- Summary

- Table Of Content

- Methodology

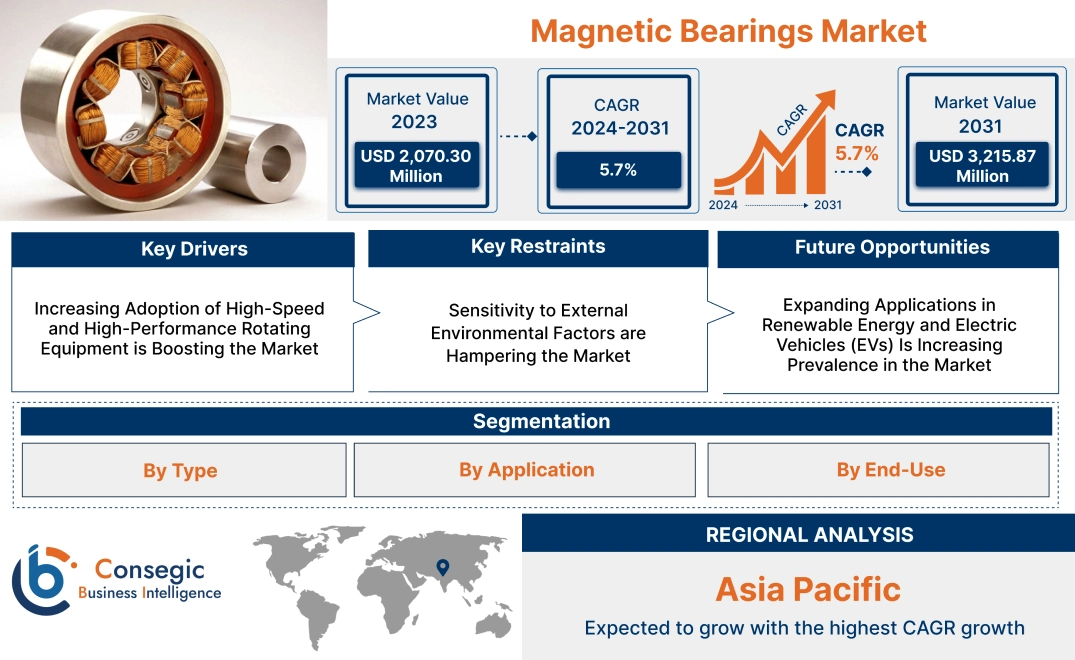

Magnetic Bearings Market Size:

Magnetic Bearings Market size is estimated to reach over USD 3,215.87 Million by 2031 from a value of USD 2,070.30 Million in 2023 and is projected to grow by USD 2,150.59 Million in 2024, growing at a CAGR of 5.7% from 2024 to 2031.

Magnetic Bearings Market Scope & Overview:

The magnetic bearings are advanced bearing systems that use magnetic fields to support and stabilize rotating components without physical contact. These systems are widely utilized in industries requiring high precision, efficiency, and reduced maintenance, such as energy, aerospace, automotive, and industrial machinery. Key characteristics of this market include low friction, high-speed operation, and the ability to function in extreme environments. The benefits include extended equipment life, reduced wear and tear, and enhanced operational efficiency. Applications span turbines, compressors, pumps, electric motors, and flywheel energy storage systems, where minimal mechanical contact and high reliability are critical. End-users include energy producers, aerospace companies, and industrial machinery manufacturers, driven by increasing adoption of energy-efficient systems, advancements in magnetic levitation technology, and growing demand for high-performance machinery in emerging markets.

Key Drivers:

Increasing Adoption of High-Speed and High-Performance Rotating Equipment is Boosting the Market

Magnetic bearings are becoming integral to high-speed and high-performance rotating machinery in industries such as aerospace, power generation, and oil and gas. These bearings operate without physical contact, eliminating friction and wear, which leads to higher operational efficiency, reduced maintenance, and extended equipment lifespan. Their ability to support precise control and stability at high speeds makes them indispensable for advanced rotating systems like turbines, compressors, and motors.

