- Summary

- Table Of Content

- Methodology

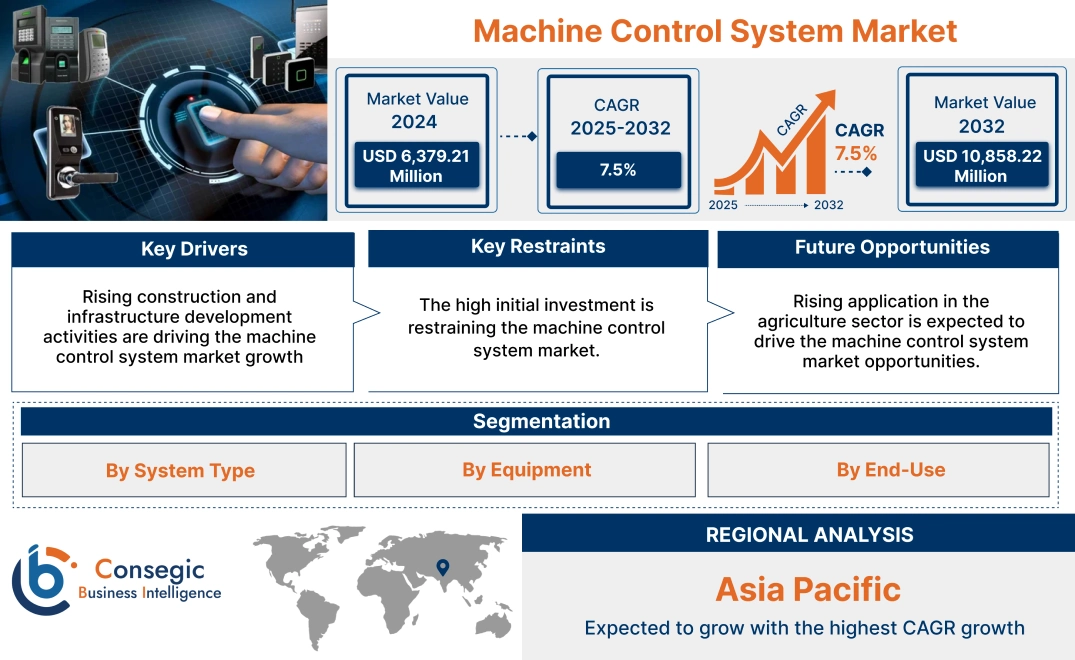

Machine Control System Market Size:

Machine Control System Market size is estimated to reach over USD 10,858.22 Million by 2032 from a value of USD 6,379.21 Million in 2024 and is projected to grow by USD 6,725.60 Million in 2025, growing at a CAGR of 7.5% from 2025 to 2032.

Machine Control System Market Scope & Overview:

Machine control system (MCS) refers to a system of hardware and software that is designed to control machinery and processes in several industrial and manufacturing environments. These systems are often used to improve the efficiency, productivity, and quality of industrial processes by automating repetitive operations while ensuring that the machinery runs within suitable parameters. Moreover, MCS offers several benefits such as improved accuracy & precision, remote control, real-time monitoring, increased operational efficiency, and others.

