- Summary

- Table Of Content

- Methodology

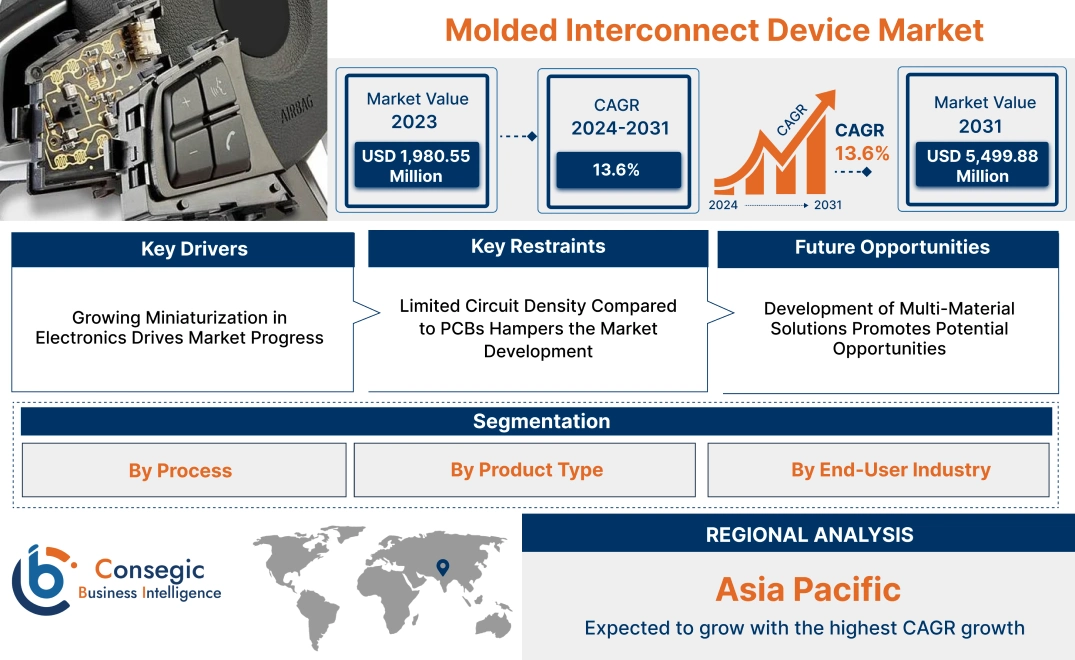

Molded Interconnect Device Market Size:

Molded Interconnect Device Market size is estimated to reach over USD 5,499.88 Million by 2031 from a value of USD 1,980.55 Million in 2023 and is projected to grow by USD 2,214.97 Million in 2024, growing at a CAGR of 13.6% from 2024 to 2031.

Molded Interconnect Device Market Scope & Overview:

Molded interconnect devices (MID) are innovative 3D electronic components that combine mechanical and electrical functionalities within a single structure. These devices are manufactured using advanced techniques such as laser direct structuring (LDS) and two-shot molding, allowing the integration of circuit pathways onto plastic substrates. MID technology offers compact designs, reduced weight, and enhanced performance, making it suitable for applications in industries such as automotive, consumer electronics, healthcare, and telecommunications.

MID components are designed to provide precise electrical connections and structural support, enabling the miniaturization of electronic devices without compromising functionality. They are used in various applications, including sensors, antennas, connectors, and medical devices. The versatility of MID technology allows seamless integration into complex assemblies, enhancing product design flexibility and efficiency.

End-users of molded interconnect devices include manufacturers of automotive components, electronic devices, and medical equipment, where lightweight, high-performance solutions are essential for improving product capabilities and operational efficiency. MID technology plays a critical role in advancing next-generation electronic designs across diverse sectors.

