- Summary

- Table Of Content

- Methodology

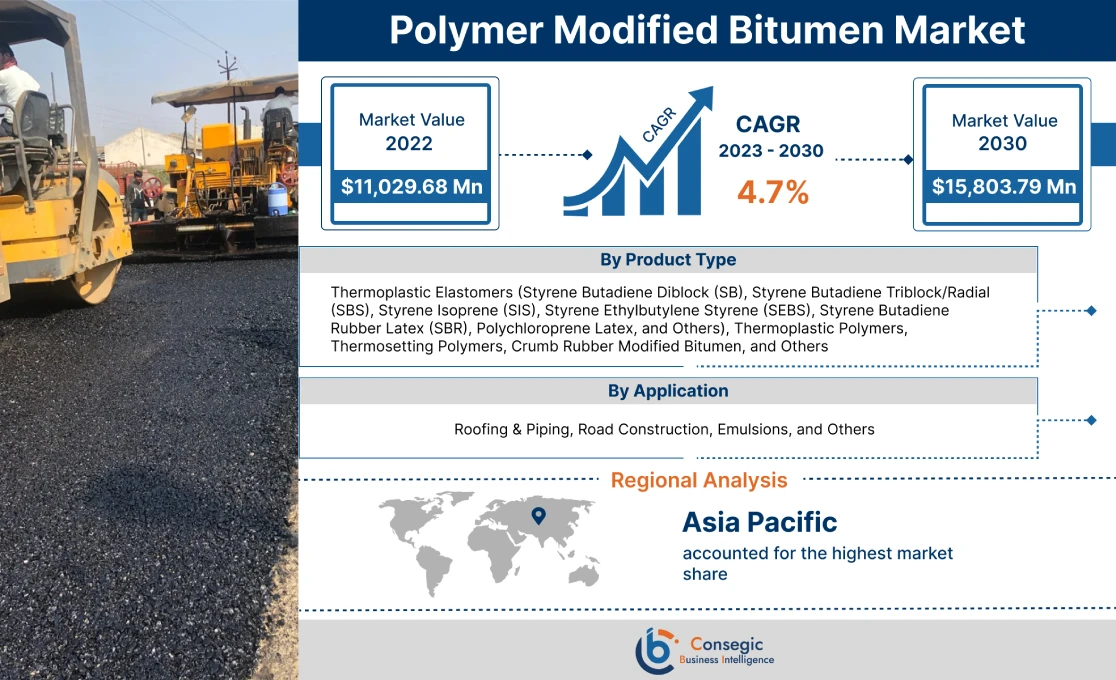

Polymer Modified Bitumen Market Size :

Consegic Business Intelligence analyzes that the Polymer Modified Bitumen market size is growing with a CAGR of 4.7% during the forecast period (2023-2030), and the market is projected to be valued at 15,803.79 Million by 2030 from 11,029.68 Million in 2022.

Polymer Modified Bitumen Market Scope & Overview:

Bitumen is a material known for being strongly adhesive and resistant to damage from water and oil spills. Polymer Modified Bitumen (PMB) represents a group of road bituminous binders specifically designed and manufactured to improve the durability of asphalt.

It is a bituminous material formed by mixing standard bitumen with polymers, which are either added to the bitumen in a pre-modification process or added during the mixing process. The addition of polymers improves the physical properties of bitumen, in terms of elasticity, durability, and resistance to weathering, aging, and cracking.

Furthermore, it is produced using various polymers such as thermoplastic elastomers, thermoplastic polymers, and thermosetting polymers. The major function is to enhance the performance of binders to withstand heavy-duty traffic or distressed pavement surfaces in adverse climatic conditions.

Polymer Modified Bitumen Market Insights :