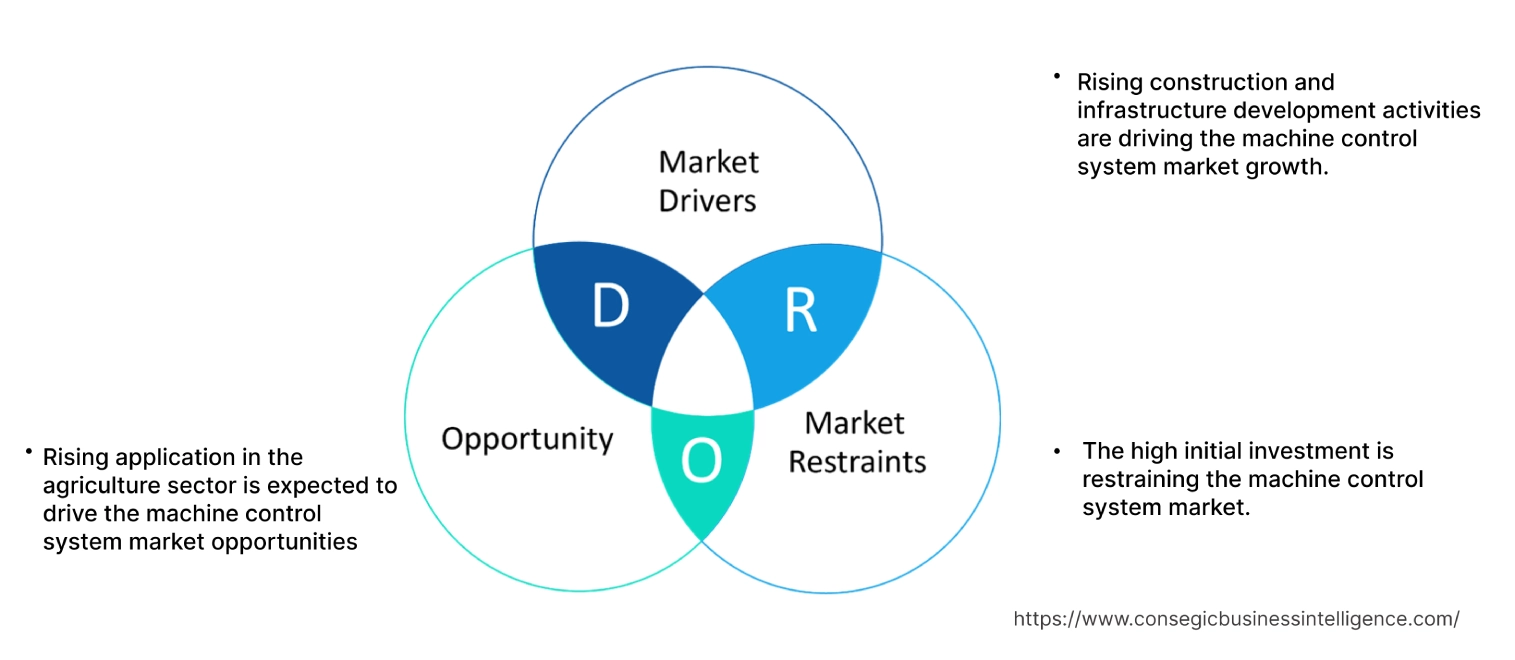

Key Drivers:

Rising construction and infrastructure development activities are driving the machine control system market growth

Machine control system plays a crucial role in the construction sector in enhancing the efficiency, accuracy, and safety of advanced machinery used on construction sites. These systems leverage advanced technologies including GPS, sensors, data analytics, and others to automate and optimize various construction equipment. Machine control solutions can offer real-time guidance and control for grading and excavation equipment used in construction sites, which ensures that the equipment operates within precise tolerances, leading to accurate site preparation and reduced rework. Additionally, MCS can manage and optimize the use of heavy equipment for material handling and transportation within the construction sites. The aforementioned benefits of machinery control systems are primary determinants for driving its adoption in the construction sector.

- For instance, according to the European Construction Industry Federation, the total number of building permits for residential construction in France reached 489,811 units in 2022, representing an increase of 3.83% as compared to 471,749 units in 2021.

Thus, the rising construction activities are increasing the adoption of control systems to improve the efficiency, accuracy, and safety of advanced machinery used on construction sites, in turn driving the machine control system market size.

Key Restraints:

The high initial investment is restraining the machine control system market.

High initial investment associated with setting up machine control systems is among the primary factors restraining the market growth. The upfront costs associated with the acquisition of MCS hardware/equipment, and software, along with integrating them into existing systems can be significantly high, which may cause financial barriers, particularly for smaller businesses or businesses operating on tighter budgets.

Additionally, advanced control systems for machinery can be quite complex to install and integrate, which further necessitates additional expenses on training personnel or hiring specialized experts to implement and maintain the systems effectively. Therefore, the high initial investment associated with setting up machine control solutions is hindering the machine control system market expansion.

Future Opportunities :

Rising application in the agriculture sector is expected to drive the machine control system market opportunities

Machine control systems are often used in the agriculture sector to automate and optimize several agriculture machinery for increasing productivity, precision, and operational efficiency. MCS is primarily used in the agriculture sector for applications involving precision farming, autonomous farming equipment, remote monitoring & management of farming equipment, and other related applications.

