- Summary

- Table Of Content

- Methodology

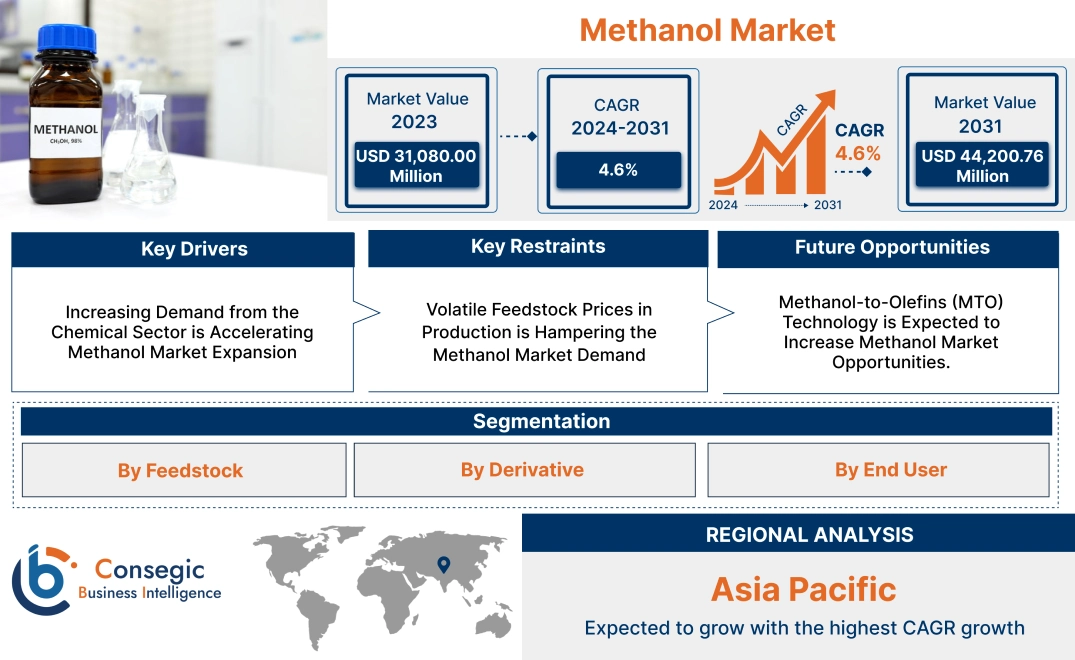

Methanol Market Size:

Methanol Market size is growing with a CAGR of 4.6% during the forecast period (2024-2031), and the market is projected to be valued at USD 44,200.76 Million by 2031 from USD 31,080.00 Million in 2023.

Methanol Market Scope & Overview:

Methanol is a versatile chemical compound with the formula CH3OH. It is also known as methyl alcohol. It's a colorless, volatile liquid with a distinctive odor. It has a relatively low boiling point and is highly flammable. It has a miscible nature, which means it dissolves in water in any proportion. Moreover, it's a weak acid and reacts with strong bases to form methoxide salts. It's also a reducing agent and undergoes oxidation to form formaldehyde. Moreover, it is a crucial feedstock for producing acetic acid, and other essential chemicals. Additionally, it serves as a clean-burning fuel that is used in engines and fuel cells. Furthermore, its excellent solvent properties make it useful in various industrial processes. It is also used as an antifreeze in vehicles and industrial equipment. Apart from all these factors, it is produced efficiently and economically.