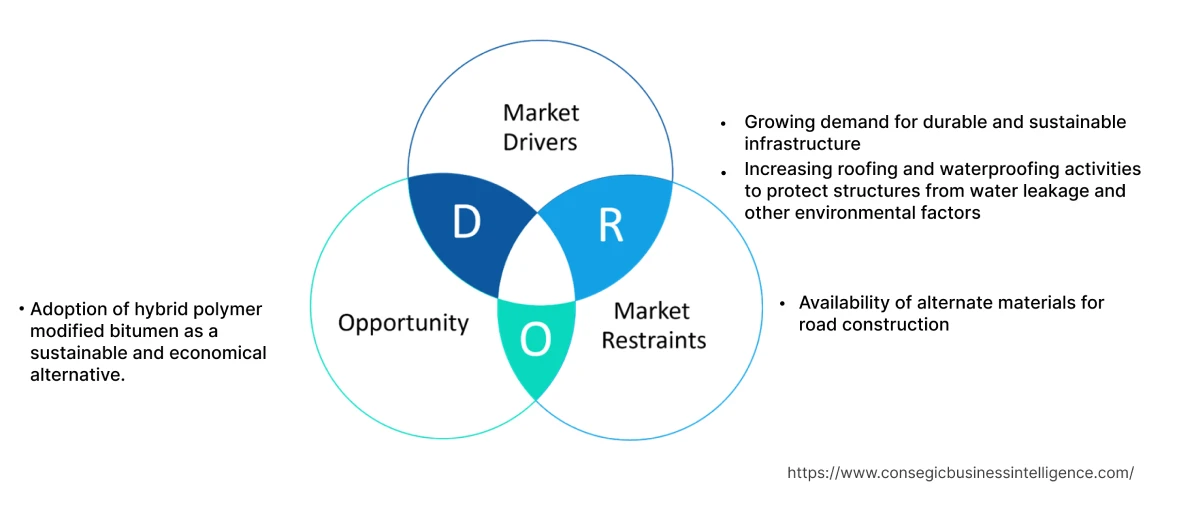

Key Drivers :

Growing demand for durable and sustainable infrastructure

The primary objective of PMB is to provide durability and sustainability to roads and other types of construction designs. Further, polymer modified bitumen provides greater rigidity, better resistance to permanent deformation, and higher resistance to road cracks. The growth of infrastructure construction including roads, bridges, and airports, requires it to enhance durability and longevity.

In the construction of airports, it is widely required to make the runway more resistant to rutting in hot weather and to improve the durability of airfield pavements. For instance, according to the Airport Construction and Investment Review Report 2022 by the Centre for Aviation (CAPA), there are 177 infrastructure projects at European airports, with a collective investment value of USD 109 billion in March 2022. Thus, the analysis of market trends shows that the increase in the number of infrastructure projects, particularly airports is driving the demand for longevity of airfield pavements which is driving the polymer modified bitumen market growth.

Increasing roofing and waterproofing activities to protect structures from water leakage and other environmental factors

Polymer modified bitumen offers greater longevity and thermal efficiency in roofing applications. It improves self-healing by preventing cracks. Further, modified bitumen is widely used for waterproofing roofs, basements, bridges, and below-ground structures, among others. The exceptional waterproofing quality of bitumen makes it perfectly suited for a range of roofing materials, such as single-ply membrane systems, felt roofing, and asphalt roofing.

Moreover, modified bitumen is the most common material used for the production of breathable membrane roofs. Such types of roof membranes are crucial in commercial and residential buildings to prevent the build-up of condensation. For instance, according to the report, the overall value of construction in the U.S. including residential, non-residential, and non/building combined increased by over 8% between 2020 and 2021. Hence, the analysis of market trends shows that the growth of the construction industry indicates the increasing demand for waterproofing roofs and walls, thereby driving the polymer modified bitumen market growth.

Key Restraints :

Availability of alternate materials for road construction

Increasing usage of alternative materials of polymer modified bitumen such as crushed stones and lignin, among others. Such alternative materials are widely used in the construction of roads which hampering the market. Crushed stone is one of the most basic mineral commodities. It is a widely available, and cost-effective product. Various types of rocks are used to make crushed stone including limestone, sandstone, granite, trap rock, marble, and slate, among others. They are highly used in the construction of highways and buildings. For instance, according to the North Carolina Department of Environmental Quality, in the construction of a two-lane asphalt highway, about 25,000 tons of crushed stone is used per mile. Thus, the market analysis shows that for this reason, the availability of alternate materials for road construction is hampering the polymer modified bitumen market demand.

Future Opportunities :

Adoption of hybrid polymer-modified bitumen as a sustainable and economical alternative.

The development of new and innovative bitumen formulations and applications is anticipated to create new opportunities for the market players. For instance, according to the article published by ResearchGate, the adoption of hybrid bitumen provides a sustainable and economical approach to mitigating problems observed in conventional bitumen including the formation of cracks under repeated loading conditions.

This involves the combination of two groups of polymers, namely elastomer, and elastomer that are involved in reducing the temperature susceptibility and providing improved performance as compared to conventional bitumen. Thus, analysis of market trends portrays that the growth of the need for pavement rehabilitation and maintenance is proving a lucrative prospect to the key players for the development of bituminous materials that are sustainable, environmentally friendly, and cost-efficient. This, in turn, drives the polymer modified bitumen market opportunities.

