- Summary

- Table Of Content

- Methodology

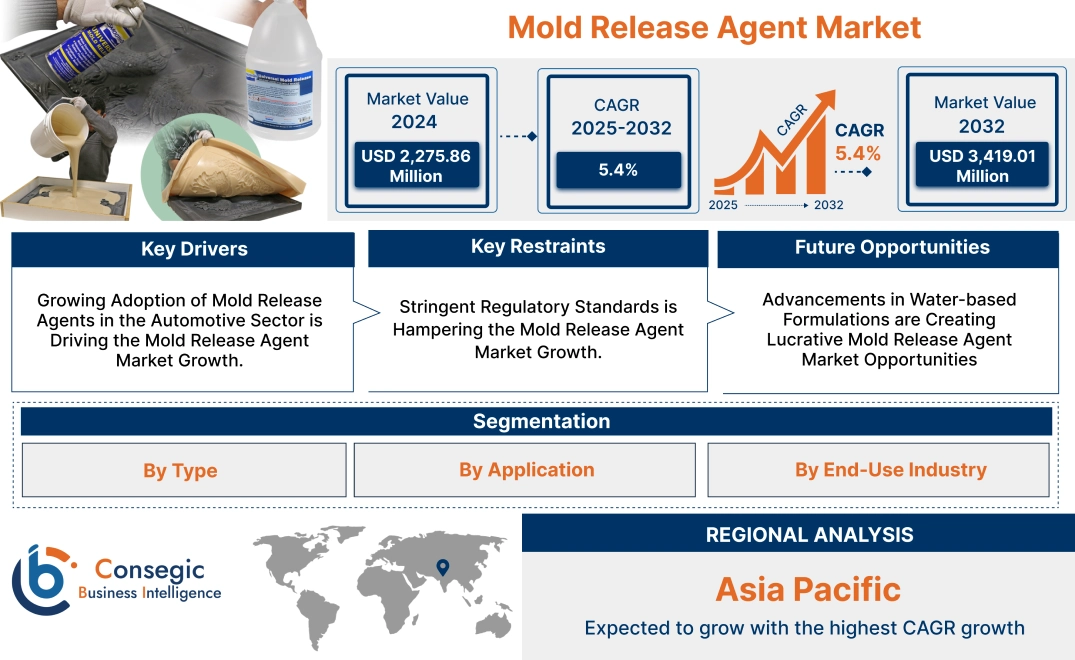

Mold Release Agent Market Size:

Mold Release Agent Market size is growing with a CAGR of 5.4% during the forecast period (2025-2032), and the market is projected to be valued at USD 3,419.01 Million by 2032 from USD 2,275.86 Million in 2024.

Mold Release Agent Market Scope & Overview:

Mold release agents are applied to surfaces to facilitate the smooth and efficient removal of products such as molded plastics, rubber parts, and composite components among others after the manufacturing process. These agents create a barrier between the mold and the product, reducing friction and preventing adhesion. They significantly reduce the risk of product defects like flash, sticking, and surface imperfections, leading to improved product quality. By minimizing friction and adhesion between the product and the mold, these agents facilitate smooth and efficient product removal, reducing cycle times and increasing production efficiency. Additionally, these release agents extend the lifespan of molds by preventing wear and tears, reducing maintenance costs.

Categorized by type, application, and end-use industry, these agents play a major role in optimizing production efficiency and product quality. Water-based and solvent-based agents among others, while differing in environmental impact and performance characteristics, are commonly employed in diverse manufacturing sectors. Additionally, specialized agents tailored for specific applications, such as plastic, rubber, metal, and concrete molding, further enhance the versatility and effectiveness of these release agents. The automotive, aerospace, electronics, and construction industries, among others, rely on these agents to maintain consistent product quality and streamline production processes.