- For instance, according to the UK Government, the agriculture sector in the United Kingdom contributed USD 16.8 billion to the UK economy in 2022, representing a growth of USD 2.2 billion in comparison to 2021. Additionally, the UK agriculture sector is made up of approximately 216,000 farm holdings.

Hence, as per the analysis, the growing agriculture sector is projected to increase the demand for machine control solutions for automating and optimizing several agriculture machinery. The above factors are anticipated to drive the machine control system market opportunities during the forecast period.

Machine Control System Market Segmental Analysis :

By Machine Type:

Based on machine type, the market is segmented into laser-based control systems, GPS-based control systems, total station-based control systems, and others.

Trends in the machine type:

- Increasing adoption of GPS-based control systems due to its several benefits including increased versatility, longer range, improved accuracy, and others.

- There is a rising trend toward the utilization of total station-based control systems in the construction sector to facilitate precise positioning and real-time data collection within construction sites.

The GPS-based control system segment accounted for significant revenue in the total machine control system market share in 2024.

- GPS-based machine control systems utilize advanced satellite technology for guiding industrial equipment.

- GPS-based control systems are capable of accurately mapping out industrial sites, which enables the operator to see the exact location and chart their progress.

- Moreover, GPS-based machinery control systems offer numerous benefits including longer range, increased versatility, and improved accuracy among others.

- For instance, in April 2024, Leica Geosystems, a part of Hexagon AB, introduced its new Leica iCON GPS 120, which is a smart antenna designed to provide flexible and scalable machine control solutions. The GPS-based control system enables streamlined operations and consistent workflows among heavy construction equipment that vary in application requirements.

- According to the machine control system market analysis, the rising innovations associated with GPS-based control systems are driving the machine control system market growth.

The total station-based control system segment is anticipated to register the fastest CAGR growth during the forecast period.

- A total station-based machine control system utilizes a remote-controlled instrument called total station, which is an instrument used in modern surveying and construction, for guiding the machinery.

- Total station-based control system combines the functionalities of a total station with a machine control solution designed to guide heavy equipment such as excavators, graders, and bulldozers among others.

- Moreover, a total station-based control system enables precise positioning and real-time data collection, which allows operators to perform grading, excavation, and other construction tasks with high accuracy and precision.

- For instance, Topcon Corporation offers an LPS model of total station-based MCS in its product offerings. The solution features robotic total stations with 360-degree prisms that are mounted onto the machinery to provide millimeter-level positional accuracy required for applications such as excavators, bulldozers, motor graders, pavers, loaders, and other related equipment.

- Therefore, the increasing advancements related to total station-based control systems are anticipated to boost the machine control system market size during the forecast period.

