- Summary

- Table Of Content

- Methodology

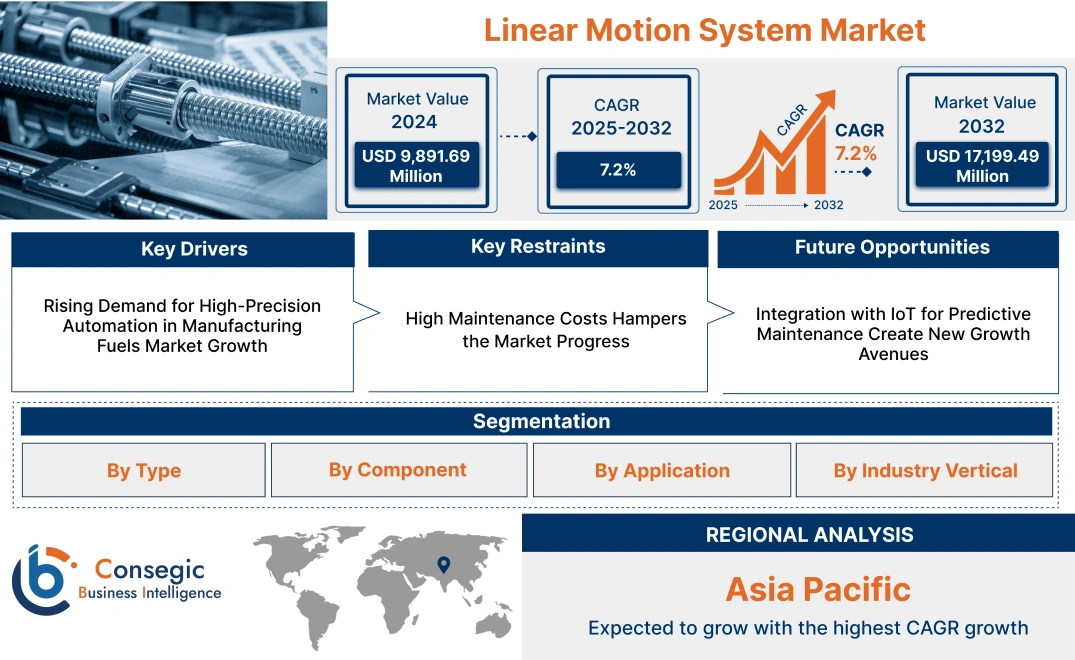

Linear Motion System Market Size:

Linear Motion System Market size is estimated to reach over USD 17,199.49 Million by 2032 from a value of USD 9,891.69 Million in 2024 and is projected to grow by USD 10,423.68 Million in 2025, growing at a CAGR of 7.20% from 2025 to 2032.

Linear Motion System Market Scope & Overview:

A linear motion system is a mechanical assembly designed to facilitate precise and controlled movement along a straight path. These systems are composed of components such as actuators, guide rails, ball screws, and bearings, which work together to deliver accurate positioning and smooth operation. They are widely utilized in applications requiring high precision, including robotics, packaging, medical devices, and industrial automation.

These systems are available in various configurations, such as single-axis and multi-axis setups, tailored to meet the specific requirements of diverse industrial processes. Engineered for durability and reliability, they provide efficient motion control even under demanding conditions. Advanced systems often integrate smart features, such as sensors and real-time feedback mechanisms, enhancing their performance and adaptability to complex operational environments.

End-users of these solutions include industries like manufacturing, electronics, healthcare, and logistics, which rely on precise motion control to improve operational efficiency and ensure product quality across various applications.