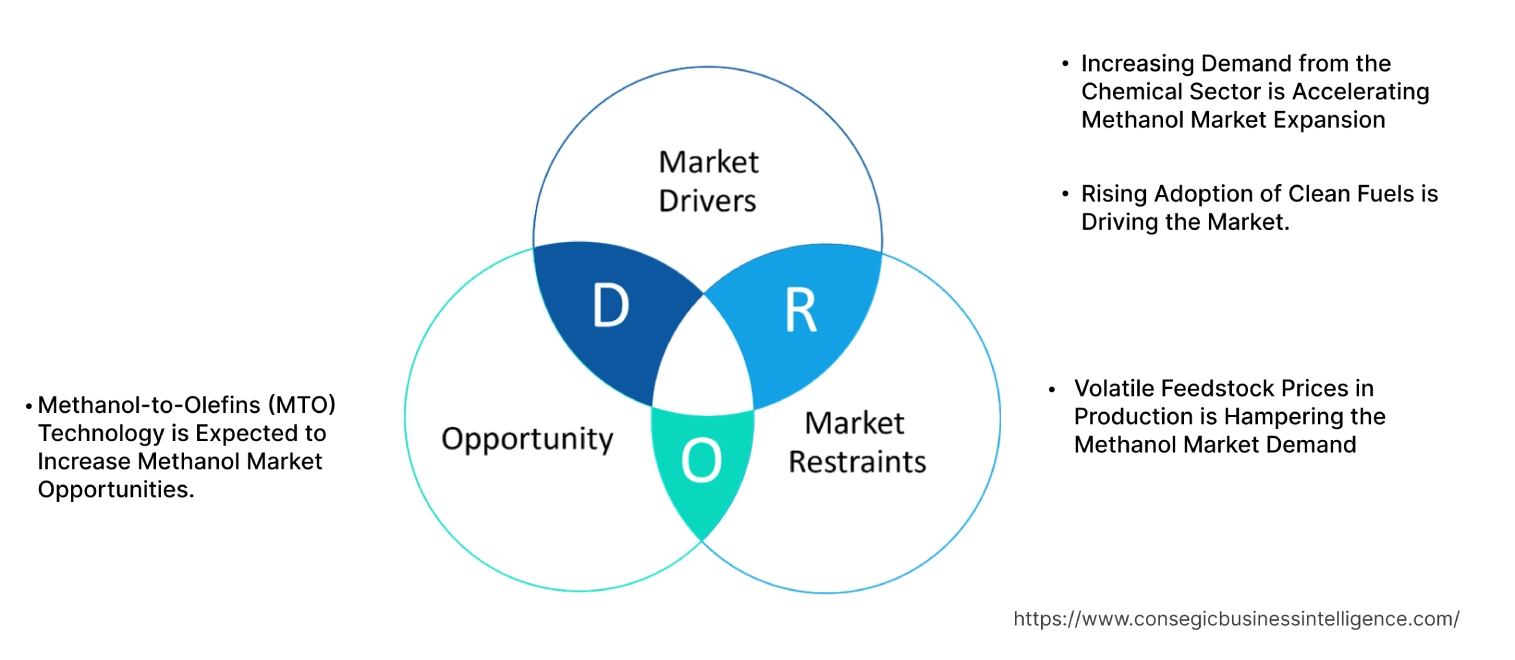

Methanol Market Dynamics - (DRO) :

Key Drivers:

Increasing Demand from the Chemical Sector is Accelerating Methanol Market Expansion

The chemical sector converts raw materials into essential chemicals used in numerous industrial and consumer products. Methyl alcohol is widely used in the chemical sector. It serves as a crucial building block for the synthesis of various products. One of its primary applications is in the production of formaldehyde, a key ingredient in the manufacturing of resins, adhesives, and building materials.

Moreover, it is used to produce acetic acid, a vital chemical used in the textile, paint, and plastic sectors. Another important application is in the synthesis of methyl tert-butyl ether (MTBE), a high-octane gasoline additive. Beyond these primary applications, it serves as an intermediate in the synthesis of a wide range of specialty chemicals and agrochemicals.

The increasing global population, urbanization, and industrialization have led to an increased need for various chemicals.

For instance,

- According to BASF's 2023 report, China's chemical production increased by 7.5% in 2023. This has positively impacted the methanol market trends by increasing the requirements for its derivatives, such as formaldehyde and acetic acid, which are crucial inputs for various sectors.

Overall, the growing chemical production, driven by population, industrialization, and urbanization, is significantly boosting the methanol market expansion.

Rising Adoption of Clean Fuels is Driving the Market.

Clean fuels are energy sources that produce fewer greenhouse gas emissions and other pollutants. Methanol, referred to as "green methanol" when produced from renewable sources, is serving as a significant compound in the clean fuel landscape. It offers several advantages compared to traditional fossil fuels.

