- Summary

- Table Of Content

- Methodology

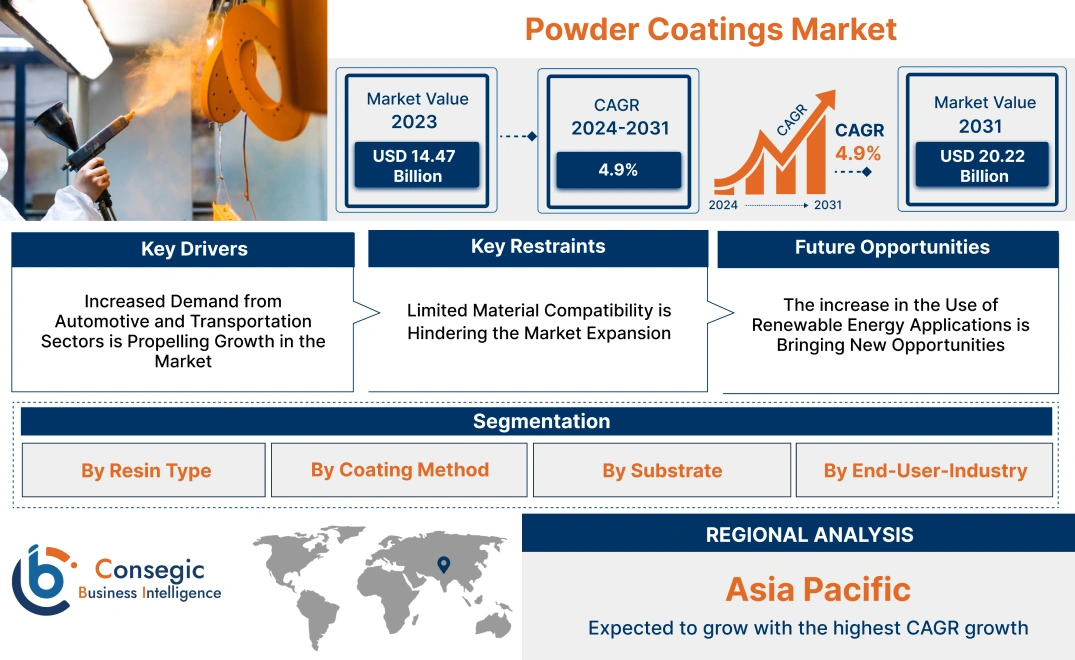

Powder Coatings Market Size:

Powder Coatings Market size is estimated to reach over USD 20.22 Billion by 2031 from a value of USD 14.47 Billion in 2023 growing at a CAGR of 4.9% from 2024 to 2031.

Powder Coatings Market Scope & Overview:

Powder coating is a type of dry finishing process used to apply a protective and decorative layer to various surfaces, primarily metals. Unlike traditional liquid paint, powder coating involves applying a dry, finely ground powder made from polymer resin, pigments, leveling agents, flow modifiers, and other additives. They are known for their toughness and resistance to chipping, scratching, fading, and wear. They allow for a wider range of colors, textures, and finishes, including glossy, matte, and metallic looks. The powder is sprayed onto the object using an electrostatic gun, which gives the powder particles a positive charge. The product's usage spans multiple industries such as automotive, architecture and construction, furniture, appliance, and aerospace due to its versatility, durability, and environmental benefits.

Powder Coatings Market Dynamics - (DRO) :

Key Drivers:

Increased Demand from Automotive and Transportation Sectors is Propelling Growth in the Market

Powder coatings provide excellent protection against corrosion, scratches, and wear, which is crucial for automotive and transportation components exposed to harsh environmental conditions like moisture, salt, and road debris. Parts such as rims, chassis, suspension components, and exterior body panels coated with powder are highly resistant to impact and weathering, extending the lifespan of vehicles and transportation equipment. Automotive manufacturers are increasingly adopting powder coatings due to the wide variety of colors, finishes, and textures available. This allows for greater design flexibility and customization of vehicle exteriors and interiors, catering to consumer preferences for visually appealing products. The heavy-duty transportation sector, including trucks, trailers, and shipping containers, requires coatings that can withstand extreme conditions. Powder coatings provide the toughness needed to protect against corrosion, chemical exposure, and impact damage, making them ideal for this sector. The adoption of automated powder coating systems in automotive manufacturing plants has increased production efficiency, allowing for consistent coating quality and faster turnaround times, driving further adoption.