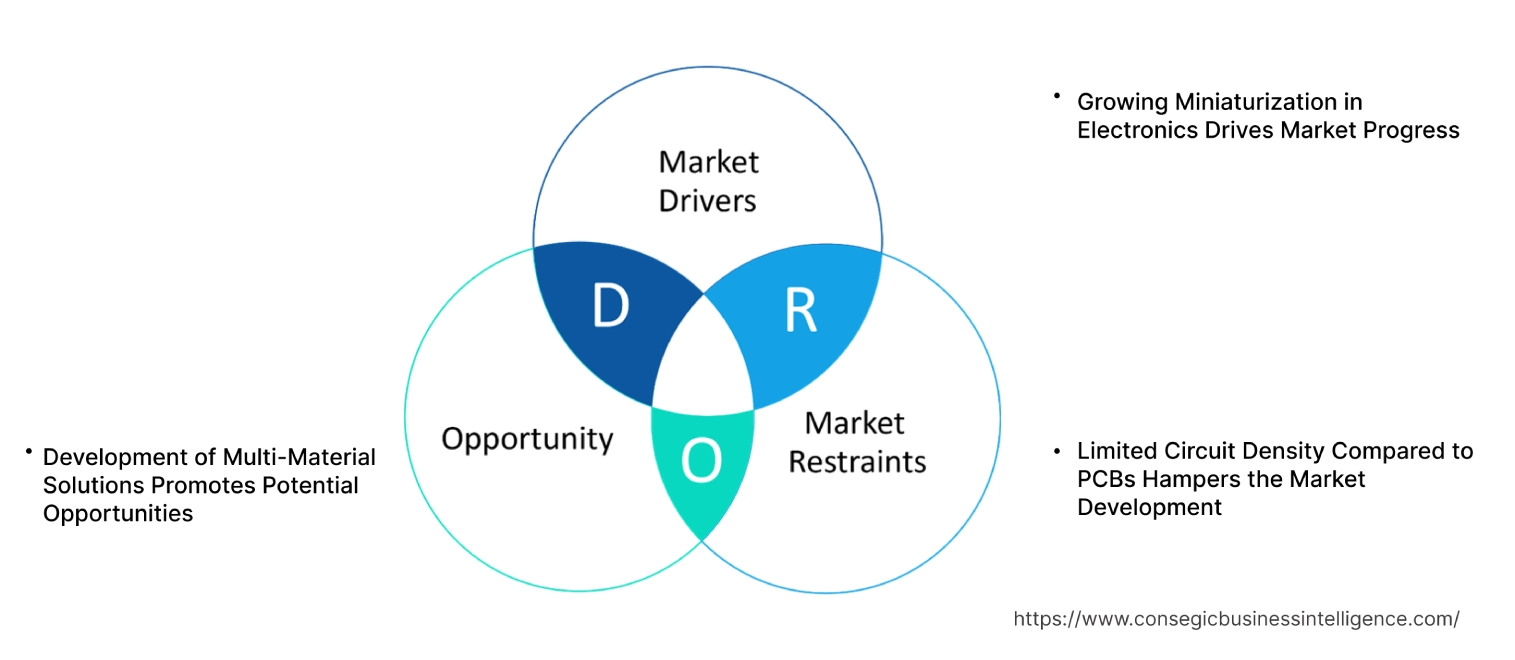

Key Drivers:

Growing Miniaturization in Electronics Drives Market Progress

The growing demand for smaller and more compact electronic devices is fueling the adoption of advanced design solutions like molded interconnect devices (MIDs). These devices enable the seamless integration of electrical and mechanical functions into a single 3D component, significantly reducing the size and complexity of electronic systems. MIDs are particularly advantageous in industries such as consumer electronics, automotive, and medical devices, where compact designs are critical. For example, in consumer gadgets, MIDs support sleek and lightweight designs, while in automotive applications, they optimize space utilization for advanced driver-assistance systems (ADAS) and infotainment systems.

Similarly, in medical devices, their compact and multifunctional nature enhances the portability of diagnostic and wearable healthcare solutions. As trends in miniaturization and high-density electronics continue to evolve, MIDs are becoming indispensable in meeting the demand for smaller, more efficient, and innovative electronic devices. Thus, the above-mentioned factors are driving the molded interconnect device market growth.

Key Restraints :

Limited Circuit Density Compared to PCBs Hampers the Market Development

Molded interconnect devices (MIDs) face a significant limitation in circuit density due to their design architecture. Unlike printed circuit boards (PCBs), which incorporate multiple conductive layers to support highly complex circuits, MIDs are restricted to only two layers — the top and bottom surfaces. This design constraint reduces their capacity to accommodate intricate electronic layouts and high-density interconnections. Industries requiring advanced, multi-layered circuitry, such as telecommunications, aerospace, and high-performance computing, often find MIDs inadequate for their technical demands.