- For instance, according to an article published inthe World Economic Forum, in 2023, in comparison to traditional fuels, green methanol has the potential to decrease carbon dioxide emissions by 60-95%, and nitrogen oxide emissions by 60-80%.

Moreover, it is mixed with conventional gasoline or diesel, providing an easy shift for vehicle owners while reducing the necessity for infrastructure enhancements. Additionally, it features a reduced sulfur content, leading to decreased emissions of sulfur oxides that play a role in air pollution and the formation of acid rain.

Stringent environmental regulations, increasing adoption of renewable energy sources, and the growing need for sustainable fuels are driving the segment. Additionally, advancements in production technologies further accelerate the green methanol market trends. Overall, the increasing global focus on sustainability, coupled with advancements in technology, is driving the segment in methanol market growth.

Key Restraints :

Volatile Feedstock Prices in Production is Hampering the Methanol Market Demand

Methyl alcohol relies on various feedstocks for production. Fluctuations in the prices of these commodities significantly impact the overall cost and, consequently, their market competitiveness. Geopolitical factors, supply imbalances, and unexpected events such as natural disasters or geopolitical tensions exacerbate price volatility.

- For instance, according to the International Energy Agency, natural gas prices rose in all major markets during the second quarter of 2024, indicating more constrained market conditions. Thus, this is hindering the methanol market demand.

In addition to that, the existing infrastructure for transporting and distributing fuels is primarily designed for gasoline and diesel. Adapting this infrastructure to handle methyl alcohol requires significant investments in storage tanks, pipelines, and fueling stations. Moreover, the safety protocols and regulations for handling methyl alcohol differ from those for traditional fuels, necessitating additional safety measures and training, increasing the overall cost. Overall, analysis shows that the volatility of raw material prices and infrastructure limitations is hampering the methanol market trends.

Future Opportunities :

Methanol-to-Olefins (MTO) Technology is Expected to Increase Methanol Market Opportunities.

Methanol-to-Olefins (MTO) technology is a process that uses methyl alcohol as an intermediate to produce basic petrochemicals from non-oil resources such as coal, natural gas, or petroleum coke. This technology converts methyl alcohol into valuable olefins such as ethylene and propylene, which are crucial building blocks for various sectors, including plastics, synthetic rubber, and fibers. By utilizing methyl alcohol as a feedstock, MTO technology reduces dependence on crude oil, which is subject to price volatility and geopolitical risks. Moreover, it offers high conversion rates of methyl alcohol to olefins, making it an economically viable process.

The increasing adoption of olefins as building blocks for various petrochemical products and growing emphasis on reducing reliance on crude oil will drive the market for the upcoming years. Furthermore, the increasing recognition of the benefits this technology provides among governmental bodies and manufacturers is resulting in enhanced adoption.

- For instance, in June 2024, the President of Uzbekistan, Shavkat Mirziyoyev, officially inaugurated the Gas Chemical Complex project that utilizes MTO technology (GCC MTO), situated within the Karakul Free Economic Zone. This will increase the production of value-added chemicals derived from methyl alcohol, creating the potential for the market.

Overall, the growing adoption of olefins and the need for more sustainable and cost-effective production is expected to increase methanol market opportunities.

Methanol Market Segmental Analysis :

By Feedstock:

Based on feedstock, the market is categorized into natural gas, coal, biomass, and others.

Trends in the Feedstock:

- Exploring a wider range of feedstocks, including waste gases and municipal solid waste.

- Carbon capture and storage technologies are being integrated into production to increase advantages.

The natural gas segment accounted for the largest market share in 2023.

- Natural gas, primarily composed of methane, serves as a crucial feedstock for methyl alcohol production. The process involves two main steps.

- Natural gas undergoes steam reforming, converting methane into a mixture of carbon monoxide (CO) and hydrogen (H2), known as synthesis gas (syngas).

- The syngas are then subjected to high pressure and temperature in the presence of a catalyst, typically copper-based, to produce methyl alcohol. The reaction involves the combination of CO and H2 to form methyl alcohol (CH3OH) and water (H2O). The process of converting natural gas to methyl alcohol is well-established, ensuring efficient and reliable production.

