- Summary

- Table Of Content

- Methodology

MDI Prepolymers Market Introduction :

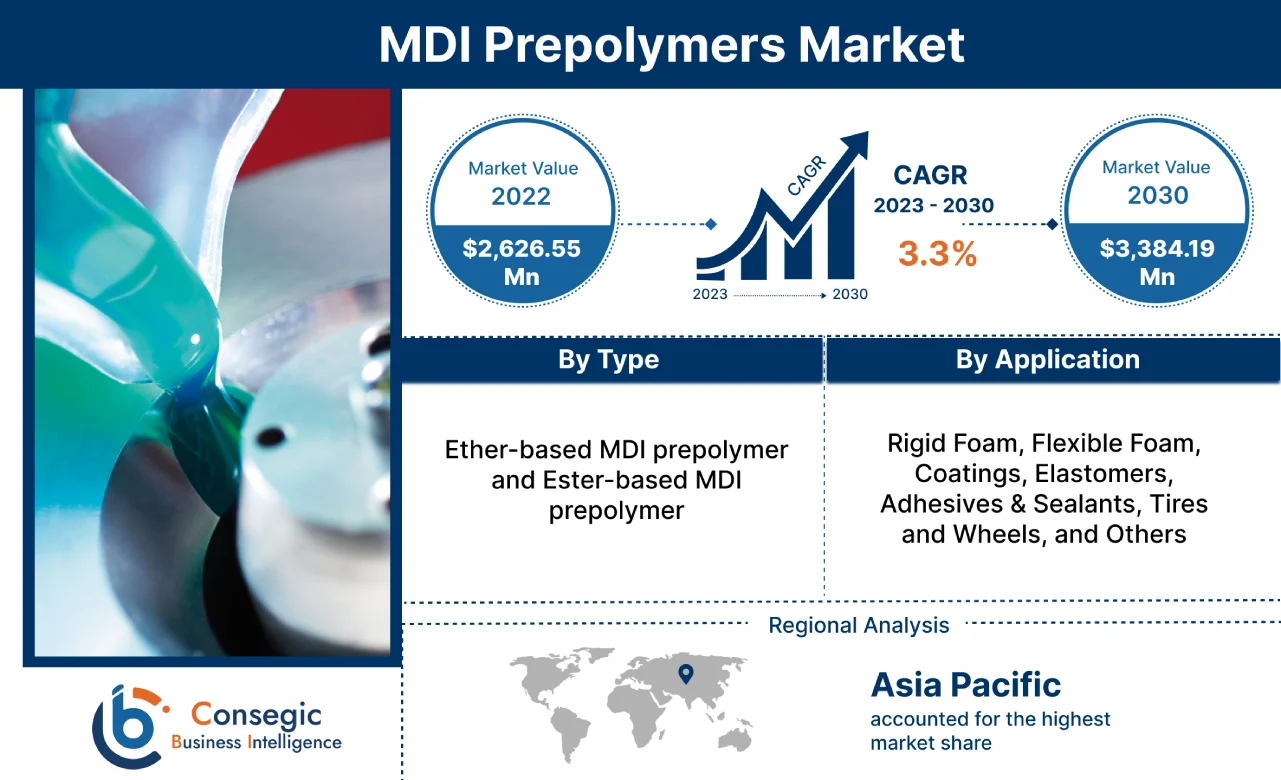

Consegic Business Intelligence analyzes that the MDI prepolymers market is growing with a healthy CAGR of 3.3% during the forecast period (2023-2030), and the market is projected to be valued at USD 3,384.19 Million by 2030 from USD 2,626.55 Million in 2022.

MDI Prepolymers Market Definition & Overview:

MDI prepolymer is a category of modified MDI substance manufactured by reacting superior purity diphenylmethane diisocyanate in combination with high molecular weight polyester polyol. This results in a material with superior storage stability at 22°C (72°F). MDI prepolymer has a medium viscosity that is produced with polyester polyols or conventional polyether and short-chain diols to ensure high physical property elastomers. The two major types of MDI prepolymers include Ether-based MDI prepolymers and Ester-based MDI prepolymers. The key benefits associated with MDI prepolymers include high elongation, excellent tear resistance, and others. As a result of the above-mentioned benefits, MDI prepolymers products are utilized in various applications, including rigid foam, flexible foam, coatings, elastomers, adhesives & sealants, tires & wheels, and others.

