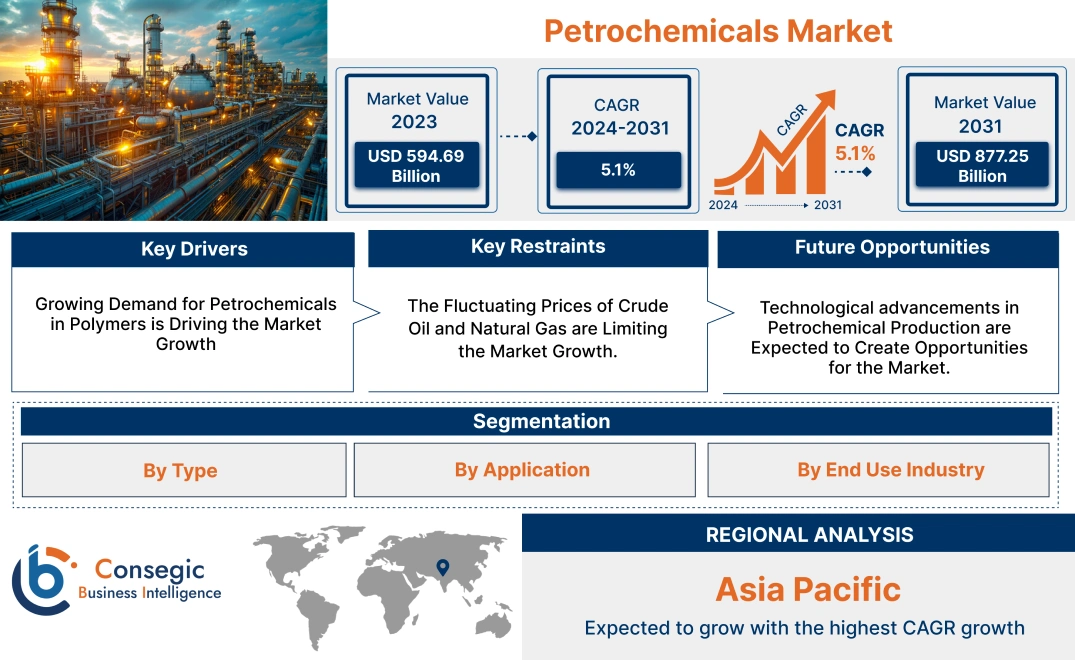

Petrochemicals Market Size:

Petrochemicals Market size is growing with a CAGR of 5.1% during the forecast period (2024-2031), and the market is projected to be valued at USD 877.25 Billion by 2031 from USD 594.69 Billion in 2023.

Petrochemicals Market Scope & Overview:

Petrochemicals is a group of chemical compounds derived from petroleum and natural gas. The production of petrochemicals involves a complex process of refining crude oil and natural gas to extract various hydrocarbons. The hydrocarbons are then subjected to a series of chemical processes, such as cracking and reforming, to produce a wide range of petrochemical intermediates. Petrochemicals including ethylene, propylene, benzene, toluene, and xylene among others are widely used for several applications such as polymers, adhesives & sealants, dyes, solvents, paints & coatings, fertilizers, and surfactants among others. Owing to these applications, they serve as critical components in building and construction, packaging, agriculture, automotive, electronics, healthcare, textile, food and beverage, and paper & pulp industries.

How is AI Transforming the Petrochemicals Market?

AI is increasingly being integrated into the petrochemicals sector for several applications, ranging from product development and process optimization to facilitating safety and sustainability. AI-driven solutions provide predictive maintenance to prevent equipment failures, improve inventory, and supply chain management, assist in the discovery of new materials and processes, and increase energy efficiency. Moreover, an AI-powered quality control system helps ensure production accuracy and consistency in complex chemical manufacturing processes. Further, petrochemical companies are also using AI for advanced sales tools, customer support through chatbots, and for achieving sustainability goals by reducing environmental impact and optimizing resource use. Consequently, the above factors are projected to boost the market growth in upcoming years.