Trends in industrial automation and energy-efficient technologies emphasize the need for components that minimize energy loss and enhance reliability. Magnetic bearings meet these requirements, offering superior performance compared to traditional mechanical bearings. The analysis highlights their increasing application in sectors prioritizing advanced engineering solutions to optimize operational outcomes.

Key Restraints:

Sensitivity to External Environmental Factors are Hampering the Market

One of the significant challenges facing the adoption of magnetic bearings is their sensitivity to external environmental factors such as temperature variations, electromagnetic interference, and dust. These factors can impact the stability and performance of the bearings, particularly in harsh or unpredictable operating conditions. For instance, extreme heat or moisture can compromise the integrity of the system's electronics and control mechanisms.

This sensitivity necessitates additional protective measures, such as insulation, shielding, or environmental control systems, which increase costs and complexity. Overcoming these challenges requires ongoing advancements in magnetic bearings market trends in material science and system design to improve the robustness and adaptability of bearings across diverse environments.

Future Opportunities :

Expanding Applications in Renewable Energy and Electric Vehicles (EVs) Is Increasing Prevalence in the Market

The transition to renewable energy and electric vehicles (EVs) is opening new avenues for the application of magnetic bearings. In renewable energy systems, such as wind turbines and energy storage units, magnetic bearings improve efficiency by minimizing friction and reducing wear, critical for the longevity of these systems. Similarly, in EVs, magnetic bearings contribute to quieter, more efficient motors, aligning with trends in sustainable and high-performance mobility solutions.

As industries prioritize cleaner and more efficient technologies, the role of magnetic bearings in supporting these initiatives is expanding. The analysis underscores the potential for manufacturers to develop tailored solutions for these emerging markets, capitalizing on trends in green energy and advanced transportation technologies. This magnetic bearings market opportunity positions magnetic bearings as a pivotal component in the evolution of sustainable industrial practices.

Magnetic Bearings Market Segmental Analysis :

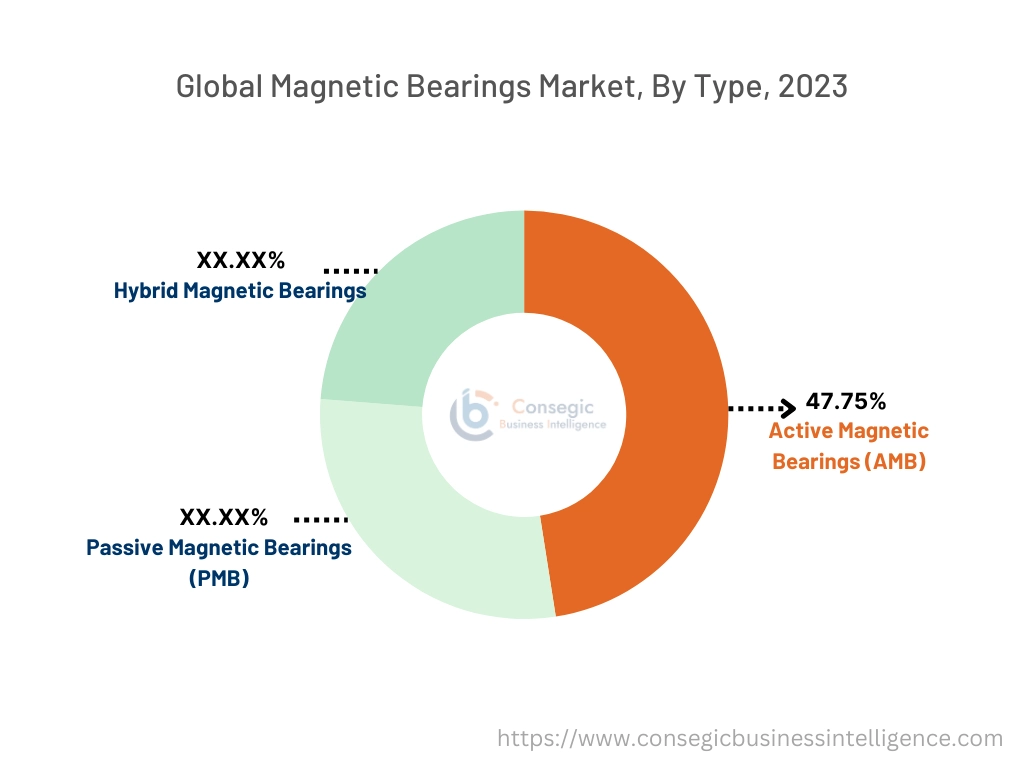

By Type:

Based on type, the market is segmented into active magnetic bearings (AMB), passive magnetic bearings (PMB), and hybrid magnetic bearings.

The active magnetic bearings (AMB) segment accounted for the largest revenue share of 47.75% in 2023.

- Active magnetic bearings (AMB) utilize advanced electromagnetic systems to levitate and stabilize rotating shafts without physical contact.

- These bearings are widely used in applications requiring high-speed and high-precision performance, such as compressors, turbines, and motors.

- AMBs provide superior efficiency, reduced wear and tear, and enhanced operational lifespan compared to conventional bearings.

- Their extensive adoption in oil and gas, aerospace, and power generation sectors, where reliability and precision are critical, has driven their trends in the market.

- Additionally, advancements in control systems and sensors have improved the performance of AMBs, further bolstering their magnetic bearings market share.

The hybrid magnetic bearings segment is anticipated to register the fastest CAGR during the forecast period.

- Hybrid magnetic bearings combine the benefits of active and passive magnetic bearings, offering superior load handling, stability, and efficiency.

- These bearings are increasingly used in applications requiring a balance of performance and cost-efficiency, such as pumps, generators, and industrial machinery.

- The growing adoption of hybrid magnetic bearings in emerging industries like renewable energy and advanced industrial processes is a key driver of this segment.

- Furthermore, their ability to provide robust performance in challenging environments is expected to propel significant magnetic bearings market growth during the forecast period.

By Application:

Based on application, the market is segmented into compressors, turbines, motors, pumps, generators, and others.

The compressors segment accounted for the largest revenue share in 2023.

- Magnetic bearings are extensively used in compressors due to their ability to operate at high speeds with minimal friction and wear.

- These bearings ensure enhanced energy efficiency, reduced maintenance, and improved reliability, making them essential for industries like oil and gas, power generation, and industrial manufacturing.

- The increasing magnetic bearings market demand for advanced compressors in gas processing, petrochemicals, and HVAC systems has driven the adoption of magnetic bearings in this segment.

- Additionally, the focus on reducing operational costs and emissions has further strengthened the magnetic bearings market trends of compressors.

The turbines segment is anticipated to register the fastest CAGR during the forecast period.

- Magnetic bearings are gaining prominence in turbine applications, including steam, gas, and wind turbines, due to their ability to operate under extreme conditions and handle high loads.

- These bearings enhance the efficiency and reliability of turbines, making them a preferred choice in power generation and aerospace industries.

- The growing demand for renewable energy solutions, such as wind and hydroelectric power, is driving the adoption of magnetic bearings in turbine applications.

- Moreover, advancements in trends in turbine design and the increasing focus on sustainability are expected to propel significant magnetic bearings market growth in this segment.

By End-User Industry:

Based on end-use, the magnetic bearings market is segmented into oil & gas, power generation, aerospace, healthcare, industrial machinery, automotive, and others.

The oil & gas segment accounted for the largest revenue of magnetic bearings market share in 2023.

- The oil and gas sectors rely heavily on magnetic bearings for critical equipment such as compressors, pumps, and turbines.

- These bearings offer superior performance in handling high-speed and high-load operations, essential for efficient extraction, processing, and transportation of oil and gas.

- The ability of magnetic bearings to operate in extreme environments, such as high temperatures and corrosive conditions, has driven their widespread adoption in these sectors.

- Additionally, the growing focus on energy efficiency and reducing operational downtime has reinforced the trends of the oil and gas segment in the market.

