- Summary

- Table Of Content

- Methodology

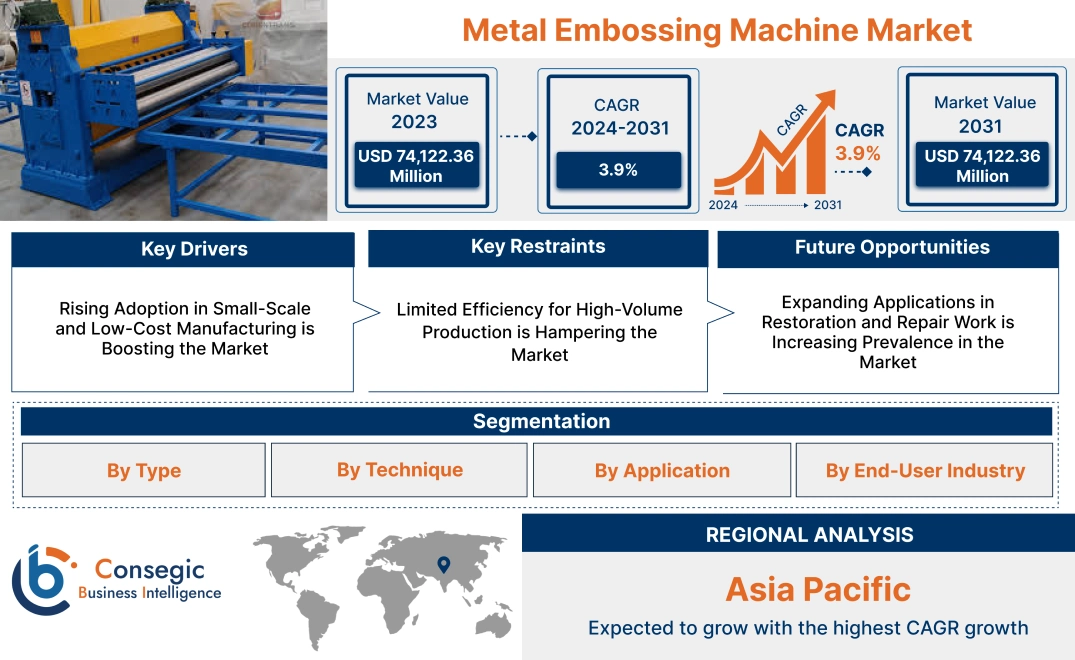

Metal Embossing Machine Market Size:

Metal Embossing Machine Market size is estimated to reach over USD 74,122.36 Million by 2031 from a value of USD 54,750.30 Million in 2023 and is projected to grow by USD 55,888.10 Million in 2024, growing at a CAGR of 3.9% from 2024 to 2031.

Metal Embossing Machine Market Scope & Overview:

The metal embossing machine is designed to create raised or recessed patterns, textures, and designs on metal sheets for functional or decorative purposes. These machines are widely used across industries such as automotive, aerospace, construction, and consumer goods to enhance product aesthetics and improve material performance. Key characteristics of metal embossing machines include high precision, durability, and the ability to handle various metals such as steel, aluminum, and copper. The benefits include improved product design, enhanced structural integrity, and reduced material waste during processing. Applications span the production of automotive components, industrial panels, HVAC systems, and decorative metal products. End-users include automotive manufacturers, construction material producers, and industrial equipment manufacturers, driven by increasing trends for customized metal designs, advancements in embossing technologies, and the growing adoption of lightweight and durable materials in industrial applications.

Key Drivers:

Rising Adoption in Small-Scale and Low-Cost Manufacturing is Boosting the Market

Manual metal embossing machines are increasingly favored in small-scale manufacturing and workshops due to their affordability, simplicity, and versatility. These machines provide an economical solution for engraving, stamping, and embossing metal surfaces, particularly in applications requiring precision and customization. Industries such as signage, decorative metalworking, and jewelry benefit from the ability of manual embossing machines to deliver high-quality results without significant upfront investment.

Trends in localized and small-batch production highlight the importance of cost-effective and reliable equipment, making manual embossing machines a preferred choice in markets with limited access to advanced automation. Analysis indicates that these machines are essential for artisans and small businesses focused on niche applications where flexibility and craftsmanship are prioritized over production speed.

Key Restraints:

Limited Efficiency for High-Volume Production is Hampering the Market

Manual metal embossing machines face significant limitations in high-volume production scenarios due to their slower operation and dependence on manual labor. Unlike automated systems, these machines cannot sustain rapid output rates, making them unsuitable for industries like automotive or large-scale packaging that require continuous, high-speed production. This inefficiency restricts their role to low-output applications, where precision and quality take precedence over throughput.