The inability to match the circuit density of PCBs limits MIDs' adoption in applications where compact, densely packed circuits are essential, particularly in high-tech and mission-critical environments. Consequently, this disadvantage poses a significant restraint to the molded interconnect device market demand, especially in sectors that prioritize scalability and advanced electronic functionality.

Future Opportunities :

Development of Multi-Material Solutions Promotes Potential Opportunities

The development of multi-material manufacturing techniques is revolutionizing the capabilities of molded interconnect devices (MIDs), allowing the integration of diverse materials into a single component. This innovation enhances the durability, functionality, and versatility of MIDs, making them suitable for a wider range of high-performance applications. By combining materials such as plastics, metals, and conductive inks, manufacturers create components that meet specific performance requirements, such as heat resistance, electrical conductivity, and mechanical strength. These advancements are particularly valuable in industries like automotive, aerospace, and healthcare, where customized and robust solutions are essential.

For instance, in automotive applications, multi-material MIDs enable the development of lightweight yet durable components for advanced driver-assistance systems (ADAS). In the healthcare sector, they facilitate the production of compact and reliable medical devices. The growing emphasis on high-performance and application-specific designs is driving the adoption of multi-material MIDs, presenting significant molded interconnect device market opportunities for innovation and growth.

Molded Interconnect Device Market Segmental Analysis :

By Process:

Based on the process, the market is segmented into Laser Direct Structuring (LDS), Two-Shot Molding, and Film Techniques.

The Laser Direct Structuring (LDS) segment accounted for the largest revenue of the total molded interconnect device market share in 2023.

- LDS enables the precise placement of conductive paths on three-dimensional surfaces, making it ideal for miniaturized and complex electronic components.

- The segment’s dominance is driven by its application in industries like automotive and consumer electronics, where compact and lightweight designs are essential.

- Increased adoption of LDS for manufacturing antennas and sensors, especially in the telecommunication and healthcare industries, boosts its market share.

- As per molded interconnect device market analysis, the need for LDS is further supported by its cost-effectiveness and ability to meet high-volume production needs.

The Two-Shot Molding segment is expected to grow at the fastest CAGR during the forecast period.

- Two-shot molding combines two materials into one part, offering enhanced design flexibility and mechanical strength.

- Its growing application in the automotive and industrial sectors for producing durable and functional components fuels the segment’s rapid growth.

- The process’s ability to reduce assembly costs and improve product reliability drives adoption across diverse industries.

- As per molded interconnect device market trends, the increasing use of two-shot molding in advanced lighting systems and switches supports its accelerated growth.

