- Summary

- Table Of Content

- Methodology

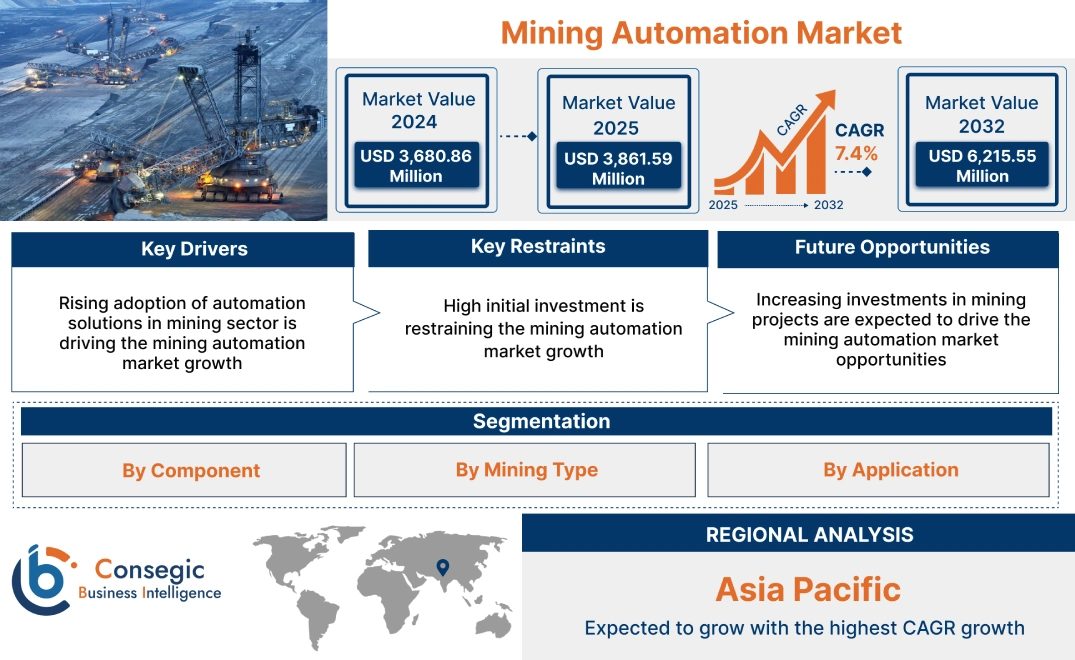

Mining Automation Market Size:

Mining Automation Market size is estimated to reach over USD 6,215.55 Million by 2032 from a value of USD 3,680.86 Million in 2024 and is projected to grow by USD 3,861.59 Million in 2025, growing at a CAGR of 7.4% from 2025 to 2032.

Mining Automation Market Scope & Overview:

Mining automation (MA) refers to the utilization of automation technologies for facilitating end-to-end mining tasks and processes. This includes automation of several mining processes including exploration, extraction, processing, and transportation of minerals among others. Moreover, MA incorporates a broad range of technologies including robotics, control systems, artificial intelligence, and data analytics, for enhancing the productivity and efficiency of mining processes. Moreover, it also offers various benefits including increased operational efficiency, increased flexibility, cost reduction, enhanced labor utilization, scalability, and others.