Furthermore, the labor-intensive nature of manual embossing introduces variability in quality, especially for intricate or repetitive designs. This challenge is amplified in regions experiencing labor shortages or lacking skilled operators, further limiting the scalability of manual embossing solutions in industrial settings.

Future Opportunities :

Expanding Applications in Restoration and Repair Work is Increasing Prevalence in the Market

Manual metal embossing machines are finding growing applications in restoration and repair projects, particularly for antique and heritage items. These machines are well-suited for replicating traditional patterns, intricate designs, and historical finishes, making them indispensable tools for preserving cultural artifacts, architectural details, and vintage machinery. Their ability to deliver precise and authentic results aligns with the needs of professionals and enthusiasts in the restoration industry.

Trends in heritage conservation and sustainable practices have amplified the importance of restoration work, creating a niche market for manual embossing machines. By catering to this specialized application, manufacturers can tap into metal embossing machines market opportunities in cultural preservation and bespoke repair projects, offering tailored solutions for a wide range of restoration needs.

Metal Embossing Machine Market Segmental Analysis :

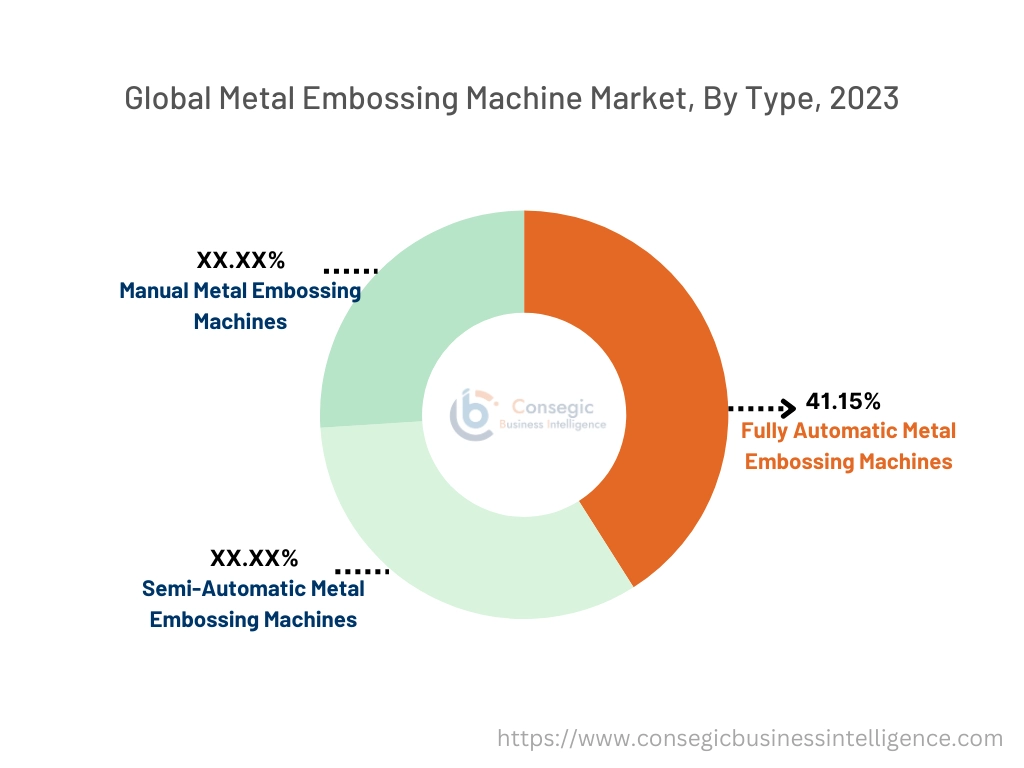

By Type:

Based on type, the metal embossing machines market is segmented into manual metal embossing machines, semi-automatic metal embossing machines, and fully automatic metal embossing machines.

The fully automatic metal embossing machines segment accounted for the largest revenue share of 41.15% in 2023.

- Fully automatic metal embossing machines are widely adopted across industries due to their high efficiency, precision, and ability to handle large-scale operations with minimal manual intervention.

- These machines are extensively used in high-volume applications such as automotive parts, industrial machinery, and construction materials, where consistency and speed are critical.

- Fully automatic machines offer advanced features like programmable controls, real-time monitoring, and seamless integration with production lines, making them a preferred choice for manufacturers aiming to enhance productivity and reduce operational costs.