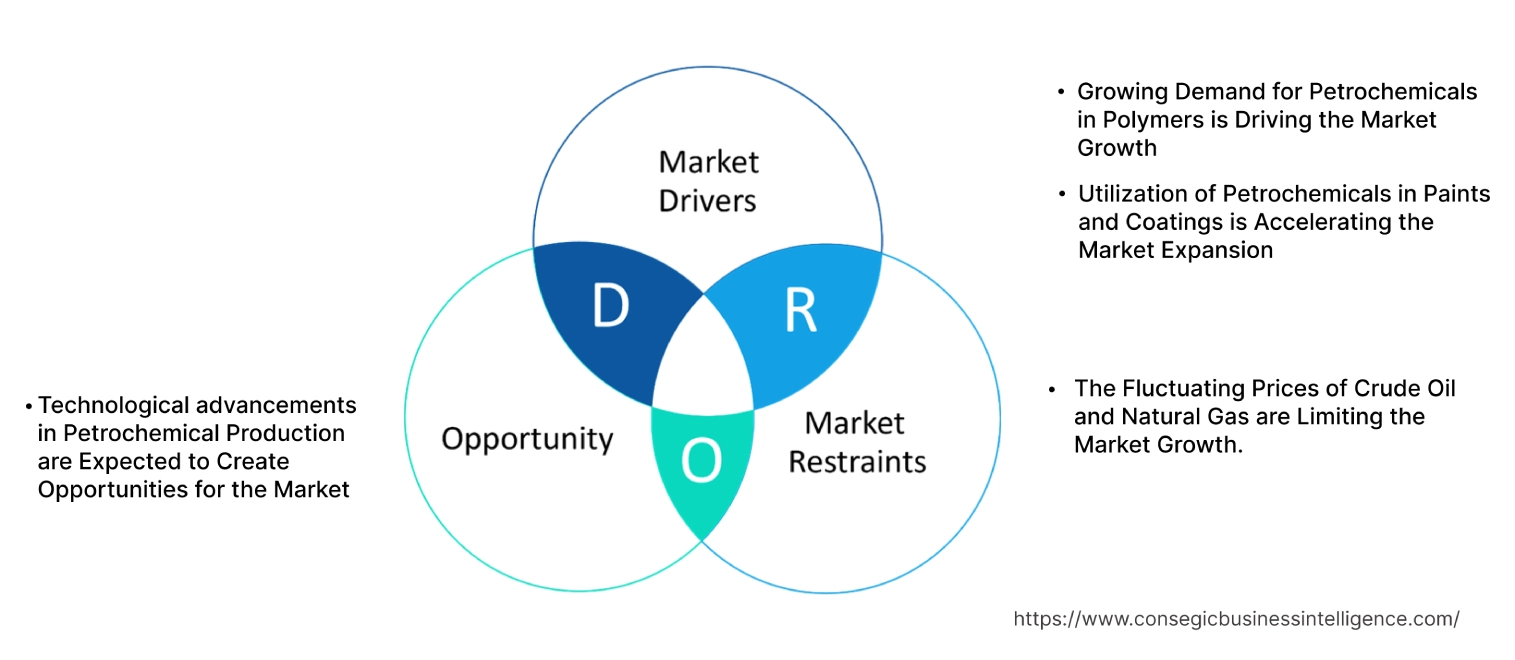

Petrochemicals Market Dynamics - (DRO) :

Key Drivers:

Growing Demand for Petrochemicals in Polymers is Driving the Market Growth

Petrochemicals serve as the key building blocks for a wide range of polymers including polyethylene, polypropylene, polyvinyl chloride, polystyrene, and polyesters among others.

Polymers, derived from petrochemicals, serve as the building blocks for a range of products across various sectors, including packaging, automotive, construction, electronics, and healthcare. Polyethylene is used in packaging materials, bottles, toys, and agricultural films. Polypropylene is employed in packaging, automotive components, and fibers. Polyvinyl chloride is widely utilized in construction materials, pipes, and packaging. Polystyrene is used in packaging, insulation, and consumer goods. Polyesters are used in packaging, textiles, and automotive components. Polyamides, or nylon, are used in textiles, engineering plastics, and fibers. Polyurethanes find applications in foams and adhesives. Moreover, acrylic polymers are used in paints, coatings, and textiles.

Such a large application basis of polymers creates the requirement for petroleum chemicals such as ethylene, propylene, C4 stream, benzene, toluene, xylene, methanol, and others in the production process. This has resulted in the development of petrochemical plants specifically designed for polymer production.

