- Summary

- Table Of Content

- Methodology

Large Circular Knitting Machine Market Introduction :

Large Circular Knitting Machine Market size is estimated to reach over USD 1,923.21 Million by 2030 from a value of USD 1,247.56 Million in 2022, growing at a CAGR of 5.7% from 2023 to 2030.

Large Circular Knitting Machine Market Definition & Overview :

A large circular knitting machine is a mechanical device deployed in the textile sector to produce knitted fabrics on a large scale. The device consists of a circular frame with numerous needles and hooks arranged in a circular pattern. Additionally, these machines are capable of high-speed production and are utilized for manufacturing various knitted products including clothing, accessories, and home textiles. Furthermore, knitting machines offer increased efficiency and productivity compared to hand knitting, thus becoming essential in modern textile manufacturing processes.

Large Circular Knitting Machine Market Insights

Key Drivers :

Increasing demand for knitted fabrics to allow better breathability is driving the growth of the market

The ability of knit fabrics to offer great breathability and soft texture in hot and humid environmental conditions serves as the major factor driving the growth of the large circular knitting machine market. Additionally, knitted fabrics also offer high waterproofing, allowing air and moisture to pass through the breathable fabric. Moreover, the demand for knitted fabrics is rising due to the additional desirable properties offered by the fabric including flexibility, stretchability, and comfort. Furthermore, these machines provide high production efficiency, enabling manufacturers to meet the increasing demand by producing knitted fabrics in bulk quantities within shorter timeframes. The machines produce seamless tubes of fabric continuously, reducing the need for additional stitching and improving production speed. Consequently, the increasing demand of knitted fabrics is contributing significantly in accelerating the global large circular knitting machine market. For instance, in 2021, according to Texprocil, The Cotton Textiles Export Promotion Council of India, the total knit fabric imported worldwide in 2020 was USD 23 Billion. Vietnam was the largest importer of knitted fabric in 2020 accounted for USD 6.1 Billion, moreover China was the largest exporter of knitted fabric accounted for USD 16.2 billion, during the same year.

Expanding textile industry has a significant impact on driving the growth of the large circular knitting machine market

The expansion in the textile industry for the production of knitted fabrics to meet the growing requirement of various sectors including fashion, sportswear, and home textiles is driving the market. They offer the ability to produce fabrics in large volumes and at a faster pace compared to traditional hand-knitting methods. Additionally, these machines are designed for high-speed production, allowing textile manufacturers to enhance productivity and efficiency.

Moreover, with the emergence of automation, machines are capable of knitting multiple fabric tubes simultaneously, thus contributing significantly in fueling the market. Furthermore, the increasing investments by the government to expand the textile sector is also contributing remarkably in accelerating the deveolopment of the global large circular knitting machine market. For instance, in March 2023, the Indian Ministry of Textiles invested approximately USD 8.48 Million for developing mega integrated textile regions and apparel parks for expanding the textile sector. PM MITRA is stimulated by the 5F vision of the Prime Minister (Farm to Fibre to Factory to Fashion to Foreign) to improve the competitiveness of the Indian textiles sector, hence contributing notably in boosting the large circular knitting machine market trend.

Key Restraints :

High manufacturing cost associated with large circular knitting machine is restraining the market growth

The cost of production of these machines is high, owing to the installation of technologically advanced equipment including gauge machines that significantly increases the upfront cost. Additionally, the cost of purchasing and setting up the machines is substantial, particularly for small and medium-sized textile manufacturers. The high initial investment acts as a barrier to entry, limiting the adoption of these machine by SMEs, thus restraining the market. Consequently, the high cost compels small companies to seek alternatives including traditional knitting machines, hence impeding the global large circular knitting machine market.

Presence of alternatives including flat knitting machines is hampering the growth of the market

Flat knitting machines generate less yarn waste as compared to large circular knitting machines, hindering the market. Additionally, flat knitting process allows more efficient utilization of yarn by avoiding the creation of excess fabric. The efficient utilization of yarn results in cost savings for manufacturers and contributes to a more sustainable production process. Furthermore, flat knitting machines excel at shaping and contouring knitted fabric by allowing precise control over garment shaping including necklines, armholes, and waistlines. Flat knitting machines easily create curved angled lines in the fabric, enabling the production of tailored and well-fitted garments. In conclusion, the ability of flat knitting machines to reduce yarn waste and provide precise shape and contour control is impeding the development of the large circular knitting machine market.

