- Summary

- Table Of Content

- Methodology

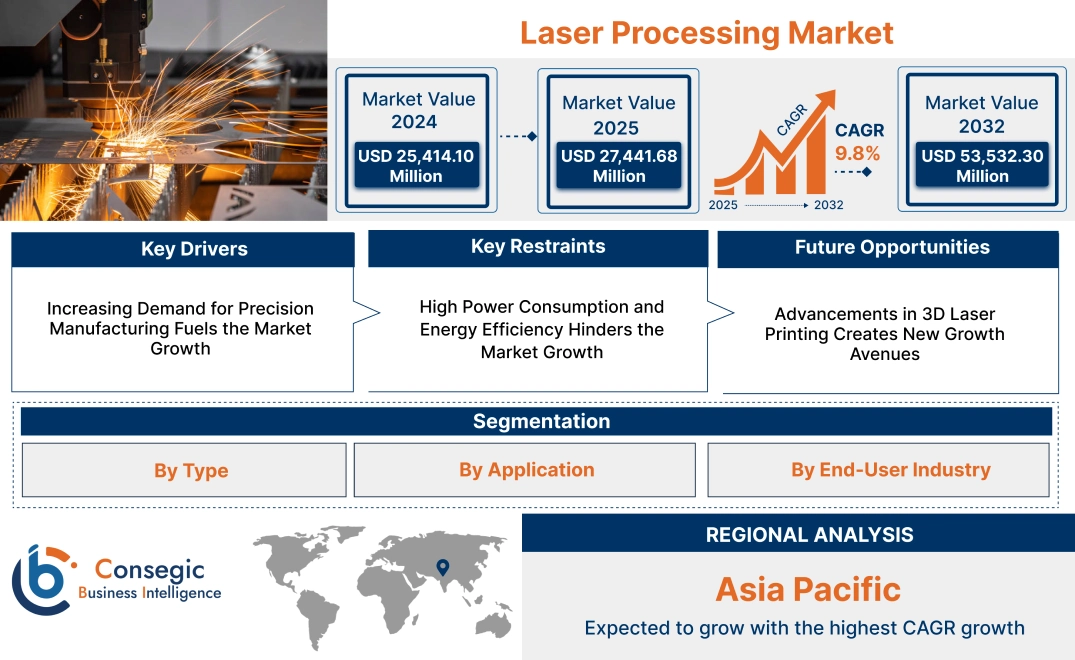

Laser Processing Market Size:

Laser Processing Market size is estimated to reach over USD 53,532.30 Million by 2032 from a value of USD 25,414.10 Million in 2024 and is projected to grow by USD 27,441.68 Million in 2025, growing at a CAGR of 9.8% from 2025 to 2032.

Laser Processing Market Scope & Overview:

Laser processing refers to the use of laser technology for material processing applications such as cutting, welding, marking, engraving, and drilling. This technique utilizes the precision and energy concentration of laser beams to perform highly accurate and efficient operations on a variety of materials, including metals, plastics, ceramics, and glass. It is widely used across industries such as automotive, electronics, aerospace, and healthcare for its reliability and versatility.

These systems are equipped with advanced laser sources, control software, and motion systems to deliver precise and repeatable results. They are designed to handle complex geometries and intricate designs, ensuring high-quality output with minimal material waste. Laser processing is suitable for applications requiring fine detail and high-speed operations, making it ideal for both large-scale manufacturing and specialized production tasks.

The market’s end-users include manufacturers in sectors such as industrial equipment, medical devices, and consumer electronics, where precision and efficiency are critical. It plays a crucial role in modern manufacturing, enabling advanced production techniques and supporting innovative design capabilities.

