- Summary

- Table Of Content

- Methodology

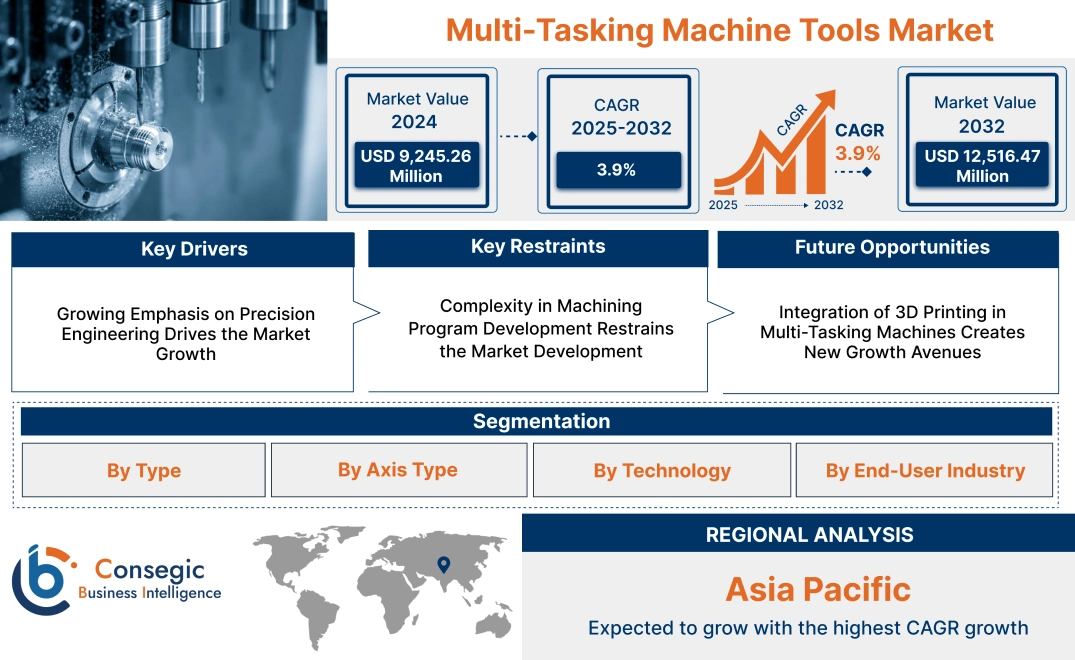

Multi-Tasking Machine Tools Market Size:

Multi-Tasking Machine Tools Market size is estimated to reach over USD 12,516.47 Million by 2032 from a value of USD 9,245.26 Million in 2024 and is projected to grow by USD 9,437.39 Million in 2025, growing at a CAGR of 3.9% from 2025 to 2032.

Multi-Tasking Machine Tools Market Scope & Overview:

Multi-tasking machine tools are advanced equipment designed to perform multiple machining operations, such as milling, turning, drilling, and grinding, within a single setup. These machines are widely utilized in industries such as aerospace, automotive, and industrial manufacturing to enhance productivity and precision while reducing operational complexity. Their ability to consolidate processes eliminates the need for multiple machines, streamlining workflows and saving time.

These tools are available in various configurations, including vertical and horizontal models, to accommodate different machining requirements and component sizes. They are equipped with advanced features such as computer numerical control (CNC), automated tool changers, and real-time monitoring systems to ensure accuracy and efficiency. The integration of multi-axis capabilities further enhances their versatility, allowing for the production of complex parts with high precision.

End-users of multi-tasking machine tools include manufacturers of automotive components, aerospace parts, and heavy machinery, where precision and operational efficiency are critical. These machines play a vital role in modernizing manufacturing processes and supporting the production of high-quality components across diverse industries.