Future Opportunities :

Sustainable and eco-friendly production practices create future opportunities for the growth of the market

The rising consumer requirement for sustainable and eco-friendly textiles is expected to create large circular knitting machine market opportunities for the development of the market. Machines contribute to sustainable production by optimizing resource usage, minimizing waste, and reducing energy consumption. Additionally, these machines accommodate recycled yarns and organic fibers, essential for sustainable production. The machines are adjusted to function ad trends with different types of materials, allowing manufacturers to incorporate recycled and sustainable fibers into the knitted fabrics. Consequently, integration provides opportunities to develop innovative eco-friendly textile products and expand the environmentally conscious customer base.

Large Circular Knitting Machine Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2017-2030 |

| Market Size in 2030 | USD 1,923.21 Million |

| CAGR (2023-2030) | 5.7% |

| Based on the Type | Single Jersey Circular Knitting Machine and Double Jersey Circular Knitting Machine |

| Based on the Application | Apparel Textiles, Home Textiles, Fashion Clothes, Sportswear, Automotive Seats, Technical Textiles, Medical Wear, and Others |

| Based on the Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | A.T.E. Private Limited, Fukuhara Industrial & Trading Co. Ltd., Mayer & Cie. GmbH & Co. KG, Quanzhou Baiyuan Machinery Science & Technology Co Ltd, Santec Precision, XINDA Knitting Machine Co., Ltd., CHIDE Technology Industry Co., Ltd. Machinery Co., Ltd., Santoni S.p.A., Smartex, SMIT S.r.l., Tayu Machine (Xiamen) Co., Ltd., Terrot GmbH, United Texmac Pte Ltd. |

Large Circular Knitting Machine Market Segmental Analysis :

Based on the Type :

The type segment is bifurcated into single jersey circular knitting machine and double jersey circular knitting machine. The double jersey circular knitting machine accounted for the largest market share in 2022 and is also predicted to witness the fastest CAGR share during the forecast period. The trend is attributed to the ability of double circular knitting machines to offer versatility in terms of fabric types and designs. The machines produce a wide range of knitted fabrics, including single jersey, rib, interlock, and piqué among others. The machine's double needle beds and multiple sets of needles allow for the simultaneous production of two layers of fabric, enabling the creation of reversible fabrics. Additionally, double circular knitting machines are known for high efficiency and productivity to produce fabrics at high speeds, enabling manufacturers to fulfill large orders. The double needle beds and simultaneous knitting of two layers of fabric contribute to faster production rates compared to single circular knitting machines. As per the analysis the efficiency and productivity offered by double circular knitting machines are particularly beneficial for mass production in the textile sector, thus contributing significantly in driving the market. For instance, Quanzhou Buen-Knit Machinery Co., Limited manufactured a double jersey circular knitting machine for the large-scale production of sportswear, fashion fabrics, and industrial fabrics. According to the analysis the machine runs smoothly generating low noise and has two needles of different lengths for simultaneously knitting two layers of fabric, thus contributing significantly in driving the trend of the double large circular knitting machine segment.

Based on the Application :

The application segment is classified into apparel textiles, home textiles, fashion clothes, sportswear, automotive seats, technical textiles, medical wear, and others. Apparel textiles accounted for the largest market share of 18.7% in 2022 as these machines are widely employed in the production of T-shirts and tops. The machines efficiently create seamless tubular fabrics with a smooth surface and good drape, meeting the requirements of casual and basic apparel. Additionally, according to the analysis these machines also produce fabrics with complex stitch patterns, textures, and designs, hence are suitable for the production of sweaters and cardigans. The machines create different stitch structures namely cables, ribs, jacquard patterns, and intarsia designs on textiles efficiently, thus raising the requirement and trend for apparel textiles segment.