- For instance, in July 2023, McDermott was awarded a project management consultancy and engineering, procurement, and construction management (EPCM) contract for the Naphtha Cracker Expansion polypropylene expansion and new ethylene derivative unit project from Indian Oil Corporation Limited (IOCL). The project will increase the ethylene production capacity of the naphtha cracker unit (NCU) by approximately 20 percent. The additional ethylene and propylene production will act as feed for downstream polymer units.

Overall, the growing requirement for these chemicals in polymers is driving market expansion across the globe.

Utilization of Petrochemicals in Paints and Coatings is Accelerating the Market Expansion

The escalating adoption for petrochemicals in paints and coatings one of the prominent factors driving the market. Petrochemicals serve as the fundamental building blocks for a wide range of components used in paint and coating formulations. These derived components play a crucial role in enhancing the performance, durability, and aesthetic appeal of paints and coatings.

One of the primary feedstocks used in the paint and coatings sector is ethylene. Ethylene is used to produce various polymers, including polyethylene and ethylene vinyl acetate (EVA), which are employed as binders and film-forming agents in paints and coatings.

Aromatic hydrocarbons are also essential chemicals in paint and coatings. These compounds are used to produce various resins, solvents, and additives that enhance the performance and properties of paints and coatings. In addition to these primary petrochemicals, other compounds including methanol and various catalysts are also utilized in the production of paint and coating formulation contributing to the overall performance and functionality of paints and coatings, such as their color, gloss, and resistance to weathering. Such a large application basis of these chemicals is leading to the development of products specifically designed for coatings.

- For instance, in March 2023, Westlake Corporation launched AZURES product range at the European Coatings Show 2023. Westlake Epoxy’s Azures products are newly developed epoxy resins that are free of any SVHC (substances of very high concern) and CMR (carcinogenic, mutagenic, or toxic for reproduction) labeled substances. This development supports the adoption of petrochemicals in the coatings.

Overall, the growing requirement for these chemicals in paints and coatings is driving the market across the globe.

Key Restraints :

The Fluctuating Prices of Crude Oil and Natural Gas are Limiting the Market Growth.

The fluctuating prices of crude oil and natural gas pose a significant constraint hampering the market growth. Crude oil and natural gas are the primary raw materials for petrochemical production. When oil and gas prices rise, the cost of feedstock for petrochemical production increases.

Several factors including geopolitical conflicts, government regulations on the environmental effects caused by the production of crude oil, and the availability of alternative materials are leading to their price sensitivity. Geopolitical conflicts are the major factor leading to the supply chain disruption of crude oil further resulting in the fluctuations in their final prices. Consequently, the rise or fall in crude oil prices affects the production of these chemicals.

The price variation in natural gas affects the operational costs of refineries, which in turn affects the pricing of petrochemicals. When the cost of these raw materials increases, manufacturers face a difficult choice as they either absorb the extra cost, which reduces their profit margins, or raise the price of their products, which potentially prices them out of the market. Further, unpredictable raw material prices deter small-scale manufacturers from producing these chemicals in bulk quantities. Further, it also becomes difficult to determine the final cost of producing these chemicals, making it tough to set prices competitively and manage inventory effectively. Thus, as per analysis, the fluctuations in the prices of crude oil and natural gas are hampering the market.

Future Opportunities :

Technological advancements in Petrochemical Production are Expected to Create Opportunities for the Market.

Technological advancements in production are Key areas of innovation include catalysis and the adoption of digital technologies. In catalysis, nanomaterials and enzyme-based catalysts are advancing production processes, enabling more efficient and selective reactions.

Digital technologies, including IoT, AI, and big data analytics, are optimizing operations, reducing downtime, and improving product quality. Predictive maintenance, advanced process control, and digital twins are key elements of this digital transformation. IoT devices, integrated into machinery and infrastructure, generate a constant flow of real-time data on crucial parameters including temperature, pressure, and vibration. AI algorithms analyze this data to detect patterns, predict potential issues, and enable proactive decision-making. Moreover, the growing preference to reduce the environmental impact of the petrochemicals process is resulting in the development of advanced production processes.