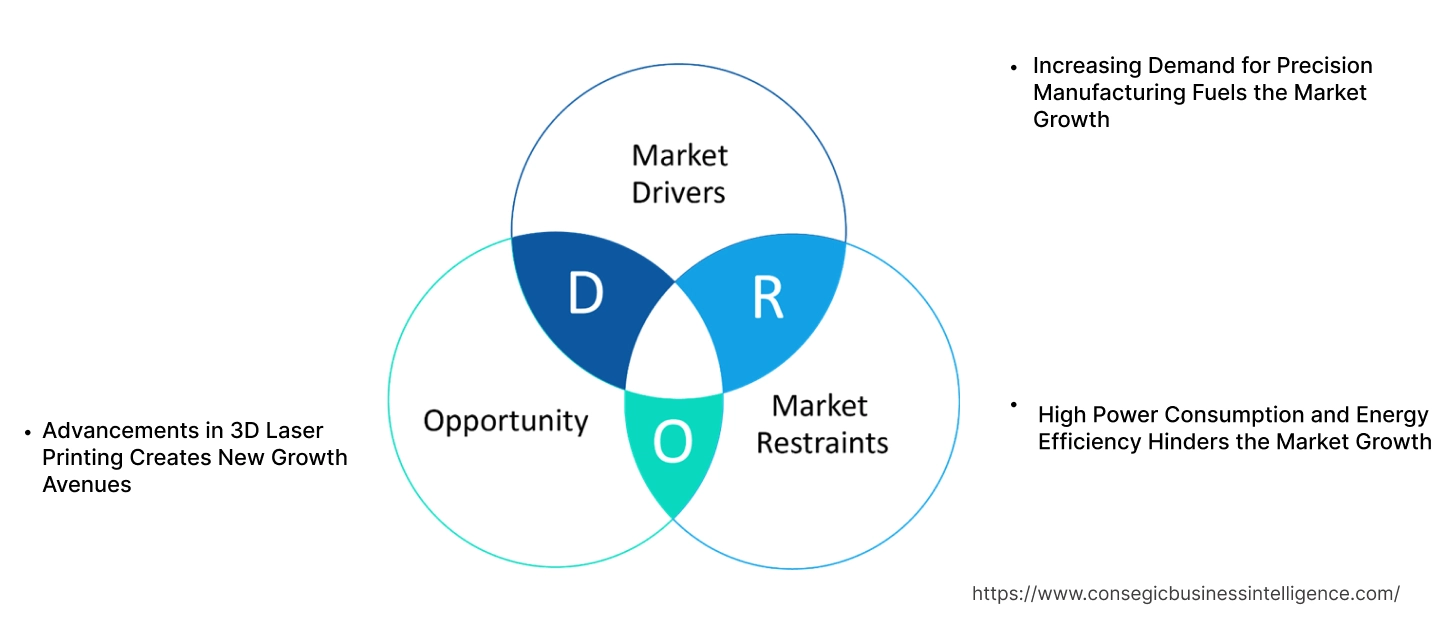

Key Drivers:

Increasing Demand for Precision Manufacturing Fuels the Market Growth

The rising demand for high-precision manufacturing across industries such as automotive, aerospace, and electronics is a key driver for the adoption of laser-based processing technologies. It offers unmatched accuracy, enabling the production of complex components with intricate designs and tight tolerances that traditional manufacturing methods may struggle to achieve. In automotive and aerospace sectors, where precision is critical for performance, safety, and efficiency, lasers provide an ideal solution for cutting, welding, engraving, and marking components. Similarly, in electronics, it ensures the production of miniaturized, high-precision parts required for advanced devices. As industries continue to demand increasingly sophisticated and high-quality products, laser processing technology is becoming essential, providing manufacturers with a reliable method to achieve the precision and consistency needed in modern production environments. This growth in need for precision drives the market for laser-based processing technologies, enhancing product quality and manufacturing efficiency. Therefore, the aforementioned factors are fueling the laser processing market demand.

Key Restraints:

High Power Consumption and Energy Efficiency Hinders the Market Growth

Power consumption and energy efficiency are significant constraints for laser processing systems, especially high-powered lasers used in industrial applications. These systems often require large amounts of energy to operate, which can result in high operational costs. In industries where energy efficiency is a priority or where electricity costs are high, the energy demands of laser systems may make them less attractive compared to other, more energy-efficient manufacturing methods. For example, traditional mechanical or chemical processes may use less energy, providing a more cost-effective solution for certain applications. Additionally, the high power requirements of laser systems can strain energy resources, especially in regions with limited or expensive power supplies. As businesses seek to reduce costs and improve sustainability, the significant energy consumption of laser systems deter adoption, particularly in industries where energy efficiency and cost savings are critical for long-term competitiveness. In conclusion, the above mentioned factors limit the laser processing market growth.

