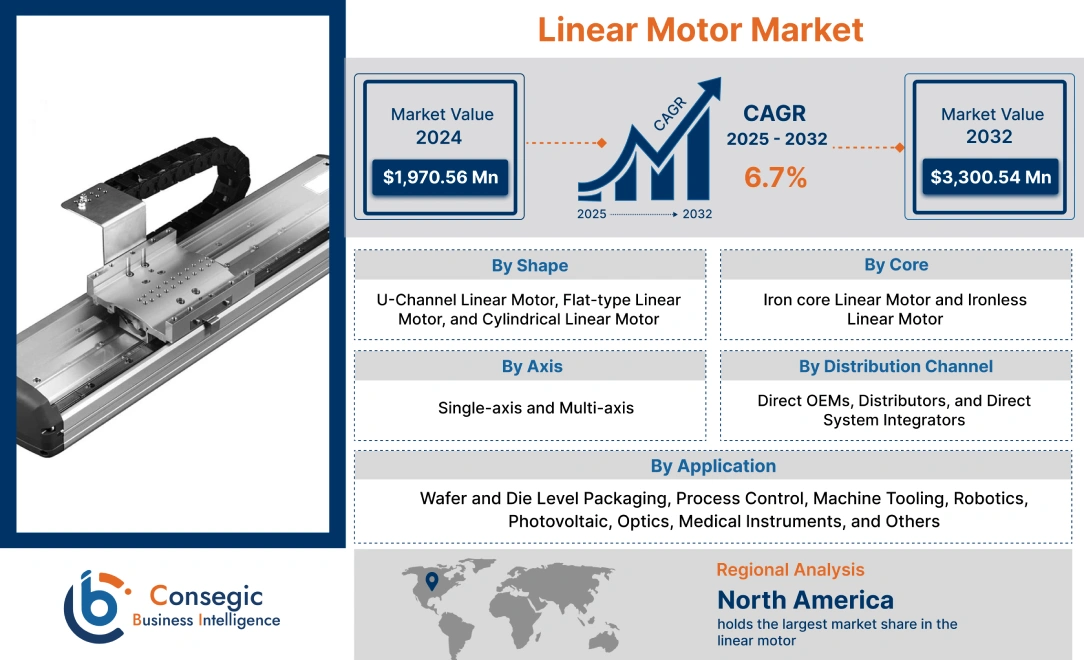

Linear Motor Market Size :

Linear Motor Market size is estimated to reach over USD 3,300.54 Million by 2032 from a value of USD 1,970.56 Million in 2024 and is projected to grow by USD 2,066.69 Million in 2025, growing at a CAGR of 6.70% from 2025 to 2032.

Linear Motor Market Scope & Overview:

A linear motor is an electromagnetic device that generates motion along a straight path. The motor consists of a primary part, referred to as the stator, which comprises a series of electromagnets or coils, and a secondary part, known as the mover or translator, which is usually a conductive element. Additionally, the motors are deployed in various sectors including transportation, robotics, and manufacturing due to the ability to provide efficient and direct linear motion eliminating the need for complex mechanical components.

Linear Motor Market Insights :