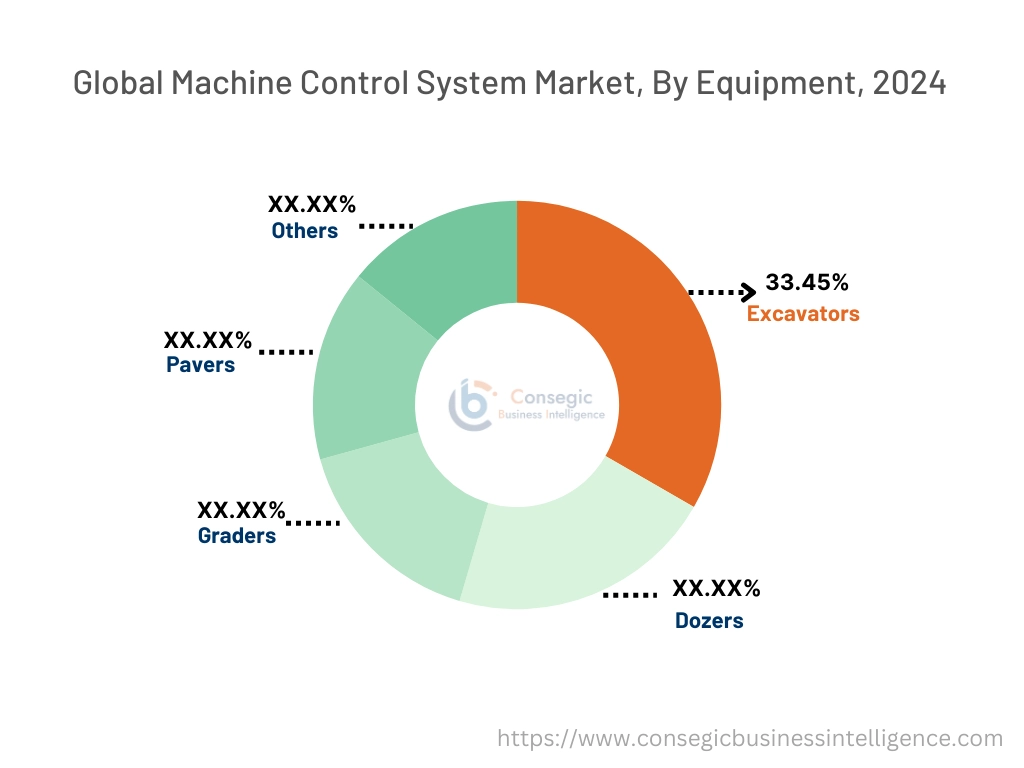

By Equipment:

Based on equipment, the market is segmented into excavators, dozers, graders, pavers, and others.

Trends in the equipment:

- There is an increasing trend towards the adoption of excavators in construction, mining, and civil engineering applications.

- Rising integration of excavators, dozers, and graders with machine control solutions to increase the accuracy, precision, and efficiency of the machinery.

The excavators segment accounted for the largest revenue share of 33.45% in the overall machine control system market share in 2024, and it is anticipated to register the fastest CAGR growth during the forecast period.

- Excavators refer to heavy construction equipment that are primarily used for digging, trenching, and earthmoving tasks.

- Moreover, machine control plays a significant role in enhancing the performance and accuracy of excavators in various construction, mining, and civil engineering applications.

- The integration of machine control in excavators provides a range of benefits including increased accuracy and precision in excavation tasks, reduced rework, increased safety, and enhanced operational efficiency among others.

- For instance, in March 2024, JCB and Leica Geosystems announced a strategic partnership for providing integrated 2D and 3D-ready semi-automated excavator control solutions.

- Therefore, the rising developments associated with the integration of machine control solutions with excavators are driving the machine control system market trends.

By End-Use:

Based on the end-use, the market is segmented into construction, mining, agriculture, oil & gas, manufacturing, and others.

Trends in the end-use:

- Factors including the growing pace of urbanization, rising infrastructure development activities, and increasing investments in residential, commercial, and industrial construction projects are key trends fueling the growth of the construction segment.

- There is an increasing trend in the adoption of machine control solutions for optimizing advanced machinery used in construction, mining, agriculture, and manufacturing sites.

The construction segment accounted for the largest revenue share in the total market share in 2024.

- This dominance is attributed to the rising adoption of machine control solutions in the construction sector to increase the efficiency, accuracy, and safety of advanced machinery used on construction sites.

- Machine control solutions offer real-time guidance and control for grading, excavation, and other related equipment used in construction sites, which ensures that the equipment operates within precise tolerances, leading to accurate site preparation and reduced rework.

- For instance, Hexagon AB offers a range of machine control solutions in its product offerings, which are primarily designed for application in the construction sector. Hexagon offers simplified and connected machine control solutions for increasing efficiency, productivity, and safety in heavy construction operations.

- According to the analysis, the rising development of machine control solutions for application in the construction sector is driving the machine control system market.

The mining segment is anticipated to register a significant CAGR during the forecast period.

- Machine control solutions are often used in the mining sector to automate and optimize several types of machinery used in mining sites to facilitate precision control and monitoring of mining operations.

- Moreover, machine control solutions are primarily used in the mining sector for applications involving drilling & blasting, excavation, material handling, site mapping, and other related applications.