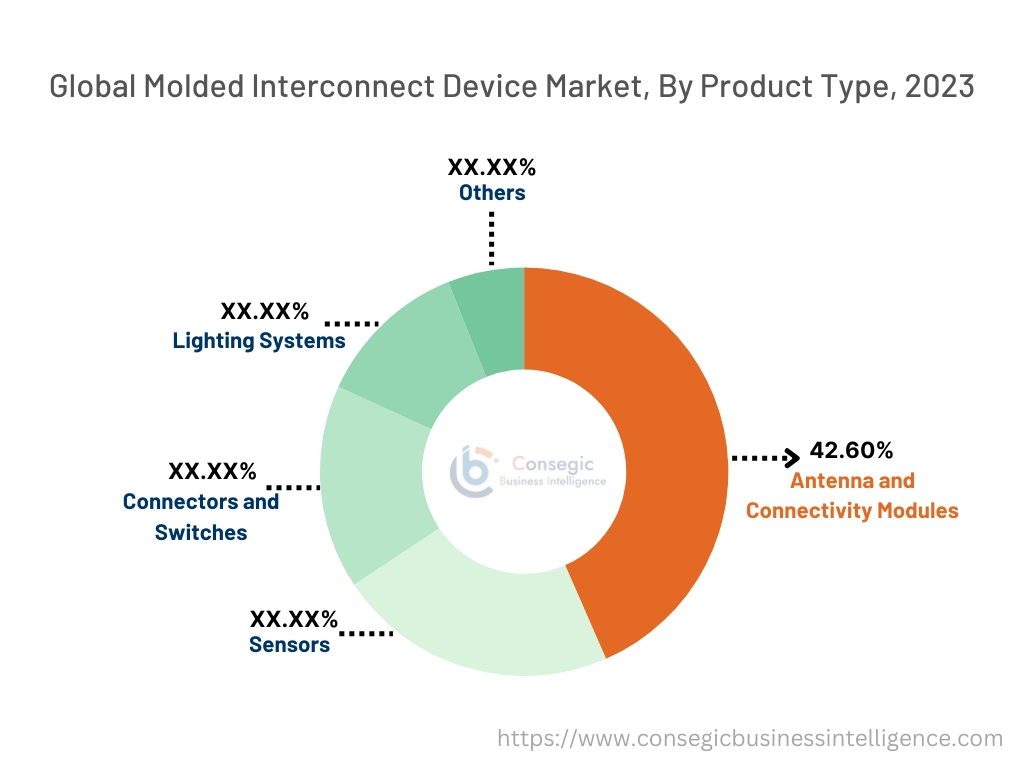

By Product Type:

Based on product type, the market is segmented into Antenna and Connectivity Modules, Sensors, Connectors and Switches, Lighting Systems, and Others.

The Antenna and Connectivity Modules segment held the largest revenue of 42.60% of the total molded interconnect device market share in 2023.

- These modules are widely used in telecommunications and consumer electronics to enable seamless connectivity in devices like smartphones and routers.

- The segment’s prominence is attributed to the increasing adoption of 5G technology, which drives the need for advanced and compact antenna designs.

- Growing demand for IoT devices and smart home solutions has further boosted the adoption of molded interconnect devices for connectivity applications.

- The rising integration of antennae modules in automotive infotainment systems and smart vehicles enhances the segment’s market share, driving the molded interconnect device market expansion.

The Sensors segment is expected to grow at the fastest CAGR during the forecast period.

- Molded interconnect devices are increasingly used in sensor applications due to their precision and ability to integrate multiple functions into a compact design.

- The automotive sector relies on sensors for ADAS and other critical functions, driving their adoption.

- Healthcare devices, such as patient monitoring systems, also incorporate sensors for accurate and real-time data collection, further supporting segment growth.

- As per the molded interconnect device market analysis, technological advancements in sensor design and the rising focus on energy efficiency propel the adoption of molded interconnect devices in this segment.

By End-User Industry:

Based on end-user industry, the market is segmented into Automotive, Consumer Electronics, Healthcare, Industrial, Telecommunication, and Others.

The Automotive segment accounted for the largest revenue share in 2023.

- Molded interconnect devices are essential in automotive applications, including advanced lighting systems, sensors, and connectivity modules.

- Increased adoption of electric vehicles (EVs) and autonomous vehicles drives the need for lightweight and compact electronic components, supporting this segment’s growth.

- Automakers leverage MID technology to enhance vehicle performance and integrate advanced features like ADAS and infotainment systems.

- The analysis of segmental trends depicts that the dominance of this segment is supported by the automotive sector's focus on sustainability and energy efficiency, contributing to the molded interconnect device market growth.

The Consumer Electronics segment is expected to grow at the fastest CAGR during the forecast period.

- The segment’s rapid growth is driven by the increasing use of MIDs in smartphones, wearables, and smart home devices.

- Compact designs, enhanced performance, and reduced manufacturing costs make MIDs a preferred choice for consumer electronics manufacturers.

- Rising adoption of 5G technology and IoT devices fuels the demand for connectivity modules and antennas in this segment.

- As per market trends, the growing consumer preference for innovative and multifunctional devices supports the proliferation of this segment, which further fuels the molded interconnect device market demand.