- Governments worldwide are implementing policies promoting renewable energy, clean fuels, and sustainable development.

- For instance, in 2023, Quebec implemented new regulations mandating a 10% low-carbon fuel composition in gasoline, rising to 15% by the year 2030, and 3% in diesel, which will escalate to 10% by 2030. This has led to increased adoption of methyl alcohol as a potential blendstock for alternative fuels, thereby stimulating the segment.

- Overall, the combination of natural gas's suitability as a feedstock, coupled with increasing global requirements for low-carbon fuels and supportive government policies, is driving the segment.

The biomass segment is expected to grow at the fastest CAGR over the forecast period.

- Biomass refers to organic matter derived from plants and animals, including agricultural residues, forestry waste, and municipal solid waste.

- Biomass is subjected to high temperatures and pressure in a limited oxygen environment, converting it into a gas mixture known as syngas, primarily composed of carbon monoxide (CO) and hydrogen (H2).

- The syngas are then purified and converted into methyl alcohol using a catalyst and specific reaction conditions.

- By utilizing renewable biomass, methyl alcohol production significantly reduces greenhouse gas emissions compared to fossil fuel-based methods.

- As per the market research analysis, the segment of biomass for the upcoming years is driven by trends such as the rising need from the energy sector, stricter regulations, and increased adoption of sustainable practices.

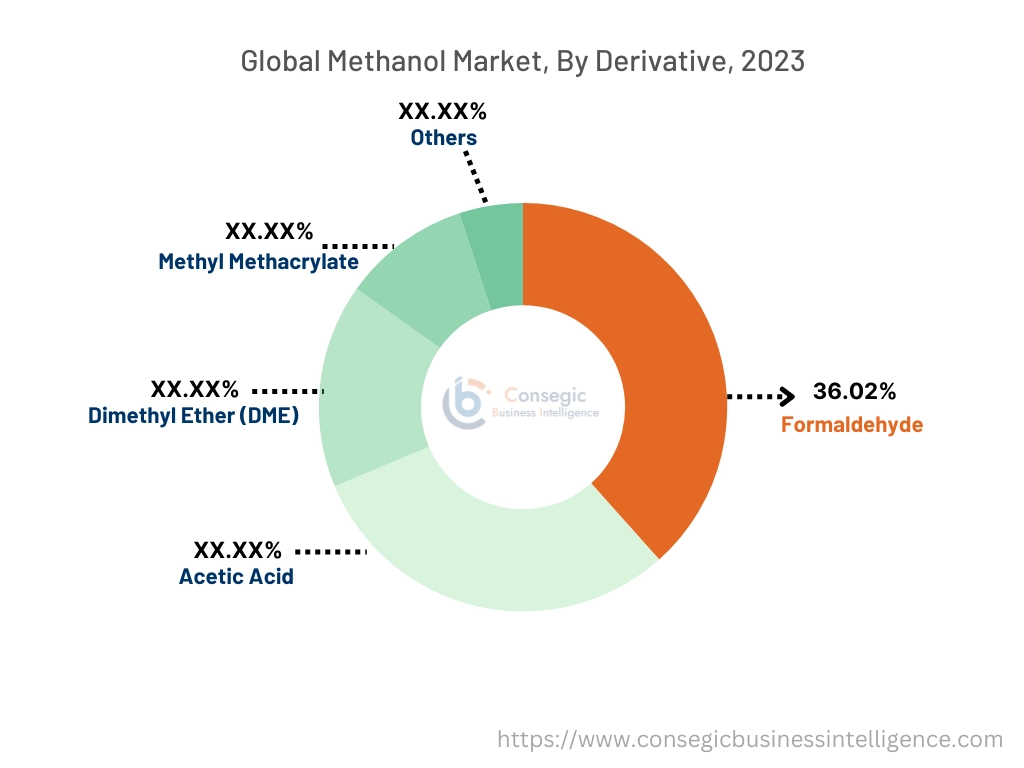

By Derivative:

The derivative segment is categorized into formaldehyde, acetic acid, dimethyl ether (DME), methyl methacrylate (MMA), and others.