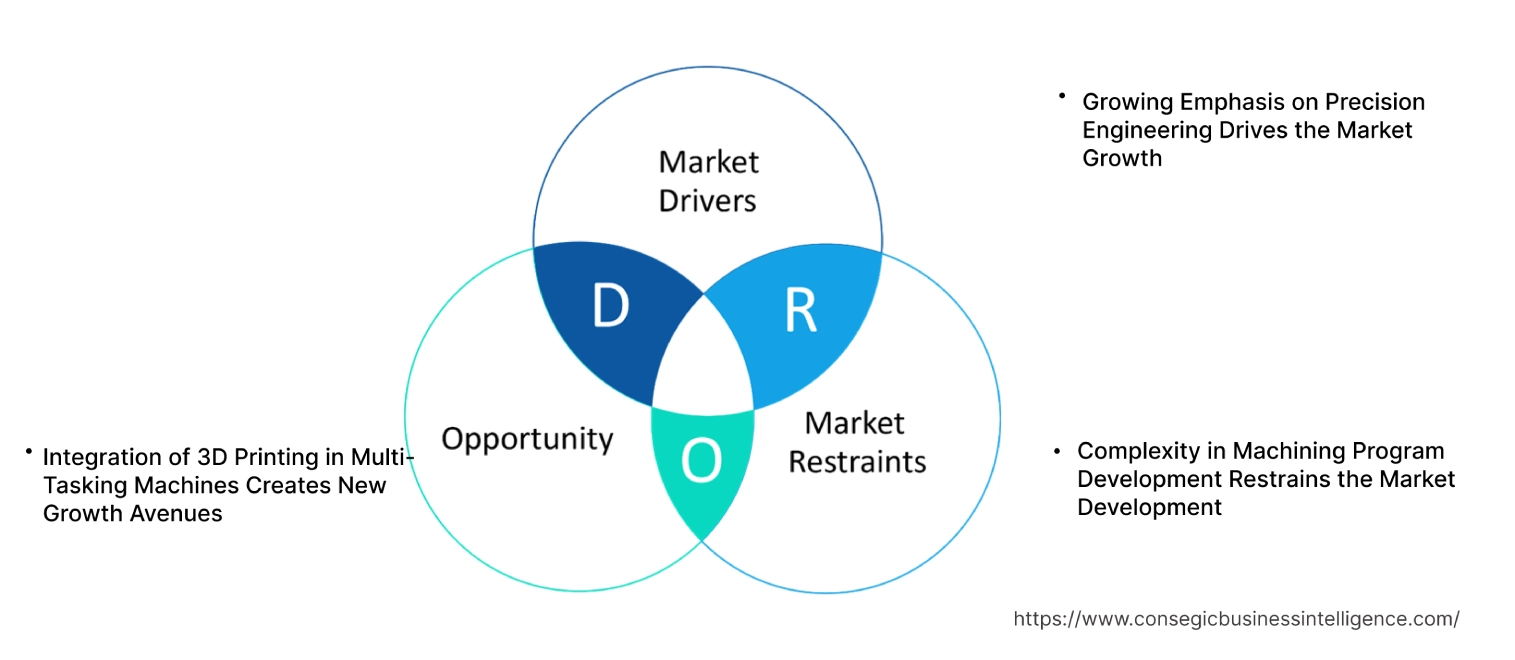

Key Drivers:

Growing Emphasis on Precision Engineering Drives the Market Growth

The growing demand for precision engineering across industries such as healthcare, defense, and electronics is significantly boosting the adoption of advanced machining solutions. These industries require components with intricate designs and extremely tight tolerances to meet stringent performance and safety standards. Multi-functional tools play a vital role by combining operations like milling, turning, and drilling into a single system, reducing the need for multiple setups and ensuring higher accuracy in production.

For instance, in the healthcare sector, precision machining is crucial for manufacturing surgical instruments and medical implants. Similarly, in electronics, it ensures the production of intricate parts for devices with compact designs. These tools also offer scalability, enabling manufacturers to meet high-volume production demands without compromising quality. As the emphasis on precision engineering continues to grow, multi-tasking machine tools are becoming indispensable for maintaining efficiency and reliability in critical applications. Therefore, the aforementioned factors are fueling the multi-tasking machine tools market growth.

