- Summary

- Table Of Content

- Methodology

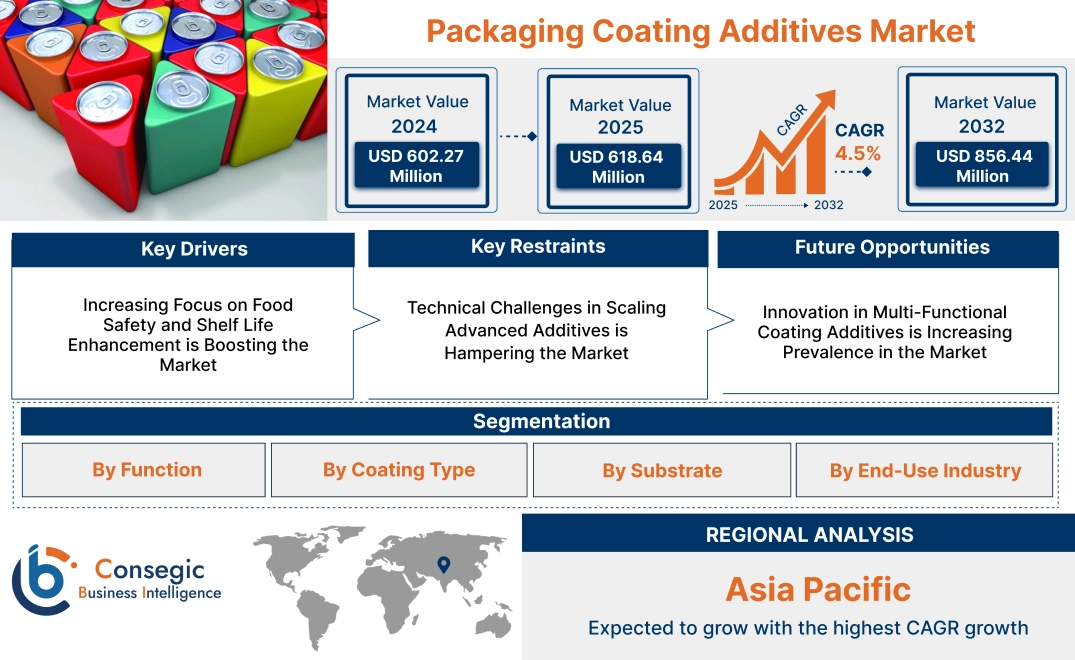

Packaging Coating Additives Market Size:

Packaging Coating Additives Market size is estimated to reach over USD 856.44 Million by 2032 from a value of USD 602.27 Million in 2024 and is projected to grow by USD 618.64 Million in 2025, growing at a CAGR of 4.5% from 2025 to 2032.

Packaging Coating Additives Market Scope & Overview:

The packaging coating additives focus on specialty chemicals and compounds used to enhance the performance and functionality of packaging materials. These additives improve properties such as barrier resistance, durability, aesthetics, and ease of processing, ensuring that packaging meets industry requirements and consumer demands. Key characteristics of packaging coating additives include their ability to provide moisture and oxygen barriers, UV protection, and anti-fogging properties while ensuring compatibility with diverse substrates like plastics, metals, and paper. The benefits include extended product shelf life, improved packaging durability, and enhanced visual appeal. Applications span food and beverages, pharmaceuticals, personal care, and industrial packaging, where functionality and product integrity are critical. End-users include packaging manufacturers, food processors, and consumer goods companies, driven by increasing packaging coating additives market opportunities for sustainable packaging solutions, growing awareness of food safety, and advancements in additive technologies.

