- Summary

- Table Of Content

- Methodology

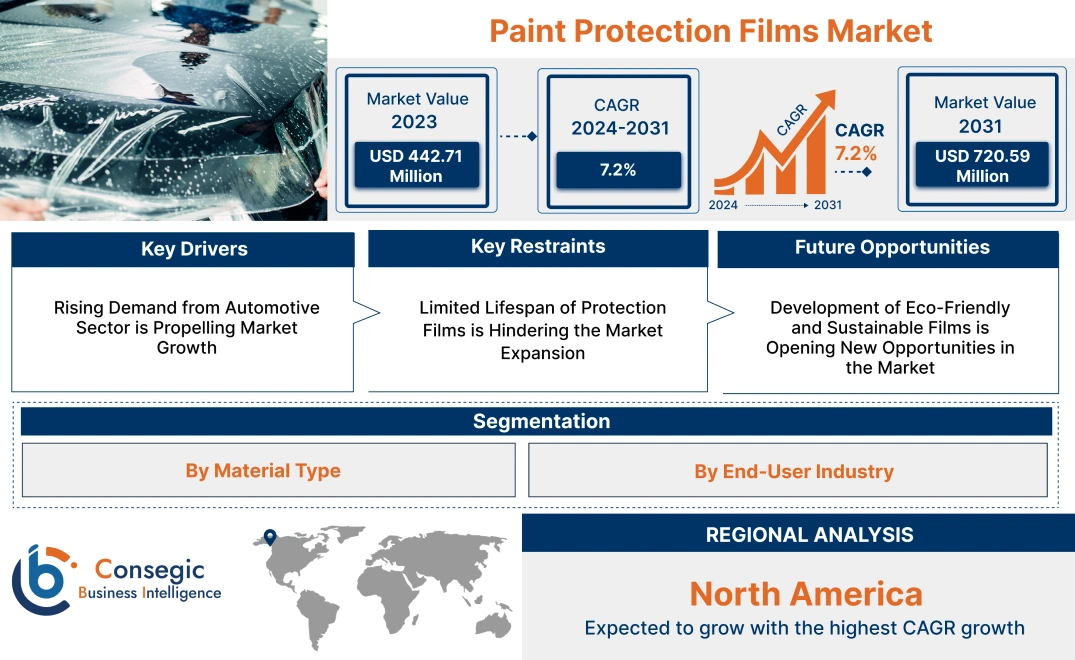

Paint Protection Films Market Size:

Paint Protection Films Market size is estimated to reach over USD 720.59 Million by 2031 from a value of USD 442.71 Million in 2023, growing at a CAGR of 7.2% from 2024 to 2031.

Paint Protection Films Market Scope & Overview:

Paint protection films (PPF) are thin, transparent layers of thermoplastic urethane or polymer that are applied to the painted surfaces of vehicles to protect them from scratches, stone chips, road debris, and other damages. There are different types of PPF such as gloss finish, matte finish, and custom textures. Many high-quality PPFs are equipped with self-healing properties which makes minor scratches disappear when exposed to heat. End users of PPF can be several key consumers such as motorcycle owners, aircraft owners and operators, automotive service providers, boating and marine sector, and electronics.