Trends in the Derivative:

- Growing adoption of emerging derivatives, such as methanol-to-olefins (MTO) and methanol-to-propylene (MTP).

- Rising interest in dimethyl ether as a clean fuel and a potential replacement for diesel and LPG.

The formaldehyde segment accounted for the largest market share of 36.02% in 2023.

- Formaldehyde is a colorless, pungent-smelling gas that is widely used as a building block for various products. It's employed in the production of resins, adhesives, and building materials such as plywood and particleboard.

- Through a process known as catalytic oxidation, methyl alcohol is converted into formaldehyde in the presence of a catalyst, typically silver. This process involves controlled oxidation of methyl alcohol to yield formaldehyde and water. Also, it acts as a stabilizer in formaldehyde solutions.

- For instance, according to a study published by the National Center for Biotechnology Information, in 2021, methyl alcohol prevents the polymerization of formaldehyde by inhibiting its tendency to self-react and form larger molecules.

- The robust expansion of the construction and furniture sector, the increasing need for composite wood products, and the expanding automotive sector have led to increased requirements for formaldehyde, thus impacting the market positively.

- Overall, the increasing need for formaldehyde in various sectors is driving the segment in methanol market growth.

The dimethyl ether (DME) segment is expected to grow at the fastest CAGR over the forecast period.

- Dimethyl ether (DME) serves as a synthetically manufactured substitute for diesel. It is specifically tailored for use in compression ignition diesel engines.

- In typical atmospheric conditions, DME appears to be a colorless gas. It finds widespread application in the chemical sector and is utilized as an aerosol propellant.

- Methyl alcohol plays a crucial role in the production of DME. Through a process called dehydration, two molecules of methyl alcohol are combined to form one molecule of DME and one molecule of water. This process is typically carried out in the presence of a catalyst, such as alumina or zeolite.

- Increasing requirements for cleaner fuels in transportation and growing environmental concerns are driving the adoption of DME, as it serves as aclean-burning fuel with low emissions, making it environmentally friendly, thus driving the segment for the upcoming years.

By End-User Industry:

The end-use industry segment is categorized into automotive, construction, electronics, pharmaceuticals, and others.

Trends in End-Use Industry:

- Rising adoption of methyl alcohol in the production of electronic components and semiconductors.

- Using it as a fuel additive and blendstock, especially in regions with stringent emission regulations.

The construction segment accounted for the largest market share in 2023.

- The construction sector encompasses building development, including residential, commercial, and infrastructure projects.

- Methyl alcohol plays a crucial role in construction, primarily through its use in the production of formaldehyde-based resins. These resins are essential components in various construction materials, including plywood, particleboard, and adhesives.

- Moreover, it acts as a solvent in many painting formulations, helping to thin the paint and ensure proper application.Methyl alcohol-based sealants are used to prevent water damage and improve the durability of construction materials.

- Growing population, urbanization, economic evolution, and rising disposable incomes have led to increased commercial and residential construction activities.

- For instance, according to the National Investment Promotion and Facilitation Agency, the construction sector in India is projected to attain a value of USD 1.4 trillion by the year 2025. This will require an increased need for methyl alcohol, as it is used in manufacturing products such as formaldehyde and adhesives, positively influencing the market.

- Overall, the analysis indicates that the rising construction activities globally are driving the segment in the global methanol market.

The automotive segment is expected to grow at the fastest CAGR over the forecast period.

- The automotive sector encompasses the design, manufacturing, and distribution of vehicles, including cars, trucks, and motorcycles.

- It is used as a high-octane fuel blend component, improving engine performance and reducing emissions.It is also used as fuel for cars, buses, and trucks, replacing diesel and gasoline.

- Moreover, methyl alcohol is used to make methyl tertiary-butyl ether (MTBE), a gasoline additive that reduces tailpipe emissions.It is also used to produce biodiesel, which is an alternative to diesel.

- Furthermore, it is used as a solvent and cleaning agent in various automotive manufacturing processes.

- As the automotive sector shifts towards cleaner and more sustainable fuels, methyl alcohol is emerging as a promising option to reduce reliance on fossil fuels. This will drive the market in the forecasted years.