For instance, in March 2022, according to the Indian Ministry of Textiles, the export of apparel and textiles in India from April-January 2021-22 was approximately USD 34.46 billion witnessing a rise of 49% in the same duration of period in 2020-21. Subsequently, the expanding apparel textiles sector contributes remarkably in bolstering the trend of the global circular knitting machine market.

Sportswear is expected to register the fastest (CAGR) among the mentioned applications for large circular knitting machine industry. The development is attributed to the significant increase in fitness consciousness and the adoption of active lifestyles worldwide. Consumers are becoming more aware of the importance of regular physical activity and are actively participating in sports and fitness activities. The trend has led to a surge in the requirement for sportswear that increases the need for these machines to knit the fabric. Additionally, sportswear requires specialized fabrics that offer features including moisture-wicking, breathability, stretchability, and durability. As per the analysis, large circular knitting machines enable the development of high-performance fabrics to enhance athletic performance and provide comfort during physical activities. Subsequently, the aforementioned factors are collectively responsible in boosting the large circular knitting machine market demand in the upcoming years.

Based on the Region :

The regional segment includes North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

North America accounted for the largest revenue share in the year 2022 as the region is known for technological advancements and innovation in various industries, including textiles. Based on the analysis the region has a strong focus on research and development, leading to the development of advanced large circular knitting machines. The machines incorporate cutting-edge technologies namely computerized controls, automation, and digitalization to enhance efficiency, productivity, and product quality. Additionally, the growing requirement for technical textiles in North America raises the need for specialized manufacturing processes and machinery. These machines are well-suited for producing technical textiles used in industries including automotive, healthcare, and protective applications. For instance, in October 2021, according to the North Carolina State University, North Carolina encompasses 395 textile manufacturing establishments and approximately 25,000 employees. Furthermore, North Carolina exports USD 1.4 billion in textiles worldwide, occupying approximately 20% of all U.S. textile exports.