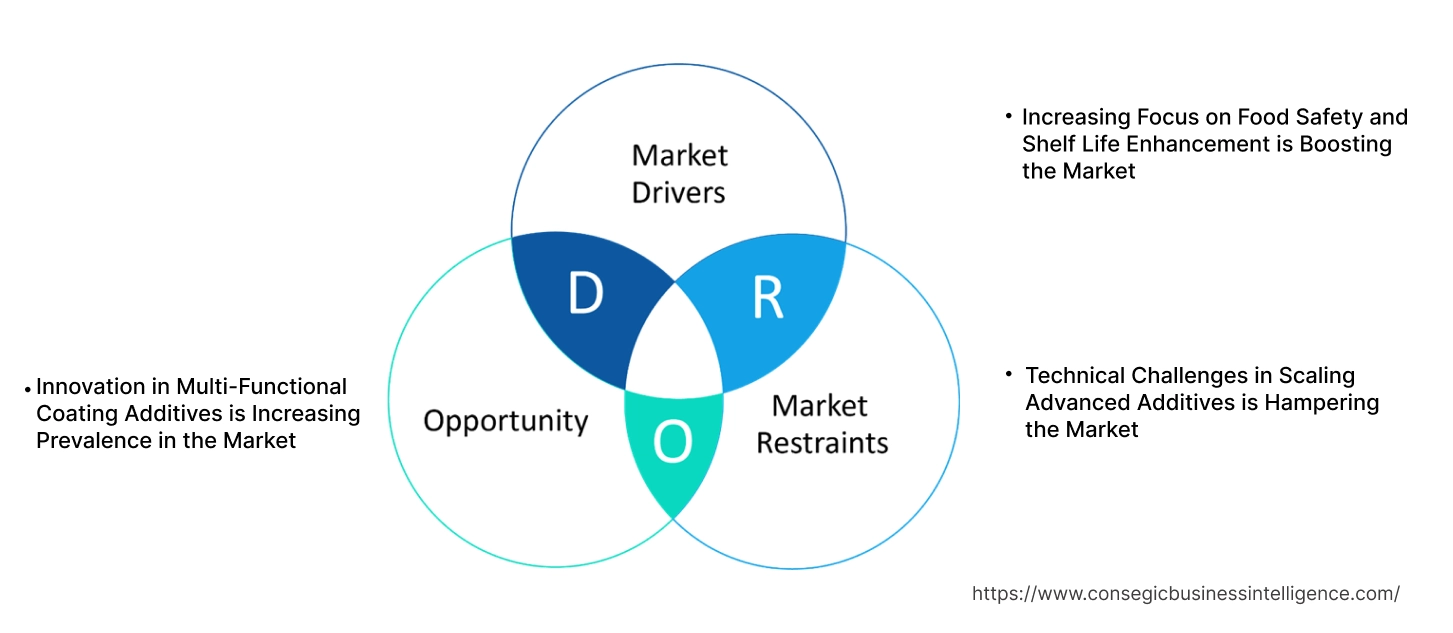

Key Drivers:

Increasing Focus on Food Safety and Shelf Life Enhancement is Boosting the Market

The importance of food safety and shelf life has significantly influenced trends in the packaging sectors, leading to the adoption of coating additives designed to protect product integrity. Coating additives such as anti-microbial agents, oxygen scavengers, and moisture barriers play a pivotal role in preventing contamination and spoilage of packaged foods and beverages. These solutions not only preserve freshness but also reduce food waste by extending the usability of perishable products, making them highly valued in both retail and consumer sectors.

Increased urbanization and changing consumption patterns have amplified the need for advanced packaging that supports convenience while ensuring safety. For instance, ready-to-eat meals and perishable goods require innovative barrier coatings to withstand varying storage conditions during transportation and distribution. Trends in sustainable packaging are also influencing the development of additives that are both functional and eco-friendly, aligning with the dual objectives of safety and environmental responsibility.

Key Restraints:

Technical Challenges in Scaling Advanced Additives is Hampering the Market

The production of advanced coating additives, particularly those involving nano-technology or multi-functional properties, poses significant technical challenges during scale-up from laboratory research to full-scale manufacturing. These additives often require specialized processes, precision equipment, and tightly controlled environments to maintain consistency in their composition and performance. Achieving uniform quality across large production volumes becomes increasingly complex as manufacturers expand their operations to meet packaging coating additives market trends.