Therefore, the increased demand from the automotive and transportation sectors is driven by the need for durable, cost-effective, and environmentally friendly coatings that can enhance the performance and longevity of vehicles and transportation infrastructure, boosting the powder coatings market growth.

Key Restraints :

Limited Material Compatibility is Hindering the Market Expansion

Powder coatings generally require curing at high temperatures (around 150°C–200°C) to adhere and form a smooth, durable surface. This restricts their use of materials that are sensitive to heat, such as certain plastics, composites, and thin metals that can warp, melt, or degrade under these conditions. To apply powder coatings to non-metallic substrates, special pre-treatment processes or conductive primers are often required, which can add to the cost and complexity. This limits the widespread use of powder coatings in industries that rely heavily on non-metallic materials, such as consumer electronics or certain packaging applications. Powder coatings work best on electrically conductive surfaces, such as metals, because the process typically relies on electrostatic attraction. Non-metallic substrates like wood, plastic, or glass do not naturally conduct electricity well, making it difficult to apply powder coatings using standard electrostatic methods.

Therefore, although powder coatings excel in many industrial applications, their restricted use in certain sectors and the need for special adaptations increase costs and complexity, limiting the powder coatings market demand.

Future Opportunities :

The increase in the Use of Renewable Energy Applications is Bringing New Opportunities.

The increasing use of powder coatings, particularly in renewable energy applications, presents numerous future opportunities as industries focus on sustainability, durability, and cost-efficiency. Wind turbine towers, especially those located offshore, are subject to constant exposure to moisture, salt, and extreme weather. Powder coatings provide excellent corrosion resistance, protecting the metal structures from rust and degradation, thus reducing downtime and increasing operational efficiency. Solar panel manufacturers are increasingly adopting energy-efficient production methods. Powder coating, with its low curing temperatures and absence of volatile organic compounds (VOCs), aligns well with the goals of reducing the environmental footprint of solar energy production. As the demand for energy storage technologies grows, particularly in renewable energy grids, powder coatings can be used to protect battery housings and enclosures. The coatings can offer protection against corrosion, extreme temperatures, and chemical exposure, enhancing the durability and safety of energy storage systems used in conjunction with solar and wind energy solutions.

- In September 2023, Powder coatings product development, or industrial applications, is becoming increasingly interwoven with sustainability concerns. Sustainable design attempts to reduce negative environmental impacts, conserve resources, and build long-lasting products and structures while maintaining the planet's delicate balance.

Therefore, the future powder coatings market opportunities in renewable energy applications are vast. As the world transitions to greener energy sources, the demand for durable, eco-friendly, and high-performance coatings will grow.

Powder Coatings Market Segmental Analysis :

By Resin Type:

Based on resin type the market is segmented into Thermoset- Epoxy, Polyester, Epoxy-Polyester Hybrid, Acrylic, Polyurethane, Thermoplastic- Polyvinyl Chloride (PVC), Polyolefin, Nylon, and Polyvinylidene Fluoride (PVDF).

Trends in resin type:

- Polyester powder coatings do not emit volatile organic compounds since they don't require any kind of solvents which makes them environment friendly.

The Polyester accounted for the largest revenue share of the total powder coatings market share in the year 2023.

- Polyester-based powder coatings are versatile and are used across numerous industries, such as automotive, furniture, architecture, and consumer goods. They are highly preferred for both indoor and outdoor applications due to their adaptability to different surfaces.

- Polyester powder coatings offer a variety of finishes, including glossy, matte, satin, and textured finishes. This flexibility allows manufacturers to meet diverse designs enhancing their appeal in the market.