- For instance, in July 2024, KBR launched KCOTKleanSM, a suite of low and zero-carbon technologies aimed at decarbonizing the catalytic olefins process. This technology integrates KBR’s Catalytic Olefins technology, K-COT, with the Korea Institute of Machinery and Materials (KIMM) CPOx technology. By integrating these technologies, KCOTKleanSM enables significant carbon reduction through the utilization of circular feedstocks, cleaner fuels, electrification, or carbon capture. K-COT is renowned for its efficiency in converting low-value feedstocks into high-value propylene and ethylene. KIMM's CPOx technology further enhances this process by converting methane-rich fuel into hydrogen-rich fuel, optimizing combustion during catalyst regeneration, and expanding the range of fuel options.

Overall, the aforementioned technologies are expected to boost the petrochemicals market in the upcoming years.

Petrochemicals Market Segmental Analysis :

By Product Type:

Based on product type, the market is categorized into ethylene, propylene, C4 stream, benzene, toluene, xylene, methanol, and others.

Trends in the Product Type:

- Growing demand for specialty chemicals.

- Development of sustainable production technologies.

The ethylene segment accounted for the largest petrochemicals market share in 2023.

- Ethylene, also known as ethane is an organic compound with the formula C₂H₄.

- Petrochemical plants employ a cracking process, using oil or natural gas as feedstock, to extract ethylene. This involves heating the feedstock with steam to break molecular bonds, releasing ethylene gas, which is then separated and sent for further processing.

- Ethylene is extensively utilized as a starting material for the production of numerous crucial industrial chemicals including polyethylene, ethanol, ethylene oxide, acetaldehyde, and vinyl chloride among others.

- The growing requirement for packaging materials, automotive components, and construction materials drives the adoption of ethylene. Additionally, the growing focus on the sustainable production processes for ethylene is the factor supporting the segment trajectory.

- For instance, in March 2023, KBR, the company focused on developing proprietary technologies for various sectors, announced the launch of SCOREKlean, a proprietary ethylene process technology utilizing 100% hydrogen-fueled burners for zero emissions from the ethylene-cracking furnaces. By achieving zero emissions from ethylene-cracking furnaces, SCOREKlean serves a major role in decarbonizing the petrochemical sector.

- Thus, as per analysis, increasing requirement for ethylene from various sectors and the growing focus on sustainable production drives segment trajectory.

The C4 stream segment is expected to grow at the fastest CAGR over the forecast period.

- The C4 stream, comprising a mixture of butenes and butadiene, is a vital feedstock for various petrochemical-derived products.

- C4 stream plays a crucial role in the production of a wide range of products, including synthetic rubber, plastics, and fuel additives. The rising requirement for tires, particularly in the automotive sector, is a major driver for the consumption of C4 stream.

- Synthetic rubber, derived from C4 stream components, is a key ingredient in tire manufacturing, providing essential properties such as durability, flexibility, and traction.

- Additionally, the increasing use of C4 stream as a feedstock for fuels, such as gasoline and diesel, is further boosting the segment trend.

By Application:

Based on application, the market is categorized into polymers, adhesives & sealants, dyes, solvents, paints & coatings, fertilizers, surfactants, and others.

Trends in Application:

- Increasing requirement for lightweight and high-performance polymers in automotive and packaging sectors.

- Growing focus on reducing volatile organic compound (VOC) emissions from solvent-based products.

- Increasing focus on water-based and low-VOC coatings to reduce environmental impact.

- Adoption of quick-drying and fast-curing coatings to reduce repair times and improve efficiency

The polymers segment accounted for the largest petrochemicals market share in the year 2023.

- A polymer is a substance composed of molecules with a large molecular mass of repeating structural units or monomers connected by covalent chemical bonds.

- Petrochemicals such as ethylene, propylene, C4 stream, benzene, toluene, xylene, and methanol among others are extensively utilized in the production of a wide range of polymers such as polyethylene, polypropylene, polyester, and polystyrene, and others.

- Polymers derived from these chemicals are versatile materials used in various sectors. They are employed in the production of plastics, synthetic fibers, and elastomers.

- The increasing requirement for packaging materials, automotive components, and construction materials is driving the adoption of polymers.

- For instance, according to the research article published by the National Institute of Health in June 2022, polyethylene terephthalate (PET) packaging accounted for 44.7% of single-serve beverage packaging in the US in 2021. Such a high adoption for polymers creates the requirement of petrochemicals as essential building blocks.

- Overall, as per analysis, the increasing adoption for polymers, driven by factors including packaging and construction, underscores the crucial role of these chemicals as their fundamental building blocks. This fuels the segment trajectory in the overall petrochemicals market trend.