- The increasing focus on industrial automation and the adoption of smart manufacturing practices have further driven the dominance of this segment.

The semi-automatic metal embossing machines segment is anticipated to register the fastest CAGR during the forecast period.

- Semi-automatic metal embossing machines provide a balance between automation and manual control, offering flexibility for low to medium-volume production.

- These machines are commonly used in applications requiring customization or intricate designs, such as consumer goods and electronics components.

- The growing metal embossing machines market trends for cost-effective solutions among small and medium-sized enterprises (SMEs) and the rising trend of customized products have driven the adoption of semi-automatic machines.

- Their versatility and adaptability to diverse production needs are expected to contribute to their rapid metal embossing machines market growth during the forecast period.

By Technique:

Based on technique, the metal embossing machines market is segmented into roll embossing, flatbed embossing, and combination embossing.

The roll embossing segment accounted for the largest revenue in metal embossing machines market share in 2023.

- Roll embossing is the most widely used technique for metal embossing, especially in applications requiring continuous patterns and high-speed production.

- This technique is ideal for embossing thin metal sheets, such as those used in automotive parts, building materials, and industrial machinery.

- Roll embossing machines are valued for their efficiency, ability to produce consistent patterns, and suitability for large-scale operations.

- The increasing trends for lightweight, embossed metal components in the automotive and construction industries have significantly driven the adoption of roll embossing.

The combination embossing segment is anticipated to register the fastest CAGR during the forecast period.

- Combination embossing combines roll and flatbed techniques to offer greater design versatility and precision.

- This technique is increasingly used in applications requiring intricate patterns or complex geometries, such as electronics components and consumer goods.

- The growing metal embossing machines market demand for high-quality, aesthetically appealing embossed products has boosted the adoption of combination embossing machines.

- Advancements in machine technology, enabling seamless transitions between techniques, are expected to further accelerate the growth of this segment.

By Application:

Based on application, the metal embossing machines market is segmented into automotive parts, building & construction materials, consumer goods, electronics components, industrial machinery, and others.

The automotive parts segment accounted for the largest revenue share in 2023.

- Metal embossing is widely used in the automotive industry for enhancing the strength, durability, and aesthetics of components such as panels, trims, and heat shields.

- Embossed metal parts are critical for improving the structural integrity of vehicles while reducing weight.

- The increasing production of electric vehicles (EVs) and lightweight vehicles has further fueled the metal embossing machines market trends for embossed metal components.

- Additionally, advancements in embossing techniques that enable high-speed, precise production have reinforced the dominance of the automotive parts segment in the market.

The electronics components segment is anticipated to register the fastest CAGR during the forecast period.

- The electronics industry is increasingly adopting metal embossing for manufacturing components such as enclosures, heat sinks, and connectors.

- Embossed metal parts are essential for enhancing thermal conductivity, electromagnetic shielding, and overall product reliability.

- The growing demand for miniaturized and high-performance electronic devices, coupled with the rising adoption of smart technologies, has driven the adoption of metal embossing in this segment.

- The focus on improving the functionality and efficiency of electronic components is expected to propel significant metal embossing machines market growth during the forecast period.

By End-User Industry:

Based on the end-user industry, the metal embossing machines market is segmented into low and medium volume and high volume.

The high-volume segment accounted for the largest revenue in metal embossing machines market share in 2023.

- High-volume end-users, including large-scale manufacturers in automotive, construction, and industrial sectors, heavily rely on metal embossing machines for mass production.

- Fully automatic and roll embossing machines are predominantly used in this segment to ensure consistent quality, high throughput, and cost efficiency.

- Therefore, the analysis shows increasing metal embossing machines market demand for mass-produced embossed metal components in global markets has solidified the dominance of high-volume end-users in the market.

The low and medium volume segment is anticipated to register the fastest CAGR during the forecast period.

- Low and medium-volume end-users, including SMEs and specialized manufacturers, utilize metal embossing machines for customized and smaller production batches.

- These users often prefer semi-automatic and combination embossing machines due to their flexibility and ability to produce intricate designs.

- The rising trend of product customization, particularly in consumer goods and electronics, has driven the trends for metal embossing machines in this segment.

- Hence, the market analysis portrays the growing adoption of advanced and cost-effective solutions by SMEs is expected to contribute to the rapid growth of this segment.