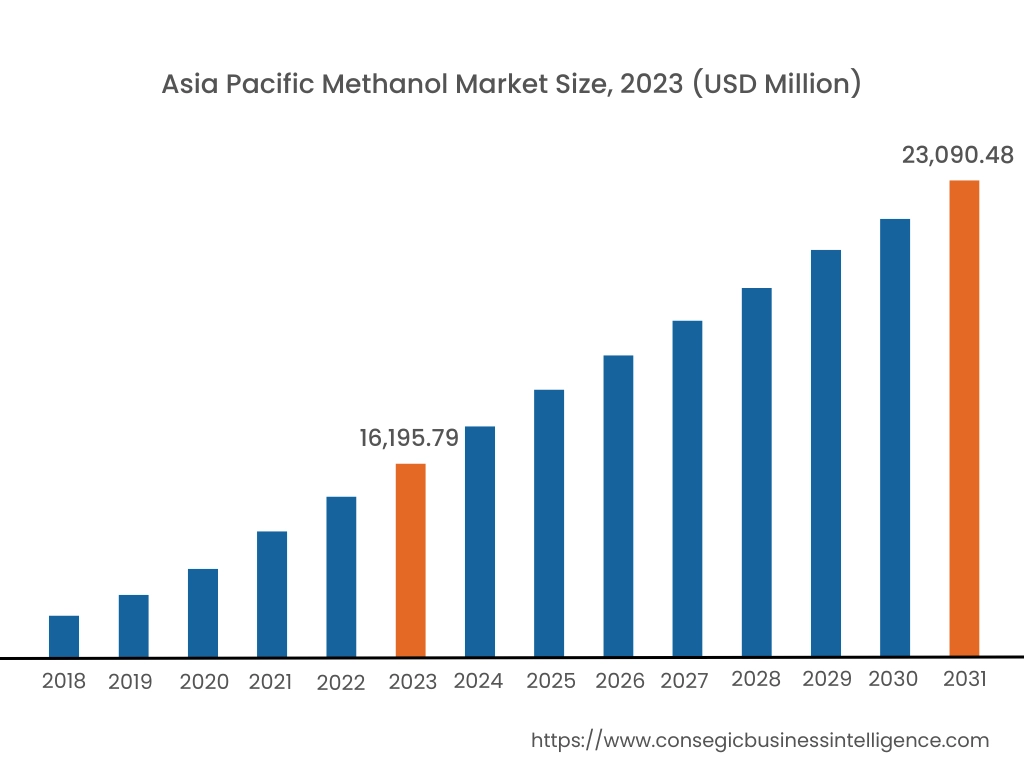

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2023, Asia Pacific accounted for the highest methanol market share at 52.11% and was valued at USD 16,195.79 Million and is expected to reach USD 23,090.48 Million in 2031. In Asia Pacific, China accounted for the highest methanol market share of 28.17% during the base year of 2023. The dominance is driven by several key trends. First, the region's rapid industrialization, particularly in countries such as China and India, is driving a significant need for methyl alcohol as a feedstock for various chemical products, including formaldehyde, acetic acid, and methyl methacrylate.

Moreover, the market research analysis shows that the booming construction sector in the region requires large quantities of construction materials driving the adoption of formaldehyde and other methyl alcohol derivatives. The rising focus on green methanol further accelerates the market.

- For instance, in November 2024, India's first CO2-to-Green Methanol plant is being developed in collaboration with Ohmium International, Spirare Energy, and the Jawaharlal Nehru Centre for Advanced Scientific Research (JNCASR).

Overall, the rapid industrialization, booming construction sector, and growing focus on green methanol are driving significant growth in the Asia Pacific methanol market.

In North America, the methanol market is experiencing the fastest growth with a CAGR of 5.1% over the forecast period. The region boasts significant natural gas reserves, a key feedstock for methyl alcohol production, making it cost-competitive. Moreover, the well-established petrochemical sector in North America provides a robust adoption of methyl alcohol as an essential feedstock. Additionally, government initiatives promoting renewable energy and alternative fuels create the potential for methyl alcohol as a clean energy source. Methyl alcohol is also increasingly used in the production of various pharmaceutical products, such as antibiotics and vaccines, which drives the market. Apart from all these factors, continuous advancements in production technologies improve efficiency and reduce costs, further driving the market.

