- Summary

- Table Of Content

- Methodology

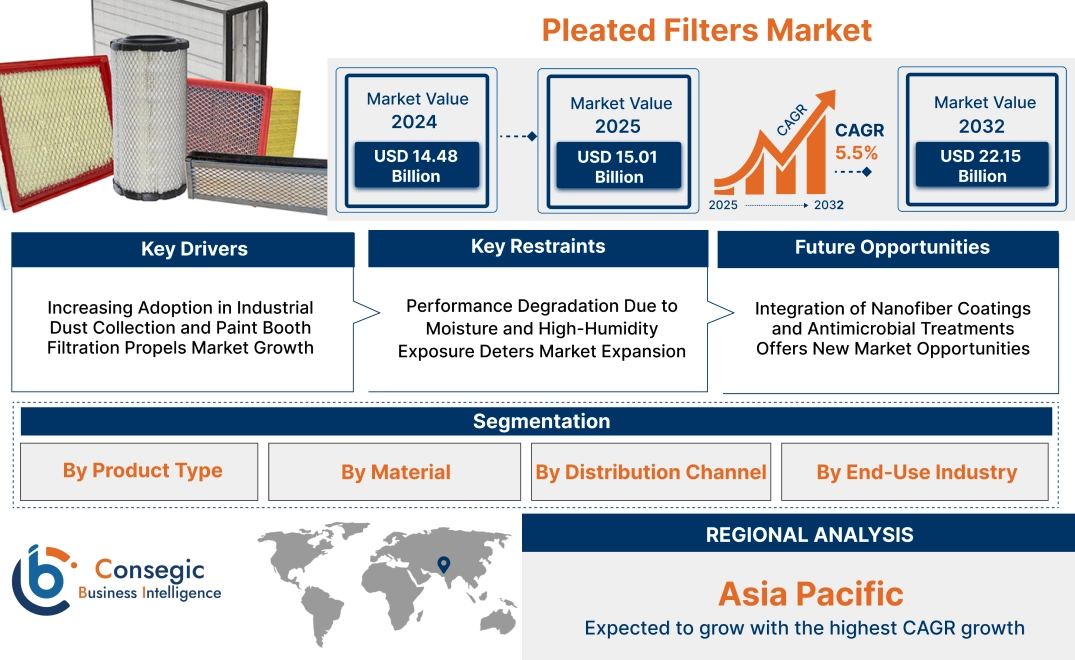

Pleated Filters Market Size:

Pleated Filters Market size is estimated to reach over USD 22.15 Billion by 2032 from a value of USD 14.48 Billion in 2024 and is projected to grow by USD 15.01 Billion in 2025, growing at a CAGR of 5.5% from 2025 to 2032.

Pleated Filters Market Scope & Overview:

Pleated filters are air or liquid filtration components with extended surface areas achieved using folded media designs, enabling more particle retention and longer service lives. The filters find applications in all HVAC systems, cleanrooms, water treatment equipment, and industrial ventilation systems to provide clean, controlled environments.

Constructed of materials like polypropylene, polyester, cellulose, and fiberglass, these filters provide superb dust-holding capacity, stable airflow, and consistent filtration efficacy. Their strength in rigid frameworks and robust pleat design is responsible for providing mechanical stability regardless of pressure variation, while adaptation to various units of housing units provides flexibility with installation.

Pleated filters provide important advantages such as less maintenance frequency, superior efficiency over ranges of particle size, and lower operating costs thanks to longer utilization cycles. Their effectiveness in the removal of airborne or fluid-borne impurities makes them a reliable option for general-purpose and high-performance filtering systems, as well as a guarantee of clean operation in non-critical as well as critical environments.