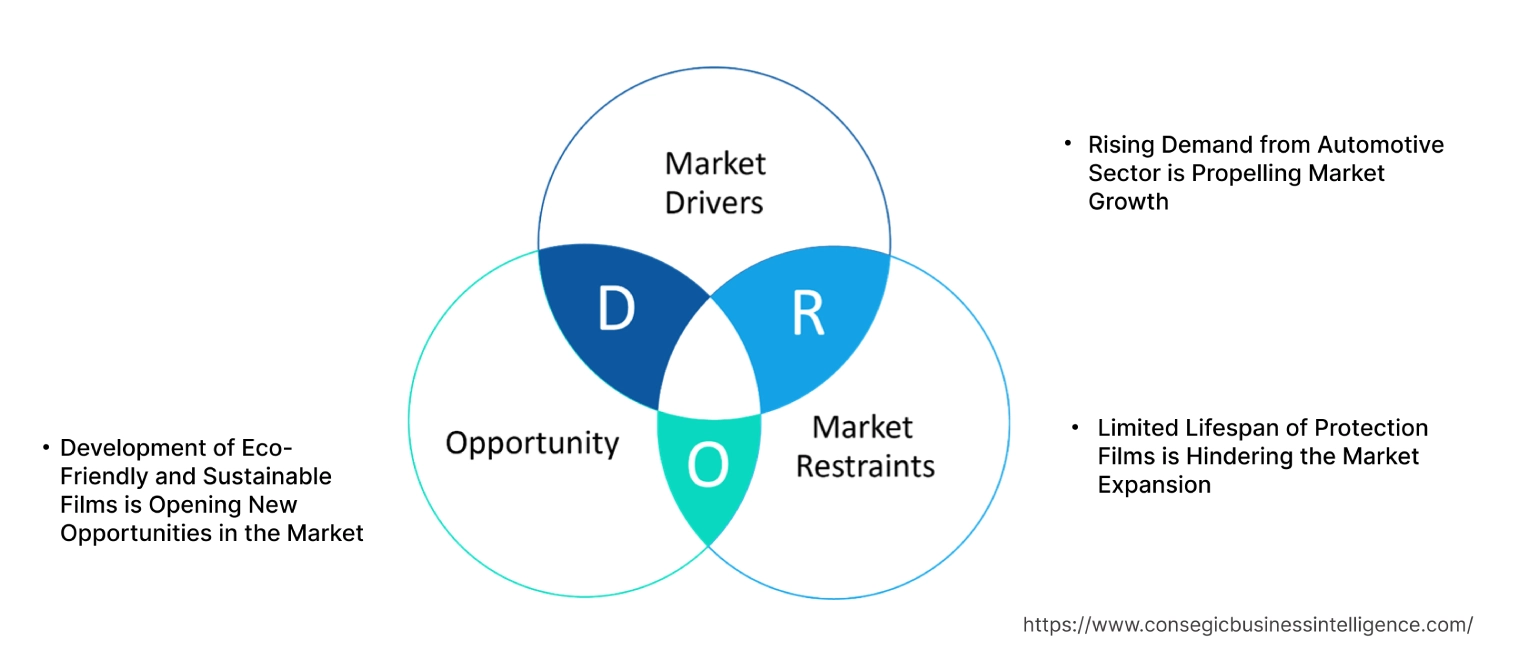

Paint Protection Films Market Dynamics - (DRO) :

Key Drivers:

Rising Demand from Automotive Sector is Propelling Market Growth

As worldwide automobile sales continue to rise, the number of vehicles on the road drives up the need for protective solutions such as PPF. Car owners want to keep their vehicles looking showroom-quality for as long as possible. PPF helps to maintain the paintwork, which contributes to the high demand for these films. PPF reduces the frequency of repainting which an environmental impact due to the chemicals has used. Keeping the car's exterior in perfect condition results in increased resale values, making PPF a popular choice for budget-conscious buyers. Furthermore, advances in PPF materials, such as self-healing qualities and increased durability, have made these films more appealing to a wider spectrum of consumers. Therefore, as consumer preferences evolve and the automotive sector grows, PPF is becoming an essential component of vehicle care contributing to the overall paint protection films market expansion.

Key Restraints :

Limited Lifespan of Protection Films is Hindering the Market Expansion

The film warps, cracks, and peels when exposed to high heat or cold constantly. In extremely heated environments, PPF loses its adhesive capabilities and begins to lift from the surface. Long-term exposure to UV radiation causes the film to deteriorate, discolor, or lose its protective characteristics. Improper care progressively shortens the film's life. Using harsh chemicals or incorrect cleaning techniques weakens the protective layer, causing cracking, yellowing, and peeling. Therefore, the analysis of market trends depicts that long exposure to harsh conditions and improper care significantly reduces their effectiveness over time which hinders the paint protection films market growth.