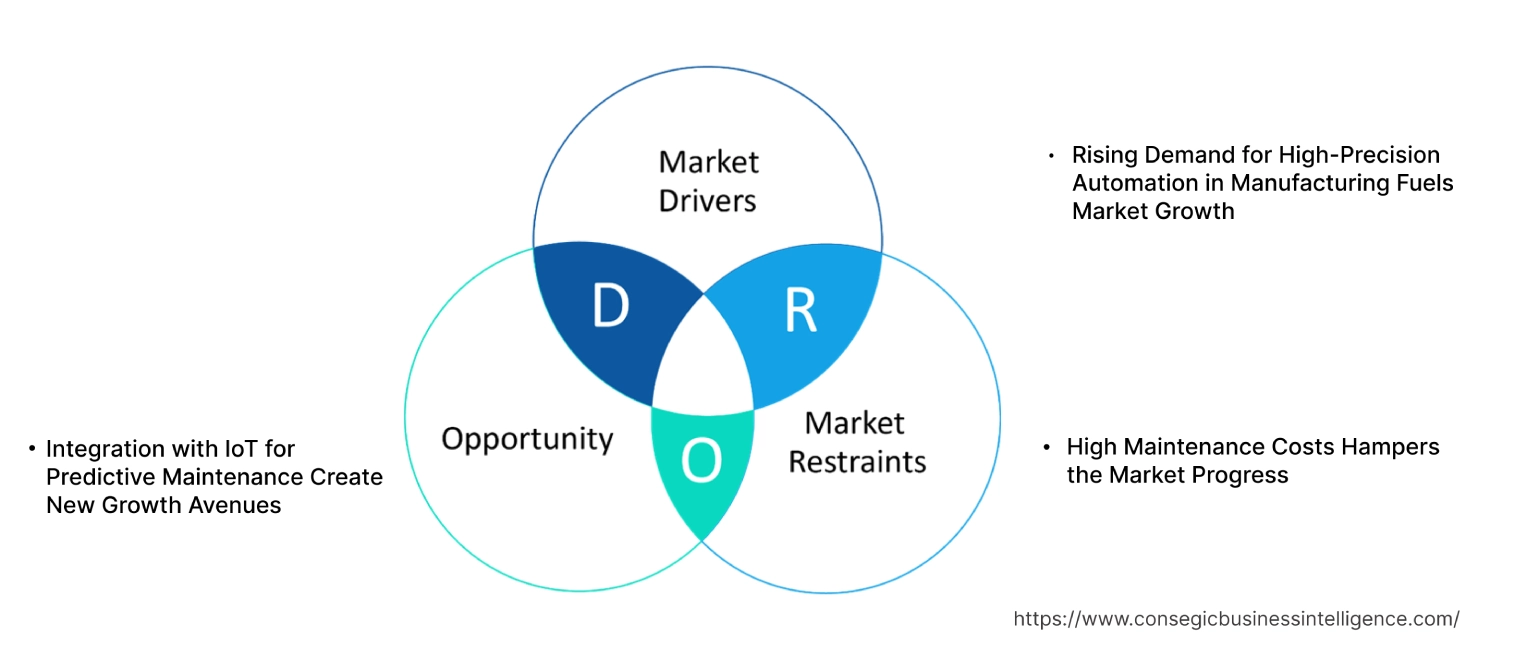

Linear Motion System Market Dynamics - (DRO) :

Key Drivers:

Rising Demand for High-Precision Automation in Manufacturing Fuels Market Growth

The increasing adoption of high-precision automation in manufacturing is a significant driver for advanced motion technologies. Industries such as automotive, electronics, aerospace, and pharmaceuticals require highly accurate systems to perform tasks like assembly, inspection, packaging, and material handling. These systems enable precise movements, reduce errors, minimize waste, and ensure consistent product quality, which is critical in sectors with stringent standards and complex production processes.

The need for automation is further fueled by the rise of Industry 4.0 and smart factory initiatives, where interconnected and automated systems play a pivotal role in enhancing efficiency and productivity. High-precision motion solutions also support faster production cycles and flexibility in handling customized or intricate designs, making them indispensable for modern manufacturing. As per the market trends analysis, manufacturers are increasingly investing in precision technologies to optimize workflows, reduce operational costs, and maintain a competitive edge, driving linear motion system market growth.

Key Restraints :

High Maintenance Costs Hampers the Market Progress

Linear motion systems rely on precision components such as actuators, ball screws, and guide rails, and require regular upkeep to ensure consistent performance and accuracy. Maintenance often involves detailed inspections, lubrication, and component replacement, which is both time-intensive and expensive. Additionally, advanced systems equipped with smart technologies and sensors demand specialized expertise for troubleshooting and repairs, further increasing maintenance expenses. Frequent wear and tear of critical components, especially in applications involving heavy loads or continuous operation, adds to the overall cost burden.

In industries with high operational demands, downtime for maintenance not only incurs direct costs but also disrupts productivity, leading to financial losses. For small and medium-sized enterprises (SMEs), these recurring expenses become a significant constraint, limiting the adoption of advanced motion systems. Moreover, the use of high-quality materials and sophisticated designs, while enhancing durability and performance, contributes to higher costs for replacement parts and servicing. These factors collectively highlight the barriers of high maintenance costs, which restrain linear motion system market demand, particularly among cost-sensitive end-users.