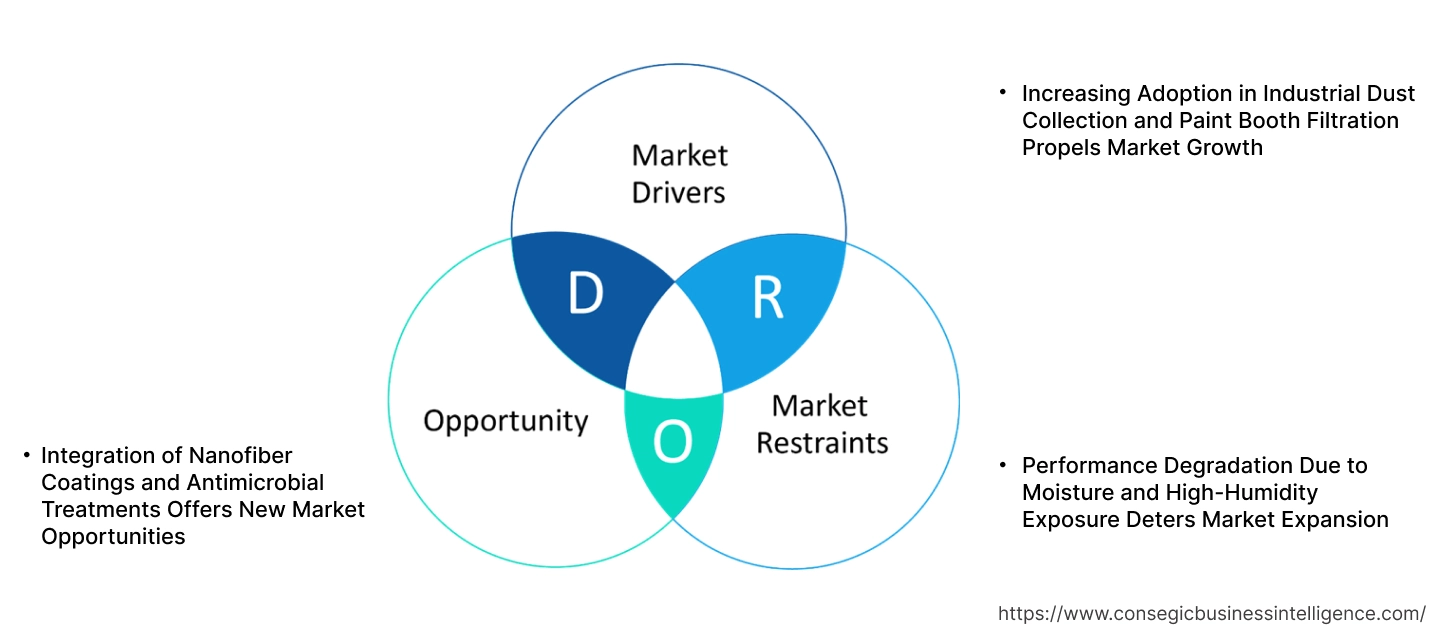

Key Drivers:

Increasing Adoption in Industrial Dust Collection and Paint Booth Filtration Propels Market Growth

Pleated filters are commonly applied in industrial dust collectors and paint booth ventilation systems to provide efficient collection of fine particulate matter. They are designed to provide a high filtration surface area in compact housings, which enables long service life and low maintenance frequency. In metalworking, woodworking, powder coating, and automotive refinishing industries, these filters provide safe air quality while safeguarding equipment against particulate damage. Their resistance to dust storage and structural durability under sustained airflow make them most suitable for process atmospheres with high airborne particulate burdens. OSHA and EPA requirements for workplace exposure limits are also driving the placement of high-efficiency filtration systems. As industrial operators themselves are paying greater attention to air quality compliance and plant continuity, demand is building for long-lasting and effective filter media—propelling pleated filters market expansion.

Key Restraints:

Performance Degradation Due to Moisture and High-Humidity Exposure Deters Market Expansion

In wetter environments or situations involving exposure to water-based aerosols, pleated filters utilizing cellulose or blended media generally suffer performance decline. Pleat collapse, microbial growth, and fiber saturation from moisture penetration diminish filtration efficiency and speed up media degradation. Such is a problem in cooling tower inlets, coastal sites, or commercial restaurants where humidity remains high. Although synthetic and hydrophobic media alternatives exist, they usually entail greater expense and longer lead times. Moisture-prone area facility operators usually experience more frequent maintenance and system inefficiencies when conventional filters prematurely fail. These operational issues restrict product suitability and lower end-user confidence in humidity-sensitive applications. Consequently, despite increasing demand for high-efficiency filtration, susceptibility to moisture exposure continues to be a major hindrance to pleated filters market growth.