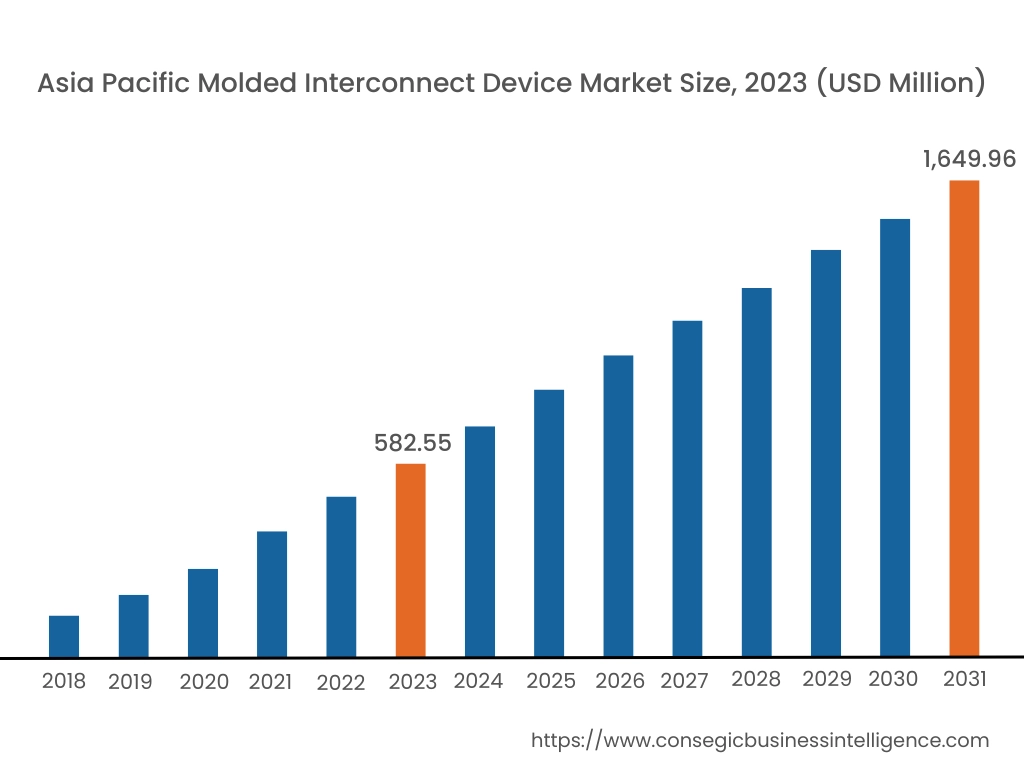

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

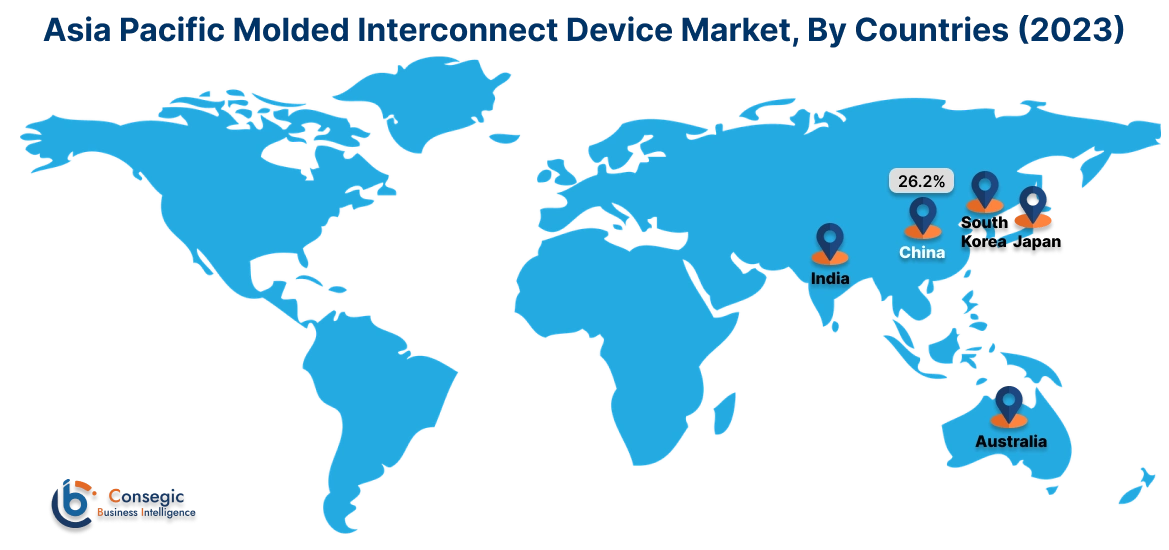

Asia Pacific region was valued at USD 582.55 Million in 2023. Moreover, it is projected to grow by USD 652.58 Million in 2024 and reach over USD 1,649.96 Million by 2031. Out of these, China accounted for the largest share of 26.2% in 2023. The Asia-Pacific region is experiencing rapid development in the MID market, driven by industrialization and technological advancements in countries such as China, Japan, and South Korea. The proliferation of consumer electronics and the expansion of the semiconductor sector have intensified the need for compact and efficient interconnect solutions. As per molded interconnect device market trends, government initiatives promoting digital transformation further influence market progress.