Polymer Modified Bitumen Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2017-2030 |

| Market Size in 2030 | USD 15,803.79 Million |

| CAGR (2023-2030) | 4.7% |

| By Product Type | Thermoplastic Elastomers (Styrene Butadiene Diblock (SB), Styrene Butadiene Triblock/Radial (SBS), Styrene Isoprene (SIS), Styrene Ethylbutylene Styrene (SEBS), Styrene Butadiene Rubber Latex (SBR), Polychloroprene Latex, and Others), Thermoplastic Polymers, Thermosetting Polymers, Crumb Rubber Modified Bitumen, and Others |

| By Application | Roofing & Piping, Road Construction, Emulsions, and Others |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | Shell Global, Nynas AB, TotalEnergies, Exxon Mobil Corporation, Colas Limited, Indian Oil Corporation Limited, Puma Bitumen, Alma Petroli, Porner Group, Maruti Bitumen Pvt Ltd., and Sika India Pvt. Ltd. |

Polymer Modified Bitumen Market Segmental Analysis :

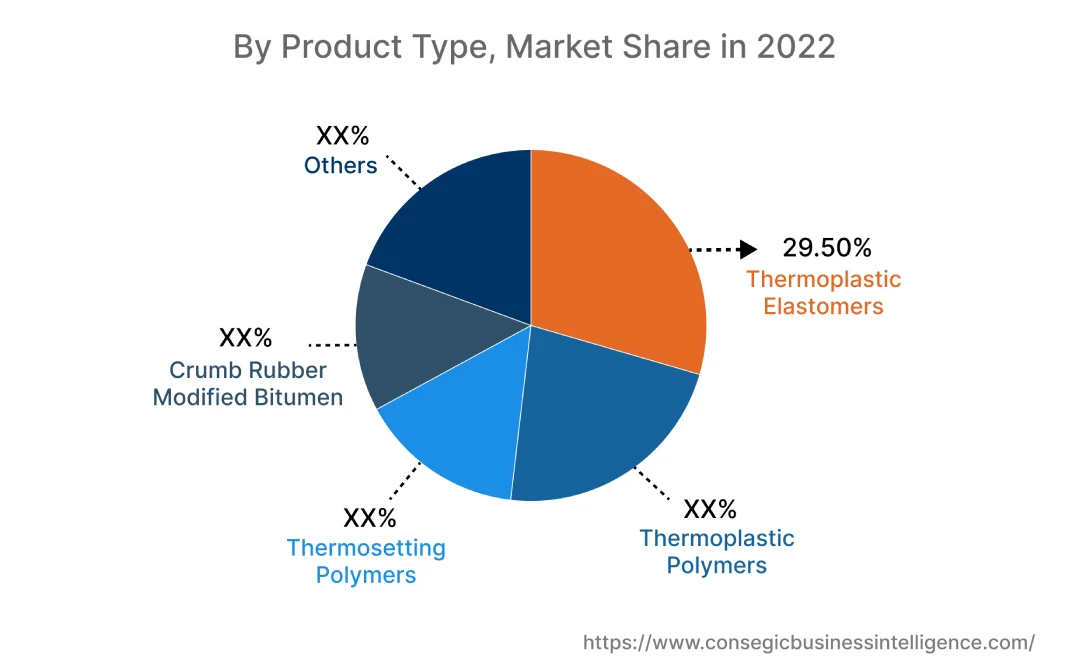

By Product Type :

The product type segment is categorized into thermoplastic elastomers, thermoplastic polymers, thermosetting polymers, crumb rubber-modified bitumen, and others. In 2022, the thermoplastic polymer segment accounted for the highest market share of 29.50% in the global polymer modified bitumen market. Thermoplastic polymer-based polymer modified bitumen has excellent flexibility, durability, and ease of processing which makes it suitable for a wide range of applications such as street and highway construction. Also, it is widely used in waterproofing and roofing activities. For instance, according to the statistics published by Statista, in 2021, highway and street construction in the U.S. reached a market size of USD 100 billion and is expected to reach USD 151 billion in 2025. Thus, the increase in the number of street and highway construction activities is the key factor proliferating the polymer modified bitumen market trends.

However, crumb rubber-modified bitumen is expected to be the fastest-growing segment in the market during the forecast period owing to its excellent mechanical properties such as durability, and fatigue resistance. As a result, crumb rubber-modified bitumen is ideal for heavy traffic areas including highways and airport construction which are expected to drive the polymer modified bitumen market opportunities.