Moreover, the integration of innovative additives into existing manufacturing workflows often necessitates modifications to equipment and processes, increasing the operational complexity and cost. For example, additives designed for high-barrier properties or environmental compatibility may require unique handling or blending techniques to ensure proper dispersion within the packaging material. These complexities limit scalability and make it challenging for manufacturers to maintain efficiency while addressing the rising need for advanced packaging solutions.

The development of these cutting-edge additives also involves substantial research and development investments, which can prolong the time-to-market for new products. This delay, coupled with the high costs of scaling production, restricts the accessibility of advanced additives, particularly for smaller manufacturers. Overcoming these challenges requires continuous innovation, investment in production technologies, and collaboration with stakeholders across the supply chain to create scalable and efficient solutions.

Future Opportunities:

Innovation in Multi-Functional Coating Additives is Increasing Prevalence in the Market

The development of multi-functional coating additives is revolutionizing the packaging sectors by offering versatile solutions that enhance efficiency and reduce complexity. Additives that combine properties such as moisture resistance, anti-microbial activity, UV protection, and printability are gaining traction as they streamline packaging processes and improve product performance. These multi-functional solutions are particularly valuable in industries such as food and beverage, healthcare, and personal care, where packaging must meet diverse and stringent requirements.

For example, anti-microbial additives with oxygen barrier properties can simultaneously enhance product safety and extend shelf life, reducing the need for additional layers or materials. Similarly, UV-resistant coatings are becoming essential for protecting sensitive products like pharmaceuticals and cosmetics. Trends in smart and intelligent packaging are also driving the integration of additives that support digital features, such as QR codes and sensors, further expanding their applicability. As industries focus on innovation and sustainability, multi-functional additives are set to play a critical role in shaping the future of packaging.

Packaging Coating Additives Market Segmental Analysis :

By Function:

Based on function, the packaging coating additives market is segmented into slip additives, anti-fog additives, anti-static additives, antimicrobial additives, and others.

The antimicrobial additives segment accounted for the largest revenue in packaging coating additives market share in 2024.

- Antimicrobial additives are widely used in food and pharmaceutical packaging to inhibit the surge of microorganisms and enhance product shelf life.

- The rising demand for safer and longer-lasting packaged products, especially in food and beverages and healthcare, is driving the adoption of antimicrobial coatings.

- Increasing consumer awareness of food safety and stringent regulatory standards further contribute to this segment’s growth.

- Additionally, the growing popularity of active packaging solutions that ensure product quality and safety enhances the surge for antimicrobial additives.

- Antimicrobial additives analysis lead the packaging coating additives market trends, driven by their critical role in ensuring product safety and shelf life, especially in food and pharmaceutical applications.

The anti-fog additives segment is anticipated to register the fastest CAGR during the forecast period.

- Anti-fog additives are increasingly used in food packaging to maintain clarity and visibility in refrigerated or humid environments.

- These additives prevent the accumulation of water droplets on the inner surface of packaging films, ensuring the product remains visible and appealing to consumers.

- The growing advancement for fresh and perishable food items in clear packaging is driving the adoption of anti-fog additives.

- Innovations in biodegradable and eco-friendly anti-fog solutions are further propelling the packaging coating additives market growth of this segment.

- Anti-fog additives analysis are expected to grow rapidly, driven by increasing packaging coating additives market opportunities for clear and appealing food packaging in perishable goods and advancements in sustainable additive technologies.

By Coating Type:

Based on coating type, the market is segmented into solvent-based coatings, water-based coatings, and powder coatings.

The water-based coatings segment accounted for the largest revenue in packaging coating additives market share in 2024.

- Water-based coatings are increasingly preferred due to their low volatile organic compound (VOC) emissions, making them an environmentally friendly option.

- These coatings are extensively used across food and beverage, pharmaceutical, and personal care packaging, where regulatory compliance and environmental sustainability are critical.

- Water-based coatings also offer superior adhesion and protection for substrates such as plastics and paper.