Future Opportunities :

Development of Eco-Friendly and Sustainable Films is Opening New Opportunities in the Market

Innovations in biodegradable or recyclable films offer a way to reduce environmental impact due to which manufacturers are exploring alternatives to traditional PPF materials. They are focusing on films that will decompose naturally and can be recycled at the end of their lifecycle. The focus will be on creating low-carbon manufacturing processes by using renewable energy sources and sustainable raw materials. Moving towards water-based or non-toxic adhesives will create safer and more sustainable PPF products that are less harmful to the environment and safer for installers and consumers. Therefore, the market trends analysis shows that the future of eco-friendly and sustainable films holds lucrative paint protection film market opportunities by focusing on biodegradable materials, non-toxic adhesives, and low-emission manufacturing units which will contribute to a more sustainable automotive ecosystem.

Paint Protection Films Market Segmental Analysis :

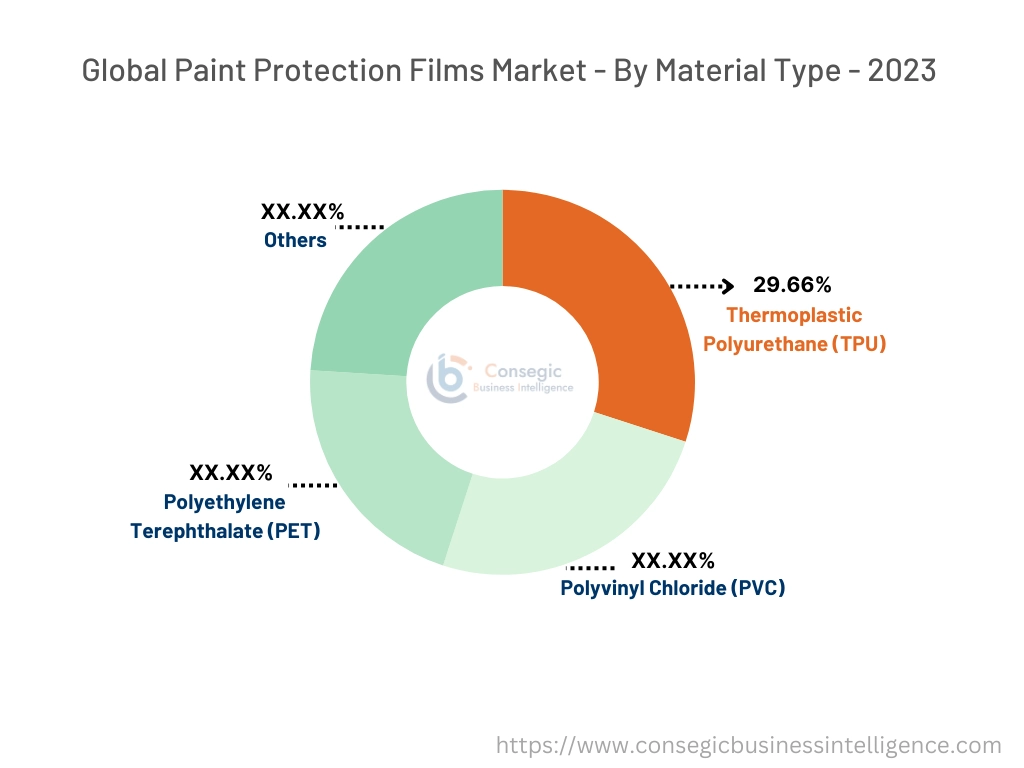

By Material Type:

Based on material type the market is segmented into Thermoplastic Polyurethane (TPU), Polyvinyl Chloride (PVC), Polyethylene Terephthalate (PET), and Others.

Trends in the Material Type:

- Ongoing advancements in TPU technology such as hydrophobic and anti-yellowing TPU films have further increased their adoption across industries.

The thermoplastic polyurethane (TPU) segment accounted for the largest revenue share of 29.66% of the total paint protection films market share in 2023.

- TPU-based PPF offers high durability, flexibility, and resistance to environmental elements like UV radiation, chemicals, and abrasion. This makes it an ideal material for use in automotive, electronics, and aerospace applications for long-lasting protection.

- TPU films are lightweight and do not significantly add to the weight of the surfaces they protect, which is particularly important in sectors like automotive and aerospace where fuel efficiency and weight reduction are key considerations.