- They typically cure at lower temperatures and faster times compared to other materials, making the manufacturing process more energy-efficient and cost-effective.

- For instance, Keystone Koating's polyester powder coating is an excellent choice for metal or outdoor workpieces, and like smooth external coatings, it is weather- and corrosion-resistant. Bulk coating materials for polyester powder coatings make its operational costs more economically reasonable.

- Thus, the polyester component in powder coatings dominated the revenue share due to its versatility, cost-effectiveness, durability, and weather resistance, boosting the powder coatings market growth.

The Polyurethane segment is anticipated to register the fastest CAGR during the forecast period.

- Polyurethane powder coatings are highly resistant to abrasion, impact, and wear, making them ideal for applications that require long-lasting finishes.

- The industrial sector's growing need for high-performance coatings that protect machinery from wear and corrosion is also propelling the demand for polyurethane coatings.

- They offer excellent UV resistance, making them a preferred choice for outdoor applications that require long-lasting color retention and gloss.

- For instance, Feihong's Polyurethane powder coating is a range of polyurethane-based powder coatings designed for outdoor use. It provides excellent UV resistance for exterior applications, as well as smoothness and high gloss.

- Thus, its expanding use in different industries for its superior durability, flexibility, and chemical resistance is making it drive the powder coatings market trends.

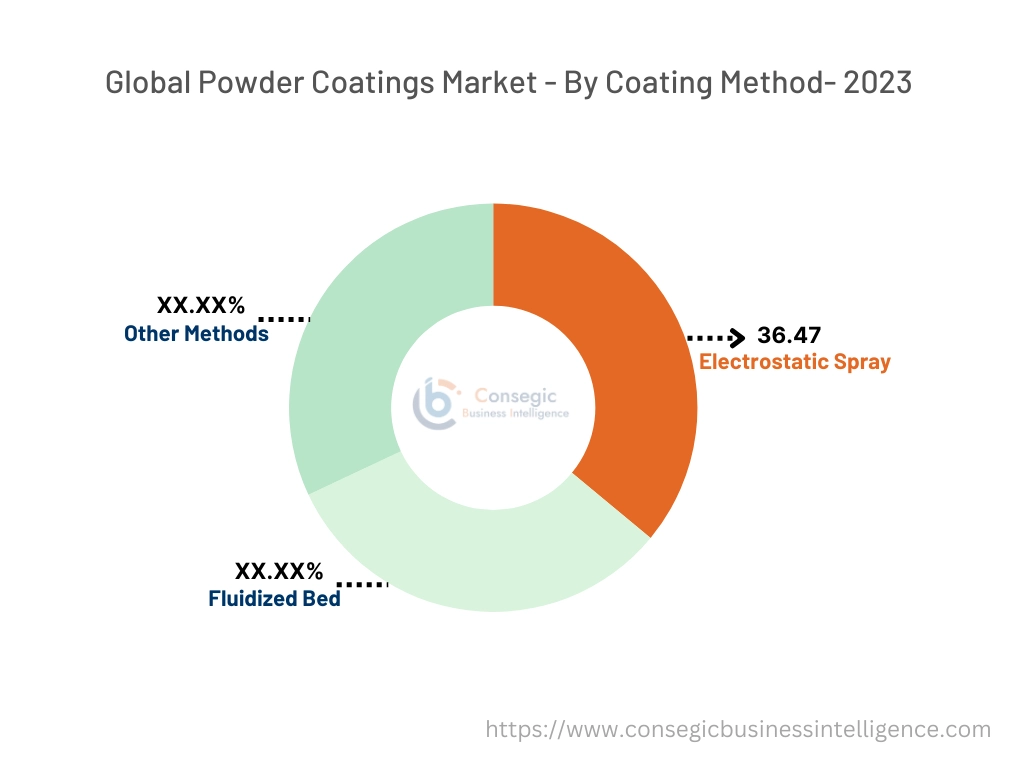

By Coating Method:

Based on coating method the market is segmented into Electrostatic Spray, Fluidized Bed, and Other Methods.