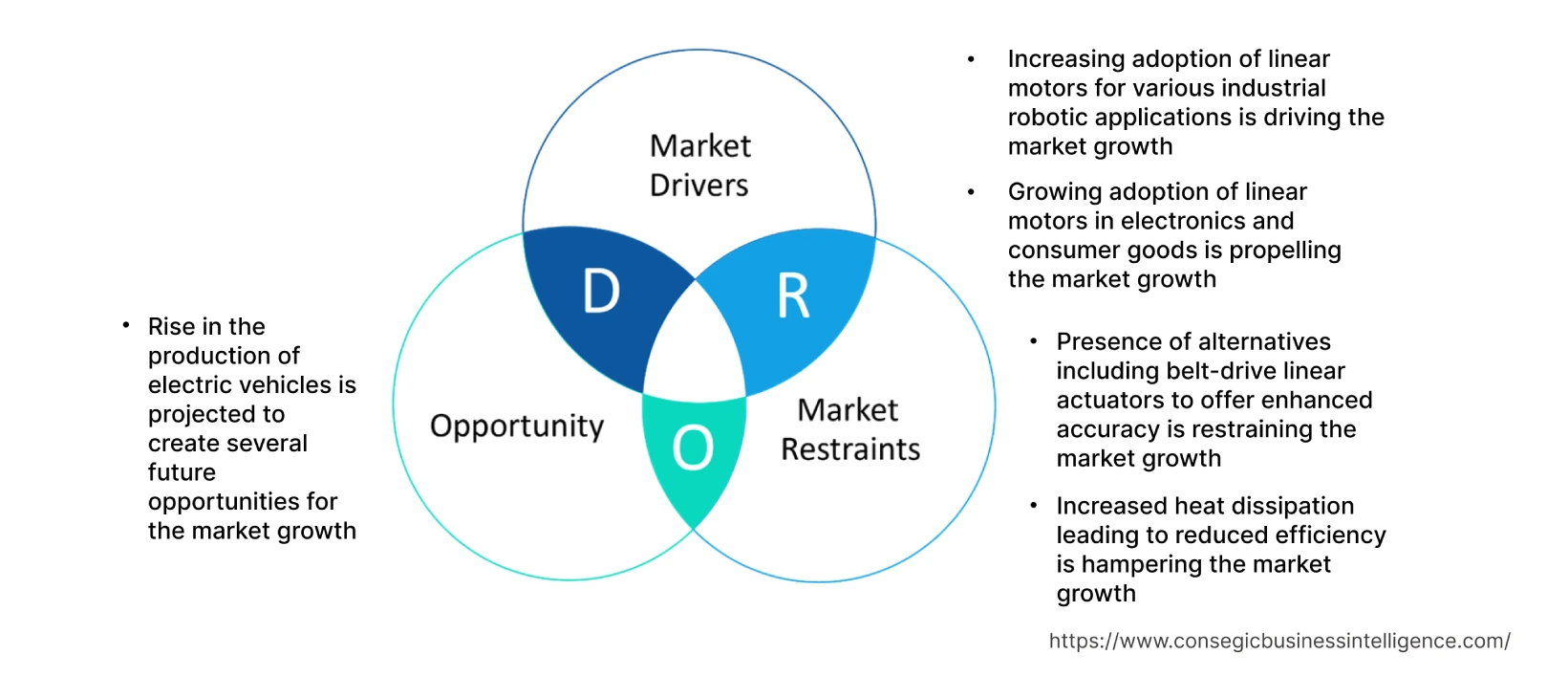

Linear Motor Market Dynamics - (DRO) :

Key Drivers :

Increasing adoption of various industrial robotic applications is driving the linear motor market

Automation and robotics require precise and accurate motion control to perform tasks with high repeatability and accuracy. Linear motors offer smooth and continuous motion along a straight path, providing the level of precision necessary for the applications. Additionally, many robotic applications require high-speed movements to achieve faster cycle times and increased productivity. They deliver rapid acceleration and deceleration rates, enabling robots to perform tasks more efficiently and reducing production times. Moreover, traditional mechanical systems in robotics namely belts, gears, and pulleys lead to friction, backlash, and wear over time, resulting in reduced accuracy and maintenance issues. These motors eliminate the need for such mechanical components, offering smoother and more reliable motion with minimal wear and tear. Consequently, the growing adoption of robotics and automation in industrial settings is driving the usage of these motors to provide enhanced accuracy. For instance, according to the International Federation of Robotics (IFR), 517,385 new industrial robots were installed in factories in 2021, exceeding the pre-pandemic record of robot installation by 22% in 2018. Furthermore, as per the market trends analysis, the operational robots' stock worldwide accounts for 3.5 million units, thus contributing significantly to accelerating the linear motor market share.

Growing adoption in electronics and consumer goods is propelling the linear motor market

Linear motors provide smoother operation compared to traditional mechanical components, namely gears and belts. In electronics and consumer goods, the application results in improved performance and efficiency of devices including hard drives, printers, optical disc drives, and home appliances. Additionally, they enable more precise movements in consumer electronics, leading to a better user experience. For instance, they are used in haptic feedback systems, offering a more realistic atmosphere in touchscreens, and gaming controllers, enhancing the overall interactivity and immersion for users.