Mold Release Agent Market Dynamics - (DRO) :

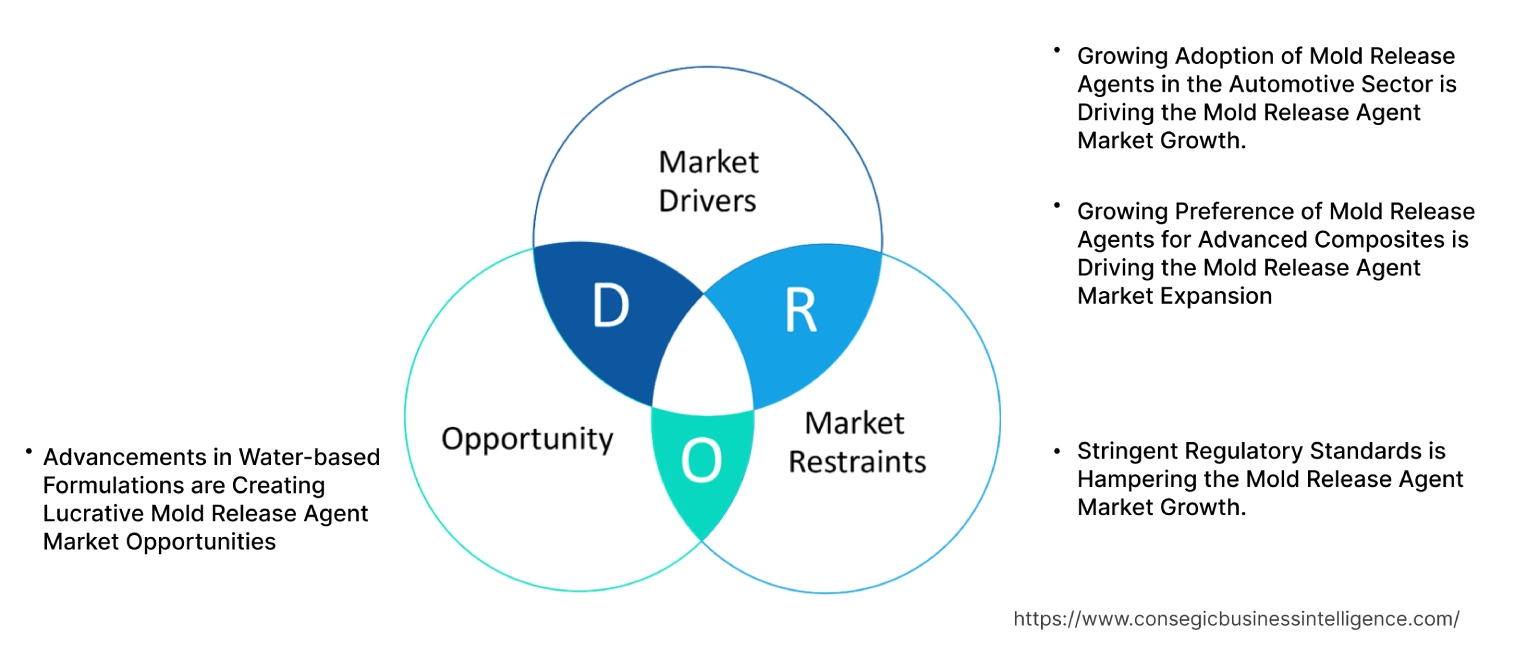

Key Drivers:

Growing Adoption of Mold Release Agents in the Automotive Sector is Driving the Mold Release Agent Market Growth.

The automotive sector is a major driver in the market. The increasing requirement for lightweight, fuel-efficient vehicles has led to the increased use of advanced materials like composites and plastics in automotive manufacturing. These materials require specialized mold release agents to ensure smooth and efficient product removal from molds. Additionally, they ensure the efficient production of various components, including seals, O-rings, and gaskets. These agents facilitate the smooth release of these parts from molds, preventing damage and improving product quality. For applications involving EPDM and FKM materials, specialized release agents are required to withstand high temperatures, pressures, and chemical exposure. Various manufacturers are introducing novel release agents for automotive manufacturing.