- The high transparency and tactile nature of TPU make it a popular choice in its fast-growing market, further boosting the segment's revenue share.

- For instance, Estane TPU the flagship brand of Lubrizol, guarantees efficient processing and creates long-lasting crystal clear PPF that keeps cars looking showroom quality.

- Thus, as per the market trends analysis, the TPU segment accounted for the largest revenue due to its superior self-healing properties, durability, and widespread use in key industries along with its long-lasting protection without compromising the aesthetics has led paint protection films market growth of.

The polyvinyl chloride (PVC) segment is anticipated to register the fastest CAGR during the forecast period.

- PVC films are used across a variety of industries, including automotive, electronics, and construction, where cost-effective protection is required.

- PVC is a lightweight material making it suitable for various applications, it is also highly versatile, capable of being customized in terms of thickness, finish, and color, which adds to its appeal in various industries.

- PVC-based PPFs are generally easier to install compared to TPU films which has made PVC an appealing choice for consumers and businesses that require a simpler, and quicker installation process which is further boosting the market growth.

- For instance, NB Protective Films uses PVC for protecting the installation and finishing work of glass windows, doors, and panels.

- Thus, the PVC segment is expected to register the fastest due to its cost-effectiveness, broad range of applications, and increasing demand in emerging markets, rising paint protection films market trends.

By End-User:

Based on the end-use industry the market is segmented into Automotive, Aerospace, Electronics, Construction, and Others.

Trends in the End-user:

- Original Equipment Manufacturers in the automotive sector are integrating PPF as part of their premium vehicle packages, during the purchase process.

- Advances in self-healing PPF technologies are making these films even more appealing to the aerospace sector.

The automotive segment accounted for the largest revenue of the total paint protection films market share in the year 2023.

- PPF provides a transparent, durable layer of protection against scratches, chips, and environmental damages making it a popular choice for car enthusiasts and everyday users alike.

- Car owners are increasingly opting for PPF as part of their customization and protection strategy, particularly for sports cars, SUVs, and other luxury vehicles.

- Growth in awareness among consumers about the benefits of PPF in terms of paint protection, UV resistance, and ease of maintenance has boosted its adoption and revenue in the market.

- For instance, 3M Paint Protect Film is professionally placed by 3M recommended installers and authorized dealers which delivers an optimal adhesive for repositioning and minimizes lift lines and marks in the vehicles.

- Thus, as per the segmental trends analysis, the automotive sector represented the largest revenue due to the increasing demand for vehicle protection, the increase of luxury cars, and technological advancements, driving the paint protection films market demand.

The aerospace segment is anticipated to register the fastest CAGR during the forecast period.

- PPF is being increasingly adopted in the aerospace sector both commercial and military. It protects the aircraft from vulnerable areas such as wing tips, leading edges, and engine cowls thus leading to increased demand in this sector.

- Airlines are increasingly looking to protect their investment in new aircraft with advanced protective coatings like PPF to reduce maintenance costs and prolong life.

- The use of PPF on military jets, helicopters, and drones is increasing as a way to mitigate damage to the airframe and reduce downtime for maintenance.

- For instance, Argotec's TPU films are becoming well-known in the field of composite aircraft materials. PPFs that have been engineered are painstakingly created to satisfy particular requirements like increased resilience to heat, chemicals, and UV radiation.

- Thus, the aerospace sector in the PPF market is growing due to its durability, lightweight, and cost-effective solutions to protect the aircraft, boosting the paint protection films market trends.