Future Opportunities :

Advancements in 3D Laser Printing Creates New Growth Avenues

Advancements in 3D laser printing have created new opportunities for laser processing, particularly in additive manufacturing. This technology allows for the creation of complex structures layer by layer with high precision, offering design flexibility that traditional manufacturing methods cannot match. In industries such as aerospace, automotive, and medical devices, 3D laser printing enables the production of lightweight, intricate parts with complex geometries that improve performance and functionality. In aerospace, for instance, it allows for the creation of optimized components that reduce weight while maintaining strength. Similarly, in the medical field, it enables the development of custom implants and prosthetics tailored to individual patients. The ability to produce these advanced structures with lasers drives market demand, as industries seek more efficient, cost-effective, and innovative ways to manufacture high-performance products. These advancements are expected to accelerate the adoption of this technology in various high-tech industries, creating substantial laser processing market opportunities.

Laser Processing Market Segmental Analysis :

By Type:

Based on type, the market is segmented into gas lasers, solid-state lasers, fiber lasers, and others.

The Fiber lasers segment accounted for the largest revenue of the total laser processing market share in 2024.

- Fiber lasers are widely used across industries such as automotive, electronics, and aerospace due to their high precision, energy efficiency, and ability to handle various materials like metals and polymers.

- These lasers are ideal for micro-fabrication processes, including intricate cutting, engraving, and marking, supporting trends toward miniaturization in the electronics industry.

- The compact and robust design of fiber lasers ensures lower maintenance costs, making them suitable for high-throughput industrial applications.

- Advancements in beam quality and power scalability enable fiber lasers to handle complex manufacturing processes with enhanced accuracy.

- Therefore, their role in sustainable manufacturing, particularly in reducing energy consumption, further reinforces their dominance, fueling the laser processing market expansion.

The Gas lasers segment is anticipated to register the fastest CAGR during the forecast period.

- Gas lasers, especially CO2 lasers, are essential for processing non-metallic materials, such as plastics, glass, and organic compounds, making them integral in packaging and textile applications.

- These lasers provide deep penetration and clean cuts, ensuring consistent quality in non-metal engraving and marking processes.

- Their cost-effectiveness and simplicity of operation keep them relevant in industries where moderate precision is required.

- Therefore, as per the laser processing market analysis, gas lasers are particularly favored in medical applications, such as laser surgery and diagnostics, due to their precision in cutting biological tissues.

By Application:

Based on application, the market is segmented into marking, cutting, welding, drilling, and others.

The cutting segment accounted for the largest revenue of the total laser processing market share in 2024.

- Laser cutting is extensively adopted in automotive and aerospace manufacturing for its precision in processing metals and alloys, essential for creating complex components.

- In the electronics sector, laser cutting is critical for delicate operations like shaping semiconductors and printed circuit boards, where accuracy is paramount.

- This process minimizes material waste, making it an environmentally favorable choice for sustainable manufacturing practices.

- The integration of robotics and automation enhances laser cutting systems, enabling high-volume production with consistent quality.

- Its ability to process a wide range of materials, including lightweight composites, metals, and plastics, positions laser cutting as a core technology in industrial production, contributing to the laser processing market expansion.

The welding segment is anticipated to register the fastest CAGR during the forecast period.

- Laser welding is widely used in automotive and aerospace industries for creating strong, defect-free joints, particularly in lightweight materials like aluminum and composites.

- The rise of electric vehicles has amplified the use of laser welding in battery production, where precision and thermal control are critical for reliability.

- Hybrid welding technologies, combining laser and arc welding, enable faster processes and higher-quality results in industrial applications.

- Its ability to weld dissimilar materials with minimal distortion makes laser welding an essential process for complex assemblies.