Future Opportunities :

Integration with IoT for Predictive Maintenance Create New Growth Avenues

The integration of IoT-enabled technologies is revolutionizing motion systems by enabling predictive maintenance and real-time monitoring, creating substantial opportunities in industrial automation. IoT-connected systems continuously collect and analyze performance data from components such as actuators, guides, and drives, allowing operators to monitor key metrics like speed, vibration, and temperature. By leveraging advanced analytics and machine learning, these systems identify potential issues before they escalate into failures, ensuring proactive maintenance and reducing unplanned downtime.

Predictive maintenance supported by IoT not only extends the lifespan of equipment but also lowers maintenance costs by replacing components only when necessary. This approach enhances operational efficiency and ensures seamless workflows, which is especially critical in high-demand industries like manufacturing, logistics, and automotive. Real-time insights provided by IoT also enable operators to optimize system performance, improve energy efficiency, and make data-driven decisions for process improvements. As per the market trends, the growing adoption of smart manufacturing, and Industry 4.0 initiatives, IoT-driven motion systems are becoming integral to achieving higher productivity, reliability, and sustainability, creating significant linear motion system market opportunities.

Linear Motion System Market Segmental Analysis :

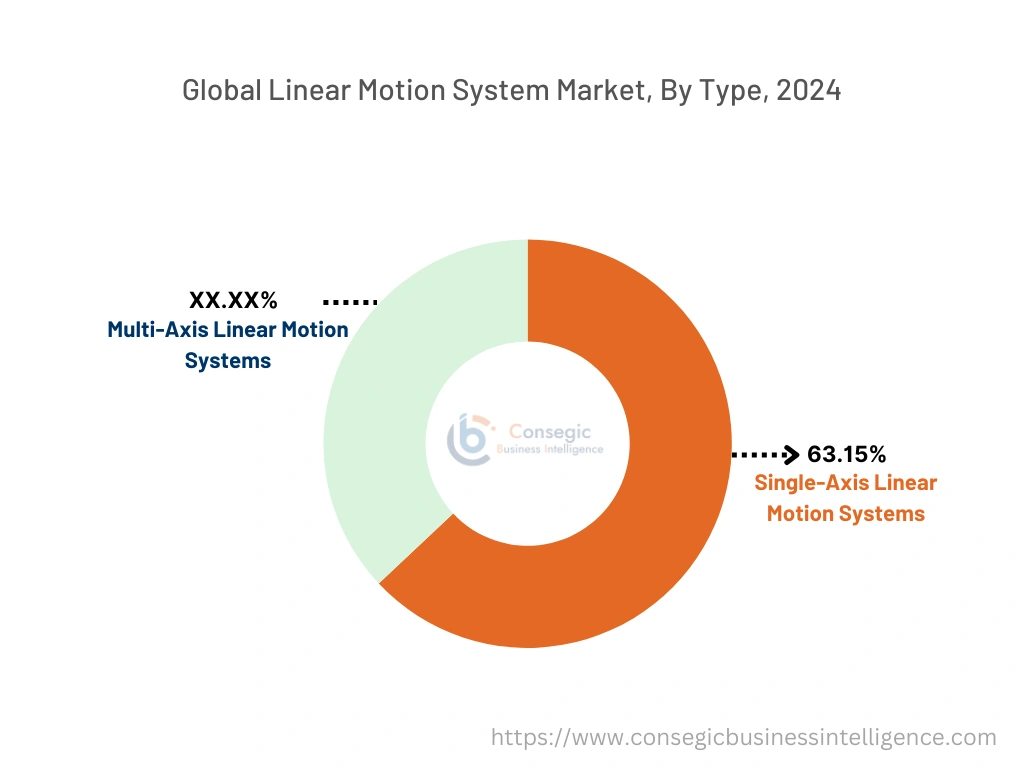

By Type:

Based on type, the market is segmented into Single-Axis Linear Motion Systems and Multi-Axis Linear Motion Systems.

The Single-Axis Linear Motion System segment accounted for the largest revenue of 63.15% of the total linear motion system market share in 2024.

- Single-axis systems are widely adopted in applications requiring controlled linear movement along one direction, such as material cutting, assembly lines, and simple packaging systems.

- These systems are cost-effective and easy to install, making them an attractive option for small-scale manufacturing units and workshops.