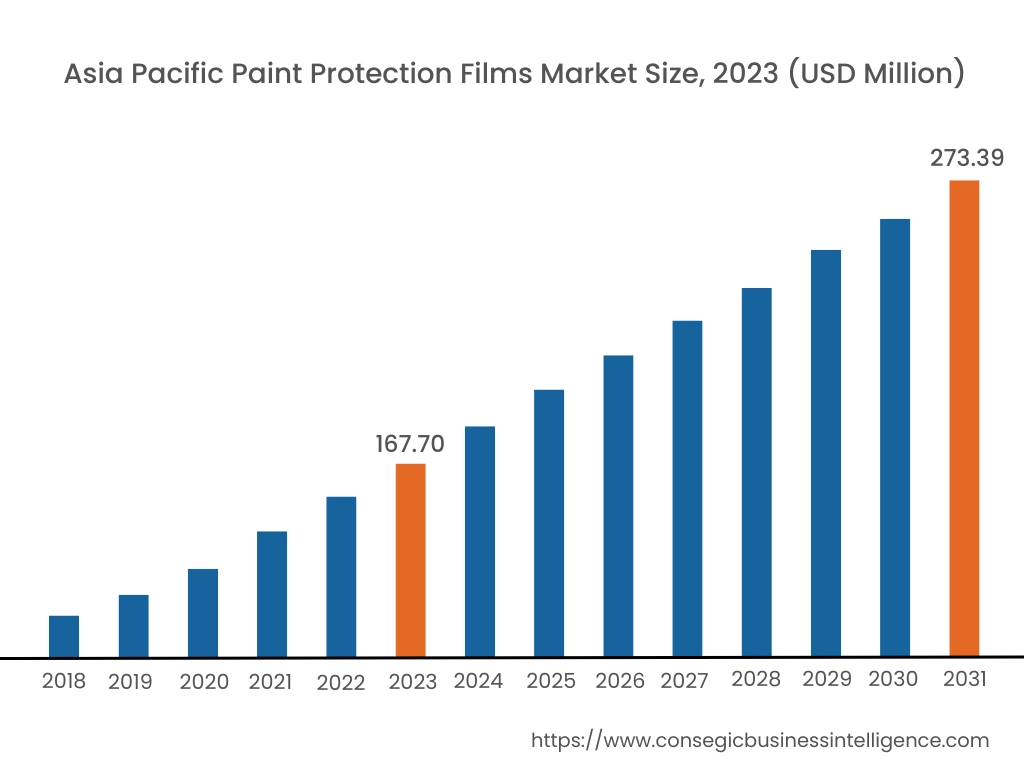

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

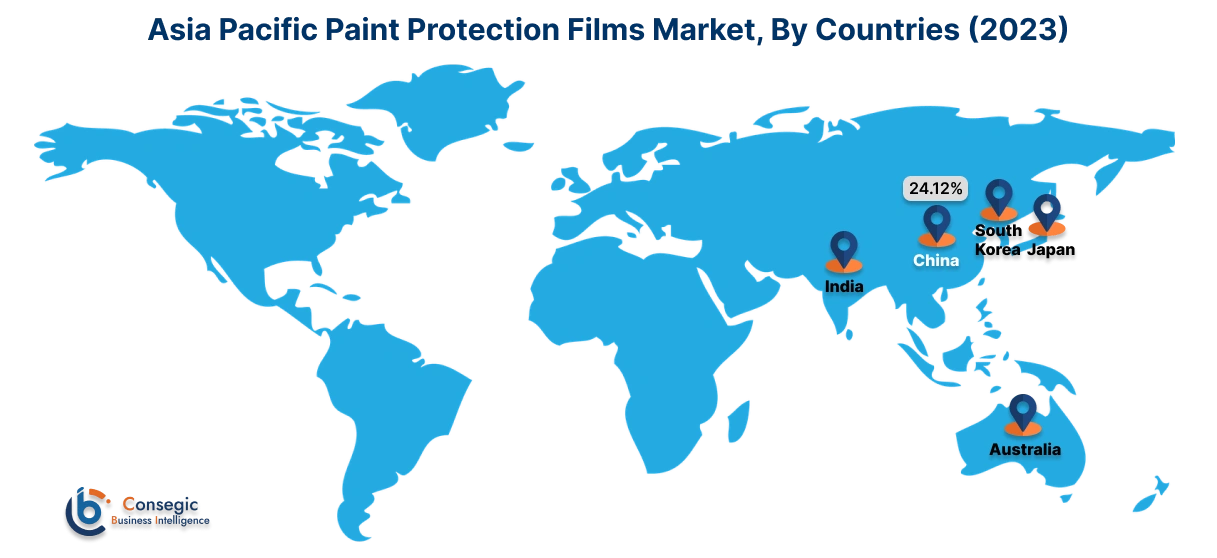

In 2023, Asia Pacific accounted for the highest market share at 37.88% and was valued at USD 167.70 Million, and is expected to reach USD 273.39 Million in 2031. In Asia Pacific, China accounted for the highest market share of 24.12% during the base year of 2023. As per the paint protection films market analysis, in Asia Pacific, the electronics sector being a hub for consumer electronics manufacturing is seeing increased use of PPF to protect devices like smartphones, tablets, and wearables from scratches and impacts. Countries like Japan, and South Korea are seeing PPF as an eco-friendly option that helps to extend the life of devices by reducing the need for frequent replacements and repairing.

North America is expected to witness the fastest CAGR over the forecast period of 7.9% during 2024-2031. In North America, the automotive sector particularly in the US and Canada plays a pivotal role in driving the demand for PPF. They have a large number of luxury and high-performance vehicles which substantially demand PPF to protect these cars from any kind of damage and scratches. Additionally, the growth in adoption of electric vehicles further bolsters the paint protection films market demand.

- In 2024, the Avery Dennison supreme paint protection film series provides the best paint protection technologies for self-healing. Their superior visual finishes, great scratch resistance, and self-healing properties are attributed to their improved polyurethane.

The European Union's commitment to reducing carbon emissions has led to a rapid increase in the adoption of EVs. Countries like Norway, Germany, and France are leading in EV sales which is also directly making owners invest in PPF to maintain aesthetics and protect from damage in the long run.

The regional analysis in the Middle East and Africa depicts that the market is expanding due to a rise in disposable incomes, increased vehicle ownership, and a growth in preference for vehicle protection solutions. Affluent countries like UAE and Qatar have a significant market for luxury and high-performance vehicles in the region which directly brings demand for PPF coatings for protection. Latin America region presents a promising paint protection films market driven by the growth of the automotive sector, increasing interest in luxury vehicles, and rising consumer awareness of vehicle maintenance.