Key Restraints:

Complexity in Machining Program Development Restrains the Market Development

The advanced capabilities of multi-tasking machines come with the constriant of developing complex machining programs. As these machines are designed to perform multiple operations, the number of axes to be controlled increases significantly. This added complexity makes programming more intricate and time-consuming, requiring skilled operators and advanced software tools. Industries relying on high precision often face delays during the initial programming stages, which impacts overall productivity.

The steep learning curve for operators unfamiliar with multi-axis systems further adds to operational restraints. This limitation discourages small and medium-sized enterprises from adopting these machines, as the need for specialized expertise and longer setup times increases operational costs. The complexity in programming remains a significant barrier to the wider adoption of multi-tasking machines in production environments, hindering the multi-tasking machine tools market demand.

Future Opportunities :

Integration of 3D Printing in Multi-Tasking Machines Creates New Growth Avenues

The incorporation of 3D printing technology into multi-tasking machines presents a transformative opportunity for industries. This integration allows manufacturers to produce complex parts with unmatched precision and efficiency, combining traditional subtractive machining with additive manufacturing capabilities.

The ability to create intricate geometries in a single setup reduces production times and eliminates the need for multiple machines, enhancing operational productivity. This innovation is particularly valuable in aerospace and medical manufacturing, where high complexity and precision are critical. For instance, aerospace components with intricate internal structures or custom medical implants will be manufactured with improved accuracy and reduced material waste. By enabling hybrid manufacturing solutions, the integration of 3D printing expands the scope of applications for multi-tasking machines, driving their adoption in high-tech and advanced engineering industries. Therefore, the above mentioned factors are boosting multi-tasking machine tools market opportunities.

Multi-Tasking Machine Tools Market Segmental Analysis :

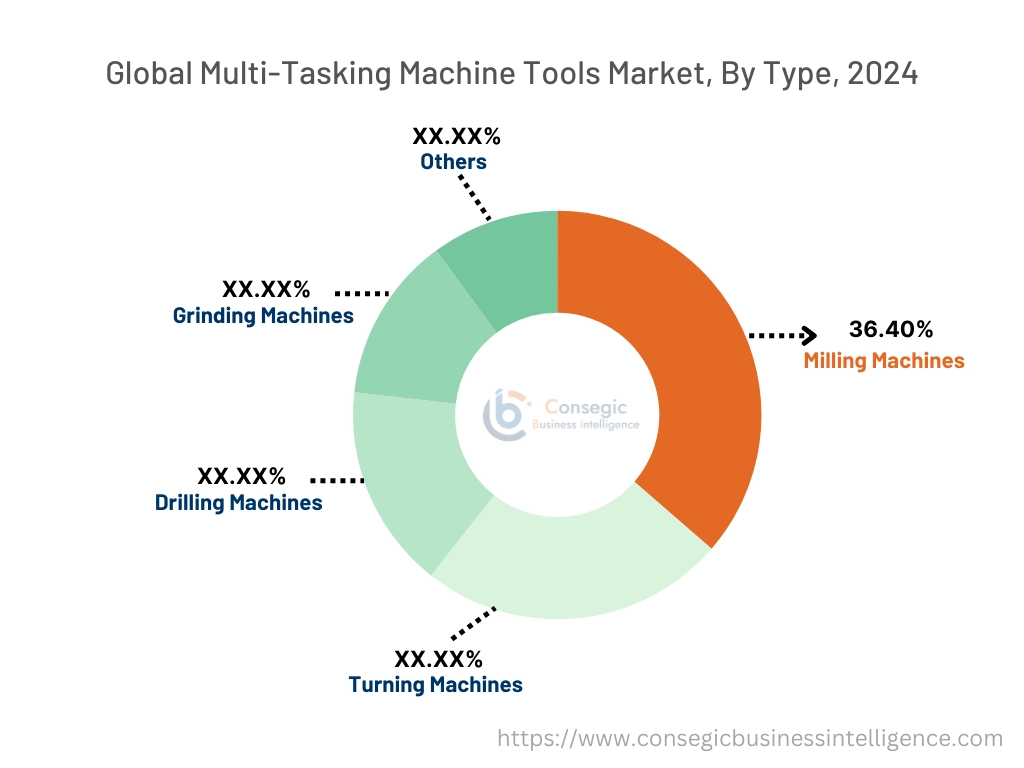

By Type:

Based on type, the market is segmented into milling machines, turning machines, drilling machines, grinding machines, and others.

The milling machines segment held the largest revenue of 36.40% of the total multi-tasking machine tools market share in 2024.

- Milling machines are highly versatile and widely used for complex machining operations in industries like automotive, aerospace, and general manufacturing.

- Their ability to handle high-precision tasks makes them essential for prototyping and small-to-medium production volumes.

- Technological advancements in milling machines, including multi-axis functionality, improve operational efficiency and productivity.

- The dominance of this segment is attributed to its widespread adoption across diverse industries, driven by increased demand for precision engineering solutions, contributing to the multi-tasking machine tools market expansion.

The grinding machines segment is expected to grow at the fastest CAGR during the forecast period.

- Grinding machines are critical for achieving high-quality finishes and ensuring precision in components used in automotive, medical devices, and aerospace applications.

- Rising demand for surface grinding and cylindrical grinding solutions in manufacturing and repair operations supports the segment’s expansion.

- Technological innovations, such as automated grinding solutions, are enhancing efficiency and reducing operational costs.

- As per the multi-tasking machine tools market analysis, the increased focus on material-specific grinding solutions, particularly for advanced composites and alloys, drives the rapid growth of this segment.

By Axis Type:

Based on axis type, the market is segmented into 3-axis, 4-axis, 5-axis, and 6-axis and above.

The 5-axis segment accounted for the largest revenue of the total multi-tasking machine tools market share in 2024.

- 5-axis machines enable complex geometrical machining with precision, making them ideal for industries like aerospace and medical manufacturing.

- Their ability to process multiple surfaces without repositioning enhances productivity and reduces errors in high-precision applications.

- Widespread adoption of 5-axis machines in automotive and energy sectors is driven by the need for intricate component manufacturing.

- As per multi-tasking machine tools market trends, the dominance of this segment is fueled by its capability to cater to advanced machining requirements, ensuring operational efficiency and cost-effectiveness.

The 6-axis and above segment is projected to grow at the fastest CAGR during the forecast period.

- 6-axis and above machines offer unparalleled flexibility and accuracy, enabling simultaneous machining of multiple surfaces.

- Their application in complex part manufacturing, particularly in aerospace and defense, supports their increasing adoption.

- Advanced automation and integration of AI in 6-axis machines enhance operational control and minimize production downtime.

- As per the market trends, growing investments in high-tech manufacturing processes across industries are driving the segment’s rapid progression, which further facilitates the multi-tasking machine tools market demand.

By Technology:

Based on technology, the market is segmented into CNC (Computer Numerical Control) and conventional.

The CNC segment held the largest revenue share in 2024.

- CNC technology offers precision, repeatability, and efficiency, making it the preferred choice for industries like automotive and aerospace.

- Integration of IoT and AI in CNC machines enhances real-time monitoring, predictive maintenance, and operational optimization.

- CNC machines are increasingly used for advanced materials machining, such as composites and titanium, in sectors like aerospace and healthcare.

- Thus, the segment’s dominance reflects its ability to address modern manufacturing challenges, ensuring high productivity and reduced operational costs, contributing to the multi-tasking machine tools market growth.

The conventional segment is expected to grow at the fastest CAGR during the forecast period.

- Conventional machines remain vital in small-scale industries and workshops due to their cost-effectiveness and ease of operation.