- The integration of advanced automation technologies, such as IoT-enabled controllers, is enhancing the operational efficiency of single-axis systems.

- As per segmental trends analysis, the segment’s dominance is supported by its high suitability for repetitive, single-direction tasks in industries like packaging and automotive manufacturing, driving linear motion system market expansion.

The Multi-Axis Linear Motion System segment is expected to register the fastest CAGR during the forecast period.

- Multi-axis systems are crucial for complex operations requiring movement along multiple axes, such as robotics, CNC machining, and 3D printing.

- These systems are extensively used in the electronics and semiconductor industries for intricate tasks such as wafer handling and precision assembly.

- The adoption of multi-axis systems is driven by the increasing requirement for advanced manufacturing techniques that require high precision and flexibility.

- As per linear motion system market analysis, continuous innovations in multi-axis designs, including modular configurations, are expanding their applicability across diverse industrial sectors.

By Component:

Based on components, the market is segmented into Actuators, Ball Screws, Linear Guides, Controllers, Motors, and Bearings.

The Actuators segment held the largest revenue of the total linear motion system market share in 2024.

- Actuators serve as the core component of motion systems, converting energy into controlled mechanical motion across various industrial applications.

- Electric actuators are gaining prominence due to their energy efficiency, precision, and ease of integration with automated systems.

- The increasing use of actuators in robotics, material handling equipment, and machine tools is a major driver for this segment.

- As per linear motion system market trends, the dominance of this segment is attributed to its critical role in ensuring accurate and reliable motion control in manufacturing processes.

The Controllers segment is expected to register the fastest CAGR during the forecast period.

- Controllers enable precise monitoring and control of motion systems, playing a pivotal role in enhancing efficiency and reducing operational errors.

- The integration of AI-powered and IoT-enabled controllers is enabling real-time monitoring and predictive maintenance, improving overall system performance.

- These components are highly sought after in industries like healthcare and aerospace, where precision and safety are paramount.

- The analysis of segmental trends shows that the controller segment’s rapid extension reflects the growing focus on automation and digitization across industrial verticals, driving linear motion system market growth.

By Application:

Based on application, the market is segmented into Packaging, Machine Tools, Palletizing, Robotics, Material Handling Equipment, and Others.

The Material Handling Equipment segment accounted for the largest revenue share in 2024.

- Material handling applications require robust and precise motion systems to ensure efficient movement and placement of heavy loads across industrial settings.

- These systems are extensively used in warehouses, logistics centers, and manufacturing plants for tasks such as sorting, stacking, and transferring materials.

- The increasing adoption of automation in logistics and warehousing operations is driving the need for advanced material handling solutions.

- The segment’s leadership is further supported by its critical role in enhancing operational efficiency and reducing labor-intensive tasks in industrial environments, fueling linear motion system market demand.

The Robotics segment is expected to register the fastest CAGR during the forecast period.

- Robotics applications rely on motion systems to enable precise movement and positioning, making them indispensable for industries like electronics and automotive.

- The rising adoption of collaborative robots (cobots) in manufacturing processes is fueling the need for advanced motion systems.

- The integration of smart sensors and AI in robotic systems is enhancing their adaptability and functionality, driving their adoption in complex industrial applications.

- As per market trends analysis, the segment’s proliferation is attributed to the increasing use of robotics in high-precision and repetitive tasks across diverse industries, driving linear motion system market expansion.

By Industry Vertical:

Based on industry vertical, the market is segmented into Automotive, Electronics & Semiconductor, Food & Beverage, Healthcare, Aerospace & Defense, and Others.

The Automotive segment held the largest revenue share in 2024.

- Automotive manufacturers use motion systems extensively in assembly lines, machining, and quality inspection processes to ensure high precision and efficiency.

- These systems enable automated welding, cutting, and assembly operations, reducing production times and enhancing product quality.

- The increasing adoption of electric vehicles is driving the need for advanced manufacturing techniques, further boosting the use of motion systems in automotive plants.

- The segment’s dominance is supported by its critical role in meeting the high-volume and high-precision requirements of the automotive industry, creating linear motion system market opportunities.

The Electronics & Semiconductor segment is expected to register the fastest CAGR during the forecast period.

- The electronics industry requires high-precision motion systems for tasks such as wafer handling, circuit assembly, and inspection processes.

- Semiconductor manufacturers use these systems to achieve the nanometer-level accuracy required for producing advanced chips and components.