- The growing focus on reducing the environmental impact of packaging materials has led to increased adoption of water-based coatings in recent years.

- Water-based coatings dominate the market due to their environmental benefits, low VOC emissions, and suitability for a wide range of packaging applications.

The powder coatings segment is anticipated to register the fastest CAGR during the forecast period.

- Powder coatings are gaining traction due to their high durability, resistance to corrosion, and eco-friendly nature, as they do not contain solvents or VOCs.

- These coatings are increasingly used in metal packaging for industrial and pharmaceutical applications, where durability and aesthetics are critical.

- The development of advanced formulations that offer improved performance and compatibility with diverse substrates is driving surge in this segment.

- Additionally, the rising focus on sustainability and waste reduction supports the adoption of powder coatings.

- Powder coatings are expected to grow rapidly, driven by their durability, eco-friendly nature, and increasing use in metal packaging for industrial and pharmaceutical applications.

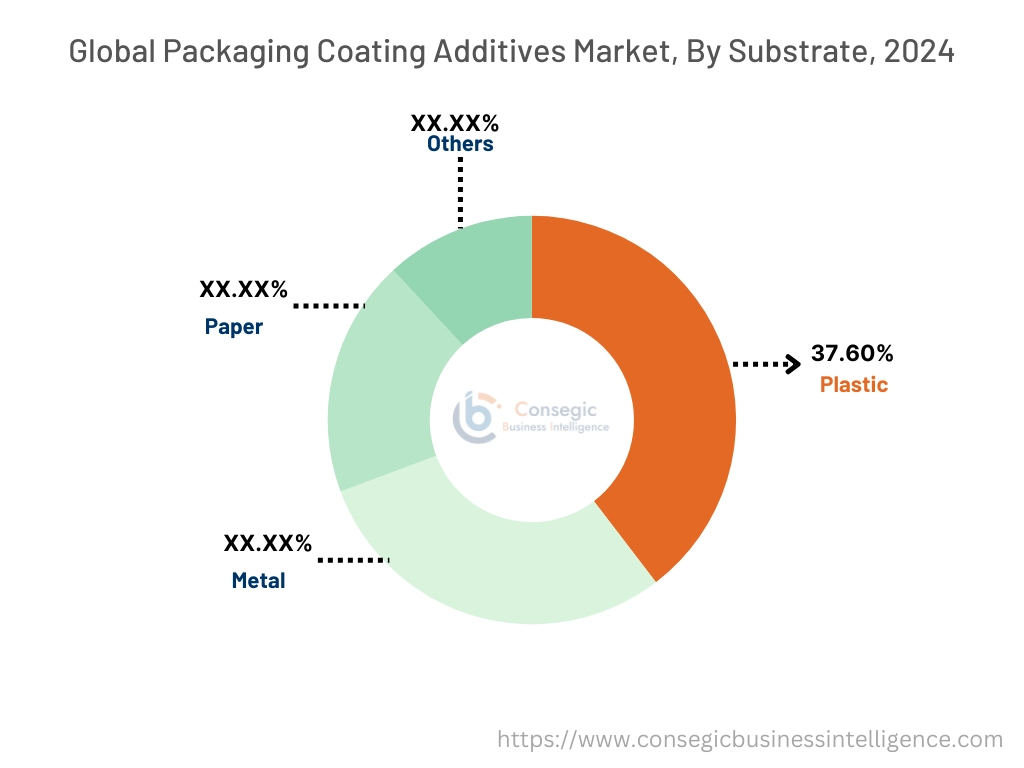

By Substrate:

Based on substrate, the market is segmented into plastics, metals, paper, and others.

The plastics segment accounted for the largest revenue share of 37.60 % in 2024.

- Plastics are the most widely used substrate in packaging due to their versatility, lightweight nature, and cost-effectiveness.

- Coating additives enhance the performance of plastic packaging by improving barrier properties, aesthetics, and functionality.

- The surge for high-performance coatings on plastic substrates is particularly high in the food and beverage and personal care industries, where maintaining product freshness and appeal is crucial.