- These machines are preferred for simple machining tasks, particularly in developing regions with limited access to advanced technology.

- Technological upgrades in conventional machines, such as retrofitting with digital controls, enhance their functionality and extend their lifecycle.

- As per the multi-tasking machine tools market analysis, continued reliance on conventional systems for repair and low-volume production applications supports their rapid growth.

By End-Use Industry:

Based on end-user industry, the market is segmented into automotive, aerospace & defense, energy & power, electronics, industrial manufacturing, and others.

The automotive segment held the largest revenue share in 2024.

- Multi-tasking machine tools are extensively used in the automotive sector for high-precision manufacturing of engine components, transmissions, and chassis parts.

- Increasing production of electric vehicles (EVs) has driven the adoption of advanced machine tools for lightweight and high-performance components.

- Automation and robotics integration in automotive manufacturing processes boost productivity and ensure consistent quality.

- As per multi-tasking machine tools market trends, the segment’s dominance is supported by the sector’s continuous focus on innovation and efficiency in component production.

The aerospace & defense segment is projected to grow at the fastest CAGR during the forecast period.

- Aerospace and defense industries rely on multi-tasking machine tools for precision machining of critical components, such as turbine blades and structural parts.

- Rising investments in aircraft production and defense modernization programs fuel the demand for advanced manufacturing solutions.

- Adoption of high-speed and high-precision machining technologies in aerospace supports the segment’s rapid growth.

- The focus on lightweight materials and complex geometries in aerospace manufacturing further drives the extension of this segment, creating significant multi-tasking machine tools market opportunities.