MDI Prepolymers Market Insights :

Key Drivers :

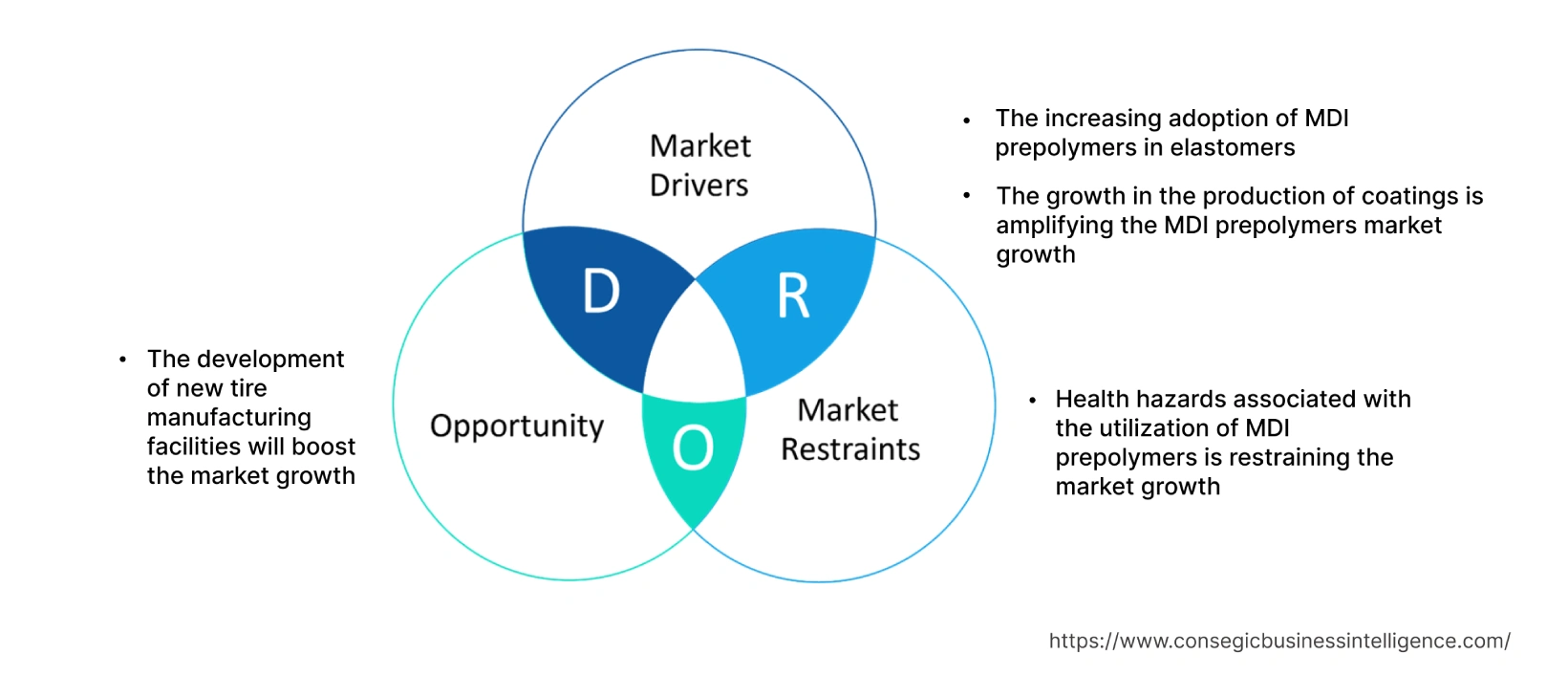

The increasing adoption of MDI prepolymers in elastomers

MDI prepolymer is an ideal solution for the elastomers to secure superior mechanical and chemical properties. The recently developed elastomer manufacturing facility at the global level is accelerating the demand for MDI prepolymers to ensure easy-to-process high-performance elastomers. For instance, in September 2022, Lion Elastomers, a rubber elastomer manufacturer in the United States invested USD 22 million in Louisiana plant expansion. The expansion strategy targeted the production expansion of elastomers. Thus, the increase in the production activities associated with elastomers is boosting the demand for MDI prepolymers to ensure superior flow characteristics. This prominent factor is propelling the market growth.