The power generation segment is anticipated to register the fastest CAGR during the forecast period.

- Magnetic bearings are increasingly used in power generation applications, including turbines and generators, due to their high efficiency, low maintenance requirements, and ability to support high rotational speeds.

- The rising magnetic bearings market demand for renewable energy sources, such as wind and solar power, has boosted the adoption of magnetic bearings in modern power generation equipment.

- Additionally, the integration of advanced technologies in power plants to enhance performance and sustainability is driving significant growth in this segment.

- The growing investments in energy infrastructure globally are further expected to propel the expansion of magnetic bearings in the power generation sector.

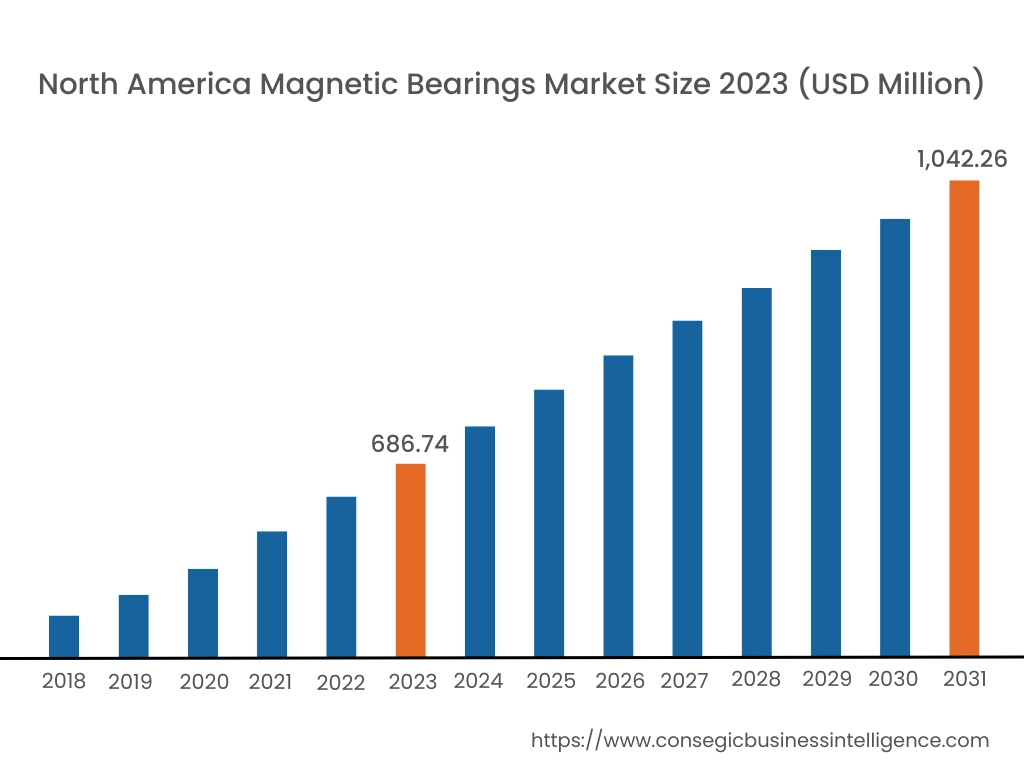

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2023, North America was valued at USD 686.74 million and is expected to reach USD 1,042.26 Million in 2031. In North America, the U.S. accounted for the highest share of 72.80% during the base year of 2023. North America holds a significant stake in the magnetic bearings market analysis, driven by its advanced aerospace, automotive, and energy sectors. The U.S. leads the region with the growing adoption of magnetic bearings in high-speed machinery, including turbines, compressors, and generators, to enhance efficiency and reduce maintenance costs. The increasing focus on renewable energy sources, such as wind turbines, further supports the market. Canada contributes with rising applications in industrial and healthcare equipment, particularly in MRI systems. However, the high cost of magnetic bearing systems may limit adoption among small and medium-sized enterprises.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 6.1% over the forecast period. Asia-Pacific is the fastest-growing region in the magnetic bearings market analysis, fueled by rapid industrialization, urbanization, and expanding applications in energy, automotive, and industrial machinery in China, Japan, and South Korea. China dominates the market analysis with the increasing adoption of magnetic bearings in wind turbines, compressors, and pumps for its growing energy and manufacturing sectors. Japan focuses on high-precision applications in aerospace and medical devices, utilizing magnetic bearings for their reliability and low-maintenance benefits. South Korea emphasizes its use in semiconductor manufacturing and advanced industrial equipment. However, high costs and lack of awareness in smaller markets may hinder broader adoption.