- Therefore, as per the laser processing market trends, laser welding is increasingly favored in medical device manufacturing, ensuring durability and precision in critical applications.

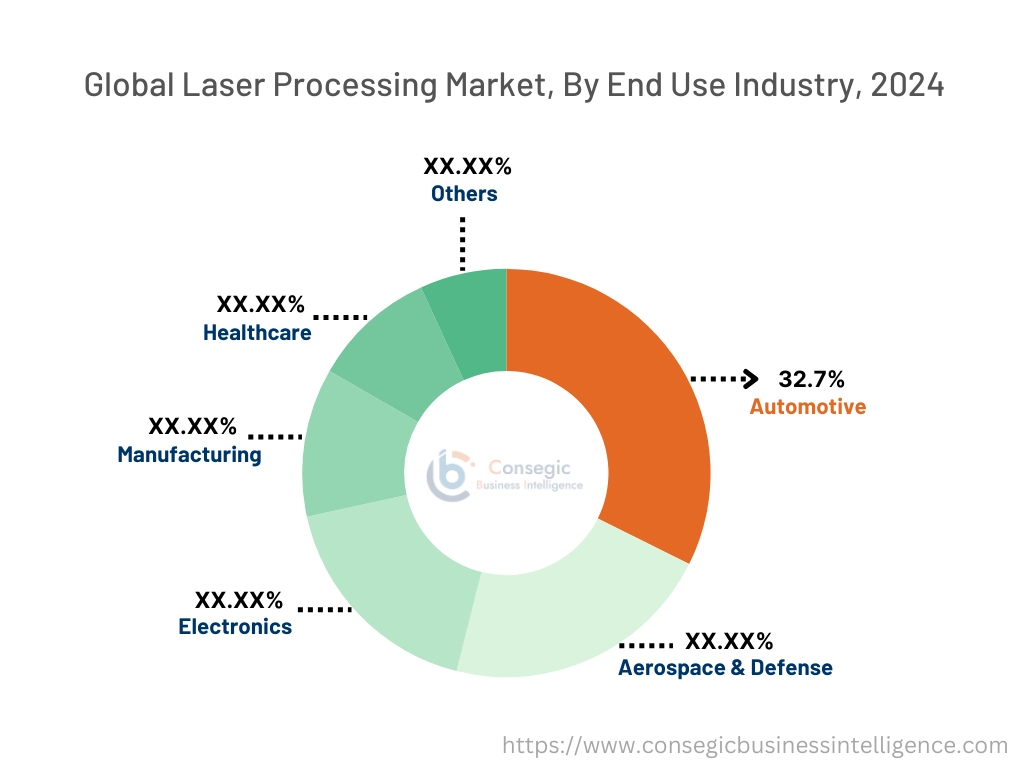

By End-User Industry:

Based on end-user industry, the market is segmented into aerospace & defense, automotive, electronics, manufacturing, healthcare, and others.

The automotive segment accounted for the largest revenue of 32.7% share in 2024.

- Laser processing is critical in automotive manufacturing for tasks like cutting, welding, and marking, ensuring precision and efficiency in vehicle assembly.

- The adoption of electric vehicles has increased the use of laser systems for battery welding, lightweight material fabrication, and structural assembly.

- Automated laser systems reduce production time and enhance consistency, meeting the automotive industry's high-performance and quality standards.

- In manufacturing lightweight vehicle components, it supports fuel efficiency and performance enhancements.

- Thus, as per the laser processing market analysis, innovations in multi-functional laser systems allow manufacturers to seamlessly switch between cutting, welding, and marking operations, streamlining production processes.

The electronics segment is anticipated to register the fastest CAGR during the forecast period.

- Laser processing is essential in electronics manufacturing for applications like micro-drilling, cutting, and marking of semiconductors, PCBs, and MEMS.

- As trends toward miniaturization and advanced technologies like IoT and 5G evolve, laser systems play a crucial role in delivering high precision and reliability in component production.

- Automated systems integrated with monitoring technologies improve yield rates, ensuring consistency in mass production.