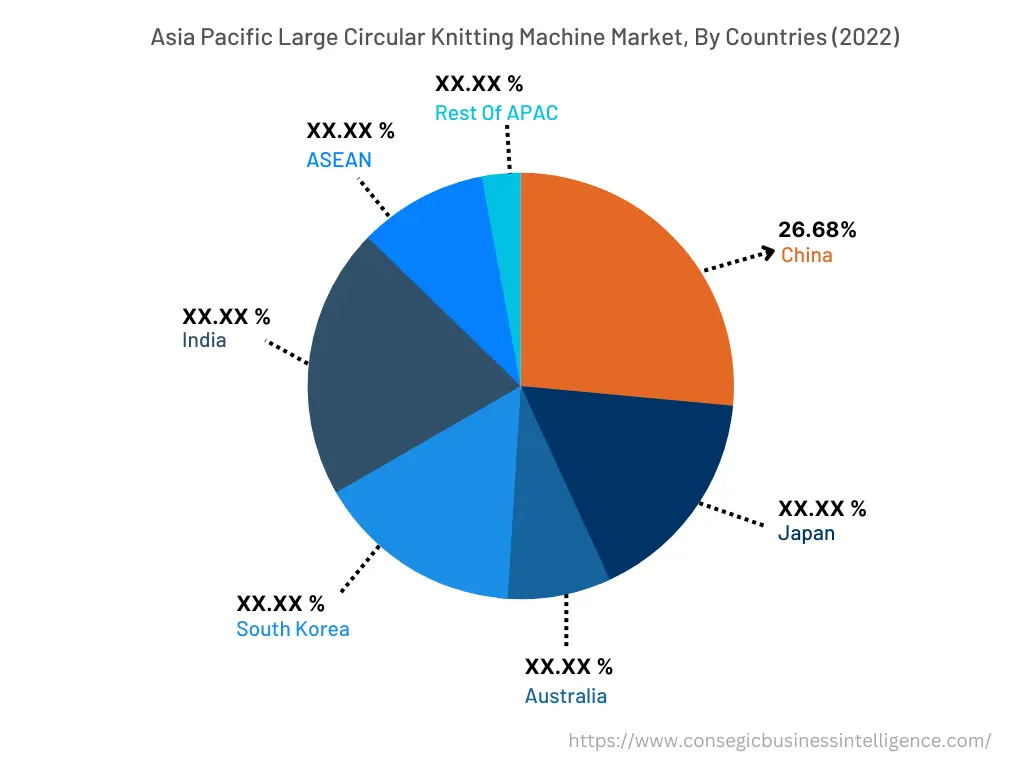

Asia Pacific accounted to USD 344.70 million in 2022 and is expected to register the fastest CAGR share of 5.8% accounting to USD 537.15 million in 2030 in the large circular knitting machine market. In addition, in the region, China accounted for the maximum global large circular knitting machine market share of 26.68% in the year 2022. As per the large circular knitting machine market analysis the high penetration rate of western culture in Asia Pacific countries increases the demand for fashion clothes including high-street fashion, luxury brands, and designer labels. Additionally, as per the analysis the growing interest of citizens in sports and fitness activities is driving the demand for sportswear, which in turn, is accelerating the market. These machines are crucial for the production of fashionable and performance-oriented textiles, thus contributing significantly in propelling the market. Moreover, many textile and apparel manufacturers are shifting their production bases to Asia-Pacific countries due to lower production costs, availability of skilled labor, and favorable government policies. The region's cost-effectiveness and production capabilities serve as an attractive destination for textile and apparel manufacturing, hence driving the large circular knitting machine market growth.

Top Key Players & Market Share Insights :

The competitive landscape of the large circular knitting machine market has been analyzed in the report, along with the detailed profiles of the major players operating in the market. Further, the surge in Research and Development (R&D), product innovation, various business strategies, and application launches have accelerated the growth of the large circular knitting machine market. Key players in the market include-

- A.T.E. Private Limited

- Fukuhara Industrial & Trading Co. Ltd.

- Terrot GmbH

- United Texmac Pte Ltd.

- XINDA Knitting Machine Co., Ltd.

- CHIDE Technology Industry Co., Ltd.

- Mayer & Cie. GmbH & Co. KG

- Quanzhou Baiyuan Machinery Science & Technology Co Ltd

- Santec Precision Machinery Co., Ltd.

- Santoni S.p.A.

- Smartex

- SMIT S.r.l.

- Tayu Machine (Xiamen) Co., Ltd.

Recent Industry Developments :

- In November 2022, Smartex invested USD 24.7 Million for the development of machine-vision software for the detection of defects in textile machines in real-time. The automated identification process is also responsible for reducing the production time, textile waste, and capital expenditure by automatically shutting down production to prevent the wastage of materials.

- In May 2021, SMIT S.r.l. and A.T.E. Private Limited partnered together for promoting SMIT's advanced rapier looms in India. The aim of the partnership is to provide momentum to the modernization of the Indian textile sector.

Key Questions Answered in the Report

What is a large circular knitting machine? +

A large circular knitting machine is defined as a mechanical device deployed in the textile industry to produce knitted fabrics on a large scale. The device consists of a circular frame with numerous needles and hooks arranged in a circular pattern.

What specific segmentation details are covered in the large circular knitting machine market report, and how is the dominating segment impacting the market growth? +

Apparel textiles accounted for the largest market share in 2022 as large circular knitting machines are widely employed in the production of T-shirts and tops. The machines efficiently create seamless tubular fabrics with a smooth surface and good drape, meeting the requirements of casual and basic apparel.

What specific segmentation details are covered in the large circular knitting machine market report, and how is the fastest segment anticipated to impact the market growth? +

Sportswear is expected to witness the fastest CAGR due to the increase in fitness consciousness and the adoption of active lifestyles worldwide. Consumers are becoming more aware of the importance of regular physical activity and are actively participating in sports and fitness activities

Which region is anticipated to witness the highest CAGR during the forecast period, 2023-2030? +

Asia Pacific is expected to witness the fastest CAGR during the forecast period owing to the high penetration rate of western culture in Asia Pacific countries that increases the demand for fashion clothes including high-street fashion, luxury brands, and designer labels. Additionally, the growing interest of citizens in sports and fitness activities is driving the demand for sportswear, which in turn, is accelerating the growth of the market.