Europe is a prominent market for magnetic bearings, supported by its strong industrial base and focus on energy-efficient technologies. Countries like Germany, France, and the UK are key contributors. Germany leads with extensive use of magnetic bearings in automotive and industrial machinery to improve performance and reliability. France emphasizes their application in aerospace and energy sectors, particularly in turbines and cryogenic systems. The UK focuses on renewable energy and medical applications, leveraging magnetic bearings for wind turbines and advanced medical equipment. However, strict EU regulations on industrial machinery and the high initial investment required for advanced technologies may pose challenges for manufacturers.

The Middle East & Africa region is witnessing steady growth in the magnetic bearings market, driven by rising investments in energy infrastructure and industrial development. Countries like Saudi Arabia and the UAE are adopting magnetic bearings in oil and gas applications, particularly for high-speed compressors and pumps in harsh environments. In Africa, South Africa is an emerging market, leveraging magnetic bearings in mining equipment and industrial machinery to improve operational efficiency. However, limited local manufacturing capabilities and reliance on imported technology may restrict market growth in the region.

Latin America is an emerging market for magnetic bearings, with Brazil and Mexico leading the region. Brazil’s expanding energy sector, particularly in hydropower and wind energy, drives the demand for magnetic bearings in turbines and compressors. Mexico’s growing industrial base and automotive manufacturing sector support the adoption of magnetic bearings for high-performance machinery and vehicles. The region is also exploring applications in healthcare equipment such as MRI systems. However, economic instability and inconsistent regulatory frameworks may pose challenges to magnetic bearings market expansion in certain countries.

Top Key Players and Market Share Insights:

The Magnetic Bearings market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global Magnetic Bearings market. Key players in the Magnetic Bearings industry include -

- SKF AB (Sweden)

- Schaeffler Technologies GmbH & Co. KG (Germany)

- Synchrony Magnetic Bearings (U.S.)

- Levitronix GmbH (Switzerland)

- KEBA AG (Austria)

- Siemens AG (Germany)

- Waukesha Bearings Corporation (U.S.)

- Calnetix Technologies, LLC (U.S.)

- MECOS AG (Switzerland)

- S2M (France)

Magnetic Bearings Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 3,215.87 Million |

| CAGR (2024-2031) | 5.7% |

| By Type |

|

| By Application |

|

| By End-Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the projected size of the Magnetic Bearings Market by 2031? +

Magnetic Bearings Market size is estimated to reach over USD 3,215.87 Million by 2031 from a value of USD 2,070.30 Million in 2023 and is projected to grow by USD 2,150.59 Million in 2024, growing at a CAGR of 5.7% from 2024 to 2031.

What are magnetic bearings, and why are they important? +

Magnetic bearings are advanced systems that use magnetic fields to support and stabilize rotating components without physical contact. They are critical for reducing friction, wear, and maintenance in high-speed and high-precision machinery, such as turbines, compressors, and electric motors.

Which type of magnetic bearing is the largest segment in the market? +

Active Magnetic Bearings (AMB) hold the largest market share, driven by their advanced electromagnetic systems offering high precision, reduced wear, and extensive application in critical industries.

Which segment is expected to grow the fastest? +

The Hybrid Magnetic Bearings segment is anticipated to grow at the fastest CAGR due to their combination of active and passive bearing benefits, making them ideal for cost-efficient, high-performance applications.