The growth in the production of coatings is amplifying the MDI prepolymers market growth

The key properties associated with MDI prepolymers include exceptional abrasion resistance, low compression set, and others. These properties ensure superior durability for coatings. Thus, Mdi prepolymers are frequently deployed in coatings. The crucial variables, including rapidly increasing new construction activities in the developing economies, economic expansion, and others are some prime determinants spurring the production activities associated with coatings. For instance, according to the recent statistics published by the British Coatings Federation Ltd (BCF), in 2021, the industrial paints and coatings industry in the United Kingdom registered a growth rate of 15.3% as compared with the year 2020. Furthermore, in the 1st quarter of 2022, the industrial paints and coatings market in the United Kingdom registered a growth rate of 8.6% as compared with the year 2021. Hence, the rise in the production of coatings is fueling the adoption of MDI prepolymers to improve handling properties or reduce toxicity. This, in turn, is driving the market growth.

Key Restraints :

Health hazards associated with the utilization of MDI prepolymers is restraining the market growth

MDI prepolymers have various beneficial features such as excellent resistance to internal heat buildup, strong dynamic properties, and others. Thus, MDI prepolymers are primarily employed in various applications such as elastomers, coatings, and others. However, on the contrary, MDI prepolymers are listed under the hazard substance list. For instance, according to OSHA Hazard Communication Standard regulation number 29 CFR 1910.1200, MDI prepolymers are considered hazardous chemicals. The health hazards associated with MDI prepolymer include skin irritation, eye irritation, and others. Therefore, the above health hazards associated with MDI prepolymers are posing a bottleneck for the growth of the MDI prepolymers market.

Future Opportunities :

The development of new tire manufacturing facilities will boost the market growth

The various benefits related to MDI prepolymers include achieving very high productivity, longer pour life, faster demolding, and others. These properties result in the efficient casting of very large and complex tire parts. Hence, MDI prepolymers are employed in tires. The growth of electric car manufacturing activities, increasing adoption of passenger cars, and others are some of the prime factors fostering the development of new tire manufacturing plants at the global level. For instance, in May 2023, Nokian Tyres, a tire manufacturer commenced the construction of a new passenger car tire factory in Romania. The new production site will be spread across 100,000m2. The construction of the new tire manufacturing facility will be completed by 2025. Henceforth, the development of a new tire manufacturing facility will supplement the demand for MDI prepolymers to ensure lower viscosity. This prominent variable will spur the growth of the market in the forecast years.

MDI Prepolymers Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2017-2030 |

| Market Size in 2030 | USD 3,384.19 Million |

| CAGR (2023-2030) | 3.3% |

| By Type | Ether-based MDI prepolymer and Ester-based MDI prepolymer |

| By Application | Rigid Foam, Flexible Foam, Coatings, Elastomers, Adhesives & Sealants, Tires and Wheels, and Others |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | Covestro AG, BASF SE, LANXESS, Huntsman International LLC, DOW, Chemline, SAPICI S.p.A., Makro Chemical, Kobe Polyurethane, and Epaflex Polyurethanes Spa |

MDI Prepolymers Market Segmental Analysis :

Based on the Type :

The type segment is categorized into ether-based MDI prepolymer and ester-based MDI prepolymer. In 2022, the ether-based MDI prepolymer segment accounted for the highest market share in the MDI prepolymers market. Ether-based MDI prepolymers are processed in combination with alcohol-based creatives to exhibit superior resistance to heat buildup. Ether-based MDI prepolymers are suitable for applications requiring dynamic properties such as resistance to abrasion and low temperature. Furthermore, ether-based MDI prepolymers are equipped with various beneficial properties such as high resilience, excellent abrasion resistance, superior hydrolysis resistance, significant resistance to microorganisms, and others. For illustration, in August 2020, LANXESS, a leading manufacturer of MDI prepolymers launched a new range of MDI polyether prepolymers. The product contains renewable raw materials. Hence, the development of sustainable MDI prepolymer is boosting the growth of the market. Therefore, the recent development of a new range of ether-based MDI prepolymers will create a lucrative opportunity for segment growth.

However, the ester-based MDI prepolymer segment is expected to be the fastest-growing segment during the forecast period. This is due to the increasing adoption of ester-based MDI prepolymers in elastomers and coatings applications.