North America is estimated to reach over USD 1,809.46 Million by 2031 from a value of USD 658.32 Million in 2023 and is projected to grow by USD 735.61 Million in 2024. This region holds a significant share of the MID market, driven by rapid technological innovation and the presence of major industry players. The United States, in particular, has seen extensive adoption of MIDs across sectors such as automotive, consumer electronics, and healthcare. A notable trend is the integration of MIDs in advanced driver-assistance systems (ADAS) and medical devices, enhancing functionality and driving molded interconnect device market opportunities.

Europe represents a substantial portion of the global MID market, with countries like Germany, France, and the United Kingdom leading in adoption and innovation. The region's emphasis on miniaturization and efficient design processes has propelled the utilization of MIDs, particularly in the telecommunications and automotive sectors. Analysis indicates a growing trend towards the deployment of MIDs in 5G infrastructure and electric vehicles, aiming to enhance performance and reliability.

The Middle East & Africa region shows a growing interest in MID solutions, particularly in the telecommunications and automotive sectors. Countries like the United Arab Emirates and South Africa are investing in advanced interconnect technologies to support digitalization efforts. Analysis suggests an increasing trend towards adopting MIDs in smart city projects and connected vehicles, enhancing connectivity and operational efficiency.

Latin America is an emerging market for MIDs, with Brazil and Mexico being key contributors. The region's growing electronics manufacturing sector and initiatives to promote technological innovation have spurred the adoption of advanced interconnect solutions. As per the market analysis, government policies aimed at modernizing infrastructure and enhancing digital capabilities influence molded interconnect device market expansion.

Top Key Players and Market Share Insights:

The Molded Interconnect Device market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global Molded Interconnect Device market. Key players in the Molded Interconnect Device industry include –

- Molex LLC (USA)

- TE Connectivity Ltd. (Switzerland)

- Arlington Plating Company (USA)

- MacDermid, Inc. (USA)

- JOHNAN Corporation (Japan)

- Amphenol Corporation (USA)

- LPKF Laser & Electronics AG (Germany)

- 2E mechatronic GmbH & Co. KG (Germany)

- Harting Technology Group (Germany)

Molded Interconnect Device Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 5,499.88 Million |

| CAGR (2024-2031) | 13.6% |

| By Process |

|

| By Product Type |

|

| By End-User Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Molded Interconnect Device Market? +

Molded Interconnect Device Market size is estimated to reach over USD 5,499.88 Million by 2031 from a value of USD 1,980.55 Million in 2023 and is projected to grow by USD 2,214.97 Million in 2024, growing at a CAGR of 13.6% from 2024 to 2031.

What specific segmentation details are covered in the Molded Interconnect Device Market report? +

The market is segmented based on process (Laser Direct Structuring, Two-Shot Molding, Film Techniques), product type (Antennae and Connectivity Modules, Sensors, Connectors and Switches, Lighting Systems, Others), end-user industry (Automotive, Consumer Electronics, Healthcare, Industrial, Telecommunications, Others), and region (Asia-Pacific, Europe, North America, Latin America, Middle East & Africa).

Which is the fastest-growing segment in the Molded Interconnect Device Market? +

The Sensors segment is expected to grow at the fastest CAGR during the forecast period, driven by their increasing adoption in automotive, healthcare, and consumer electronics applications.

Who are the major players in the Molded Interconnect Device Market? +

Major players in the Molded Interconnect Device market include Molex LLC (USA), TE Connectivity Ltd. (Switzerland), Amphenol Corporation (USA), LPKF Laser & Electronics AG (Germany), 2E mechatronic GmbH & Co. KG (Germany), Harting Technology Group (Germany), Arlington Plating Company (USA), MacDermid, Inc. (USA), and JOHNAN Corporation (Japan).