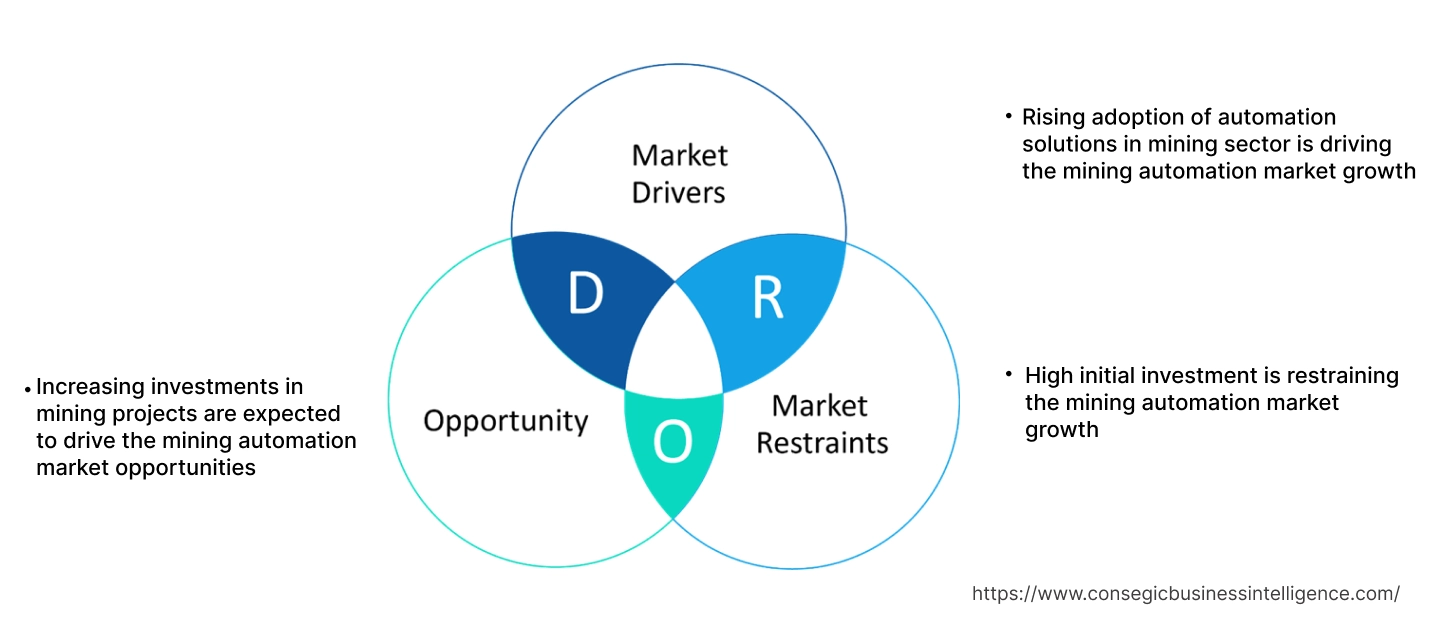

Key Drivers:

Rising adoption of automation solutions in mining sector is driving the mining automation market growth

Mining companies are increasingly focusing on improving operational efficiency in their mining processes, with minimal human intervention, extreme flexibility, and highest productivity. Moreover, the integration of automation solutions in mining processes enables improved capabilities, minimized downtime, and maximized throughput. Additionally, the utilization of automated systems in mining sector assists in analyzing workflows and optimizing operations, helping mining companies to become more agile and responsive to the market demands.

- For instance, Boliden Group collaborated with ABB to deploy its advanced process control solution, Ability Expert Optimizer in Bolden Atik mine located in Sweden, with the aim of developing an optimal control strategy. The adoption of ABB’s Ability Expert Optimizer in Bolden Atik mine offers several benefits including multivariable control, constraint aware control, optimization of key process variables, maximization of feed, and improved handling in several conditions among others.

Thus, the rising adoption of automation solutions in mining sector is driving the mining automation market size.

Key Restraints:

High initial investment is restraining the mining automation market growth

High initial investment associated with setting up automation systems in mining sector is among the key factors limiting the market growth. The initial costs associated with acquisition of MA hardware/equipment, software, along with integrating them into existing systems can be significantly high, which may cause financial barriers, specifically for smaller businesses or businesses with budget constraints.

Additionally, automation systems can be quite complex to install and integrate, which further requires additional expenses on training personnel or hiring specialized experts for integrating and maintaining the automated systems effectively. Hence, the high initial investment associated with setting up MA systems is hindering the mining automation market expansion.