Based on the Capacity :

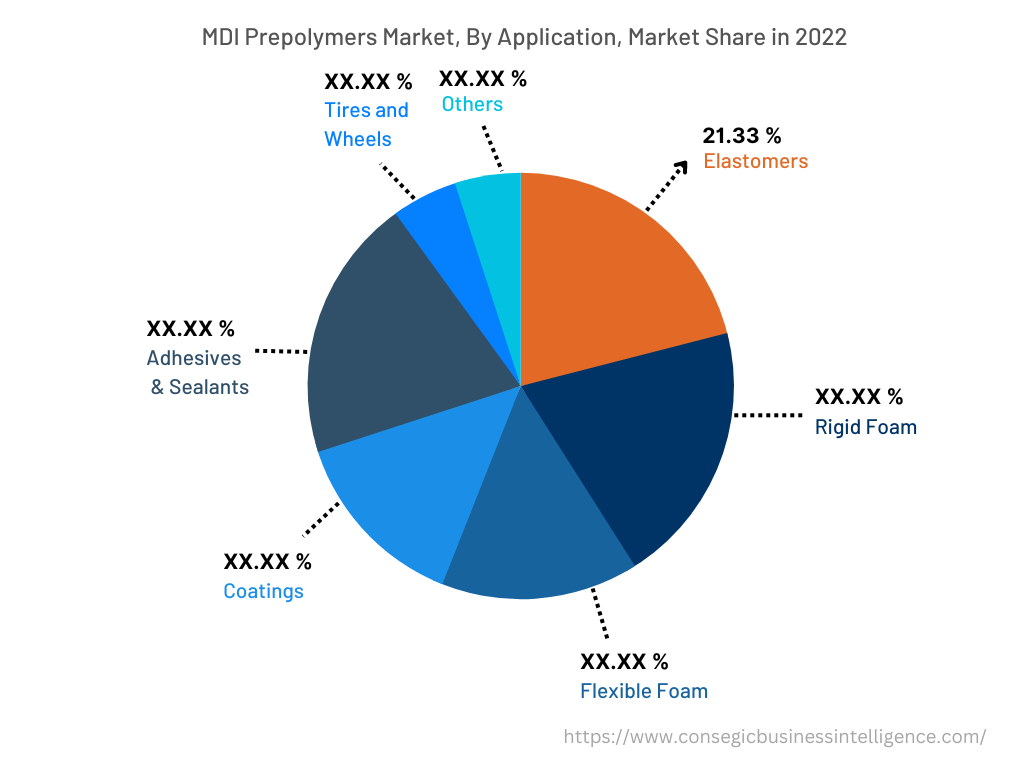

The application segment is categorized into rigid foam, flexible foam, coatings, elastomers, adhesives & sealants, tires and wheels, and others. In 2022, the elastomers segment accounted for the highest market share of 21.33% in the overall MDI prepolymers market. The elastomers manufactured from MDI prepolymers result in excellent resistance to abrasion & tears and ensure protection against oils, hydrocarbons, and solvents. The MDI prepolymers are ideal for elastomers to ensure superior resistance to internal heat buildup and strong dynamic properties. For instance, in September 2022, the Hueber Group, one of the leading manufacturers of elastomers in the European region, opened its new elastomer compounding plant in Nyíregyhaza, Hungary. Thus, the development of a new elastomer manufacturing facility is accelerating the demand for MDI prepolymers to ensure superior mechanical properties, which, in turn, is favoring the growth of the market.

However, the coatings segment is expected to be the fastest-growing segment during the forecast period. This growth is attributed to factors such as increasing investment in new residential projects, government initiatives for infrastructure projects, and others.

Based on the Application :

The application segment is categorized into rigid foam, flexible foam, coatings, elastomers, adhesives & sealants, tires and wheels, and others. In 2022, the elastomers segment accounted for the highest market share of 21.33% in the overall MDI prepolymers market. The elastomers manufactured from MDI prepolymers result in excellent resistance to abrasion & tears and ensure protection against oils, hydrocarbons, and solvents. The MDI prepolymers are ideal for elastomers to ensure superior resistance to internal heat buildup and strong dynamic properties. For instance, in September 2022, the Hueber Group, one of the leading manufacturers of elastomers in the European region, opened its new elastomer compounding plant in Nyíregyhaza, Hungary. Thus, the development of a new elastomer manufacturing facility is accelerating the demand for MDI prepolymers to ensure superior mechanical properties, which, in turn, is favoring the growth of the market.