The adhesives & sealants segment is expected to grow at the fastest CAGR over the forecast period.

- Adhesives & sealants are materials capable of attaching different surfaces, thereby filling the space between them to provide an effective barrier or protection.

- Petrochemicals play a crucial role in the formulation of adhesives and sealants. Petrochemical-based adhesives and sealants are essential for bonding and sealing various materials.

- Polyurethane adhesives, derived from petrochemicals, offer excellent adhesion and durability. Silicone sealants, based on silicone polymers, are highly resistant to extreme conditions.

- Acrylic adhesives provide good adhesion and weather resistance. Hot melt adhesives, derived from these chemicals such as EVA (Ethylene vinyl acetate), are used in various packaging applications. These materials are crucial in construction, automotive, electronics, and aerospace sectors.

- They offer numerous advantages over traditional mechanical fastening methods, including improved aesthetics, reduced weight, and enhanced design flexibility.

- Overall, as per analysis, the growing adoption in several end-use sectors coupled with advancements in adhesive and sealant technologies, are expected to create segment trajectory in the upcoming years.

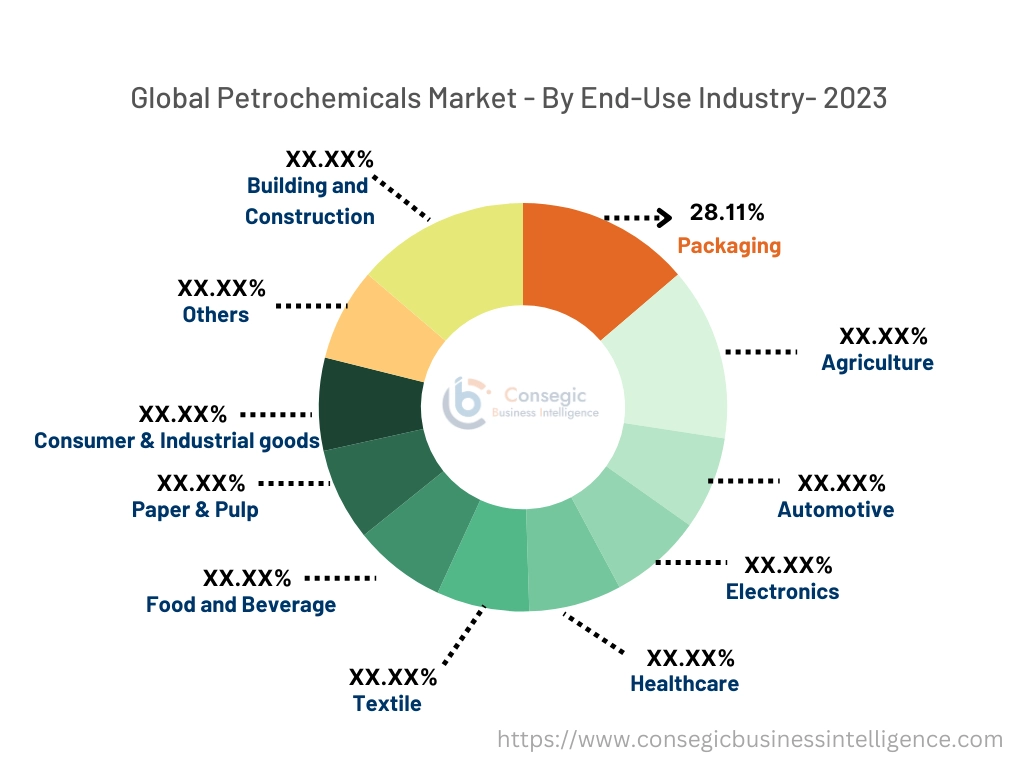

By End Use Industry:

Based on end use industry, the market is categorized into building and construction, packaging, agriculture, automotive, electronics, healthcare, textile, food and beverage, paper & pulp, consumer & industrial goods, and others.

Trends in the End Use Industry:

- Growing focus on home renovation and remodeling.

- Increasing preference for lightweight plastics and composites to improve fuel efficiency and vehicle performance.

- Increasing adoption of customized automotive interiors.

- Rising preference for e-commerce fueling the requirments for flexible packaging materials.

The packaging segment accounted for the largest market share of 28.11% in the year 2023.