In conclusion, the expanding electronics industry is contributing notably to bolstering the market. For instance, according to the Ministry of Electronics & Information Technology, Government of India Report of 2022-2023, the production value of the electronics industry in India, in the financial year 2022, reached nearly 6.5 trillion Indian rupees. Additionally, mobile phone production was the most valuable sector with an estimated production value of 2.7 trillion rupees, further raising the demand to offer improved performance. Hence, as per the market trends analysis, the aforementioned factors drive the linear motor market growth.

Key Restraints :

Presence of alternatives including belt-drive linear actuators to offer enhanced accuracy is restraining the market

Belt-drive linear actuators, namely ServoBelt serve as a cost-effective alternative to motor systems and possess the same force regime. Additionally, belt-drive actuators offer improved accuracy in comparison to these motors, further strengthening the market. As per the market analysis, the low cost and enhanced precision of linear actuators compel users to seek alternatives, thus hindering the linear motor market growth.

Increased heat dissipation leading to reduced efficiency is hampering the market

The heat generated during the operation of linear motors results in energy losses, reducing overall system efficiency. The dissipated heat represents wasted energy, leading to increased operational costs and negatively impacting the market. Additionally, excessive heat causes thermal stress on the components of this motor, leading to premature wear and reduced lifespan. Prolonged exposure to high temperatures degrades the performance and reliability of the motor, leading to more frequent maintenance and replacement, and increasing operational expenses. Furthermore, to manage heat dissipation effectively, motor systems require additional cooling mechanisms including fans, heat sinks, and liquid cooling systems. The implementation and maintenance of the cooling systems lead to additional upfront costs, hence limiting the adoption, hence restraining the linear motor market demand.

Future Opportunities :

Rise in the production of electric vehicles is projected to create several future opportunities

Linear motors offer high-precision motion control in regenerative braking systems and suspension systems to achieve more accurate and responsive movements. They convert the kinetic energy of the vehicle's motion back into electrical energy during deceleration. The energy is then stored in the vehicle's battery, enhancing overall energy efficiency, and extending the driving range of electric vehicles. Additionally, these motors provide smoother and quieter operation compared to traditional mechanical systems, leading to reduced noise and vibration levels. Furthermore, the motors potentially reduce the weight and complexity of automotive components by eliminating the need for mechanical linkages and transmission systems. Subsequently, the growing adoption of electric vehicles is anticipated to create potential linear motor market opportunities.

Linear Motor Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 3,300.54 Million |

| CAGR (2025-2032) | 6.7% |

| By Shape | U-Channel, Flat-type, and Cylindrical |

| By Core | Iron core and Ironless core |

| By Axis | Single-axis and Multi-axis |

| By Distribution Channel | Direct OEMs, Distributors, and Direct System Integrators |

| By Application | Wafer and Die Level Packaging, Process Control, Machine Tooling, Robotics, Photovoltaic, Optics, Medical Instruments, and Others |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | Aerotech Inc., ETEL S.A., KML Linear Motion Technology GmbH, Kollmorgen Corporation, Moog Inc., NTI AG LinMot, PiezoMotor Uppsala AB, Yaskawa Electric Corporation, NUM |

Linear Motor Market Segmental Analysis :