Future Opportunities:

Integration of Nanofiber Coatings and Antimicrobial Treatments Offers New Market Opportunities

Technological advancements in pleated filter media are enabling performance improvements by incorporating nanofiber coatings and antimicrobial surface treatments. Nanofiber coatings enhance the ability to capture submicron particles with low airflow resistance, which increases filtration efficiency and energy performance. Concurrently, antimicrobial coatings prevent microbial growth on the filter surface, increasing service life and enabling hygienic practices in healthcare, cleanroom, and transportation environments. These technologies are being implemented in hospitals, life science labs, and food processing facilities where air cleanliness and contamination control are mission-critical. The trend toward multifunctional filtration solutions is being driven by end-user need for sophisticated features that extend beyond particulate capture. As business increasingly demands better air quality, less bio-contamination, and more efficient operating expenses, engineered filter media such as these are gaining popularity—building new pleated filters market opportunities fueled by necessity and growth in performance-based applications.

Pleated Filters Market Segmental Analysis :

By Product Type:

Based on product type, the pleated filters market is segmented into air filters, oil filters, food and beverage filters, and others.

The air filters segment accounted for the largest revenue share in 2024.

- Air filters are widely used in HVAC systems, cleanrooms, and industrial air handling units due to their high efficiency in capturing airborne contaminants.

- The dominance of this segment is supported by strict indoor air quality regulations and growing awareness regarding respiratory health in commercial and residential spaces.

- Increasing installations of centralized air purification systems in urban developments is one of the major segmental trends.

- For instance, in February 2025, Filter King LLC, USA’s largest custom pleated air filter manufacturer, specializing in high-quality HVAC and furnace filters, opened a new manufacturing and distribution center in Las Vegas, Nevada. This decision enabled the company to increase their presence across the Southeastern United States.

- The consistent expansion of construction and healthcare sectors globally supports the strong pleated filters market demand in air filtration.

Oil filters segment is expected to grow at the fastest CAGR during the forecast period.

- Rising vehicle production and increasing adoption of preventive maintenance services in the automotive sector is propelling oil filter need.

- The oil filters segment benefits from the growing requirement for equipment efficiency and longer operational life in heavy-duty industrial machinery.

- This trend is further reinforced by technological improvements in pleated filter media, enhancing contaminant retention and flow efficiency.

- According to the pleated filters market analysis, rising industrial automation and vehicular dependency contribute to segment growth.

