Industrial Wireless Solution Market Introduction :

Industrial Wireless Solution Market is estimated to reach over USD 42,960.89 Million by 2030 from a value of USD 12,783.29 Million in 2022, growing at a CAGR of 16.8% from 2023 to 2030.

Industrial Wireless Solution Market Definition & Overview:

An industrial wireless solution refers to a comprehensive and reliable communication network specifically designed for industrial environment, enabling seamless data transmission and control between various devices and systems. The solution utilizes wireless technologies including Wi-Fi and WLAN, tailored to withstand harsh conditions and interference that are found in industrial settings. The solution optimizes productivity, enhances safety, and facilitates real-time monitoring and automation, empowering businesses to streamline operations and improve the efficiency of industrial processes.

Industrial Wireless Solution Market Insights :

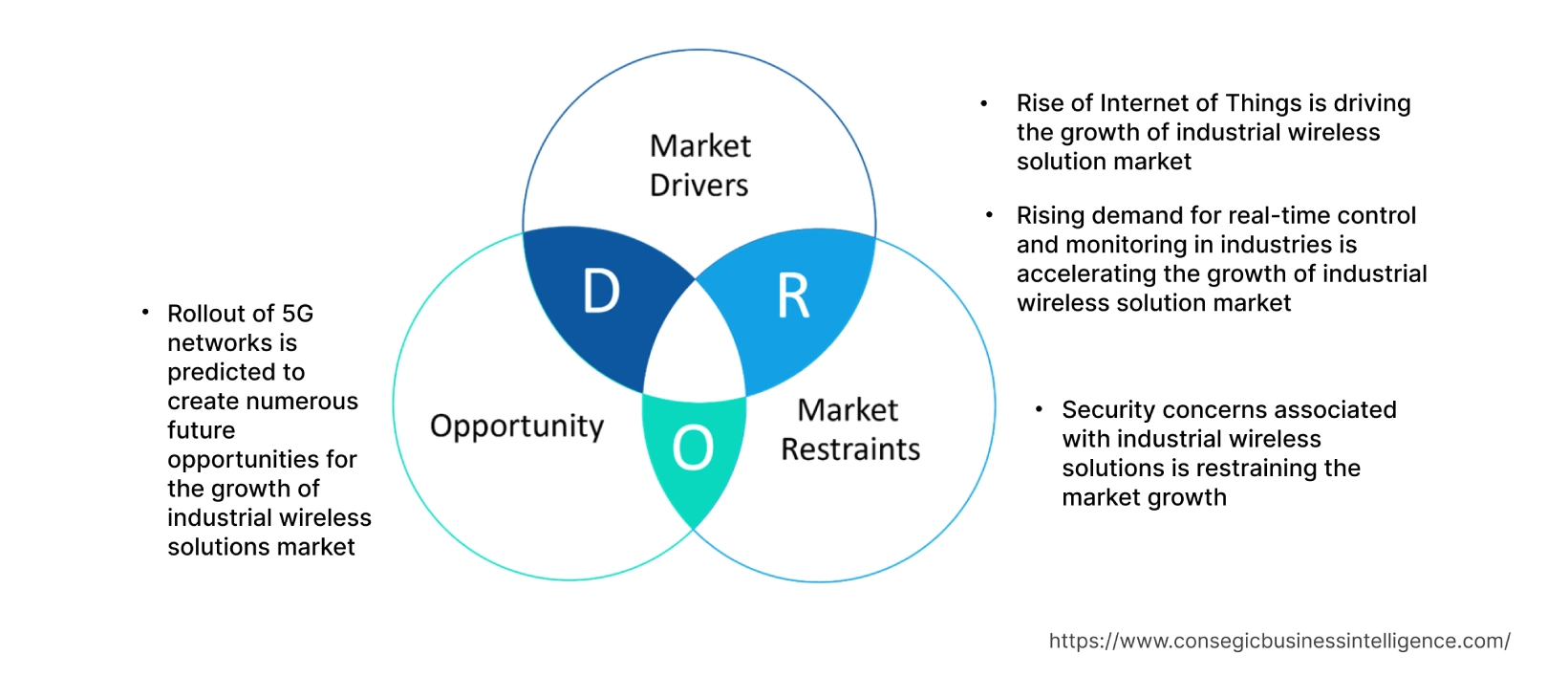

Industrial Wireless Solution Market Dynamics - (DRO) :

Key Drivers :

Rise of Internet of Things is driving the growth of industrial wireless solution market

IoT relies on interconnected smart devices and sensors to gather and exchange data. Industrial settings require robust and reliable wireless networks to handle the growing number of connected devices and also to facilitate seamless data transmission. Industrial wireless solutions provide the necessary connectivity to support the vast network of IoT devices. Additionally, industrial wireless solutions deliver highly secure data even in harsh industrial environmental conditions, further driving the adoption of industrial wireless solution. For instance, in September 2019, Emerson and Cisco collaborated together to launch industrial wireless networking solution to improve the productivity, reliability and safety in industrial settings. The advanced solution provides enhanced Wi-Fi bandwidth, withstand extreme conditions in remote locations, thus contributing significantly in driving the growth of industrial wireless solution market.