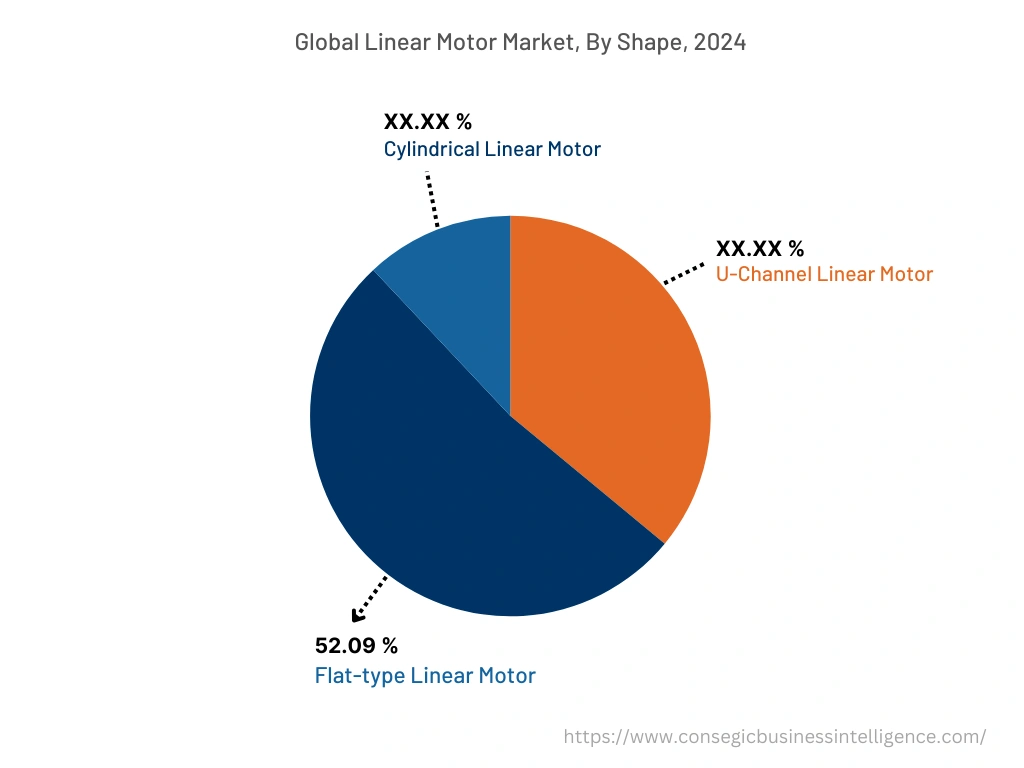

By Shape :

The shape segment is trifurcated into U-channel, flat-type, and cylindrical. Flat-type accounted for the largest market share of 52.09% in 2024 as the motors offer higher power density and deliver more power in a smaller footprint. Additionally, these have lower friction compared to other motor designs, resulting in a smoother and more precise motion. Moreover, the advancements in technology including the integration of NdFeB magnets with the motor to prevent rotor loss and promote high speed are further contributing to the market. For instance, in August 2019, Oswald Elektromotoren GmbH launched a LE flat linear motor with an electric direct drive to provide high power density. Furthermore, the advanced motor is equipped with an NdFeB magnet to prevent rotor loss, thus contributing remarkably to boosting the segment trends.

U-channel is predicted to witness the fastest CAGR in the upcoming years. They offer a more cost-effective solution compared to flat motors. Additionally, they are relatively easy to integrate into existing systems and structures, thus becoming a viable option for retrofitting or upgrading older equipment and machinery. Moreover, they provide substantial force output, suitable for applications that require heavy-duty operation including material handling, metal cutting, and industrial automation. Furthermore, the motors are designed to accommodate various lengths and configurations, offering improved reliability and reduced maintenance requirements. Consequently, as per the analysis of the segment trends, the aforementioned factors are expected to bolster the segment trends, thus in turn, driving the linear motor market demand.

By Core :

The core segment is bifurcated into iron core and ironless core. Iron core accounted for the largest market revenue in 2024 of the total linear motor market share, as the motors provide high force and power density, suitable for applications including industrial automation, machine tools, and other heavy-duty applications. In addition, they offer a cost-effective solution compared to other types of motors, especially for applications that demand high-force output. The construction and materials used to manufacture iron-cored motors are less expensive, further contributing to the dominance of the segment. Moreover, the analysis shows that the growing adoption of iron-cored motors in numerous industries including manufacturing, semiconductor processing, and packaging due to the ability to deliver high force and precise motion is also driving the market. Subsequently, the above-mentioned factors are collectively responsible for accelerating the segment.

The ironless core segment is predicted to register the fastest CAGR during the forecast period. This is attributed to the lower moving mass of ironless motors, resulting in lower inertia, and allowing for faster acceleration and deceleration. Additionally, they offer higher efficiency compared to iron-cored motors due to the absence of an iron core. The elimination of iron losses and eddy currents leads to improved energy efficiency, ideal for applications where energy consumption is a critical concern. Moreover, ironless motors also eliminate cogging, resulting in a smooth motion, hence projected to fuel the market in upcoming years. For instance, in May 2021, point launched the nPL70 family of these motors for applications that require high-speed sample positioning and scanning. The advanced motor is coupled with unique windings, eliminating cogging while sustaining high force density and smooth motion. Hence, the segment trends analysis shows that it is projected to promote the segment, thus, in turn, boosting the linear motor market opportunities.