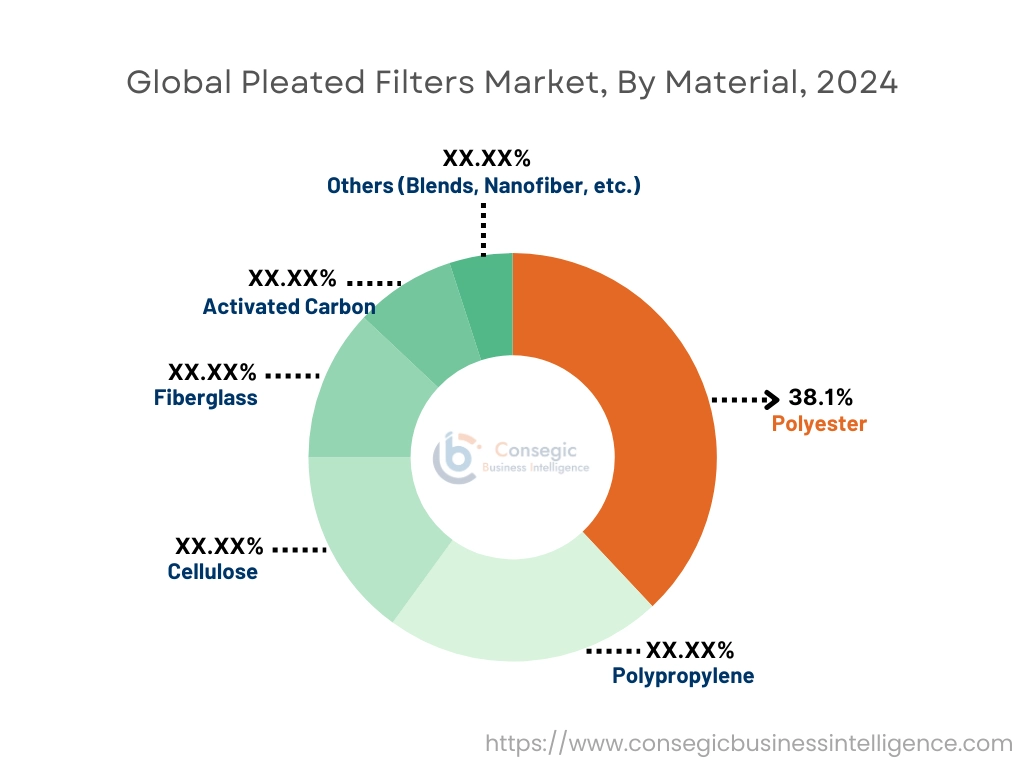

By Material:

Based on material, the market is segmented into polyester, polypropylene, cellulose, fiberglass, activated carbon, and Others (Blends, Nanofiber, etc.).

Polyester held the dominant pleated filters market share by 38.1% in 2024.

- Polyester filters are preferred for their durability, resistance to moisture, and ability to withstand higher temperatures.

- These filters offer excellent particulate removal performance in both dry and humid environments, making them suitable across HVAC and industrial applications.

- The need for long-lasting and cost-effective filter materials continues to rise, supporting the market expansion.

- Advancements in nonwoven polyester media and lamination technologies are among the key pleated filters market trends influencing this segment.

The Others (Blends, Nanofiber, etc.) segment is projected to witness the fastest CAGR.

- Nanofiber-based pleated filters provide ultra-fine filtration capabilities, enabling superior efficiency even in high-flow systems.

- They are gaining popularity in pharmaceutical, cleanroom, and semiconductor environments where submicron filtration is critical.

- The increasing focus on energy-efficient filtration solutions and compact design is driving innovation in material compositions.

- According to the pleated filters market analysis, the rising use of smart filtration systems integrating advanced media is boosting this subsegment’s outlook.

By Distribution Channel:

Based on distribution channel, the market is divided into OEM and aftermarket.

The aftermarket segment generated the highest revenue in 2024.

- The replacement frequency of pleated filters in HVAC, industrial, and automotive systems makes aftermarket channels essential to meet recurring demand.

- Strong distributor networks and the availability of a wide range of specifications drive consumer preference toward aftermarket purchases.

- The rising trend of DIY maintenance and serviceability of filter units further accelerates requirements in this channel.

- This segment plays a crucial role in supporting the pleated filters market growth by ensuring product accessibility across regional markets.

OEMs are expected to register the fastest CAGR during the forecast period.

- Their integration into HVAC systems, industrial equipment, and medical devices is pushing OEM partnerships.

- Manufacturers are increasingly collaborating with filter media developers to offer high-performance integrated solutions.

- OEMs benefit from offering application-specific customization, appealing to a growing end-user base seeking turnkey solutions.

- The expanding industrial and infrastructure sectors across developing nations are creating significant pleated filters market demand through OEM channels.

By End-Use Industry:

Based on end-use industry, the pleated filters market is segmented into HVAC, automotive, pharmaceuticals & healthcare, food & beverage, chemicals, oil & gas, water & wastewater treatment, electronics, power generation, aerospace & defense, and others.

The HVAC segment held the dominant pleated filters market share in 2024.

- Rising demand for energy-efficient air filtration in commercial buildings, data centers, and public institutions is propelling HVAC adoption.

- Regulatory mandates for air quality and environmental certifications continue to drive upgrades in HVAC filtration standards.