- The packaging sector is one of the largest consumers of petrochemicals. They serve pivotal role in the modern packaging sector, providing a diverse range of materials that enhance product protection, shelf life, and consumer convenience.

- Plastics including polyethylene, polypropylene, polyvinyl chloride, polystyrene, and polyethylene terephthalate derived from petrochemicals are widely used for flexible and rigid packaging.

- Beyond plastics, synthetic polymers such as nylon and polycarbonate also play significant roles. Nylon's strength and durability make it suitable for packaging films and bags, while polycarbonate's impact resistance and heat resistance make it ideal for food packaging trays and beverage bottles.

- Petrochemical-based packaging offers numerous advantages. It provides durability, protecting products during transportation and storage. Its barrier properties prevent moisture, oxygen, and light from affecting product quality.

- Additionally, it is lightweight, reducing transportation costs and carbon emissions. The versatility of these materials allows them to be molded into various shapes and sizes to suit different products. Furthermore, they often provide a cost-effective packaging solution. This creates the adoption of these chemicals in packaging.

- For instance, according to the report published by Plastics Europe, a leading European trade association, in October 2022, packaging applications dominated the global plastics market in 2021, capturing approximately 44% of the total market share.

- Moreover, the growing e-commerce sector and increasing consumer requirement for convenience are driving the rise of the packaging sector further boosting the segment trajectory in the petrochemicals market trends.

The automotive segment is expected to grow at the fastest CAGR over the forecast period.

- The automotive sector is a potential consumer of petrochemicals, with plastics being a key material in vehicle manufacturing.

- Plastics are employed in various components, including interior elements like dashboards, seats, and door panels. They are also utilized in exterior components such as bumpers and fenders. Additionally, plastics find applications in engine components such as intake manifolds and fuel tanks.

- The growing automotive sector with increasing requirement for lightweight and fuel-efficient vehicles is expected to create rise in the automotive sector in the future years creating the requirement for these chemicals in the production of several automotive part’s materials.

- Overall, the automotive sector's increasing focus on lightweight and fuel-efficient vehicles is driving requirement in the production of various automotive components, ensuring its continued rise. This is epexted to propel segmental trend in the overall petrochemicals market growth.