Trends in coating method:

- The electrostatic spray method has gained popularity due to its ability to achieve high transfer efficiency. The charged particles of powder coatings adhere better to the grounded substrate, reducing waste and ensuring a more uniform application. This trend is particularly beneficial in automotive and industrial applications, where precision is crucial.

- The fluidized bed method is increasingly utilized for coating large parts and complex shapes, especially in the industrial sector. This method allows for uniform coverage and is effective for items such as metal furniture and automotive components, driving demand for fluidized bed applications.

The Electrostatic Spray accounted for the revenue share of 36.47% in the year 2023.

- Electrostatic spray technology allows for the precise application of powder coatings, ensuring that the powder adheres efficiently to the substrate with minimal waste.

- The efficiency of electrostatic spraying reduces the amount of labor required to coat products, as well as material costs since the excess powder can be reused. This makes the process highly cost-effective, particularly for high-volume production runs.

- It is widely used in the automotive industry for coating parts like wheels, bumpers, and frames. It provides a durable, corrosion-resistant finish that protects vehicles from harsh environmental conditions.

- For instance, Dorken states that electrostatic powder spraying (EPS) is done during air spraying where powder particles become electrostatically charged and attach to the earthed component as a powder cloud. When heated, the powder layer melts and cools to produce a closed covering.

- Thus, the electrostatic spray component accounted for the largest revenue share due to its efficiency, high-quality finish, and versatility in the powder coating industry, boosting the powder coatings market demand.

The Fluidized Bed component segment is anticipated to register the fastest CAGR during the forecast period.

- The thicker coatings achieved through fluidized bed processes offer superior durability, impact resistance, and protection against corrosion and chemicals, which is critical in industries like construction, marine, and oil and gas.

- Fluidized bed powder coating is ideal for batch processing, where large numbers of items are dipped into the fluidized bed simultaneously. This increases production efficiency and reduces labor costs, driving its growth in high-volume manufacturing industries.

- For instance, Precision Dip Coating uses fluidized bed powder coating, which involves immersing a hot component in a bed of powder, enabling the powder to melt on the part and form a film, and then providing enough time and heat for the film to flow into a continuous coating.

- Thus, the fluidized bed segment is increasingly used in industries like oil and gas, construction, and other heavy industries due to its durable coatings and cost-effectiveness, driving the powder coatings market trends.

By Substrate:

Based on substrate the market is segmented into Metal and Non Metal.

Trends in substrate:

- The introduction of more color options and textures has made powder coatings an aesthetic as well as a functional choice for various industries.

- Advances in low-temperature curing technologies, which enable powder coatings to be applied to heat-sensitive materials like plastics and wood without damaging the substrate.

Metal accounted for the largest revenue share of the overall powder coatings market share in the year 2023.

- Powder coatings are extensively used on metal substrates due to their excellent durability, corrosion resistance, and aesthetic finish. This includes applications in automotive parts, appliances, furniture, industrial machinery, and construction materials, where metal is the primary material.

- Structural metal parts, including steel beams, metal doors, and window frames, are often powder-coated to improve durability, corrosion resistance, and aesthetics. The growing global infrastructure development has significantly increased the demand for powder coatings on metals.

- The thick, uniform layer of powder coatings can withstand impacts, scratches, and wear, making it ideal for metal surfaces in industries like automotive and industrial manufacturing.

- For instance, the powder coating process requires preheating of items before applying fluidized powder indicating that this technology is mostly for metal parts. Although steel is the most commonly coated material, copper and aluminum are also viable options.

- Thus, the metal component accounted for the largest revenue share in the powder coatings market because of its durability, environmental benefits, cost-effectiveness, and protective properties of powder coatings making them ideal for metal surfaces, driving powder coatings market expansion.

The Non-Metal segment is anticipated to register the fastest CAGR during the forecast period.

- Recent technological advancements have enabled powder coatings to be applied on non-metal surfaces, such as plastics, wood, glass, and composites. This has significantly expanded the scope of powder coatings beyond traditional industries like automotive and construction.