- Technological developments in filter design, including low-pressure-drop filters, support system efficiency.

- Consistent global urbanization and the construction of smart infrastructure projects boost pleated filters market trends in HVAC.

The pharmaceuticals & healthcare segment is expected to exhibit the fastest CAGR.

- Pharmaceutical cleanrooms and hospital air handling units require high-efficiency particulate filters to maintain sterility and safety.

- Pleated filters are favored for their compatibility with HEPA pre-filtration systems and ease of replacement in sterile environments.

- For instance, in April 2025, Rensa received the UL 900 Safety Standards certification for SuperFlo HEPA V-Bank and HEPA Deep Pleat filters. This ensures that these filters provide increased safety to customers in critical environments such as healthcare, data centres and advanced manufacturing.

- With the rising need for biopharmaceuticals and global vaccine manufacturing, the segmental analysis reflects robust growth potential in healthcare.

- Enhanced hygiene protocols and investments in hospital infrastructure post-pandemic have boosted the pleated filters market expansion.

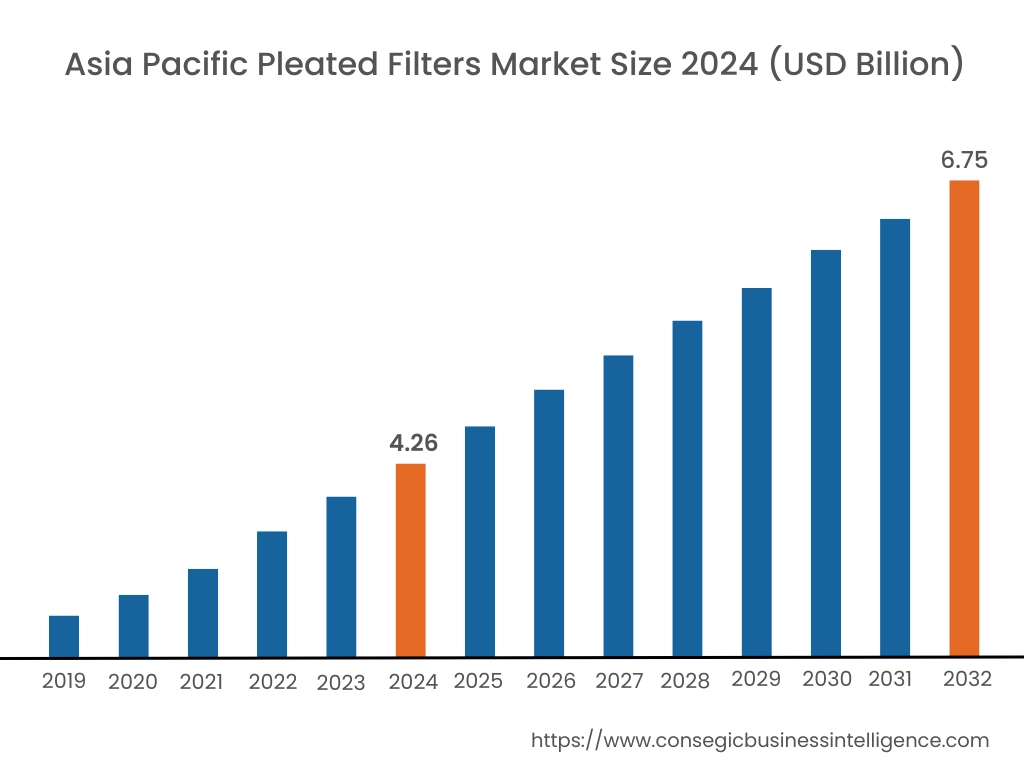

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

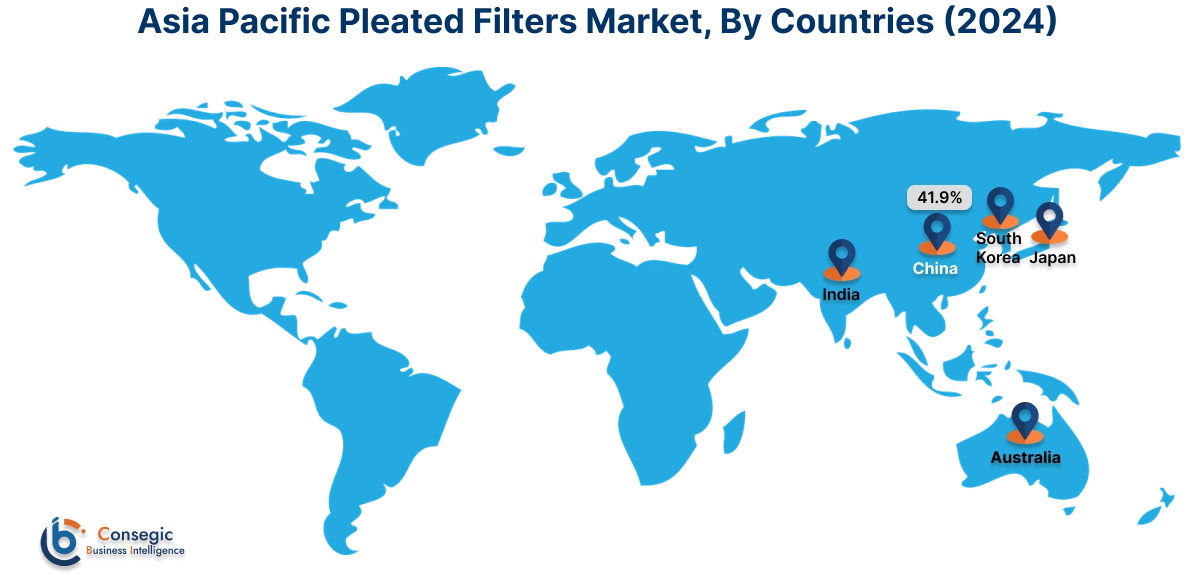

Asia Pacific region was valued at USD 4.26 Billion in 2024. Moreover, it is projected to grow by USD 4.43 Billion in 2025 and reach over USD 6.75 Billion by 2032. Out of this, China accounted for the maximum revenue share of 41.9%. The region is undergoing substantial expansion in the pleated filters industry, led by rapid urbanization, deteriorating air pollution levels, and increasing commercial infrastructure. China, India, South Korea, and Japan are witnessing a steep demand for particulate and odor control solutions in residential and industrial markets. Regional analysis indicates that the growth is being driven by tighter environmental regulations, government-sponsored public health programs, and growth in HVAC and