However, the coatings segment is expected to be the fastest-growing segment during the forecast period. This growth is attributed to factors such as increasing investment in new residential projects, government initiatives for infrastructure projects, and others.

Based on the Region :

The regional segment includes North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

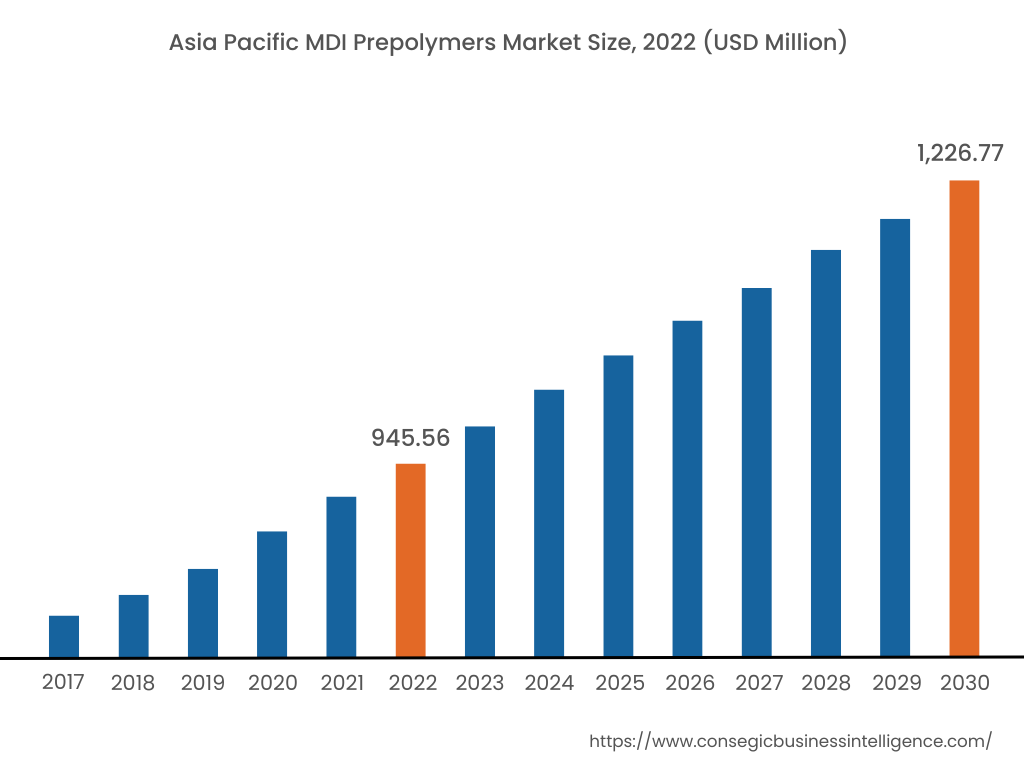

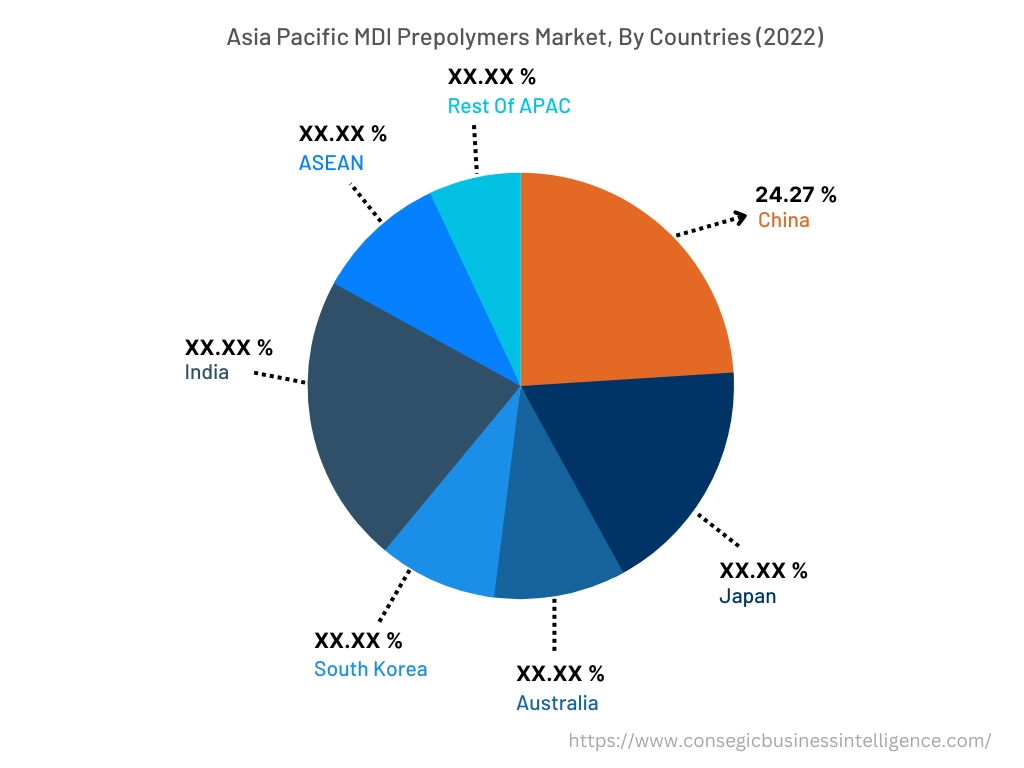

In 2022, Asia Pacific accounted for the highest market share at 36.00% and was valued at USD 945.56 million, and is expected to reach USD 1,226.77 million in 2030. In Asia Pacific, China accounted for the highest market share of 24.27% during the base year of 2022. The growth in the production activities associated with products such as coatings, elastomers, and others is favoring the market growth in the region. For instance, in October 2022, Audia Elastomers, a China-based elastomers manufacturer, added a new elastomers manufacturing site in Changshu, China. The focus of Audia Elastomers was to expand its presence in the elastomers market in China. Moreover, in September 2021, Axalta, a global player in liquid coatings started the development of a highly advanced coatings facility in Jilin City, China. The new 46,000-square-meter coatings manufacturing plant in China will produce mobility coatings to meet growing Chinese customer demand for commercial vehicles, light vehicles, and automotive components. This project's construction will be completed by the end of 2023. Thus, the growth in the production of elastomers, coatings, and others in the Asia Pacific region is boosting the MDI prepolymers market growth.

Furthermore, North America is expected to witness significant growth over the forecast period, growing at a CAGR of 3.9% during 2023-20230. This is due to the exponential growth in the adoption of MDI prepolymers in applications, including coatings, tires & wheels, elastomers, and others.