- Powder coatings are being widely adopted for wood and medium-density fiberboard (MDF) in the furniture industry. The ability of powder coatings to offer a variety of textures and colors, while also being more sustainable, has fueled their growth in this sector.

- Powder coatings on non-metal surfaces offer significant cost savings due to their minimal waste, efficient application process, and reduced curing times.

- Thus, the Non-Metal component segment is expected to register the fastest in the powder coatings market due to the expanding range of applications across industries such as furniture, electronics, automotive, and consumer goods.

By End-User-Industry:

Based on end-user industry the market is segmented into architectural, electronics, automotive, industrial, aerospace, marine, and others.

Trends in end user industry:

- The rapid adoption of smart home devices, IoT (Internet of Things) devices, and wearables is further fueling the demand for powder coatings in the electronics segment.

The Automotive accounted for the largest revenue share in the year 2023.

- Powder coatings are widely used across a variety of automotive components, including wheels, body panels, underbody parts, frames, engine parts, and even interior components. The automotive industry favors powder coatings for their durability, aesthetic appeal, and protection against harsh environmental conditions.

- Powder coatings are highly effective on these non-metal components, providing a strong finish without adding significant weight to the vehicle.

- EV manufacturers are using powder coatings on components such as battery enclosures, frames, and electrical parts, as they offer insulation properties and protection from heat, chemicals, and environmental wear.

- For instance, Precision Coating Technology and Manufacturing Inc. powder coating offers numerous benefits to large automobile sector customers. It is rust-resistant, provides superior protection against the elements, coats uniformly, and is environmentally friendly.

- Thus, trends such as the growth of electric vehicles, the use of lightweight materials, and the focus on sustainability have further driven the dominance of the automotive segment in the powder coatings market.

The Electronics component segment is anticipated to register the fastest CAGR during the forecast period.

- The surge in demand for consumer electronics, including smartphones, wearables, and home appliances, is driving the electronics segment's growth. As consumers seek more durable, sleek, and visually appealing devices, manufacturers are turning to powder coatings to meet these requirements.

- The electronics industry requires high-performance coatings to protect sensitive components from environmental factors such as moisture, chemicals, and mechanical wear. Powder coatings provide a tough, durable finish that can extend the lifespan of electronic devices and components by offering protection against corrosion, impact, and scratches.

- Plastics and polymers in electronic devices benefit from powder coatings as they protect the surfaces from wear and improve the device's overall appearance without affecting the weight or design.

- For instance, APCL has a deep understanding of the pre-treatment, masking, and coating needs for switchboard panels, and they expertly coat and finish them as needed. The toughness and longevity of their powder coatings boost productivity, increase yields, and reduce downtime.

- Thus, the Electronics component segment is projected to register the fastest in the powder coatings market due to the increasing demand for durable, protective, and aesthetically pleasing coatings in the consumer electronics, smart devices, and electric vehicle sectors.