- In March 2021, ITW Pro Brandsintroduced DiamondKote™ DKW-4168 which is a high-performance mold release agent specifically designed to optimize the manufacturing processes within the automotive sector. By providing exceptional release properties and reducing cycle times, this innovative solution empowers automotive manufacturers to streamline production, improve product quality, and ultimately enhance overall operational efficiency.

Thus, the rising use of these releasing agents in automotive sectors is influencing the mold release agent market demand.

Growing Preference of Mold Release Agents for Advanced Composites is Driving the Mold Release Agent Market Expansion.

The growing preference for advanced composites in various industries, including aerospace, electronics, and renewable energy among others, is significantly driving the mold release agent market demand. These high-performance materials require specialized release agents that withstand extreme temperatures, pressures, and harsh chemical environments. As the requirement for lightweight, durable, and high-performance composite components increases, the need for efficient and reliable release agents becomes paramount. Manufacturers are introducing novel release agents for advanced composite materials.

- In January 2021, ChemTrend introduced Chemlease 2754W, which is a water-based release agent specifically engineered for the requirements of advanced composites and high-performance carbon fiber components. This semi-permanent solution delivers exceptional release properties, enabling multiple releases per application and significantly reducing costs. It is designed to offer exceptional release properties on molds and minimal transfer to the finished product, making it ideal for processes such as infusion, autoclaving, and compression molding.

Thus, this surge in advanced composite materials is driving the development of innovative release agents to meet the stringent requirements of these high-performance applications.

Key Restraints:

Stringent Regulatory Standards is Hampering the Mold Release Agent Market Growth.

Stringent regulatory standards imposed by government bodies worldwide pose significant constraints in the Mold Release Agent market. These regulations, designed to protect the environment and public health, increase production costs and slow down product development. Governments worldwide are imposing stricter regulations on chemical emissions and environmental impact, particularly concerning volatile organic compounds (VOCs) and hazardous substances. These regulations are compelling for manufacturers to reformulate their products to meet compliance standards, often leading to increased production costs and complexities.

Additionally, the stringent testing and approval processes required to introduce new products delay market entry and hinder innovation. While these regulations are essential for environmental protection and public health, they also stifle market growth and limit the development of advanced mold-release technologies.

Future Opportunities :

Advancements in Water-based Formulations are Creating Lucrative Mold Release Agent Market Opportunities

The market is experiencing significant mold release agent market opportunities, influenced by advancements in water-based formulations. These eco-friendly alternatives are gaining traction due to their reduced environmental impact and improved safety profiles. Water-based formulations offer several benefits, including lower VOC emissions, reduced fire hazards, and easier cleanup. Additionally, they are compatible with a wide range of materials, making them suitable for various applications. As regulatory standards become more stringent, the requirement for sustainable and non-toxic mold release agents is increasing. Manufacturers are developing advanced formulations that offer several benefits.

- In May 2024, Kao Corporation introduced LUNAFLOW RA, an innovative mold release agent formulated using cutting-edge cellulose nanofiber (CNF) technology. It offers superior demolding performance and durability. Its solvent- free and fluorine-free composition makes it both worker-friendly and environmentally responsible, aligning with global sustainability goals.

Thus, as per the market analysis, the advancements in formulation are propelling the market forward, creating lucrative opportunities for manufacturers and suppliers.

Mold Release Agent Market Segmental Analysis :

By Type:

Based on type, the market is categorized into water-based, solvent-based, and others.

Trends in the Type:

- Water-based agents are less hazardous to human health and pose fewer risks in terms of flammability and toxicity.

- The trends for solvent-based agents in rubber and plastic molding are influencing the segment.

The water-based segment accounted for the largest market share in 2024 and is expected to grow at the fastest CAGR over the forecast period.

- Water-based mold release agents have gained significant popularity in recent years due to their environmentally friendly nature and improved safety profiles.

- Unlike solvent-based agents, they emit fewer volatile organic compounds (VOCs), reducing air pollution and improving indoor air quality.

- These agents are typically formulated using water as the primary solvent, along with various additives such as surfactants, emulsifiers, and release agents.