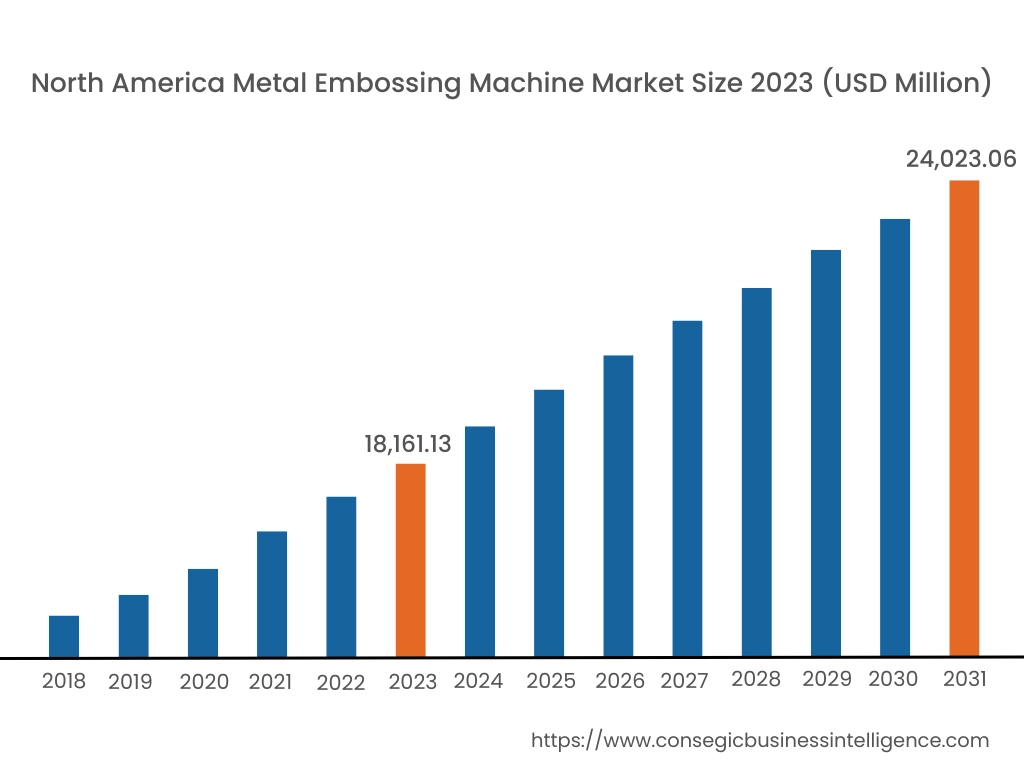

Regional Analysis:

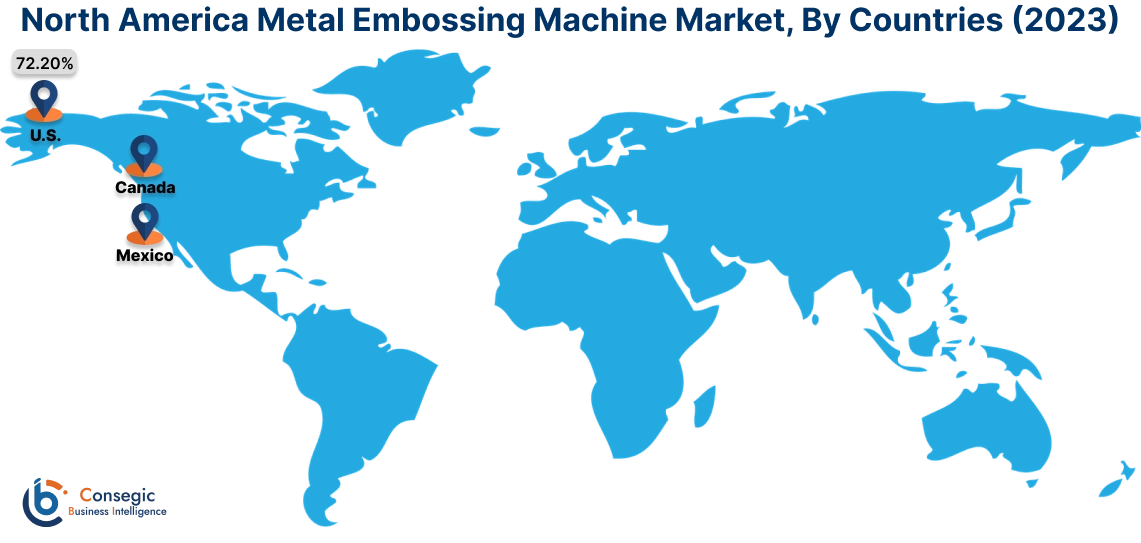

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2023, North America was valued at USD 18,161.13 Million and is expected to reach USD 24,023.06 Million in 2031. In North America, the U.S. accounted for the highest share of 72.20% during the base year of 2023. North America holds a significant share in the metal embossing machine market analysis, driven by the presence of advanced manufacturing industries such as automotive, aerospace, and defense. The U.S. leads the region with high trends for metal embossing machines in applications such as nameplates, automotive parts, and decorative panels. The growing trend of customization and product branding further supports the adoption of embossing machines in industrial and commercial sectors. Canada contributes to the market with the increasing adoption of industrial machinery and metal fabrication. However, high equipment costs and maintenance requirements may limit adoption among smaller manufacturers.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 4.3% over the forecast period. Asia-Pacific is the fastest-growing region in the metal embossing machine market analysis, fueled by rapid industrialization, urbanization, and the expansion of the automotive, construction, and electronics industries in China, India, and Japan. China dominates the market with the extensive use of embossing machines in metal fabrication for automotive and industrial applications. India’s growing infrastructure and construction activities drive demand for embossing machines for decorative and structural metalwork. Japan focuses on high-precision embossing machines for electronics and consumer goods manufacturing. However, fluctuating raw material prices and a lack of skilled labor in certain areas may hinder the market’s growth in some parts of the region.

Europe is a prominent market for metal embossing machines, supported by the region's strong automotive, construction, and packaging industries. Countries like Germany, Italy, and France are key contributors. Germany’s robust automotive manufacturing sector drives the use of metal embossing machines for components such as license plates and interior trims. Italy emphasizes its use in architectural applications and decorative metal fabrication, while France focuses on high-precision embossing for packaging and branding purposes. However, rising energy costs and stringent EU regulations on machinery safety may pose challenges for manufacturers in the region.

The Middle East & Africa region is witnessing steady growth in the metal embossing machine market, driven by increasing investments in infrastructure and industrial development. In the Middle East, countries like Saudi Arabia and the UAE are adopting embossing machines for architectural applications, decorative panels, and branding purposes in large-scale construction projects. In Africa, South Africa is an emerging market, leveraging metal embossing machines in mining equipment and industrial machinery production. However, limited local manufacturing capabilities and reliance on imports for advanced machinery may restrict broader metal embossing machines market expansion in the region.

Latin America is an emerging market for metal embossing machines, with Brazil and Mexico leading the region. Brazil’s analysis portrays the growing construction and industrial manufacturing sectors drive the trends for embossing machines in decorative metal fabrication and structural applications. Mexico’s expanding automotive and electronics industries also support the adoption of embossing machines for branding, labeling, and precision metalwork. However, economic instability and inconsistent regulatory frameworks may pose challenges for broader adoption across the region.

Top Key Players and Market Share Insights:

The Metal Embossing Machine market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global Metal Embossing Machine market. Key players in the Metal Embossing Machine industry include -

- Nanjing Harsle Machine Tool Co., Ltd. (China)

- Pannier Corporation (U.S.)

- Big City Manufacturing (U.S.)

- Identification Systems Group (U.S.)

- GUCLUPOL - Poliüretan Kauçuk ve Makina SAN.TİC. LTD (Turkey)

- Jawo Sheng Precise Machinery Works (Taiwan)

- Zhengzhou Ellsen Machinery Equipment Co., Ltd. (China)

- Alliance Machine & Engraving LLC (U.S.)

- YURI ROLL Machine Co., Ltd. (China)

- Anhui LIFU Machinery Technology Co., Ltd. (China)

Metal Embossing Machine Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 74,122.36 Million |

| CAGR (2024-2031) | 3.9% |

| By Type |

|

| By Technique |

|

| By Application |

|

| By End-User Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the projected size of the Metal Embossing Machine Market by 2031? +

Metal Embossing Machine Market size is estimated to reach over USD 74,122.36 Million by 2031 from a value of USD 54,750.30 Million in 2023 and is projected to grow by USD 55,888.10 Million in 2024, growing at a CAGR of 3.9% from 2024 to 2031.

What are metal embossing machines used for? +

Metal embossing machines are used to create raised or recessed patterns, textures, and designs on metal sheets for functional or decorative purposes. Applications span automotive components, construction materials, consumer goods, and industrial machinery.

Which application segment holds the largest market share? +

The Automotive Parts segment leads the market, driven by the demand for durable and lightweight embossed components in vehicles.

Which application segment is expected to grow the fastest? +

The Electronics Components segment is anticipated to register the fastest CAGR due to the increasing adoption of embossed parts for enhanced thermal conductivity, electromagnetic shielding, and reliability.