Top Key Players & Market Share Insights :

The MDI prepolymers market is highly competitive, with several large players and numerous small and medium-sized enterprises. These companies have strong research and development capabilities and a strong presence in the market through their extensive product portfolios and distribution networks. The market is characterized by intense competition, with companies focusing on expanding their product offerings and increasing their market share through mergers, acquisitions, and partnerships. The key players in the market include-

- Covestro AG

- BASF SE

- Makro Chemical

- Kobe Polyurethane

- Epaflex Polyurethanes Spa

- LANXESS

- Huntsman International LLC

- DOW

- Chemline

- SAPICI S.p.A.

Recent Industry Developments :

- In June 2021, Dow a global player in MDI prepolymer manufacturing announced its plans for the development of an MDI prepolymer manufacturing facility in Texas, United States. The development of a new MDI prepolymer manufacturing facility will boost the growth of the market.

Key Questions Answered in the Report

What was the market size of the MDI prepolymers industry in 2022? +

In 2022, the market size of MDI prepolymers was USD 2,626.55 million

What will be the potential market valuation for the MDI prepolymers industry by 2030? +

In 2030, the market size of MDI prepolymers will be expected to reach USD 3,384.19 million.

What are the key factors driving the growth of the MDI prepolymers market? +

The increasing adoption of MDI prepolymers in elastomers is accelerating the growth of the market.

What is the dominating segment in the MDI prepolymers market by application? +

In 2022, the elastomers segment accounted for the highest market share of 21.33% in the overall MDI prepolymers market.

Based on current market trends and future predictions, which geographical region is the dominating region in the MDI prepolymers market? +

Asia Pacific accounted for the highest market share in the overall MDI prepolymers market.