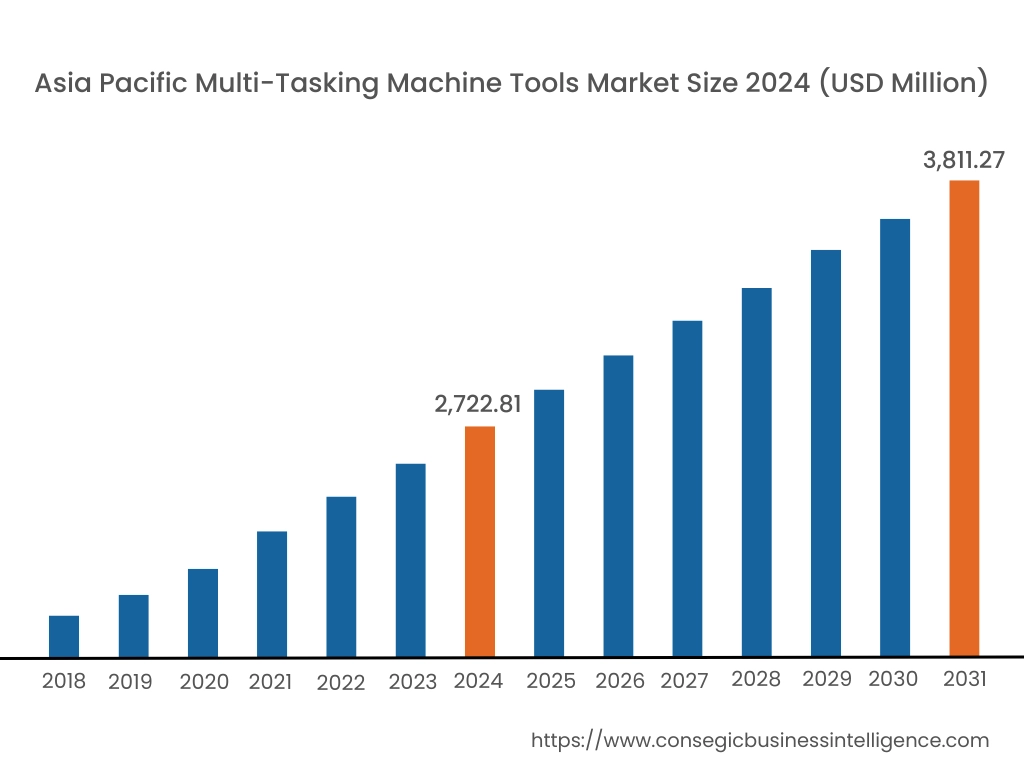

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

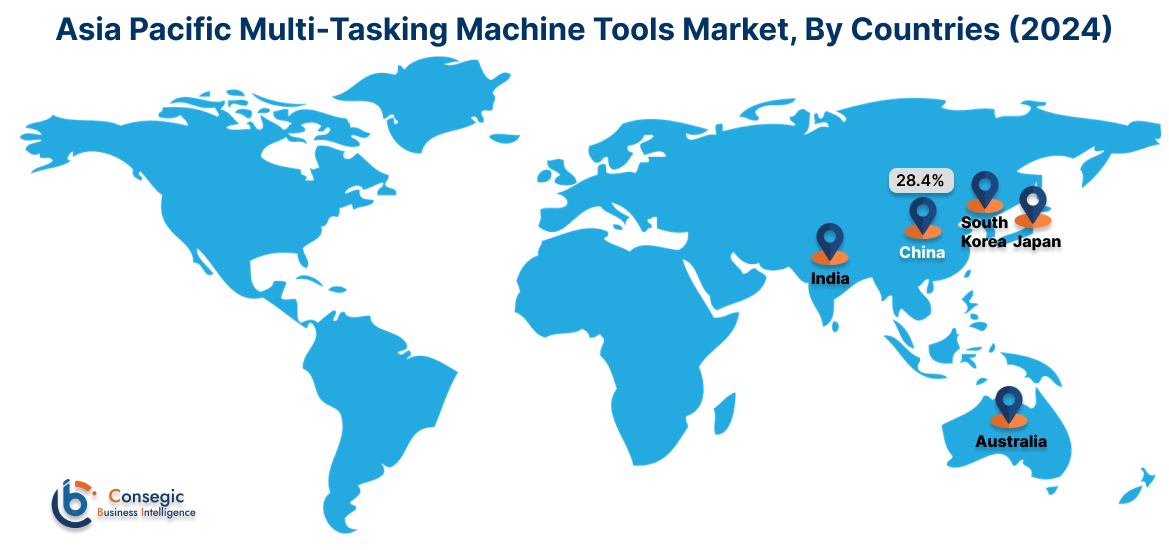

Asia Pacific region was valued at USD 2,722.81 Million in 2024. Moreover, it is projected to grow by USD 2,787.25 Million in 2025 and reach over USD 3,811.27 Million by 2032. Out of this, China accounted for the maximum revenue share of 28.4%. Asia-Pacific is witnessing rapid adoption of multi-tasking machine tools, with China, Japan, and South Korea leading the market. The region’s strong manufacturing base, particularly in automotive and consumer electronics, has fueled the need for versatile machining solutions. Trends indicate a rising inclination towards machines with automated tool-changing capabilities to minimize downtime and enhance productivity. Analysis of the market dynamics highlights that increasing investments in smart factories and the transition towards automated production lines are prominent factors influencing the requirement in this region.

North America is estimated to reach over USD 4,056.59 Million by 2032 from a value of USD 3,066.73 Million in 2024 and is projected to grow by USD 3,124.48 Million in 2025. The North American market is a key contributor to the adoption of multi-tasking machine tools, primarily driven by the aerospace and automotive industries in the United States. The region emphasizes automation and precision engineering, which aligns with the advanced functionalities of these tools. A notable trend is the integration of computer numerical control (CNC) systems with multi-tasking machines to achieve high customization and precision levels. Analysis reveals that small and medium enterprises (SMEs) in the region are gradually adopting these tools to compete with larger manufacturers, signaling a shift toward operational efficiency, which further influences the multi-tasking machine tools market expansion.