- Water-based agents offer several advantages, including easy application, reduced fire hazards, and compatibility with a wide range of materials.

- They are particularly well-suited for applications in the food sector, medical device manufacturing, and other sectors where cleanliness and safety are paramount.

- Various water-based release agents are being introduced to provide reliable release of these agents across various substrates.

- For instance, Miller-Stepheson introduced ReleaSys 8200 which is a high-performance, water-based, semi-permanent mold release agent that offers exceptional release properties for a wide range of materials. This innovative solution is designed to provide reliable, consistent release across various moldable substrates, including rubbers, elastomers, and silicones.

- Thus, based on the market analysis, the rise in the utilization of water-based release agents is driving the mold release agent market trends.

By Application:

Based on applications, the market is categorized into die casting, plastic molding, rubber molding, concrete molding, and others

Trends in Application:

- The growing trends for mold release agents in composite molding are influencing the segment

- There is a rise in the requirement for mold-releasing agents for rubber molding

The die-casting segment accounted for the largest market share in the year 2024.

- Mold release agents play a crucial role in the die-casting process, ensuring the smooth and efficient ejection of cast parts from the mold.

- By creating a barrier between the molten metal and the mold surface, these agents prevent adhesion and facilitate the release of the finished product.

- In die casting, these release agents are typically applied to the mold cavity surface before each casting cycle.

- This is done manually, using spray-on or brush-on techniques, or through automated systems for large-scale production.

- The agent penetrates the mold surface, creating a thin film that reduces friction and prevents metal from adhering to the mold.

- This prevents defects such as flash, cold shuts, and porosity, which significantly impact the quality of the cast part.

- Manufacturers are introducing novel releasing agents for die-casting applications.

- For instance, Shin-Etsu Chemicals Co., Ltd developed SILCAST-U which is a specialized mold release agent designed for die-casting applications. It is a concentrated emulsion-type release agent that offers excellent performance and cost-effectiveness. SILCAST-U is formulated to provide smooth and efficient part release, reducing cycle times and minimizing defects.

- Thus, the use of these agents for die casting is driving the mold release agent market expansion.

The plastic molding segment is expected to grow at the fastest CAGR over the forecast period.

- Mold release agents are crucial in the plastic molding process, ensuring the smooth and efficient ejection of molded parts from the mold cavity.

- By creating a barrier between the molten plastic and the mold surface, these agents prevent adhesion and minimize defects such as flash, sink marks, and poor surface finish.

- These agents are typically applied to the mold cavity before each molding cycle, either manually or through automated systems.

- Water-based, solvent-based, silicone-based, and wax-based agents are commonly used.

- Additionally, by optimizing the application of these release agents, manufacturers are improving product quality, reducing cycle times, and increasing overall productivity.

- Thus, these factors are influencing the mold release agent market trends in coming years.