By Application :

The application segment is divided into roofing & piping, road construction, emulsions, and others. In 2022, the road construction segment accounted for the highest market share in the polymer modified bitumen market share. Polymer modified bitumen is widely used for road construction due to its enhanced durability and greater resistance to fatigue and cracking properties. For instance, according to the India Brand Equity Foundation, the Indian government aims to construct 65,000 km of national highways worth USD 741.51 billion by 2022. As a result, the analysis of segment trends shows that the increasing number of road construction projects is driving the demand for durability and longevity of road pavements which is proliferating the polymer modified bitumen market demand.

However, the roofing & piping segment is expected to grow at the fastest CAGR during the forecast period driven by the increasing use of polymer modified bitumen in the roofing industry due to its excellent properties such as weathering and waterproofing and high-temperature resistance. Additionally, the analysis of segment trends shows that it reduces maintenance costs and increases the lifespan of roofing and piping systems, thereby, expected to drive the polymer modified bitumen market trends.

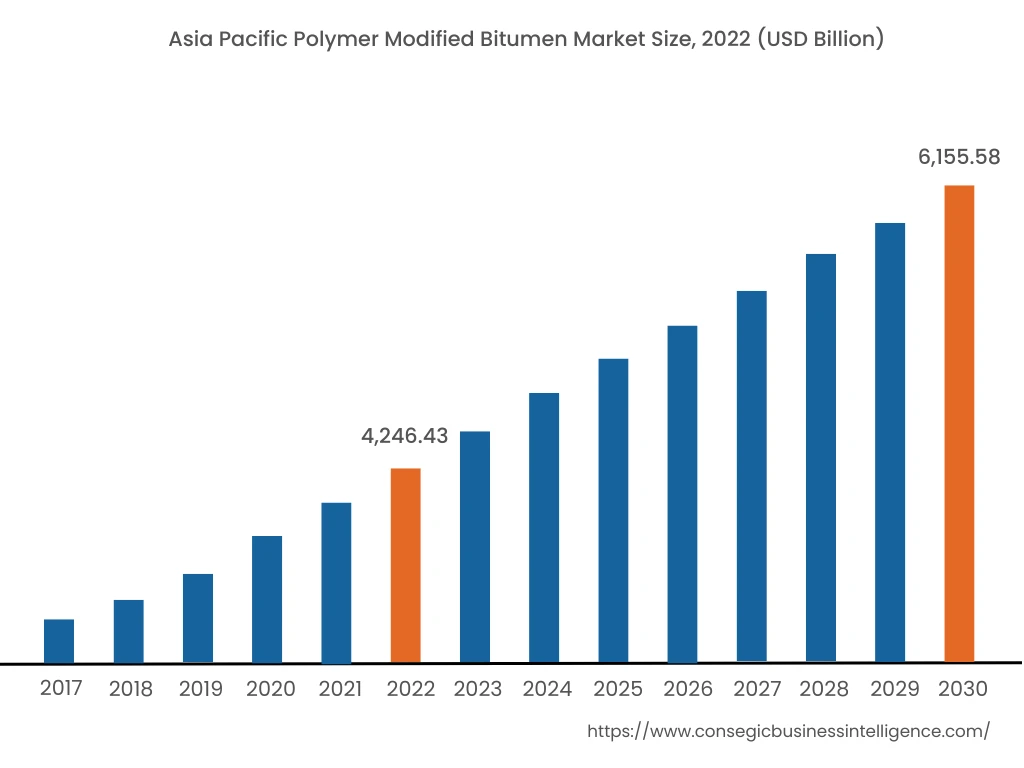

By Region :