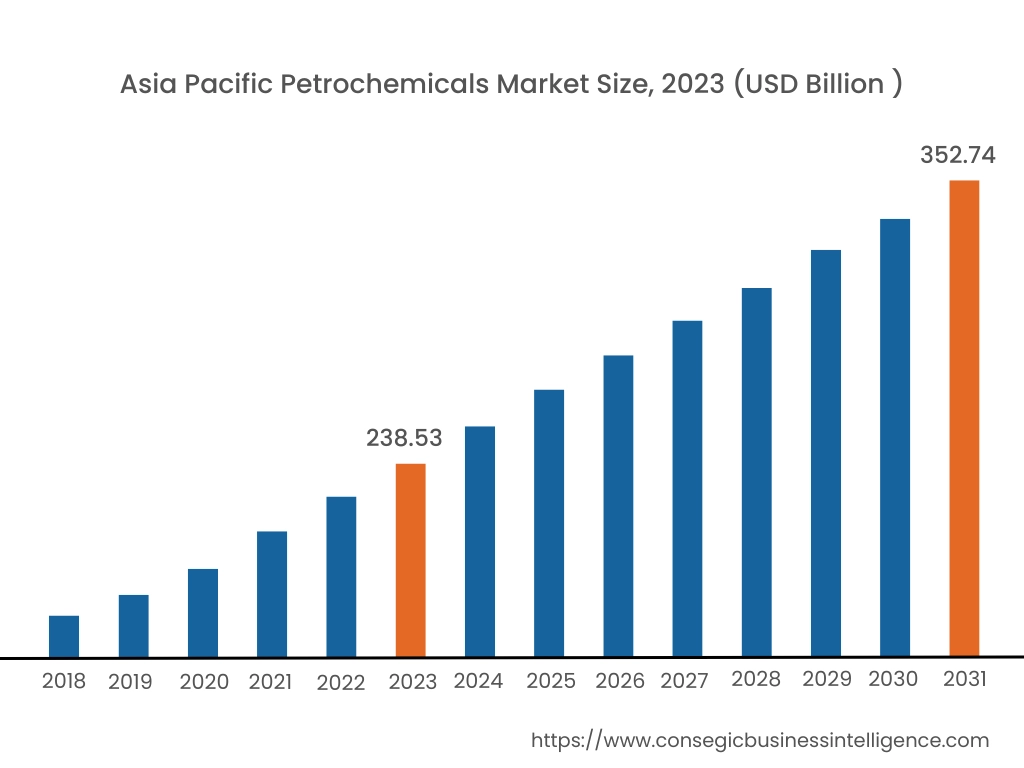

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

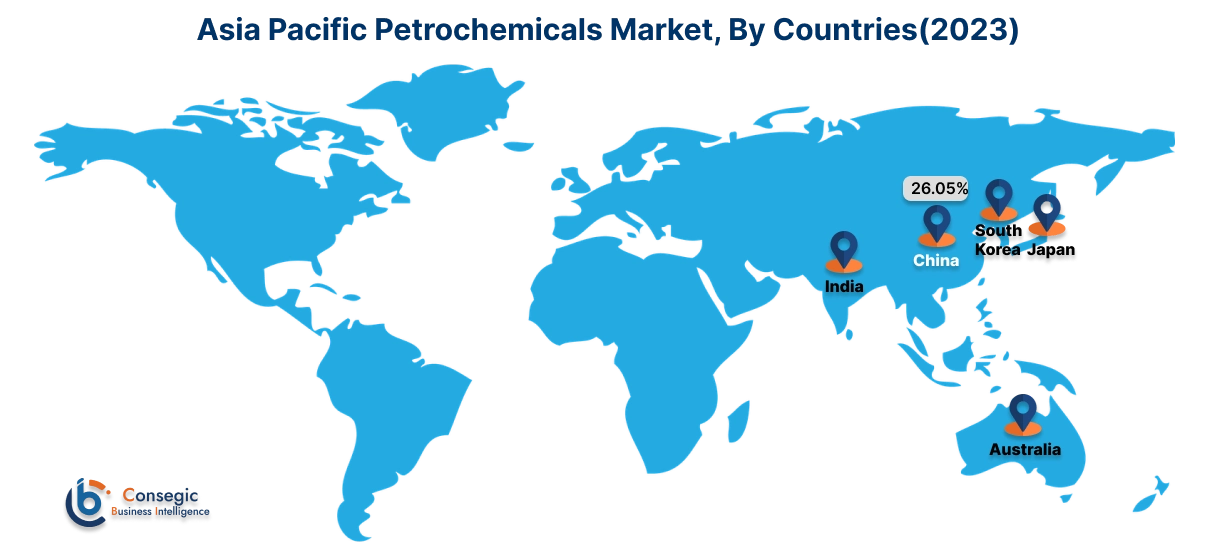

In 2023, Aisa Pacific accounted for the highest market share at 40.11% and was valued at USD 238.53 Billion and is expected to reach USD 352.74 Billion in 2031. In Asia Pacific, China accounted for the highest market share of 26.05% during the base year of 2023. Asia Pacific dominates the global petrochemicals market demand, primarily due to the requirement from several end-use sectors. This dynamic region, fueled by rapid industrialization, urbanization, and increasing consumer requirements, is experiencing a significant rise in various sectors, including automotive, packaging, construction, and electronics among others. Countries like China, India, and South Korea are experiencing robust economic growth, leading to increased requirements for petrochemical products. China, the world's largest petrochemical consumer, plays a pivotal role in shaping the regional market. Its massive infrastructure projects and automotive manufacturing drive the demand for various petrochemical products.

- For instance, according to the China Association of Automobile Manufacturers, in 2023, China's car output exceeded 30.16 million units, with an 11.6% year-on-year rise.

India’s focus on infrastructure development and manufacturing sectors is propelling the requirement for these chemicals. Additionally, many countries in the region have implemented favorable regulatory policies to attract investments in the petrochemical sector. The combination of the aforementioned factors and trends is driving a substantial trajectory in the Asia Pacific petrochemicals market.