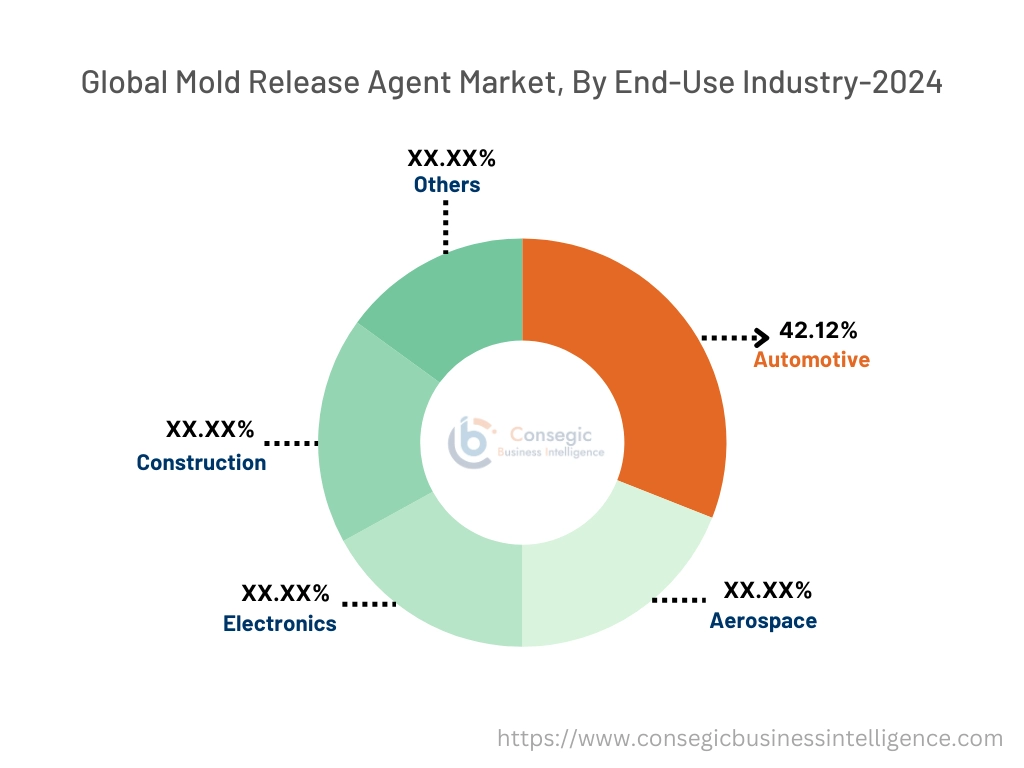

By End Use Industry:

Based on the end-use industry, the market is categorized into automotive, aerospace, electronics, construction, and others.

Trends in the End-Use Industry:

- The trends for lightweight vehicles are influencing the use of mold release agents.

- The growing requirement for mold release agents in aerospace component manufacturing is influencing segment growth.

The automotive segment accounted for the largest market share of 42.12% in the year 2024.

- The automotive sector is a significant end-use market for mold release agents.

- As the requirement for vehicles continues to grow, so does the need for efficient and reliable manufacturing processes.

- These release agents play a crucial role in the production of various automotive components, including engine blocks, cylinder heads, and body panels.

- These agents ensure the smooth and efficient release of components from molds, preventing defects and improving product quality.

- Additionally, as the automotive sector shifts towards lightweight materials and advanced manufacturing techniques, the requirement for specialized release agents capable of handling complex materials and processes is increasing, influenced by the rise in the production activity of automotives.

- For instance, according to the data provided by TD Economics in April 2024, automotive production activity has grown significantly with 15.6 million vehicles produced in North America in 2023, a 9.6% gain relative to 2022. U.S. light vehicles sales in turn grew 12.7% in 2023. This analysis creates a higher requirement for release agents in automotive manufacturing.

- Overall, as per the market analysis, consumer preference for durable vehicles is driving a requirement for these release agents with enhanced properties. Additionally, the automotive sector’s focus on lightweight to improve fuel efficiency benefits from these solutions.

The electronics segment is expected to grow at the fastest CAGR over the forecast period.

- The electronics sector is a rapidly growing end-use market for mold release agents.

- The electronics sector relies heavily on these release agents for the production of intricate components.

- These agents ensure the smooth release of delicate parts from mold, preventing damage and maintaining high-quality standards.

- Additionally, the increasing requirement for miniaturized and complex electronic components necessitates the use of specialized release agents that withstand high temperatures, pressures, and corrosive environments. These agents ensure the smooth and efficient release of intricate components from molds, preventing defects and optimizing production yields.

- These agents are specifically formulated to withstand high temperatures, resist chemical attacks, and provide excellent release properties.

- Thus, based on the mold release agent market analysis, as the electronics sector continues to innovate and evolve, the requirement for high-performance release agents is expected to grow significantly, driving market expansion.