- The increasing use of recyclable and biodegradable plastics further supports growth in this segment.

- Plastics lead the market as the dominant substrate, driven by their versatility and the growing adoption of high-performance coatings to enhance functionality and sustainability.

The paper segment is anticipated to register the fastest CAGR during the forecast period.

- The paper segment is experiencing rapid growth due to increasing advancement for sustainable and recyclable packaging materials.

- Coating additives improve the barrier properties and durability of paper-based packaging, making it suitable for applications such as food, beverages, and personal care products.

- The rising focus on reducing plastic usage and the implementation of stringent regulations promoting sustainable packaging solutions are driving the adoption of coated paper substrates.

- Paper is expected to grow rapidly as a substrate, driven by increasing surge for sustainable packaging solutions and the need for improved barrier properties in paper-based materials.

By End-Use Industry:

Based on end-use industry, the market is segmented into food & beverages, pharmaceuticals, personal care & cosmetics, industrial packaging, and others.

The food & beverages segment accounted for the largest revenue share in 2024.

- The food and beverage sectors is the largest consumer of packaging coating additives due to the critical need for maintaining product quality, freshness, and safety.

- Additives such as antimicrobial and anti-fog coatings are widely used to extend shelf life and enhance product appeal.

- The growing packaging coating additives market demand for packaged food and beverages, particularly in emerging markets, further supports the dominance of this segment.

- The shift towards sustainable packaging solutions, including bio-based coatings, is also driving innovation and growth in the food and beverage segment.

- Food and beverages dominate the market, driven by the critical need for shelf-life extension, product safety, and sustainability in packaging solutions.

The pharmaceuticals segment is anticipated to register the fastest CAGR during the forecast period.

- Pharmaceutical packaging requires high-performance coatings that ensure product integrity, safety, and regulatory compliance.

- Coating additives, such as antimicrobial and anti-static agents, are crucial in protecting sensitive drugs from contamination and maintaining their efficacy.

- The rising demand for advanced packaging solutions in the pharmaceutical sectors, driven by the increasing production of biologics and specialty drugs, is fueling growth in this segment.

- Innovations in intelligent coatings for pharmaceutical packaging, such as temperature indicators, are also contributing to the rapid rise of this segment.

- Pharmaceuticals are expected to grow rapidly, driven by the demand for high-performance, regulatory-compliant coatings that ensure drug safety and integrity.