By Axis :

The axis segment is bifurcated into single-axis and multi-axis. Single-axis segment accounted for the largest market share in 2024 as the motors offer a direct, one-dimensional motion along a single axis and are convenient to integrate into existing systems. Additionally, they are more cost-effective compared to other complex motion systems, thus contributing to reduced manufacturing and maintenance costs. Moreover, the increasing adoption of these motors in various applications including conveyor systems, cutting machines, and other automated processes is also spurring the market. As per the analysis, the aforementioned factors collectively contribute notably to driving the single-axis segment.

The multi-axis segment is expected to witness the fastest CAGR in the linear motor market during the forecast period. This is endorsed by the ability of these motors to allow simultaneous control of motion in multiple directions, providing versatility and flexibility in various applications. Additionally, multi-axis motors offer higher degrees of freedom compared to single-axis motors suitable for applications namely robotics, 3D printing, and advanced manufacturing. Moreover, they also reduce the size and weight and increase the speed of the equipment, further contributing to the market. For instance, in April 2022, Sanyo Denki Co., Ltd. developed an ANMOTION multi-axis integrated unit. The motor consists of a 4-axis unit, which is easily customized, and suitable for semiconductor manufacturing and inspection equipment. In conclusion, the ability of these motors to offer improved flexibility and enable simultaneous control of motion in multiple directions is anticipated to accelerate the linear motor market trends.

By Distribution Channel :

The distribution channel is trifurcated into direct OEMs, distributors, and direct system integrators. Direct OEMs accounted for the largest market revenue in 2024 as OEMs have strong brand identities and reputations in the industry. Customers trust their products and solutions and prefer buying directly from the OEM to ensure product authenticity and reliability. Additionally, by purchasing directly from the OEM, customers have quicker access to technical support, after-sales service, and warranty assistance. Direct communication with the manufacturer leads to faster issue resolution and reduced downtime. Moreover, dealing directly with the OEM allows customers to negotiate pricing and terms directly, potentially leading to better pricing and cost control. In conclusion, the aforementioned factors are contributing substantially to propelling the direct OEM segment.

Distributors are projected to witness the fastest CAGR in the linear motor market during the forecast period. Distributors often have an established network of customers and contacts, allowing manufacturers to reach new markets and customer segments. Additionally, distributors tap into local markets, cultural nuances, and customer preferences, helping manufacturers to expand their global presence. Moreover, distributors possess valuable market knowledge, insights, and expertise, which help manufacturers tailor their products and marketing strategies to meet specific regional or sector requirements. Furthermore, the analysis portrays, that the distributors have established sales and distribution channels, offering convenience to manufacturers to get the products to market quickly and efficiently, hence predicted to fuel the market in the upcoming years.

By Application :

The application segment is categorized into wafer and die level packaging, process control, machine tooling, robotics, photovoltaic, optics, medical instruments, and others. Machine tooling holds the maximum revenue in 2024 as these motors are integrated into conveyors and transfer systems, allowing for the efficient movement of products along the assembly line. The motor enables smooth and continuous motion, reducing the risk of jams and improving overall throughput. Additionally, they are employed in testing and inspection stations to move test probes and inspection tools precisely over products, ensuring thorough testing and quality control. Furthermore, the motors also enable precise movement of adhesive dispensing or gluing heads, ensuring accurate and consistent application of adhesives in assembly processes. Consequently, the ability of these motors to offer the above-mentioned benefits in machine tooling is driving the market.

Robotics is anticipated to witness the fastest CAGR in the linear motor market during the forecast period. This is credited to the ability of motors to drive the linear motion of robotic arms and manipulators. The motors provide smooth and precise movement, allowing robots to pick and place objects with high accuracy. Additionally, these motors are deployed in gantry systems to provide the linear motion required for moving heavy loads or performing tasks that cover a large workspace. Moreover, the growing adoption of robotic linear motions in various industries including food and beverage to optimize production and perform high-speed picking and placing tasks is further contributing to the market. For instance, in July 2023, LinMot USA introduced robotic linear motion solutions for the food and beverage sector at PACK EXPO in Las Vegas. The linear motion robotic solution was launched to optimize production to meet sustainability goals, thus expected to bolster linear motor market trends.