North America is experiencing the fastest growth with a CAGR of 5.6% over the forecast period. North America, comprising the United States and Canada, is a mature market with a strong demand for petrochemicals. The region's advanced economies, coupled with a focus on innovation and sustainability, have positioned it as a key player in the petrochemicals market demand. The region's robust economy, advanced infrastructure, and abundant natural resources, particularly shale gas, have contributed to its prominence. The region's diverse sectors, including automotive, packaging, construction, and healthcare, consume significant quantities of petrochemical products. This robust domestic requirement drives the North American market. Additionally, North America is a key player in technological innovation, particularly in the areas of catalysis, process engineering, and materials science. These advancements enable the development of more efficient and sustainable petrochemical production processes further creating petrochemicals market opportunities across the region.

Europe presents a significant contribution to the petrochemicals market analysis. Europe is a mature market with a diverse range of end-use sectors, including automotive, packaging, and construction creating constant requirements for polymers, adhesives & sealants, and paints & coating solutions. This drives the adoption of petrochemicals in several applications. Countries including Germany, the United Kingdom, France, and Italy are significant players in the region. Germany is a major producer and consumer of petrochemicals. The country's strong manufacturing base and focus on high-quality products have positioned it as a key player in the global market. Additionally, the countries across the region have a strong focus on innovation and sustainable practices, which is creating petrochemicals market opportunities across the region.

The Middle East and Africa (MEA) region is witnessing a significant trajectory in the global petrochemicals market growth, primarily driven by its abundant hydrocarbon resources. Countries including Saudi Arabia, Iran, and the United Arab Emirates are key players in the region. With substantial reserves of crude oil and natural gas, the region has a strong foundation for the petrochemicals sector. Vast reserves of oil and natural gas provide reliable and cost-effective feedstock for petrochemical production. Governments in the region are actively promoting the development of the petrochemical industry through supportive policies and infrastructure investments. Additionally, countries in the region are focusing on downstream integration, producing value-added petrochemical products to improve profitability. The region is increasingly focusing on the production of specialty chemicals, which command higher margins.

Based on the overall petrochemicals market analysis, Latin America is an emerging region in the petrochemicals market expansion, with significant potential for innovations. Countries including Brazil and Argentina are major players in the region. Brazil, the largest economy in Latin America, has a strong petrochemical industry. The country's abundant natural resources, coupled with government support, have fueled the sector. Argentina’s low-cost labor and favorable investment climate have attracted significant foreign investments in the petrochemical sector. The country's abundant natural gas reserves and government initiatives to promote industrial development are driving the market.

Top Key Players & Market Share Insights:

The petrochemicals market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global petrochemical market. Key players in the petrochemicals industry include-

- Reliance Industries Limited (India)

- BASF (Germany)

- Exxon Mobil Corporation (U.S.)

- TotalEnergies SE (France)

- Chevron Phillips Chemical Company LLC (U.S.)

- Shell (United Kingdom)

- LyondellBasell Industries Holdings B.V. (Netherlands)

- SABIC (Saudi Arabia)

- Dow (U.S.)

- China Petroleum & Chemical Corp (China)

Recent Industry Developments :

New Launch:

- In July 2024, KBR launched KCOTKleanSM, a suite of low and zero-carbon technologies aimed at decarbonizing the catalytic olefins process. This technology integrates KBR’s Catalytic Olefins technology, K-COT, with the Korea Institute of Machinery and Materials (KIMM) CPOx technology.

- in March 2023, KBR announced the launch of SCOREKlean, a proprietary ethylene process technology utilizing 100% hydrogen-fueled burners for zero emissions from the ethylene-cracking furnaces.

Expansion:

- In July 2023, McDermott was awarded a project management consultancy and engineering, procurement, and construction management (EPCM) contract for the Naphtha Cracker Expansion polypropylene expansion and new ethylene derivative unit project from Indian Oil Corporation Limited (IOCL). The project will increase the ethylene production capacity of the naphtha cracker unit (NCU) by approximately 20 percent. The additional ethylene and propylene production will act as feed for downstream polymer units.

Petrochemicals Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 877.25 Billion |

| CAGR (2024-2031) | 5.1% |

| By Type |

|

| By Application |

|

| By End Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Petrochemicals market? +

In 2023, the Petrochemicals market is USD 594.69 Billion.

Which is the fastest-growing region in the Petrochemicals market? +

North America is the fastest-growing region in the Petrochemicals market.

What specific segmentation details are covered in the Petrochemicals market? +

Product Type, Application, and End-Use Industry segmentation details are covered in the Petrochemicals market.

Who are the major players in the Petrochemicals market? +

BASF, SABIC, and Dow are some of the major players in the market.