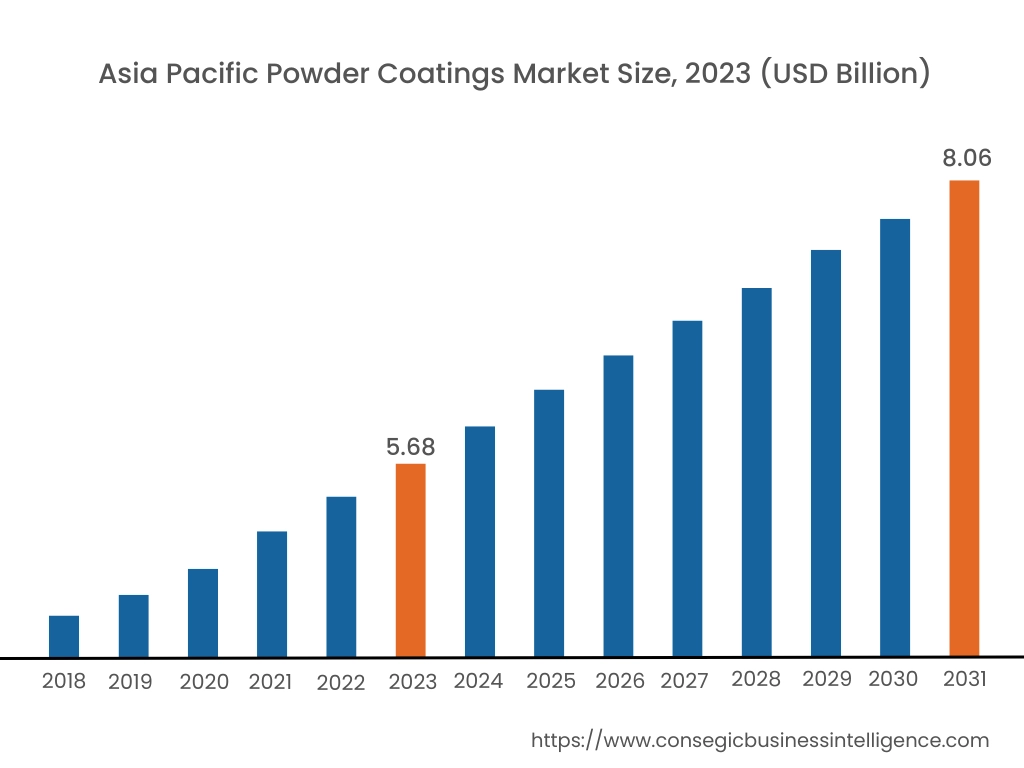

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

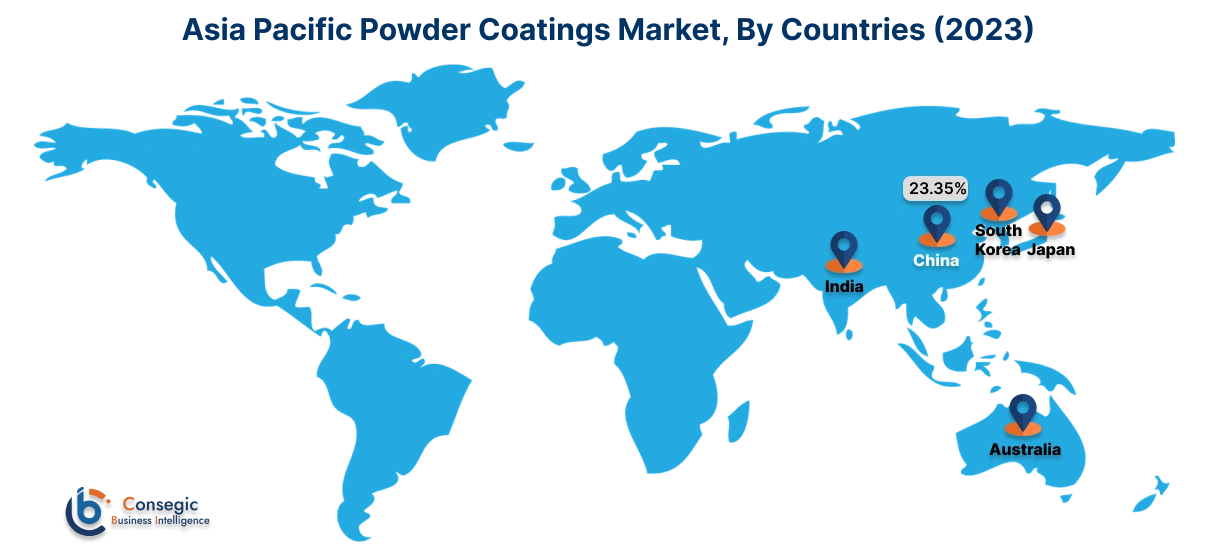

In 2023, Asia Pacific accounted for the highest market share at 39.27% and was valued at USD 5.68 Billion, and is expected to reach USD 8.06 Billion in 2031. In Asia Pacific, China accounted for the highest market share of 23.35% during the base year of 2023. As per the powder coatings market analysis, in the Asia Pacific region, the construction industry is experiencing rapid growth due to urban development and infrastructure projects. Powder coatings are being utilized for architectural applications, including window frames, doors, and other exterior elements, owing to their corrosion resistance and aesthetic versatility.