Europe plays a pivotal role in the market, with Germany, Italy, and Switzerland being major hubs for machine tool innovation. The region’s focus on Industry 4.0 principles has driven the incorporation of IoT and AI technologies into multi-tasking machine tools. A key trend observed in this market is the need for hybrid tools that combine additive and subtractive manufacturing capabilities, catering to the aerospace and defense sectors. Detailed analysis shows that the stringent regulations on production accuracy and efficiency in Europe further encourage the adoption of high-performance equipment.

The Middle East & Africa market is gradually adopting multi-tasking machine tools, particularly in the oil and gas, construction, and heavy equipment industries. Countries like the UAE and Saudi Arabia are focusing on industrial diversification, which supports the deployment of advanced manufacturing technologies. Analysis reveals a growing trend toward high-capacity machines capable of handling large components, aligning with the region’s infrastructure development needs.

Latin America showcases emerging potential in the market, with Brazil and Mexico being key players. The automotive sector’s presence in these countries significantly influences the need for multi-tasking machine tools. A notable trend in the region is the gradual adoption of compact and modular machines to address the space constraints in manufacturing facilities. Analysis suggests that while economic fluctuations may pose challenges, governmental initiatives promoting industrial modernization are expected to support market penetration.

Top Key Players and Market Share Insights:

The Multi-Tasking Machine Tools market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the Multi-Tasking Machine Tools market. Key players in the Multi-Tasking Machine Tools industry include –

- Yamazaki Mazak Corporation (Japan)

- DMG Mori Co., Ltd. (Japan)

- Haas Automation, Inc. (USA)

- Makino Milling Machine Co., Ltd. (Japan)

- Gleason Corporation (USA)

- Okuma Corporation (Japan)

- Doosan Machine Tools (South Korea)

- Nakamura-Tome Precision Industry Co., Ltd. (Japan)

- Tsugami Corporation (Japan)

Recent Industry Developments :

- In August 2024, Mazak expanded its NEO Series with the HQR 200/3 NEO and HQR 250/3 NEO Multi-Tasking Turning Centers. These machines feature two spindles and three turrets, enabling efficient DONE IN ONE part processing. They are equipped with the new MAZATROL SmoothG control technology, which supports three-turret functionality and includes Ai Thermal Shield for enhanced machining accuracy.

Multi-Tasking Machine Tools Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 12,516.47 Million |

| CAGR (2025-2032) | 3.9% |

| By Type |

|

| By Axis Type |

|

| By Technology |

|

| By End-Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the size of the Multi-Tasking Machine Tools Market? +

Multi-Tasking Machine Tools Market size is estimated to reach over USD 12,516.47 Million by 2032 from a value of USD 9,245.26 Million in 2024 and is projected to grow by USD 9,437.39 Million in 2025, growing at a CAGR of 3.9% from 2025 to 2032.

What are the segments and sub segments covered in the Multi-Tasking Machine Tools Market report? +

The market is segmented into machine type (Milling Machines, Turning Machines, Drilling Machines, Grinding Machines, Others), axis type (3-Axis, 4-Axis, 5-Axis, 6-Axis and Above), technology (CNC (Computer Numerical Control), Conventional), and end-user industry (Automotive, Aerospace & Defense, Energy & Power, Electronics, Industrial Manufacturing, Others).

Which is the fastest-growing segment in the Multi-Tasking Machine Tools Market? +

The aerospace & defense segment is projected to grow at the fastest CAGR during the forecast period, driven by increasing investments in aircraft production and defense modernization programs.

Who are the key players in the Multi-Tasking Machine Tools Market? +

Major players in the Multi-Tasking Machine Tools Market include Yamazaki Mazak Corporation (Japan), DMG Mori Co., Ltd. (Japan), Okuma Corporation (Japan), Doosan Machine Tools (South Korea), Nakamura-Tome Precision Industry Co., Ltd. (Japan), Tsugami Corporation (Japan), Haas Automation, Inc. (USA), Makino Milling Machine Co., Ltd. (Japan), and Gleason Corporation (USA).