- For instance, in June 2022, Talison Lithium Pty Ltd commenced operations in the Greenbushes lithium mine expansion project located in Western Australia with an initial investment of approximately USD 202 million. The project aims at expanding the area of the mine and upgrading the existing ore facilities. The processing capacity for the complete project is estimated to increase up to 9.5MM tons per year from 4.7MM tons per year.

- Therefore, the increasing mining projects are expected to drive the demand for machine control solutions for automating and optimizing several machinery used in mining sites, in turn propelling the market during the forecast period.

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

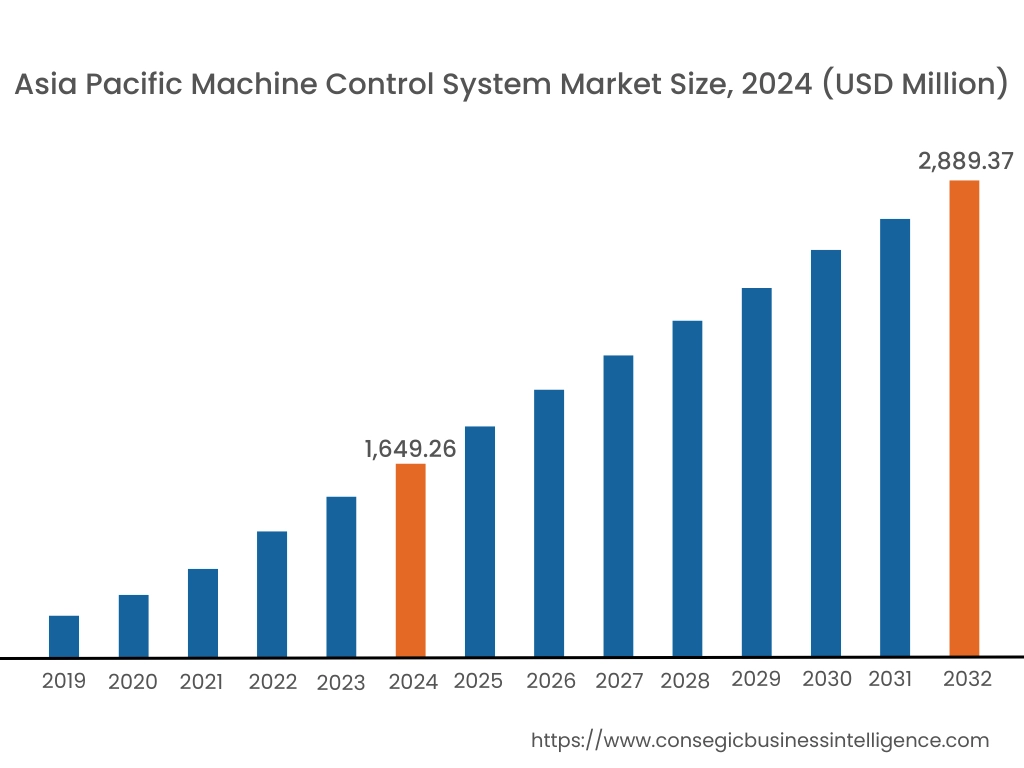

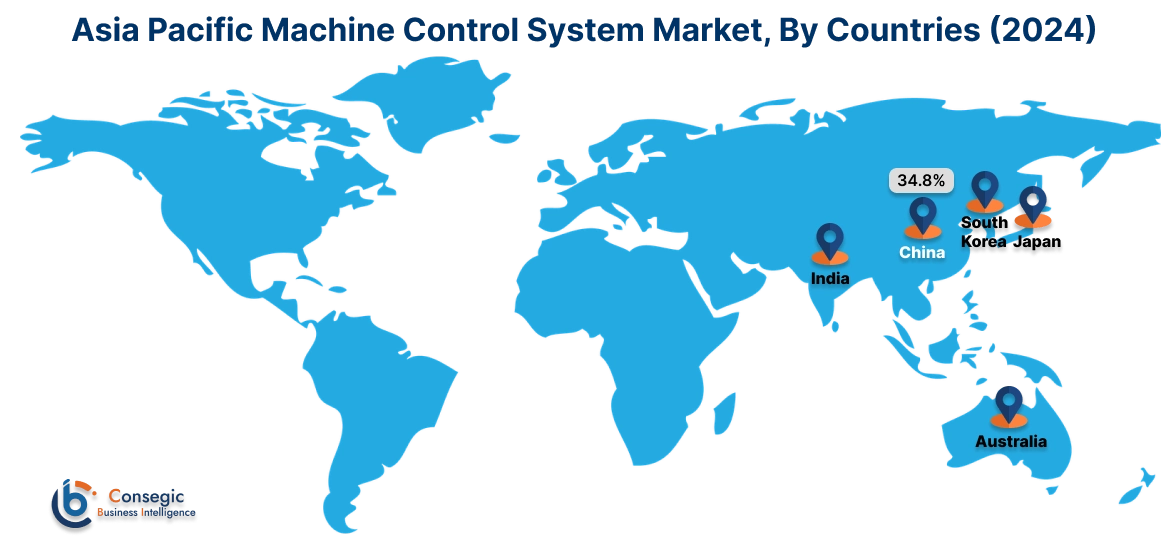

Asia Pacific region was valued at USD 1,649.26 Million in 2024. Moreover, it is projected to grow by USD 1,743.06 Million in 2025 and reach over USD 2,889.37 Million by 2032. Out of this, China accounted for the maximum revenue share of 34.8%. As per the machine control system market analysis, the adoption of machine control solutions in the Asia-Pacific region is primarily driven by the growing construction, mining, agriculture, manufacturing, and other sectors. Additionally, increasing investments in construction and infrastructure development activities are further accelerating the machine control system market expansion.

- For instance, according to the Ministry of Trade and Industry of Singapore, the total construction output including residential and commercial construction in Singapore increased by 17.7% year-on-year, reaching up to USD 8.2 billion in the fourth quarter of 2022. The above factors are driving the adoption of machine control solutions for improving the efficiency, accuracy, and safety of advanced machinery used on construction sites, in turn driving the market in the Asia-Pacific region.

North America is estimated to reach over USD 3,809.06 Million by 2032 from a value of USD 2,239.97 Million in 2024 and is projected to grow by USD 2,361.41 Million in 2025. In North America, the growth of the machine control system industry is driven by the rising adoption of machine control solutions in construction, mining, oil & gas, and other sectors. Similarly, the rising advancements associated with machine control solutions are contributing to the machine control system market demand.

- For instance, in October 2024, the U.S. Bureau of Land Management approved the Rhyolite Ridge Lithium-Boron Mine project in Nevada, marking a significant step in expanding domestic lithium production in the United States. The construction of the mine is scheduled to commence in January 2025, with production projected by 2028. The rising mining projects are projected to increase the demand for machine control solutions for automating and optimizing several machinery used in mining sites, in turn driving the machine control system market trends in North America during the forecast period.

The regional analysis depicts that rising construction and infrastructure development activities along with significant progressions in the manufacturing sector are driving the machine control system market demand in Europe. Furthermore, as per the market analysis, the demand in Latin America, Middle East, and African regions is expected to grow at a considerable rate due to factors such as increasing investments in the development of manufacturing, construction, and mining sectors and rising adoption of machine control solutions within industrial sectors for improved operational efficiency.