- The increasing requirement for consumer electronics, IoT devices, and wearable technology is driving investments in advanced manufacturing facilities, fueling the adoption of motion systems.

- As per linear motion system market trends, the segment’s rapid progress reflects its pivotal role in ensuring accuracy and efficiency in electronics production processes.

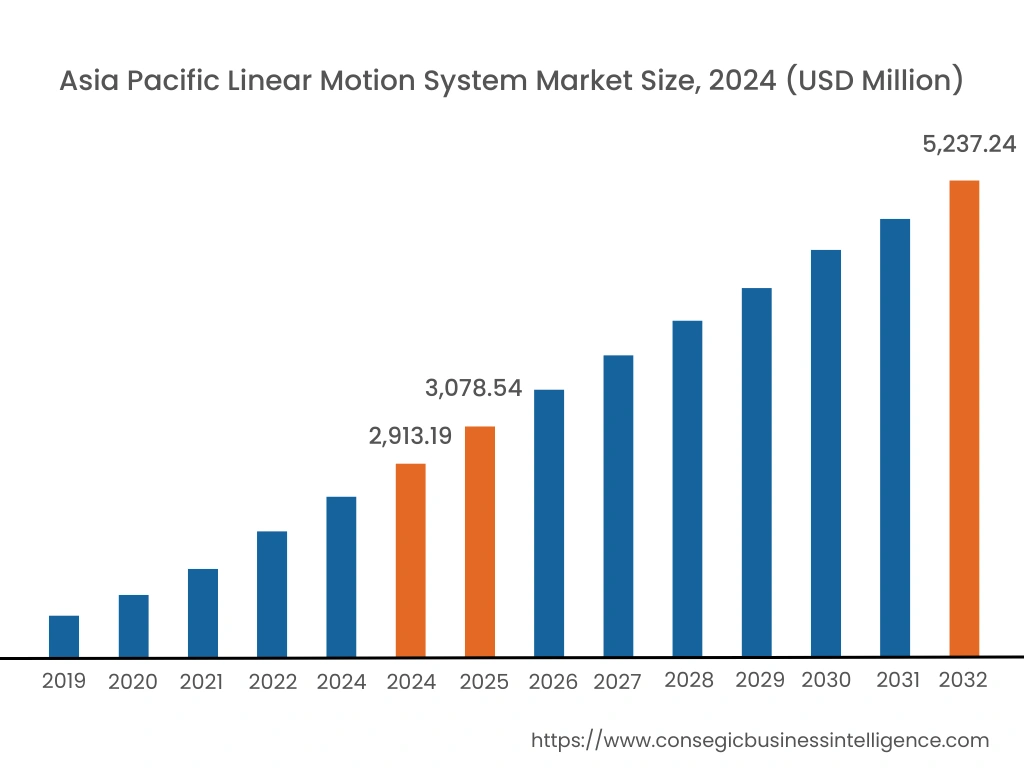

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

Asia Pacific region was valued at USD 2,913.19 Million in 2024. Moreover, it is projected to grow by USD 3,078.54 Million in 2025 and reach over USD 5,237.24 Million by 2032. Out of these, China accounted for the largest share of 41.5% in 2024. Asia-Pacific is witnessing the fastest growth in the market, driven by rapid industrialization and urbanization in countries like China, India, and Japan. The region has become a global hub for manufacturing, with a strong emphasis on automation to enhance production efficiency. As per linear motion system market analysis, the increasing investments in industrial activities, technological advancements, and government investments in industrial automation systems are further propelling market growth.

North America is estimated to reach over USD 5,574.35 Million by 2032 from a value of USD 3,281.16 Million in 2024 and is projected to grow by USD 3,451.01 Million in 2025. North America holds a substantial share of the linear motion system market, primarily due to the robust presence of automated industrial equipment manufacturers. The United States, in particular, leads the market with extensive use of automated assembly lines and material handling equipment installed with linear motion systems for precision operations. The availability of a skilled workforce and technology leaders providing innovative linear motion solutions have established North America's dominance.

Europe represents a significant portion of the global market, with countries like Germany, France, and the United Kingdom leading in terms of adoption and innovation. The region benefits from a well-established industrial base and a strong emphasis on automation and precision engineering. The demand for linear motion systems is increasing, driven by the need for high efficiency and accuracy in manufacturing processes.