semiconductor production. Local manufacturers are increasing production capacity and emphasizing cost-efficient filter innovations specific to high-dust environments. Growing consumer requirements for indoor air cleaning and centralized ventilation in newly built urban residences provide additional traction.

North America is estimated to reach over USD 7.18 Billion by 2032 from a value of USD 4.80 Billion in 2024 and is projected to grow by USD 4.97 Billion in 2025. North America represents an established market for filtration systems, with pleated products well accepted in the HVAC, automotive, and healthcare industries. The United States and Canada are leaders in adopting indoor air quality standards, especially in commercial facilities, schools, and cleanroom applications. Market research indicates robust replacement cycles fueled by growing awareness of airborne pollutants, especially in urban and industrial areas. In addition, sustainability requirements are driving the need for energy-efficient and recyclable filters that minimize HVAC system load. The trend toward high-MERV-rated filters and antimicrobial media is opening up new opportunities for innovation in the regional market.

Europe has sophisticated adoption trends because of a well-developed regulatory environment focused on emissions reduction, workplace safety, and ventilation performance. Germany, France, the UK, and the Nordic countries all integrate pleated filtration into public and private infrastructure, such as healthcare facilities, manufacturing facilities, and transportation centers. Analysis shows that the region's continued retrofitting of old buildings and adherence to EN air filtration standards continue to underpin stable market demand. In addition, increased investment in intelligent building solutions is combining sophisticated monitoring with filtration technology to maximize maintenance cycles and air flow efficiency. Sustainability goals have also promoted the application of low-pressure drop filters and environmentally friendly materials.