- The ability to handle delicate materials and achieve intricate designs makes it indispensable in electronics manufacturing.

- As per the laser processing market trends, increasing investments in advanced electronics manufacturing facilities, especially in Asia-Pacific, drive the adoption of these technologies.

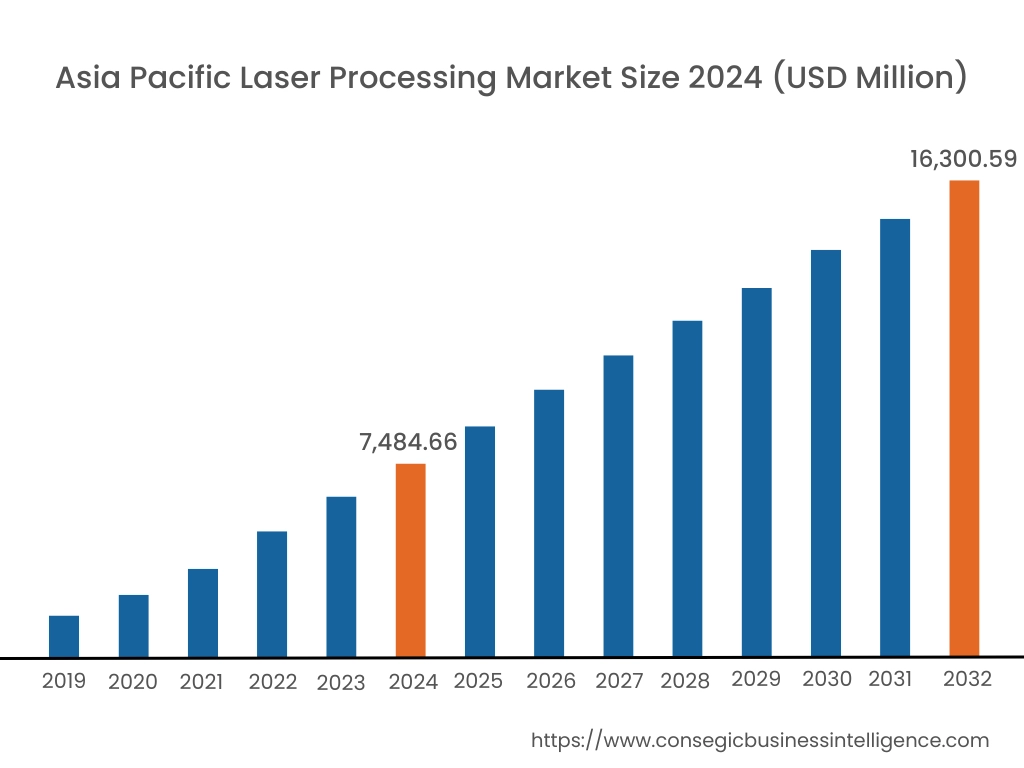

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

Asia Pacific region was valued at USD 7,484.66 Million in 2024. Moreover, it is projected to grow by USD 8,104.65 Million in 2025 and reach over USD 16,300.59 Million by 2032. Out of this, China accounted for the maximum revenue share of 32.6%. The Asia-Pacific region dominates the laser processing market with significant share, attributed to rapid industrialization and urbanization leading to increased energy consumption. A prominent trend is its adoption in consumer electronics, automotive, telecom, and industrial applications. Analysis indicates that the region's focus on energy efficiency and the growth in development of renewable energy infrastructure are contributing to laser processing market growth.

North America is estimated to reach over USD 17,349.82 Million by 2032 from a value of USD 8,430.07 Million in 2024 and is projected to grow by USD 9,085.23 Million in 2025. This region maintains a substantial share in the laser processing sector, propelled by the rapid expansion of renewable energy sources such as solar and wind power. The integration of these renewables necessitates efficient power conversion and management systems, roles fulfilled by laser processing technologies. A notable trend is the increasing adoption of electric vehicles (EVs), which require sophisticated techniques for energy use and battery management. Analysis indicates that investments in smart grid infrastructure and energy storage solutions further bolster the laser processing market demand in North America.