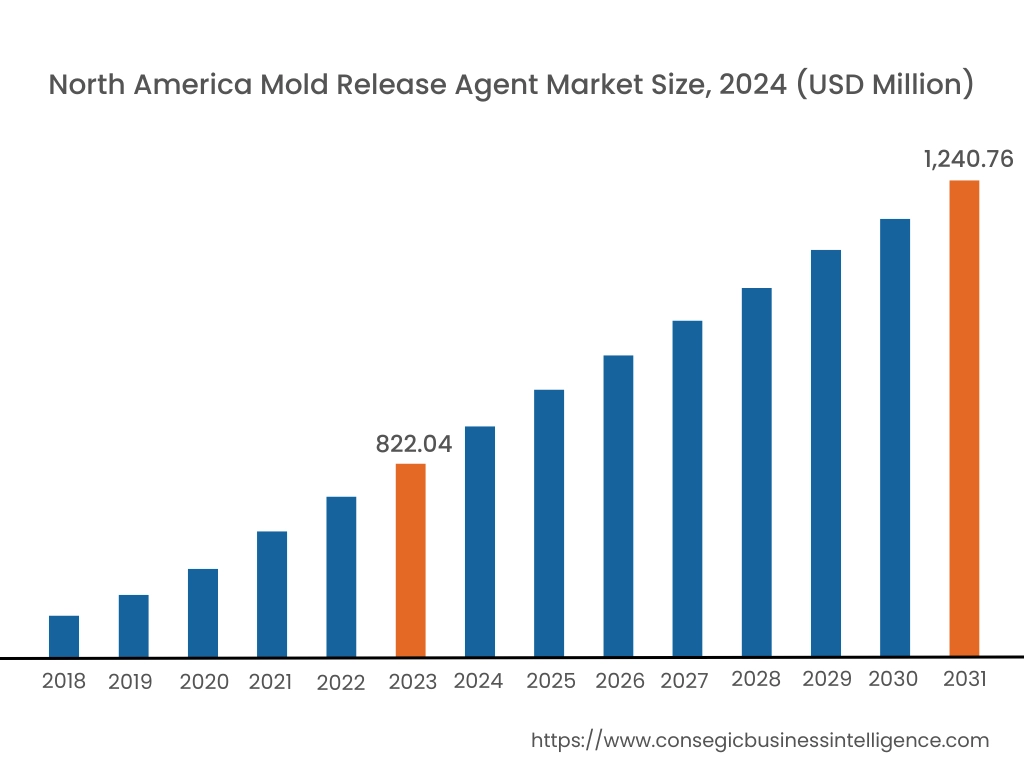

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, North America accounted for the highest mold release agent market share at 36.12% and was valued at USD 822.04 Million and is expected to reach USD 1,240.76 Million in 2032. In North America, the U.S. accounted for the highest mold release agent market share of 73.22% during the base year of 2024. North America is a significant market for mold release agents, driven by the robust manufacturing sectors, particularly in the automotive, aerospace, and electronics industries. The region's stringent environmental regulations and increasing focus on sustainable manufacturing practices have led to a growing requirement for eco-friendly release agents. Water-based and low-VOC formulations are gaining popularity as they align with these environmental concerns. Additionally, the automotive sector’s shift towards lightweight materials and advanced manufacturing techniques has created a need for specialized release agents that withstand high temperatures and pressures. The aerospace sector, with its stringent quality and performance standards, also relies heavily on high-performance release agents. As the North American manufacturing landscape is evolving, the requirement for innovative and sustainable release agents is expected to remain strong.

Asia Pacific is experiencing the fastest growth with a CAGR of 5.9% over the forecast period. As per the mold release agent market analysis, the Asia-Pacific region is a major consumer of mold-release agents, driven by rapid industrialization and economic growth. Countries like China, India, Japan, and South Korea are significant markets for these products. The automotive, electronics, and construction industries are key drivers, as they require high-quality release agents to ensure efficient production and product quality. Additionally, the increasing adoption of advanced manufacturing techniques, such as injection molding and die casting, has fueled the requirement for specialized release agents. Moreover, the growing vehicle production creates a higher requirement for release agents.