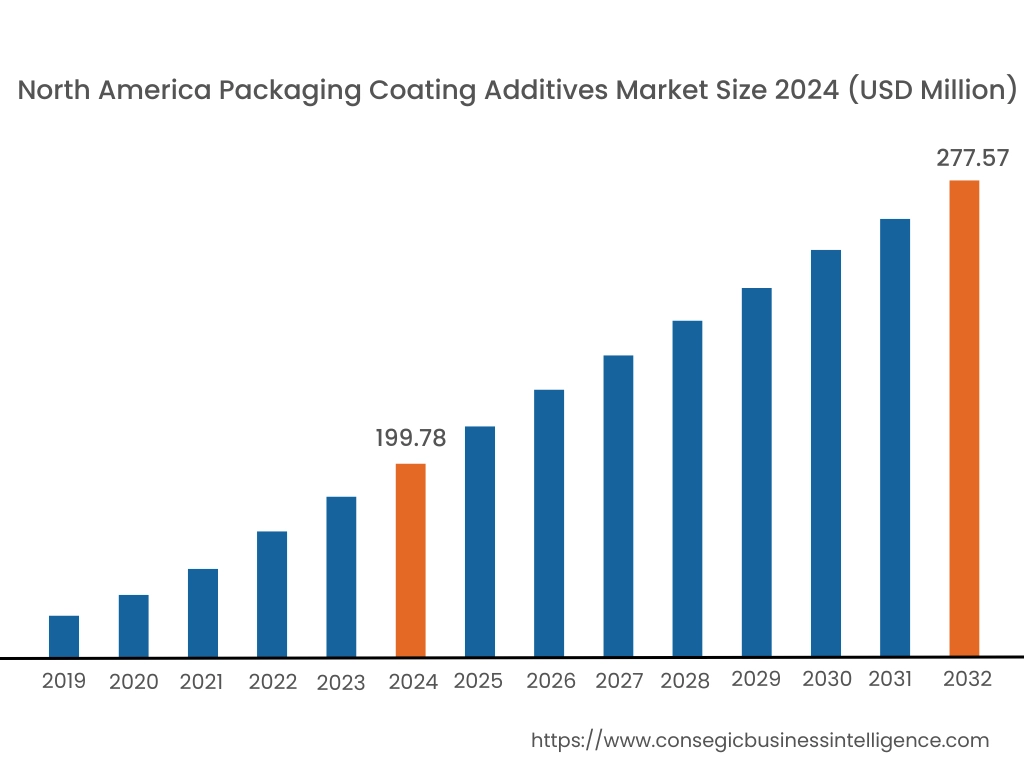

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

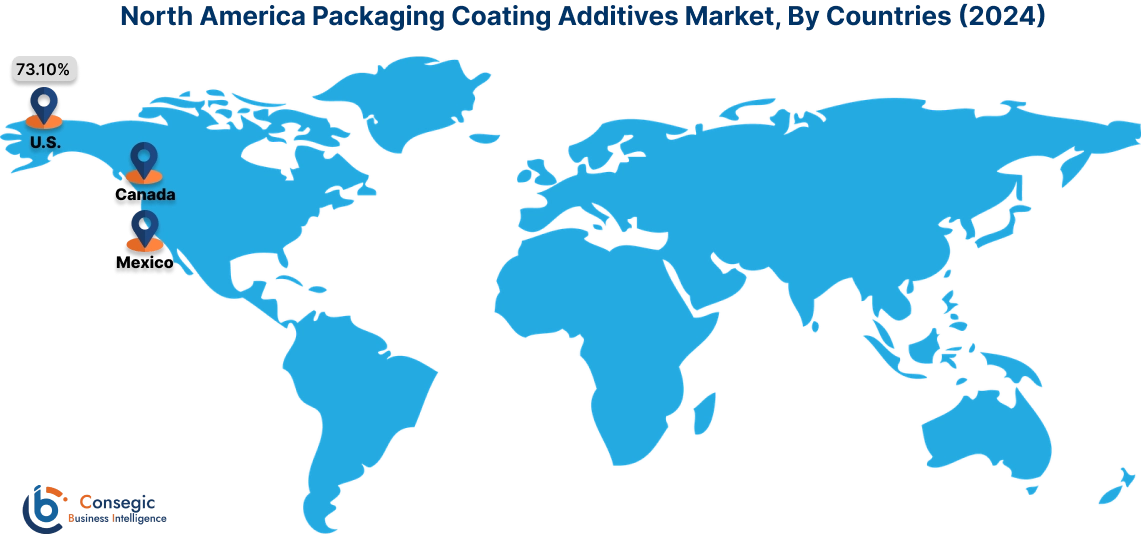

In 2024, North America was valued at USD 199.78 Million and is expected to reach USD 277.57 Million in 2032. In North America, the U.S. accounted for the highest share of 73.10% during the base year of 2024.

North America holds a significant stake in the packaging coating additives market analysis, due to the region's focus on sustainable packaging and advanced packaging technologies. The U.S. leads the market with a strong rise from the food and beverage, personal care, and pharmaceutical sectors. Coating additives are widely used to enhance the performance of packaging materials, including moisture resistance, anti-fogging, and anti-microbial properties, to meet consumer packaging coating additives market demands for product freshness and safety. Canada also contributes through its emphasis on eco-friendly additives in sustainable packaging solutions. However, strict regulatory requirements on chemical additives may challenge packaging coating additives market growth in the region.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 4.9% over the forecast period. Asia-Pacific is the fastest-growing region in the packaging coating additives market analysis, driven by rapid industrialization, urbanization, and increasing consumption of packaged goods in China, India, and Japan. China leads the market with its extensive food packaging and e-commerce industries, where coating additives improve packaging functionality and product protection. India’s expanding food and beverage and pharmaceutical sectors support the adoption of coating additives to enhance packaging performance and shelf life. Japan focuses on advanced coating technologies for high-quality packaging in electronics and premium food products. However, inconsistent regulations across countries and cost sensitivity may hinder the market’s full potential in the region.