The Middle East & Africa region shows promising potential in the market, particularly in countries like Saudi Arabia, the United Arab Emirates, and South Africa. Increasing investments in infrastructure projects and the expansion of the manufacturing sector are driving the need for linear motion systems. The focus on diversifying economies and reducing dependence on oil revenues has led to progress in the industrial sector.

Latin America is an emerging market for linear motion systems, with Brazil and Mexico being the primary growth drivers. The rising adoption of automation in manufacturing, improving industrial infrastructure, and increasing focus on enhancing production efficiency contribute to the market’s enlargement. As per market trends, government initiatives aimed at modernizing industrial operations and promoting technological adoption are supporting market development.

Top Key Players & Market Share Insights:

The Linear Motion System market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global Linear Motion System market. Key players in the Linear Motion System industry include –

- Bosch Rexroth AG (Germany)

- Schneeberger Group (Switzerland)

- Ewellix AB (Sweden)

- Hiwin Corporation (Taiwan)

- Thomson Industries Inc. (USA)

- Nippon Bearing Co. Ltd (Japan)

- NSK Ltd (Japan)

- HepcoMotion Inc. (UK)

- THK Co. Ltd (Japan)

- The Timken Company (USA)

Recent Industry Developments :

Product Launches:

- In April 2024, Thomson unveiled miniature metric ball screwsdesigned to deliver high load capacity in small footprints. Ideal for space-constrained applications, these ball screws combine precision engineering with high efficiency, making them suitable for medical devices, lab automation, and semiconductor production equipment. The miniature screws offer superior durability, smooth operation, and customizable configurations to meet diverse application needs, enhancing precision and performance in critical operations.

- In February 2022, Tolomatic introduced its new twin profile rail stage actuator, designed to improve accuracy and stability in XYZ motion systems. This actuator features a rigid twin rail designthat enhances precision and load handling, ideal for applications requiring tight tolerances and high-performance motion. Its advanced mechanics ensure smoother motion and greater repeatability, making it suitable for industrial automation, material handling, and robotics. By addressing the need for reliable and efficient motion control, Tolomatic's innovation caters to industries needing precision and durability.

Acquisitions & Mergers:

- In August 2023, Emerson entered into an agreement to acquire Afag Holding AG, a Swiss-based leader in electric linear motion, feeding, and handling automation solutions. This acquisition bolsters Emerson’s factory automation offerings by integrating Afag's innovative electric motion technologies with Emerson’s pneumatic motion solutions. Serving industries such as battery manufacturing, automotive, medical, and electronics, Afag’s portfolio addresses a $9 Million market segment, expected to grow mid-single digits annually. The move aligns with Emerson’s strategy for long-term organic growth in automation and digital transformation.

Linear Motion System Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 17,199.49 Million |

| CAGR (2025-2032) | 7.2% |

| By Type |

|

| By Component |

|

| By Application |

|

| By Industry Vertical |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Linear Motion System Market? +

Linear Motion System Market size is estimated to reach over USD 17,199.49 Million by 2032 from a value of USD 9,891.69 Million in 2024 and is projected to grow by USD 10,423.68 Million in 2025, growing at a CAGR of 7.20% from 2025 to 2032.

What specific segmentation details are covered in the Linear Motion System Market report? +

The Linear Motion System Market report includes segmentation details for type (Single-Axis Linear Motion System, Multi-Axis Linear Motion System), component (Actuators, Ball Screws, Linear Guides, Controllers, Motors, Bearings), Application (Packaging, Machine Tools, Palletizing, Robotics, Material Handling Equipment, Others), industry vertical (Automotive, Electronics & Semiconductor, Food & Beverage, Healthcare, Aerospace & Defense, Others), and region (Asia-Pacific, Europe, North America, Latin America, Middle East & Africa).

Which is the fastest-growing segment in the Linear Motion System Market? +

The Multi-Axis Linear Motion System segment is expected to register the fastest CAGR during the forecast period due to the increasing adoption of advanced manufacturing techniques and the need for high precision and flexibility in complex applications.

Who are the major players in the Linear Motion System Market? +

The major players in the Linear Motion System Market include Bosch Rexroth AG (Germany), Schneeberger Group (Switzerland), Ewellix AB (Sweden), Hiwin Corporation (Taiwan), Thomson Industries Inc. (USA), Nippon Bearing Co. Ltd (Japan), NSK Ltd (Japan), HepcoMotion Inc. (UK), THK Co. Ltd (Japan), and The Timken Company (USA).