North America is expected to witness the fastest CAGR over the forecast period of 5.6% during 2024-2031. The automotive industry in North America, particularly in the U.S. and Canada, is a significant driver for powder coatings. The demand for durable, corrosion-resistant coatings for automotive components such as wheels, chassis, and exterior parts is high, especially with the rise of electric vehicles (EVs), where powder coatings are being used to coat lightweight components.

- In 2024, American Powder Coatings' (APC) mission was to develop throughout North America as a leader in the production of high-quality coatings while providing timely and dependable service to OEMs and Custom Coaters. A strong work ethic, along with a highly experienced workforce, has helped APC become a recognized industry leader in powder paints, offering high-quality coatings, exceptional customer service, and competitive pricing.

In Europe, the powder coating market is witnessing steady growth, driven by a combination of technological advancements, increasing environmental regulations, and rising demand across various industries such as automotive, construction, and consumer goods. The region's strong manufacturing base and focus on sustainability make it a key player in the global powder coating market.

The Middle East and Africa markets are witnessing innovations in powder coating technologies, including the development of specialized formulations for high-temperature applications and improved color consistency. These advancements are making powder coatings more versatile and appealing to various industries.

Latin America is becoming more focused on sustainable practices, especially in industries like automotive, construction, and manufacturing. Powder coatings are a preferred option in this context due to their low environmental impact and zero VOC emissions.

Top Key Players & Market Share Insights:

The powder coatings market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the powder coatings market. Key players in the powder coatings industry include-

- AkzoNobel N.V.(Netherlands)

- PPG Industries, Inc. Ltd. (USA)

- Axalta Coating Systems (USA)

- BASF SE (Germany)

- Jotun Group (Norway)

- Sherwin-Williams Company (USA)

- Kansai Paint Co., Ltd. (Japan)

- Nippon Paint Holdings Co., Ltd. (Japan)

- TCI Powder Coatings (USA)

- DSM Coating Resins (Netherlands)

Recent Industry Developments :

Product Launches:

- In June 2024, Jotun launched CX-rated anticorrosive powder coating which is the industry's first and only CX-rated anticorrosive powder coating solution, industries now have access to tried-and-true methods for protecting vital equipment in the harshest conditions.

Partnerships and Collaborations:

- In December 2023, AkzoNobel Powder Coatings partnered with CoatingAI to explore new sustainable frontiers. Flightpath, an industry-first technology, optimizes machine settings to eliminate errors and overspray while improving powder usage, hence lowering costs, avoiding rework, and saving time and energy.

Powder Coatings Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 20.22 Billion |

| CAGR (2024-2031) | 4.9% |

| By Resin Type |

|

| By Coating Method |

|

| By Substrate |

|

| By End-User Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Powder Coatings Market? +

Powder Coatings Market size is estimated to reach over USD 20.22 Billion by 2031 from a value of USD 14.47 Billion in 2023 growing at a CAGR of 4.9% from 2024 to 2031.

What is the key market trend? +

The powder coating market is experiencing several key trends driven by advancements in technology, environmental concerns, and evolving consumer demand across multiple industries.

What specific segmentation details are covered in the coatings market report? +

The specific segments that are covered in the powder coatings market report are resin type, coating method, substrate, and end-user industry.

Who are the major players in the powder coatings market? +

The major players in the powder coatings market are AkzoNobel N.V. (Netherlands), PPG Industries, Inc. Ltd. (USA), Sherwin-Williams Company (USA), Axalta Coating Systems (USA), BASF SE (Germany), Jotun Group (Norway), Kansai Paint Co., Ltd. (Japan), Nippon Paint Holdings Co., Ltd. (Japan), TCI Powder Coatings (USA), and DSM Coating Resins (Netherlands)