Key Players and Market Share Insights:

The powder processing equipment market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the powder processing equipment market. Key players in the powder processing equipment industry include -

- Hosokawa Micron Corporation (Japan)

- Baker Perkins Limited (UK)

- Powder Process-Solutions (USA)

- Bepex International LLC (USA)

- British Rema (UK)

- Syntegon Technology GmbH (Germany)

- Hänsel Processing GmbH (Germany)

- Sollich UK Ltd (UK)

- Dongsun Powder Processing Equipment Co., Ltd. (China)

- Sanovo Technology Group (Denmark)

Recent Industry Developments :

Product Expansion:

- In January 2024, IDEX India expanded its range of powder milling and processing equipment to cater to various industries, including pharmaceuticals, food, and chemicals. Their offerings include the SDx Series, a versatile platform that utilizes a single drive with interchangeable heads for hammer milling, security screening, and conical milling. This system ensures repeatability and accuracy in powder processing, reducing capital investment and ownership costs.

Powder Processing Equipment Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 8,881.39 Million |

| CAGR (2025-2032) | 5.2% |

| By Technology |

|

| By Equipment Type |

|

| By Application |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the projected size of the Powder Processing Equipment Market by 2032? +

Powder Processing Equipment Market size is estimated to reach over USD 8,881.39 Million by 2032 from a value of USD 5,920.74 Million in 2024 and is projected to grow by USD 6,123.12 Million in 2025, growing at a CAGR of 5.2% from 2025 to 2032.

What are the key factors driving the growth of the Powder Processing Equipment Market? +

The market is driven by increasing adoption in additive manufacturing, battery production, and advancements in automation and smart processing technologies.

What challenges are restraining the growth of the Powder Processing Equipment Market? +

Key challenges include difficulties in processing heat-sensitive and fine powders, dust management, and operational inefficiencies during handling.

What opportunities exist in the Powder Processing Equipment Market? +

Advancements in Industry 4.0 technologies, IoT-enabled sensors, and automated processing systems offer significant opportunities for manufacturers to enhance operational efficiency and precision.

Which technology segment accounted for the largest market share in 2024? +

The dry processing segment dominated the market in 2024 due to its efficiency, cost-effectiveness, and widespread use in industries such as food, chemicals, and pharmaceuticals.