Future Opportunities :

Increasing investments in mining projects are expected to drive the mining automation market opportunities

Automation solutions are often used in mining industry for automating mineral and metal processing and delivering flexibility for engineering, operations, and maintenance. Moreover, the utilization of automation solutions in mining sector offers numerous benefits including high accuracy and precision, faster processes, improved worker safety, and enhanced operational efficiency among others. As a result, rising investments in mining projects are expected to provide lucrative aspects for market growth.

- For instance, according to the Minerals Council of Australia, there are over 100 prospective mining and processing projects with a total investment of approximately USD 50 billion in Australia.

Thus, as per the mining automation market analysis, rising investments in mining projects are anticipated to drive the mining automation market opportunities.

Mining Automation Market Segmental Analysis :

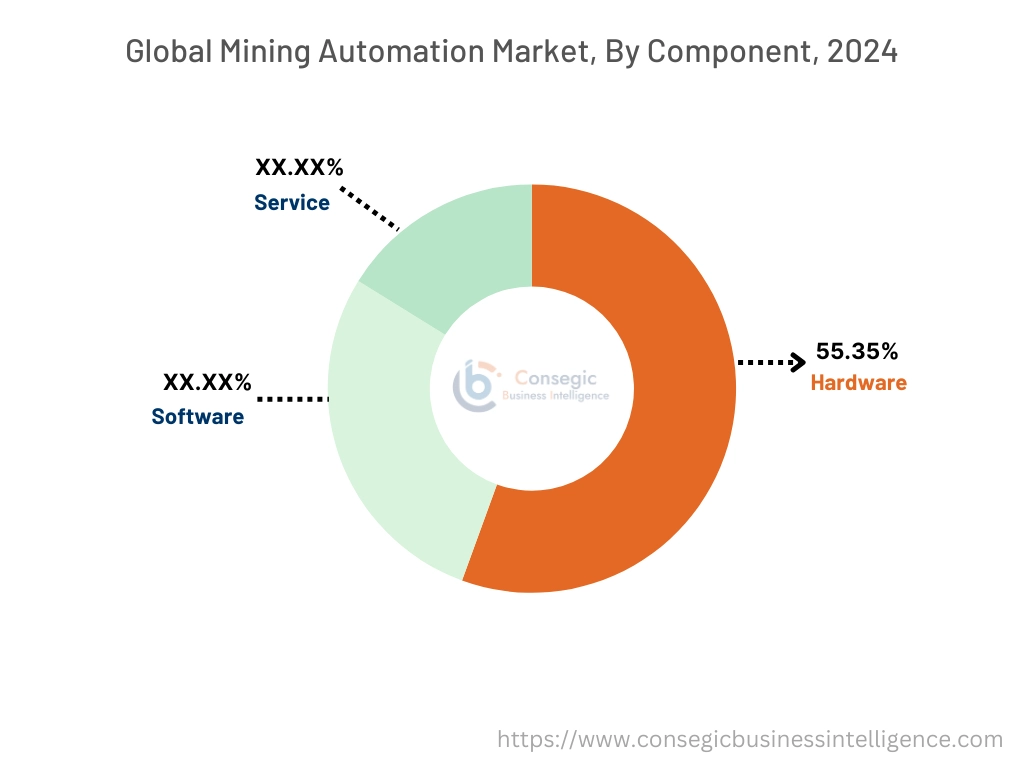

By Component:

Based on component, the market is segmented into hardware, software, and services.

Trends in the component:

- Increasing technological advancements associated with mining automation devices such as sensors, controllers, power supply systems, and others.

- Rising trend towards adoption of automation devices in mining sector for constant process monitoring, optimization, and improved operational efficiency.

The hardware segment accounted for the largest revenue share of 55.35% of the total mining automation market share in 2024.

- The primary hardware components include programmable logic controllers (PLCs), sensors, power supply systems, mining equipment, and others

- PLCs are industrial computers used to control machinery and processes automatically. Meanwhile, connected sensors and data loggers are used for collecting real-time data on equipment performance and environmental conditions.