- According to the China Association of Automobile Manufacturers, in 2023, China's car output exceeded 30.16 million units, with 11.6% year-on-year growth, and presents significant prospects for the mold release agent market. This surge in automotive production necessitates the use of high-performance release agents to ensure efficient manufacturing processes and the production of high-quality automotive components.

Thus, as the Asia-Pacific region continues to experience robust economic development, the requirement for release agents is expected to remain strong.

Europe is a significant market for mold release agents, driven by the region's strong manufacturing base and focus on sustainability. The automotive, aerospace, and electronics industries are key drivers, as they require high-quality release agents to ensure efficient production and product quality. The region's stringent environmental regulations have led to a growing requirement for eco-friendly release agents, particularly water-based formulations. Additionally, the increasing adoption of advanced manufacturing techniques, such as injection molding and die casting, has fueled the demand for specialized release agents. The European Union's emphasis on sustainable manufacturing practices has further accelerated the adoption of environmentally friendly release agents. As the European market continues to evolve, the requirement for innovative and sustainable release agents is expected to remain strong.

The Middle East and Africa (MEA) regions are witnessing remarkable development across a multitude of industries, notably in sectors such as automotive, construction, and plastics manufacturing. This robust industrial development is significantly driving the demand for mold release agents, which are essential for improving operational efficiency and product quality in these manufacturing processes. Countries including Saudi Arabia, the United Arab Emirates, and Egypt are making substantial investments in infrastructure development and the establishment of advanced manufacturing facilities. Additionally, the MEA region's commitment to economic diversification is fostering a conducive environment for development in manufacturing sectors, ranging from consumer goods to advanced materials. This shift not only elevates the demand for release agents but also encourages innovation and the adoption of cutting-edge technologies to meet the evolving needs of various industries.

The Latin American region, with its diverse industries and growing economy, presents a significant market for mold release agents. Countries like Brazil, Mexico, and Argentina are key consumers, driven by the automotive, aerospace, and electronics sectors. The automotive sector, in particular, is a major driver of demand, as it requires high-performance release agents to ensure the efficient production of automotive components. The region's increasing focus on industrialization and infrastructure development is also contributing to the growth of the global mold release agent industry. As the region continues to develop and modernize, the demand for high-quality release agents is expected to increase.

Top Key Players and Market Share Insights:

The Mold Release Agent market is highly competitive with major players providing precise products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Mold Release Agent market. Key players in the Mold Release Agent industry include-

- Henkel Central Eastern Europe GmbH (Austria)

- DAIKIN INDUSTRIES, Ltd (Japan)

- Dow, Inc. (United States)

- Miller-Stephenson, Inc (United States)

- LANXESS AG (Germany)

- Shin-Etsu Chemical Co., Ltd. (Japan)

- Momentive Performance Materials (United States)

- Kao Corporation(Japan)

- ChemTrend (United States)

- McGee Industries, Inc. (United States)

Recent Industry Developments :

Product Launch:

- In May 2024, Kao Corporation introduced LUNAFLOW RA, an innovative mold release agent formulated using cutting-edge cellulose nanofiber (CNF) technology. It offers superior demolding performance and durability. Its solvent-free and fluorine-free composition makes it both worker-friendly and environmentally responsible, aligning with global sustainability goals.

Mold Release Agent Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 3,419.01 Million |

| CAGR (2025-2032) | 5.4% |

| By Type |

|

| By Application |

|

| By End Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Mold Release Agent market? +

In 2024, the Mold Release Agent market is USD 2,275.86 Million.

Which is the fastest-growing region in the Mold Release Agent market? +

Asia Pacific is the fastest-growing region in the Mold Release Agent market.

What specific segmentation details are covered in the Mold Release Agent market? +

Type, Application, and End-Use Industry segmentation details are covered in the Mold Release Agent market.

Who are the major players in the Mold Release Agent market? +

Henkel Central Eastern Europe GmbH (Austria), DAIKIN INDUSTRIES, Ltd (Japan), and Shin-Etsu Chemical Co., Ltd. (Japan) are some of the major players in the market.