Latin America is slowly coming into focus as an expanding market, with Brazil, Mexico, and Chile leading regional adoption. Requirement is increasing in pharmaceutical manufacturing, food processing, and commercial office buildings, where compliance with regulations and reliability of filtration are becoming increasingly vital. Analysis indicates increasing concern regarding air quality and energy efficiency, especially in urban locations subject to pollution and humidity. Affordability is still a prime consideration, with scope arising in the creation of long-life and simple-to-replace filter products. Increased public sector investment in hospital facilities and cold chain logistics also supports regional need.

The Middle East and Africa are showing growing use of pleated filters in industries such as hospitality, healthcare, and light manufacturing, particularly in urban and high-temperature areas. The UAE, Saudi Arabia, and South Africa are using filters in large-scale HVAC applications in commercial buildings and airports to combat particulate exposure and ensure air comfort. Market research points towards an increasing emphasis on ISO air cleanliness standards and HVAC energy efficiency, which is leading to investments in air filtration system upgrades. Though distribution challenges and awareness issues in some segments of the region, increasing infrastructure modernization makes a robust pleated filters market opportunity in the long run.

Top Key Players & Market Share Insights:

The pleated filters market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global pleated filters market. Key players in the pleated filters industry include -

- Parker Hannifin Corporation (USA)

- 3M Company (USA)

- Koch Filter Corporation (USA)

- Honeywell International Inc. (USA)

- Siemens AG (Germany)

- Donaldson Company, Inc. (USA)

- Freudenberg Filtration Technologies SE & Co. KG (Germany)

- Camfil AB (Sweden)

- Atlas Copco AB (Sweden)

- MANN+HUMMEL Group (Germany)

Recent Industry Developments :

Product Launches:

- In June 2024, Rensa Filtration launched a new product line of high-performing HEPA filters with advanced mini-pleat technology. These filters are able to achieve high dust loading and less resistance to airflow as compared to aluminum separator-style HEPA filters. It also provides lower pressure drop, resulting in energy and cost savings.

Acquisitions:

- In January 2025, Blade Air, a leading provider of sustainable indoor air quality solutions for commercial spaces, acquired InnerEco Environmental Inc., a pioneer in residential HVAC filtration. This decision enables Blade Air to expand into the residential sector and deliver sustainable solutions across North America.

- In November 2024, the Micronics Engineered Filtration Group, an established industrial filtration solutions leader, acquired Action Filtration, an aftermarket leader in high-quality, reliable replacement pleated filters and cartridge dust collector filters for air pollution control and environmental protection. This allowed Micronics to better serve their clients’ filtration needs in demanding industries.

Pleated Filters Market Report Insights:

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 22.15 Billion |

| CAGR (2025-2032) | 5.5% |

| By Product Type |

|

| By Material |

|

| By Distribution Channel |

|

| By End-Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Pleated Filters Market? +

Pleated Filters Market size is estimated to reach over USD 22.15 Billion by 2032 from a value of USD 14.48 Billion in 2024 and is projected to grow by USD 15.01 Billion in 2025, growing at a CAGR of 5.5% from 2025 to 2032.

What specific segmentation details are covered in the Pleated Filters Market report? +

The Pleated Filters market report includes specific segmentation details for Product Type, Material, Distribution Channel and End-use industry.

What are the end-use industries of the Pleated Filters Market? +

The end-use industries of the Pleated Filters Market are HVAC, automotive, pharmaceuticals & healthcare, food & beverage, chemicals, oil & gas, water & wastewater treatment, electronics, power generation, aerospace & defense and others (mining, marine, etc.).

Who are the major players in the Pleated Filters Market? +

The key participants in the Pleated Filters market are Parker Hannifin Corporation (USA), 3M Company (USA), Donaldson Company, Inc. (USA), Freudenberg Filtration Technologies SE & Co. KG (Germany), Camfil AB (Sweden), Atlas Copco AB (Sweden), MANN+HUMMEL Group (Germany), Koch Filter Corporation (USA), Honeywell International Inc. (USA) and Siemens AG (Germany).