By Region :

The regional segment includes North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

North America is estimated to reach over USD 1,069.71 Million by 2032 from a value of USD 653.65 Million in 2024 and is projected to grow by USD 684.23 Million in 2025, due to the expanding manufacturing, electronics, and automation sector that increases the adoption of advanced motor technologies in the region. Additionally, the region has a diverse industrial base, encompassing sectors namely automotive, semiconductor, and healthcare, further raising the demand for these motors to improve productivity, precision, and efficiency in the production processes. For instance, in July 2019, Parker Hannifin Corporation launched the Parker LM-Pro linear motor for respiratory and anesthesia markets. The Parker LM-Pro utilizes motor technology to enable flow up to 540 SLPM to provide resolution at lower power consumption than traditional solenoids, hence driving the adoption of these motors in the North American region.

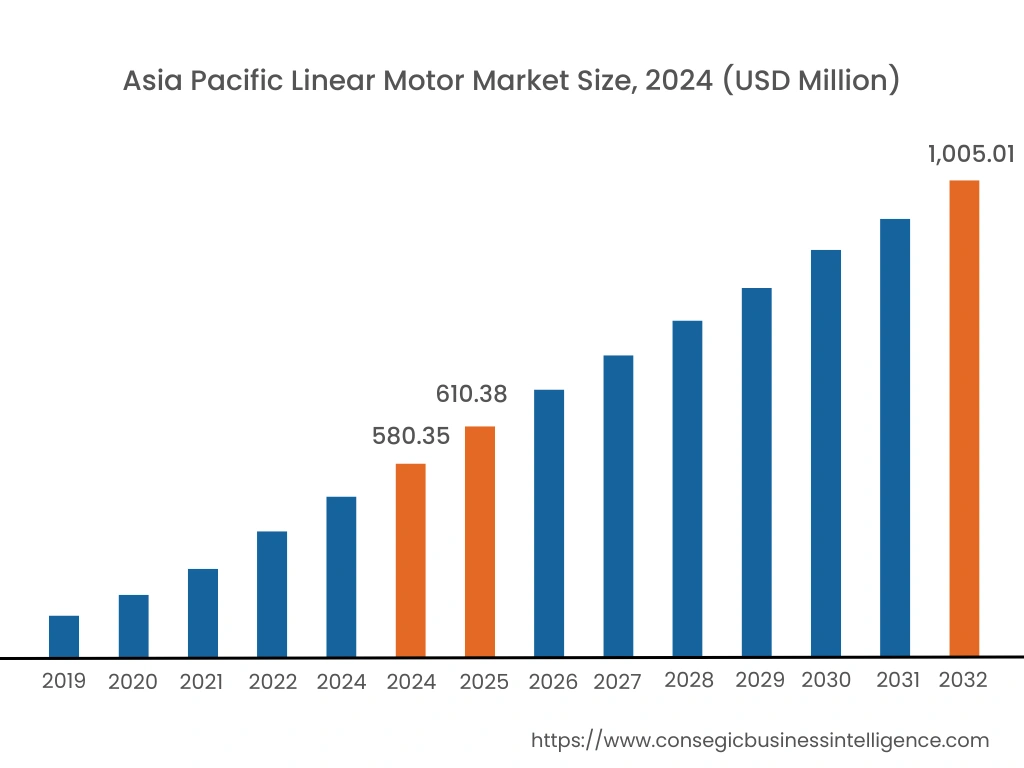

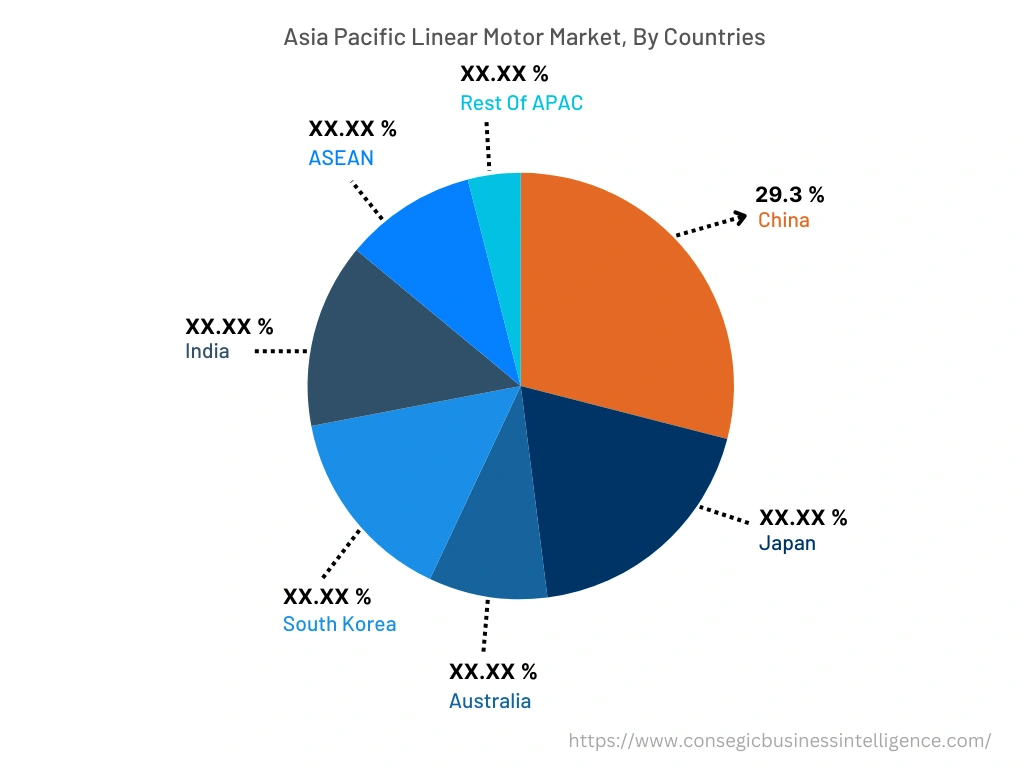

Asia Pacific region was valued at USD 580.35 Million in 2024. Moreover, it is projected to grow by USD 610.38 Million in 2025 and reach over USD 1,005.01 Million by 2032. In addition, in the region, China accounted for the maximum revenue share of 29.3% in the year 2024. The growth is attributed to the expanding electronics and semiconductor sector in countries including China, India, and South Korea. The expansion in the electronics sector raises the demand for advanced motors to improve the production and operation efficiency of machines. Additionally, the presence of key players in the region including Yaskawa Electric Corporation and Beijing Leadshine Technology Co., Ltd, investing heavily in research and development to launch innovative motors is also propelling the market growth. In conclusion, the expanding electronics sector, and the presence of key players in the region are projected to accelerate the growth of the market in Asia Pacific countries.

Top Key Players & Market Share Insights:

The landscape of the market is highly competitive and has been examined in the report, along with complete profiles of the key players operating in the industry. In addition, the surge in innovations, acquisitions, mergers, and partnerships has further accelerated the growth of the transit card market. Major players in the linear motor industry include-

- Aerotech Inc.

- ETEL S.A.

- PiezoMotor Uppsala AB

- Yaskawa Electric Corporation

- NUM

- KML Linear Motion Technology GmbH

- Kollmorgen Corporation

- Moog Inc.

- NTI AG LinMot

Recent Industry Developments :

- In September 2022, NUM introduced a series of brushless linear servo motors, particularly designed for continuous duty cycle applications in machine tools.

- In June 2019, Mitsubishi Electric Corporation invested in Akribis Systems Pte Ltd, a leading manufacturer of linear servo motors to expand the industrial automation portfolio utilizing Akribis's linear motor technology.

Key Questions Answered in the Report

What is a linear motor? +

A linear motor is an electromagnetic device that generates motion along a straight path.

What specific segmentation details are covered in the linear motor market report, and how is the dominating segment impacting the market growth? +

Iron core linear motors accounted for the largest market share in 2024 as the motors provide high force and power density, suitable for applications including industrial automation, machine tools, and other heavy-duty applications.

What specific segmentation details are covered in the linear motor market report, and how is the fastest segment anticipated to impact the market growth? +

Multi-axis segment witnessed the fastest growth due to the ability of multi-axis linear motors to allow simultaneous control of motion in multiple directions, providing versatility and flexibility in various applications.

Which region is anticipated to witness the highest CAGR during the forecast period, 2025-2032? +

Asia Pacific is anticipated to witness the fastest CAGR during the forecast period due to the expanding electronics sector and the presence of key players in the region.