- Moreover, the aforementioned hardware components help in facilitating automation within mining sector, in turn leading to improved efficiency, precision, and safety in mining processes.

- For instance, in February 2024, WEG launched its new PLC410 model of programmable logic controller. The new programmable logic controller offers a versatile solution for industrial automation, which can be applied in several industrial sectors.

- According to the analysis, the rising innovations associated with hardware components for facilitating automation within mining sector are driving the mining automation market.

The software segment is anticipated to register fastest CAGR growth during the forecast period.

- Mining automation software provides a centralized platform for monitoring and controlling the automation systems used within mines. The software has ability to capture, organize and analyze data to monitor mining equipment and system performance.

- Moreover, the benefits of integrating automation software include smarter maintenance and effective analysis of mining equipment performance. Automation software also assists in managing the operation of mining machinery and equipment while allowing remote control and autonomous functionality.

- In October 2022, Schneider Electric launched EcoStruxure Automation Expert 22.1, its next-generation of industrial automation software. The upgraded industrial automation software is capable of supporting larger industrial operations and additional communication protocols.

- Therefore, the increasing advancements associated with automation software are anticipated to boost the mining automation market size during the forecast period.

By Mining Type:

Based on mining type, the market is segmented into surface mining and underground mining.

Trends in the mining type:

- There is an increasing trend towards adoption of surface mining for retrieving sand, coal, gravel, stones, copper, iron, and other minerals/metals.

- Rising trend in utilization of automation solutions in surface and underground mining for increasing operational safety and efficiency of mining operations.

Surface mining segment accounted for the largest revenue share in the overall mining automation market share in 2024.

- Surface mining involves the process of removing the terrain surface for accessing minerals underneath. Surface mining is primarily used for retrieving sand, gravel, coal, stones, copper, iron, and other minerals/metals.

- Moreover, surface mining is often preferred by mining companies, attributing to its lower costs, increased safety, and fewer complications in terms of electricity and water.

- Additionally, automation solutions are primarily employed in surface mining for enhancing operational efficiency, safety, and productivity.

- Automation solutions are typically used in surface mining to facilitate automated drilling, autonomous haulage systems, remote monitoring and control, and other related mining operations.

- For instance, in December 2023, Epiroc launched its new digital solutions for surface mining. The offering includes the new release for safe blasting, blast support and situational awareness. Situational awareness solution is integrated with zone-based messages, which is a new feature that has the ability to direct warning messages to individuals located in defined risk zones. Zone-based messages can be automated through event automation scripts that are activated by IoT sensors for improved ground stability,

- Therefore, the rising developments associated automation solutions for surface mining are driving the mining automation market trends.

Underground mining segment is anticipated to register a substantial CAGR growth during the forecast period.

- Underground mining refers to a type of mining technique that involves the extraction of minerals that are situated deep within the earth, which cannot be easily accessed from the surface.

- Underground mining method usually involves creation of tunnels or shafts to reach the deposits, which enables extraction of materials without disturbing the surface above.

- Moreover, automation solutions play a crucial role in underground mining for improving safety and efficiency of underground operations. Automation solutions are primarily used in underground mining for applications including automated mining equipment, autonomous drilling systems, real-time monitoring systems, automated transport systems, and others.

- For instance, in November 2023, Sandvik AB launched AutoMine for underground drills, which is a tele-remote solution that allows mining operators to remotely control and manage numerous automated Sandvik underground drills. The AutoMine solution for underground drills offers increased safety, improved efficiency, and enhanced productivity in mining operations.

- Therefore, the rising advancements associated with automation solutions for underground mining are expected to drive the market during the forecast period.

By Application:

Based on the application, the market is segmented into metal mining and mineral mining.

Trends in the application:

- Factors including growing demand for metals and minerals along with rising investments in mining projects are driving the utilization of automation solutions in metal mining and mineral mining applications.