Top Key Players & Market Share Insights:

The paint protection films market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global paint protection films market. Key players in the paint protection film industry include-

- 3M Company (USA)

- Eastman Chemical Company (USA)

- Argotec LLC (USA)

- XPEL, Inc. (USA)

- Saint-Gobain (France)

- Renolit SE (Germany)

- Avery Dennison Corporation (Switzerland)

- Hexis S.A.S. (France)

- SunTek Films (USA)

- STEK Automotive (South Korea)

Recent Industry Developments :

Product Launch:

- In May 2023, Convestro opened a new production facility and launched the Desmopan UP TPU paint protection film line for the wind and automotive industries. Desmopan UP-based TPUs for PPF provide superior UV durability, excellent hydrolysis, and chemical resistance, as well as outstanding optical clarity which ensures long-lasting performance.

Product Expansion:

- In 2023, Covestro for the Changsha production site is expanding its production capacity of Paint Protection Film. They are one of PPF's largest overseas suppliers of TPU for car coatings and many others.

Paint Protection Films Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 720.59 Million |

| CAGR (2024-2031) | 7.2% |

| By Material Type |

|

| By End-User |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Paint Protection Films Market? +

The Paint Protection Films Market size is estimated to reach over USD 720.59 Million by 2031 from a value of USD 442.71 Million in 2023, growing at a CAGR of 7.2% from 2024 to 2031.

Which is the fastest-growing region in the paint protection films market? +

The fastest-growing region in the paint protection films market in North America.

What specific segmentation details are covered in the paint protection films market report? +

The specific segments that are covered in the paint protection films market are material type, application, and end-user industry.

Who are the major players in the paint protection films market? +

The major players in the paint protection films market are 3M Company (USA), Eastman Chemical Company (USA), Avery Dennison Corporation (USA), XPEL, Inc. (USA), Saint-Gobain (France), Hexis S.A.S. (France), Renolit SE (Germany), SunTek Films (USA), Argotec LLC (USA), and STEK Automotive (South Korea).