Europe is a prominent market for packaging coating additives, supported by stringent environmental regulations and growing trends that focus on sustainable packaging solutions. Countries like Germany, France, and the UK are major contributors. Germany’s advanced packaging sectors adopt coating additives to enhance durability and improve barrier properties, particularly in food and pharmaceutical packaging. France emphasizes the use of bio-based additives to align with EU sustainability goals, while the UK focuses on anti-fogging and moisture-resistant coatings for food packaging. However, the analysis portrays the high cost of developing eco-friendly additives and strict compliance requirements that pose challenges for manufacturers.

The Middle East & Africa region is witnessing steady advancement in the packaging coating additives industry, primarily driven by increasing investment trends in food safety and pharmaceutical industries. Countries like Saudi Arabia and the UAE are adopting coating additives to improve packaging efficiency and meet rising consumer expectations for fresh and safe products. In Africa, South Africa is an emerging market where additives are used in food and beverage packaging to extend product shelf life under challenging storage conditions. However, limited local production capabilities and dependence on imports for advanced additives may constrain packaging coating additives market expansion.

Latin America is an emerging market for packaging coating additives, with Brazil and Mexico leading the region. Brazil’s growing food and beverage sectors use additives for moisture resistance and barrier enhancements in food packaging. Mexico’s expanding pharmaceutical sector and increasing focus on e-commerce packaging drive the adoption of anti-static and scratch-resistant coatings. The regional analysis is also exploring bio-based coating additives to align with global sustainability trends. However, economic instability and inconsistent regulatory frameworks may pose challenges for packaging coating additives market expansion in certain countries.

Top Key Players and Market Share Insights:

The packaging coating additives market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global packaging coating additives market. Key players in the packaging coating additives industry include -

Recent Industry Developments :

Research and Development:

- In 2024, AkzoNobel introduced new innovative packaging coatings for the metal packaging industry, particularly focusing on food and beverage cans. These innovations are designed to improve sustainability and performance. AkzoNobel's Securshield 500 coating, for example, is a notable advancement for food can coatings, offering enhanced protection and barrier properties. The coatings are tailored to meet the growing demand for environmentally responsible solutions, addressing the need for recyclable and eco-friendly packaging. AkzoNobel’s investment in research and development continues to push the boundaries of packaging coatings, providing superior performance while also adhering to sustainability goals. These innovations are positioning AkzoNobel as a leader in the evolving packaging coatings market.

Packaging Coating Additives Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 856.44 Million |

| CAGR (2025-2032) | 4.5% |

| By Function |

|

| By Coating Type |

|

| By Substrate |

|

| By End-Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the expected market size of the Packaging Coating Additives Market by 2032? +

Packaging Coating Additives Market size is estimated to reach over USD 856.44 Million by 2032 from a value of USD 602.27 Million in 2024 and is projected to grow by USD 618.64 Million in 2025, growing at a CAGR of 4.5% from 2025 to 2032.

What drives the growth of the Packaging Coating Additives Market? +

The increasing focus on food safety, shelf life enhancement, and the growing demand for sustainable and advanced packaging solutions are key drivers.

Which function segment dominates the market? +

The antimicrobial additives segment holds the largest share due to its critical role in enhancing product safety and shelf life, particularly in food and pharmaceutical packaging.

What are the challenges faced by the market? +

Technical challenges in scaling advanced additives, high production costs, and strict regulatory requirements for chemical additives pose significant hurdles for manufacturers.