- The prevalence of favorable government initiatives for industrial automation is among the key factors driving the adoption of automation solutions in mining sector.

Metal mining segment accounted for a significant revenue share in the total market in 2024.

- Metal mining primarily involves the extraction of precious and base metals including gold, silver, copper, iron, and others.

- Automation solutions such as autonomous haul trucks, robotic drills, real-time control/monitoring systems, and others are primarily used in metal mines for increasing operational efficiency and safety, along with handling operational complexities associated with metal mining.

- For instance, Rockwell Automation offers automated mining solutions in its product offerings for utilization in metal mining and processing applications among others. The automated mining solutions offer improved metal refining and material handling along with facilitating optimized operations and increased operational efficiency.

- According to the analysis, the rising advancements related to automated mining solutions for use in metal mining applications are driving the mining automation market growth.

Mineral mining segment is anticipated to register the fastest CAGR during the forecast period.

- Mineral mining typically involves the extraction of non-metallic minerals such as sand, coal, gravel, gypsum, and others.

- Moreover, the expansion of mineral mining segment is attributed to the rising adoption of automation solutions in mineral mining sector for optimizing mining processes and operations with minimal human intervention.

- For instance, ABB offers a broad range of automation solutions for use in mineral mining applications in its solution offerings. ABB’s automated solutions are designed to attain the highest plant productivity, increased safety, and improved operational efficiency in mineral mining applications.

- Hence, the increasing advancements associated with automation solutions for mineral mining applications are projected to boost the market during the forecast period.

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

Asia Pacific region was valued at USD 1,300.83 Million in 2024. Moreover, it is projected to grow by USD 1,368.44 Million in 2025 and reach over USD 2,268.67 Million by 2032. Out of this, China accounted for the maximum revenue share of 34.7%. As per the mining automation market analysis, there is an increasing adoption of mining automation solutions in the Asia-Pacific region for improving operational efficiency in mining operations. Additionally, increasing investments in mining sector and prevalence of substantial number of operating mines are further accelerating the mining automation market expansion.

- For instance, according to India Brand Equity Foundation (IBEF), the total number of reporting mines in India reached approximately 1,320 mines as of 2022, among which reporting mines for metallic minerals reached 545 mines while non-metallic mineral mines reached 775 respectively. The above factors are further driving the adoption of automated solutions in mines, thereby, propelling the market in the Asia-Pacific region.

North America is estimated to reach over USD 1,768.32 Million by 2032 from a value of USD 1,046.90 Million in 2024 and is projected to grow by USD 1,098.33 Million in 2025.

In North America, the growth of mining automation industry is driven by rising adoption of industrial automation and increasing development of mining projects in the region. Similarly, rising advancements related to automated mining solutions are contributing to the mining automation market demand.

- For instance, in September 2024, Epiroc launched its new its Surface Mining Automation Center (SMAC) in Utah, United States. The new facility aims at developing autonomous haulage solutions for the surface mining sector. The rising developments related to automated mining solutions are driving the mining automation market trends in North America.

Additionally, the regional analysis depicts that the prevalence of favorable government measures for facilitating industrial automation and increasing investments in mining projects are driving the mining automation market demand in Europe. Further, as per the market analysis, the market demand in Latin America, Middle East, and African regions is expected to grow at a considerable rate due to increasing investments in development of mining sector and rising adoption of automation solutions in mining sites among others.