Europe's methanol market analysis states several factors are responsible for the progress of the market in the region. The region's robust chemical sector, particularly in countries such as Germany and the Netherlands, is a major consumer of methyl alcohol. Additionally, the automotive sector's shift towards cleaner fuels and the rising popularity of methyl alcohol-based additives are contributing to the market. Moreover, the European Union's stringent environmental regulations are incentivizing the adoption of sustainable methyl alcohol production processes. Furthermore, it is used in the production of packaging materials, such as PET bottles and plastic films. The growth of the packaging sector is driving the market further.

The Middle East and Africa (MEA) market research analysis states that the region possesses vast natural gas reserves, a primary feedstock for methyl alcohol production. This resource advantage positions the region favorably for large-scale methyl alcohol manufacturing. Moreover, Many MEA countries are actively seeking to diversify their economies away from oil and gas dependence. Methyl alcohol offers a promising avenue for industrial growth and value addition. Additionally, advancements in methanol-to-chemicals (MTC) technology enable the conversion of methyl alcohol into valuable chemicals, further boosting its adoption in the region. Several MEA governments are implementing supportive policies and incentives to promote the methanol industry, attracting investments and fostering growth.

Latin America's methanol market size is also emerging. The region's growing petrochemical sector, fueled by rising demand for plastics, paints, and other chemicals, drives methyl alcohol demand. Moreover, governments here also are promoting methyl alcohol as an alternative fuel source to reduce reliance on fossil fuels. This is leading to increased adoption in transportation and power generation sectors. Additionally, the automotive sector in Latin America is experiencing growth, which drives demand for methyl alcohol-based additives and fuels. The construction sector's demand for formaldehyde, a key methyl alcohol derivative, is also driving the market. Furthermore, strategic partnerships and collaborations are increasing the production plants and usage across various sectors.

Top Key Players & Market Share Insights:

The methanol market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global methanol market. Key players in the methanol industry include-

- Methanex Corporation (Canada)

- HELM AG (Germany)

- BASF SE (Germany)

- Metafrax Chemicals (Russia)

- Yankuang Energy Group (China)

- SABIC (Saudi Arabia)

- Mitsubishi Gas Chemical Company, Inc. (Japan)

- Zagros Petroleum (Iran)

- PETRONAS (Malaysia)

- Celanese Corporation (U.S.)

Recent Industry Developments :

Launches:

- In October 2024, the inaugural demonstration phase of a 500,000-ton green methanol production initiative in Alxa, which has a capacity of 100,000 tons, was officially launched. This green methanol project located in Inner Mongolia marks China's first endeavor at the 500,000-ton scale, which involves synthesizing green methanol by harnessing wind and solar energy for water electrolysis to generate hydrogen, subsequently combining it with carbon dioxide captured from industrial activities.

Agreement:

- In November 2024, Vast Renewables, a company focused on concentrated solar thermal power (CSP) systems that produce zero-carbon, has entered into a development services agreement with energy transition development company GGS Energy to explore methanol production in the Southwestern region of the United States (U.S.).

Methanol Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 44,200.76 Million |

| CAGR (2024-2031) | 4.6% |

| By Feedstock |

|

| By Derivative |

|

| By End-User |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Methanol market? +

In 2023, the Methanol market is USD 31,080.00 Million.

Which is the fastest-growing region in the Methanol market? +

North America is the fastest-growing region in the Methanol market.

What specific segmentation details are covered in the Methanol market? +

Feedstock and Derivative segmentation details are covered in the Methanol market.

Who are the major players in the Methanol market? +

Methanex Corporation (Canada), HELM AG (Germany), SABIC (Saudi Arabia), Mitsubishi Gas Chemical Company, Inc. (Japan), Zagros Petroleum (Iran), PETRONAS (Malaysia), Celanese Corporation (U.S.), BASF SE (Germany), Metafrax Chemicals (Russia), and Yankuang Energy Group (China).