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

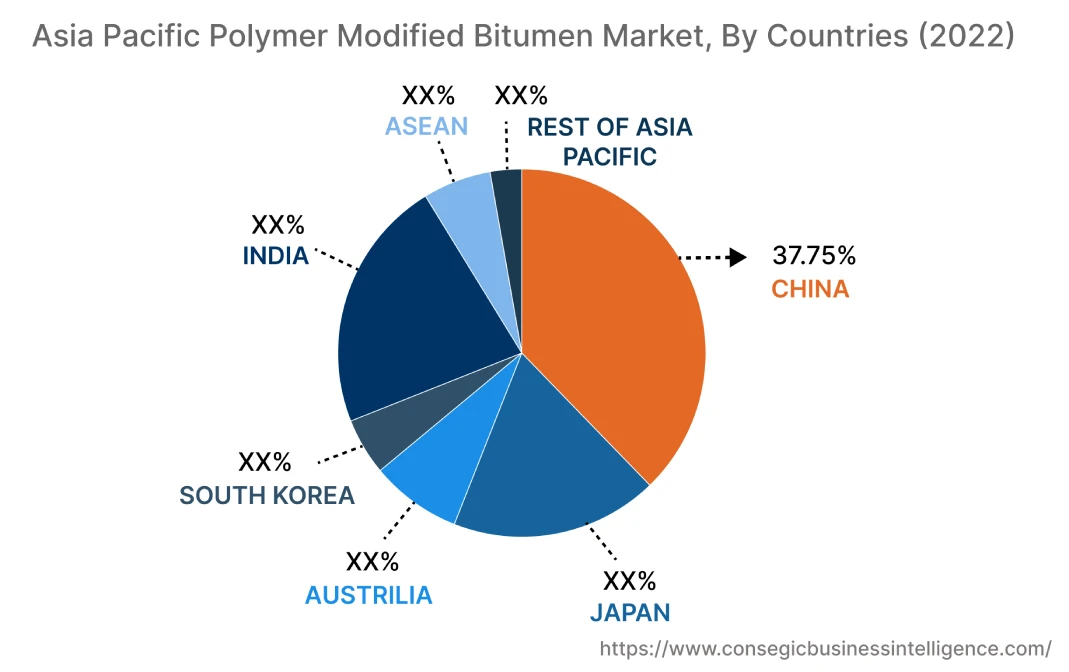

In 2022, Asia Pacific accounted for the highest market share at 38.50% valued at USD 4,246.43 billion, and is expected to reach USD 6,155.58 billion in 2030. In Asia Pacific, China accounted for the highest market share of 37.75% of the region's polymer modified bitumen market share during the base year of 2022. As per the polymer modified bitumen market analysis, this is due to the growth of investment in infrastructure development particularly in countries including China and India which is propelling the demand to withstand heavy-duty traffic and extreme weather conditions. For instance, according to the India Brand Equity Foundation in June 2022, the Minister of Road Transport and Highways opened 15 national highway projects worth USD 1.7 billion in Patna and Hajipur, Bihar. As a result, the growth of infrastructure activities is driving the polymer modified bitumen market expansion in the region.

Moreover, North America is expected to grow at the fastest CAGR of 5.5% during the forecast period. The analysis of regional trends shows that this is due to the increasing construction activities, particularly in the U.S. that require polymer modified bitumen to provide robust roads with higher stability and rigidity, and improved resistance to rain.

Top Key Players & Market Share Insights:

The polymer modified bitumen market is highly competitive, with several large players and numerous small and medium-sized enterprises. These companies have strong research and development capabilities and a strong presence in the polymer modified bitumen market through their extensive product portfolios and distribution networks. The market is characterized by intense competition, with companies focusing on expanding their product offerings and increasing their polymer modified bitumen market share through mergers, acquisitions, and partnerships. The key players in the polymer modified bitumen industry include-

- Shell Global

- Nynas AB

- TotalEnergies

- Exxon Mobil Corporation

- Colas Limited

- Indian Oil Corporation Limited

- Puma Bitumen

- Alma Petroli

- Porner Group

- Maruti Bitumen Pvt Ltd.

- Sika India Pvt. Ltd.

Recent Industry Developments :

- In February 2023, Sika South Africa announced the acquisition of Index Construction Systems to help expand the company's product range with the addition of the renowned Bitumen range.

- In December 2022, Puma Bitumen announced the launch of a sustainable binder to lower the carbon footprint of bituminous products, supporting the efforts of the industry toward sustainability.

Key Questions Answered in the Report

What was the market size of the polymer modified bitumen market in 2022? +

In 2022, the market size of polymer modified bitumen was USD 11,029.68 million.

What will be the potential market valuation for the polymer modified bitumen market by 2030? +

In 2030, the market size of polymer modified bitumen will be expected to reach USD 15,803.79 million.

What are the key factors driving the growth of the polymer modified bitumen market? +

Growing demand for durable and sustainable infrastructure and increasing roofing and waterproofing activities are the key factors driving the growth of the polymer modified bitumen market.

What is the dominating segment in the polymer modified bitumen market by product type? +

In 2022, the thermoplastic polymer segment accounted for the highest market share of 29.50% in the overall polymer modified bitumen market.

Based on current market trends and future predictions, which geographical region will have the fastest impact on the polymer modified bitumen market's growth in the coming years? +

North America is expected to be the fastest-growing region in the market during the forecast period.