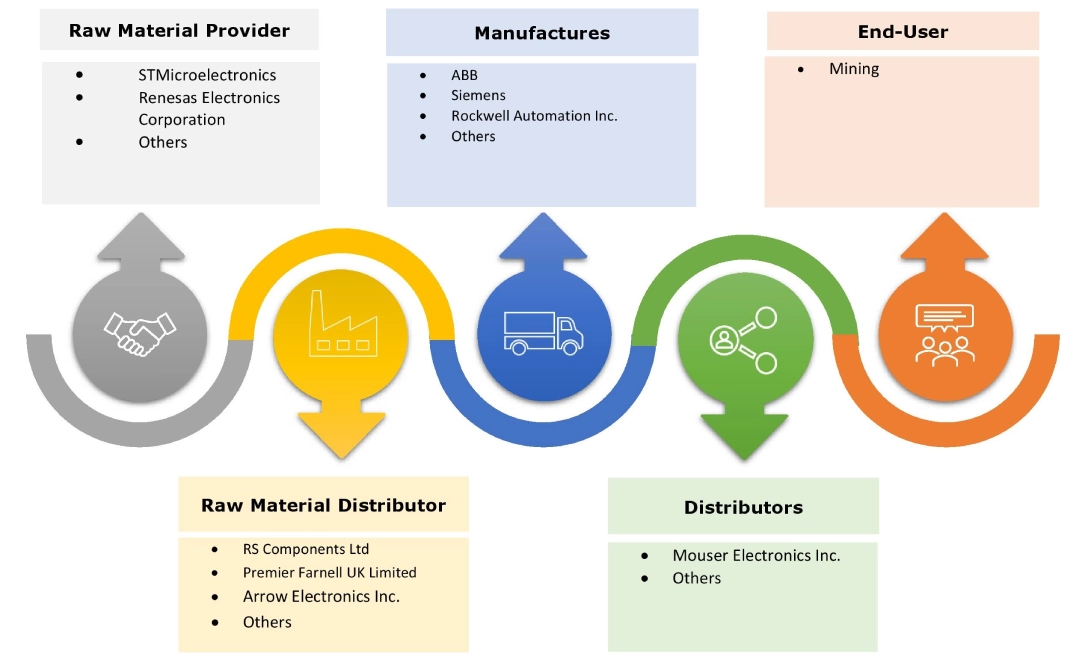

Top Key Players and Market Share Insights:

The global mining automation market is highly competitive with major players providing solutions to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global mining automation market. Key players in the mining automation industry include -

- ABB (Switzerland)

- Rockwell Automation Inc. (U.S)

- Siemens (Germany)

- Emerson Electric Co. (U.S)

- Honeywell International Inc. (U.S)

- Schneider Electric (France)

- General Electric (U.S)

- FLSmidth (Denmark)

- Caterpillar (U.S)

- Metso (Finland)

- Sandvik AB (Sweden)

Recent Industry Developments :

Product Launches:

- In September 2024, ABB launched its new range of service offerings that are designed for simplifying maintenance and improving the operational health of crucial mining assets. The launch extends ABB’s inclusive ABB care program to mining automation and hoisting, integrating the company’s mining and technology expertise to provide an evolved approach for maintenance.

- In November 2023, Sandvik AB launched AutoMine for underground drills, which is a tele-remote solution that allows mining operators to remotely control and manage numerous automated Sandvik underground drills.

- In October 2022, Schneider Electric launched EcoStruxure Automation Expert 22.1, its next-generation of industrial automation software. The upgraded industrial automation software is capable of supporting larger industrial operations and additional communication protocols.

Mining Automation Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 6,215.55 Million |

| CAGR (2025-2032) | 7.4% |

| By Component |

|

| By Mining Type |

|

| By Application |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the mining automation market? +

The mining automation market was valued at USD 3,680.86 Million in 2024 and is projected to grow to USD 6,215.55 Million by 2032.

Which is the fastest-growing region in the mining automation market? +

Asia-Pacific is the region experiencing the most rapid growth in the mining automation market.

What specific segmentation details are covered in the mining automation report? +

The mining automation report includes specific segmentation details for component, mining type, application, and region.

Who are the major players in the mining automation market? +

The key participants in the mining automation market are ABB (Switzerland), Rockwell Automation Inc. (U.S), Siemens (Germany), Emerson Electric Co. (U.S), Honeywell International Inc. (U.S), Schneider Electric (France), General Electric (U.S), FLSmidth (Denmark), Caterpillar (U.S), Metso (Finland), Sandvik AB (Sweden), and others.