European countries are pivotal in this market, driven by a strong commitment to sustainability and renewable energy integration. The region emphasizes the development of high-efficiency laser processing devices to support green energy initiatives. A significant trend is the rise of smart grids and the increasing adoption of electric vehicles, amplifying the need for advanced techniques. Analysis suggests that substantial investments in research and development foster innovation, with collaborations between universities, research institutes, and industry players driving technological advancements.

In the Middle East and Africa, the laser processing market is influenced by the adoption of advanced electronic and semiconductor technologies across industries such as defense, telecommunications, and industrial automation. The focus is on enhancing energy efficiency and reliability through the implementation of sophisticated laser processing systems. Analysis suggests that investments in infrastructure development and the push for sustainable energy solutions are pivotal in shaping the market landscape in these regions.

Latin American countries are increasingly recognizing the importance of laser processing in improving energy efficiency and supporting industrial applications. A notable trend is its integration in renewable energy projects and the modernization of power infrastructure. Analysis indicates that economic development and the pursuit of sustainable energy solutions are key factors influencing the laser processing market opportunities in this region.

Top Key Players and Market Share Insights:

The Laser Processing market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global Laser Processing market. Key players in the Laser Processing industry include -

- Coherent Corp. (USA)

- TRUMPF GmbH + Co. KG (Germany)

- MKS Instruments, Inc. (USA)

- NKT Photonics A/S (Denmark)

- Trotec Laser GmbH (Austria)

- IPG Photonics Corporation (USA)

- Amada Co., Ltd. (Japan)

- Han's Laser Technology Industry Group Co., Ltd. (China)

- Jenoptik AG (Germany)

- Lumentum Holdings Inc. (USA)

Recent Industry Developments :

Acquisitions & Mergers:

- In October 2024, Machine Solutions Inc. acquired Alpine Laser LLC, a Minneapolis-based provider of laser processing solutions for medical devices. The acquisition enhances Machine Solutions’ position as a comprehensive medical device equipment provider by integrating Alpine's laser expertise. Alpine Laser's founding engineers see this partnership as an opportunity for accelerated growth and innovation. This marks Machine Solutions’ ninth acquisition since joining BW Forsyth Partners in 2012, reinforcing its commitment to expanding advanced manufacturing capabilities.

Laser Processing Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 53,532.30 Million |

| CAGR (2025-2032) | 9.8% |

| By Type |

|

| By Application |

|

| By End-User Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the size of the Laser Processing Market? +

The Laser Processing Market size is estimated to reach over USD 53,532.30 Million by 2032 from a value of USD 25,414.10 Million in 2024 and is projected to grow by USD 27,441.68 Million in 2025, growing at a CAGR of 9.8% from 2025 to 2032.

What are the key segments in the Laser Processing Market? +

The market is segmented by type (gas lasers, solid-state lasers, fiber lasers, and others), application (marking, cutting, welding, drilling, and others), and end-user industry (aerospace & defense, automotive, electronics, manufacturing, healthcare, and others).

Which segment is expected to grow the fastest in the Laser Processing Market? +

The gas lasers segment is anticipated to register the fastest CAGR during the forecast period, particularly due to their applications in medical, packaging, and non-metal material processing.

Who are the major players in the Laser Processing Market? +

Key players in the Laser Processing market include Coherent Corp. (USA), TRUMPF GmbH + Co. KG (Germany), IPG Photonics Corporation (USA), Amada Co., Ltd. (Japan), Han's Laser Technology Industry Group Co., Ltd. (China), Jenoptik AG (Germany), Lumentum Holdings Inc. (USA), MKS Instruments, Inc. (USA), NKT Photonics A/S (Denmark), Trotec Laser GmbH (Austria).

What are the key trends in the laser processing Market? +

The laser processing market is being shaped by several key trends including increasing utilization in the automotive and consumer electronics industry and increasing need for high-quality cuts, welds, engraves and others, as well as a trend toward rising adoption in the healthcare sector for surgical equipment manufacturing, are the key trends driving the market.