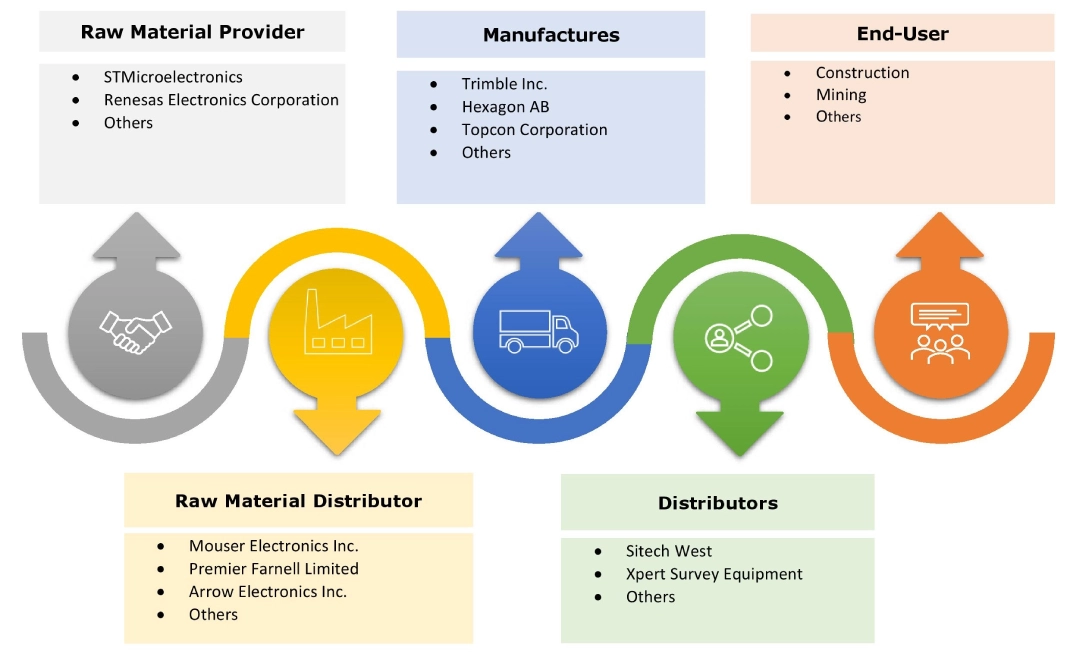

Top Key Players and Market Share Insights:

The global machine control system market is highly competitive with major players providing services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the machine control system market. Key players in the machine control system industry include-

- Trimble Inc. (U.S.)

- Hexagon AB (Sweden)

- Volvo Construction Equipment AB (Sweden)

- J C Bamford Excavators Ltd. (United Kingdom)

- Hitachi Industrial Products Ltd. (Japan)

- Topcon Corporation (Japan)

- Caterpillar Inc. (U.S)

- Dynamic Measurement & Control Solutions LLC (U.S.)

- Komatsu Ltd (Japan)

- Deere & Company (U.S.)

Recent Industry Developments :

Product Launches:

- In April 2024, Leica Geosystems, a part of Hexagon AB, introduced its new Leica iCON GPS 120, which is a smart antenna designed to provide flexible and scalable machine control solutions. The GPS-based machine control solution enables streamlined operations and consistent workflows in heavy construction equipment.

- In November 2021, Topcon introduced its MC-Max machine control solution. MC-Max provides a scalable and efficient solution for mixed-fleet heavy equipment environments.

- In March 2021, CASE Construction Equipment integrated machine control from Leica Geosystems on its dozers. The integration of Leica’s machine control solution enables dozer owners to group the precision solution of their choice while increasing operational accuracy and efficiency.

Partnerships & Collaborations:

- In March 2024, JCB and Leica Geosystems announced a strategic partnership, with the aim of providing integrated 2D and 3D-ready semi-automated excavator control solutions.

Mergers & Acquisitions:

- In August 2024, Spectra Precision announced the acquisition of Unicontrol, a manufacturer of machine control solutions. The acquisition aims to integrate Unicontrol’s machine control solutions with Spectra’s laser positioning product lines and further strengthen the company’s portfolio of construction-related business.

Machine Control System Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 10,858.22 Million |

| CAGR (2025-2032) | 7.5% |

| By System Type |

|

| By Equipment |

|

| By End-Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the machine control system market? +

The machine control system market was valued at USD 6,379.21 Million in 2024 and is projected to grow to USD 10,858.22 Million by 2032.

Which is the fastest-growing region in the machine control system market? +

Asia-Pacific is the region experiencing the most rapid growth in the machine control system market.

What specific segmentation details are covered in the machine control system report? +

The machine control system report includes specific segmentation details for system type, equipment, end-use, and region.

Who are the major players in the machine control system market? +

The key participants in the machine control system market are Trimble Inc. (U.S.), Hexagon AB (Sweden), Topcon Corporation (Japan), Caterpillar Inc. (U.S), Dynamic Measurement & Control Solutions LLC (U.S.), Komatsu Ltd (Japan), Deere & Company (U.S.), Volvo Construction Equipment AB (Sweden), J C Bamford Excavators Ltd. (United Kingdom), and Hitachi Industrial Products Ltd. (Japan).