Rising demand for real-time control and monitoring in industries is accelerating the growth of industrial wireless solution market

Real-time control and monitoring require data to be transmitted and received promptly. Industrial wireless solution offers low-latency and high-speed data transmission, enabling real-time feedback, crucial for time-sensitive industrial processes. Additionally, with real-time monitoring, industrial operators quickly identify and respond to issues, leading to enhanced efficiency and productivity. Wireless solutions enable immediate access to critical data from various locations, allowing operators to make adjustments to optimize performance. Therefore, the rising demand for real-time monitoring in various industrial processes is propelling the growth of industrial wireless solution market. For instance, in April 2023, Emerson and CoreTigo collaborated together to introduce the industrial wireless solution technology at Hannover Messe to enable real-time control & monitoring, data analysis, and optimization in the manufacturing processes.

Key Restraints :

Security concerns associated with industrial wireless solutions is restraining the market growth

Industrial wireless solutions enable the transmission of data across networks and are vulnerable to data breaches and theft. Cyber attackers exploit weak security measures, gain unauthorized access, and steal valuable intellectual property, or other confidential information, leading to financial losses. Additionally, for companies that rely heavily on intellectual property including manufacturing and pharmaceuticals, cybersecurity breaches lead to the theft of proprietary information and research data. In conclusion, the cybersecurity concerns associated with industrial wireless solution is hampering the growth of the market.

Future Opportunities :

Rollout of 5G networks is predicted to create numerous future opportunities for the growth of industrial wireless solutions market

5G networks provide significantly higher data transfer speeds and throughput compared to previous generations. The high speed allows industrial devices and sensors to transmit and receive large amounts of data in real-time, enabling remote monitoring, and control of critical processes. Additionally, 5G networks offer ultra-low latency, reducing the time for data to travel between devices and the network, crucial for applications that require immediate responses, namely robotics, automation, and industrial IoT devices. Moreover, 5G supports a larger number of connected devices per square kilometer, ideal for creating dense and interconnected industrial IoT networks. Subsequently, the rollout of 5G networks is projected to create potential opportunities for the growth of industrial wireless solution market.

Industrial Wireless Solution Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2017-2030 |

| Market Size in 2030 | USD 42,960.89 Million |

| CAGR (2023-2030) | 16.8% |

| By Type | Wireless Field Instrument, Wireless Network, and Wireless Computing Devices |

| By Connectivity | 3G, 4G, 5G, and 6G |

| By Frequency Band | Below 1000 MHz, 1000 HHz-2000 MHz, 2000 MHz-3000 MHz, and Above 3000 MHz |

| By Enterprise Size | Large Enterprise and Small Enterprise |

| By Industry Vertical | Automotive, Medical, Power & Energy, Transportation, Mining, Industrial Automation, Manufacturing, and Other |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | NEXCOM International Co., Ltd., Advantech Co., Ltd., HMS Networks, Phoenix Contact India Pvt. Ltd., Belden Inc., Cisco Systems, Inc., Emerson Electric Co., ProSoft Technology, Inc., Siemens AG, Eaton Corporation PLC, WiTricity Corporation, ABB |

Industrial Wireless Solution Market Segmental Analysis :

Based on the Type :

The type segment is trifurcated into wireless field instrument, wireless network, and wireless computing devices. Wireless network accounted for the largest market share in 2022 as the networks provide real-time data transmission, enabling industries to monitor control processes with minimal delay. The real-time capability is essential for optimizing energy consumption, managing demand-response programs, and ensuring reliable operations. Additionally, in hazardous and remote industrial environments, wireless networks improve safety by reducing the need for personnel to physically access certain areas. Moreover, industrial applications involve challenging environments including extreme temperatures, vibration, and dust. Wireless networks designed for industrial use are built to withstand the conditions, ensuring reliable performance in harsh environments. Consequently, the growing adoption of wireless networks in the industrial sector to offer secure high-bandwidth at low latency is boosting the market growth. For instance, in April 2021, Nokia provided 5G private wireless network to KATCH Network, enabling automotive and manufacturing sectors to deploy Internet of Things, resulting in improved safety, efficiency, and productivity. Wireless network provides secure high-bandwidth and low latency, hence contributing notably in bolstering the growth of wireless network segment.

Wireless computing devices are predicted to witness the fastest CAGR in the industrial wireless solution market during the forecast period. Mobile computing devices are equipped with GPS and RFID technology to track and manage assets, inventory, and personnel in real-time. Additionally, mobile computing devices facilitate data collection at the point of operation, ensuring accurate and timely data capture. The data is instantly transmitted to central systems for analysis, enabling better insights into industrial processes. Moreover, mobile devices enable maintenance personnel to access equipment manuals, schematics, and troubleshooting. The quick access to information aids in rapid issue identification and resolution, reducing downtime and maintenance costs. Furthermore, mobile computing devices also play a fundamental role in the integration of the Internet of Things and Industry 4.0 concepts in industrial settings. The devices act as gateways to connect with IoT devices and collect sensor data, facilitating data-driven decision-making and process optimization. In conclusion, the aforementioned factors are anticipated to drive the growth of wireless computing devices during the forecast period.

Based on the Frequency Band :

The frequency band segment is classified into below 1000 MHz, 1000 HHz-2000 MHz, 2000 MHz-3000 MHz, and above 3000 MHz. Below 1000 MHz segment accounted for the largest market share in 2022 as lower frequency bands have better penetration capabilities through obstacles and travel longer distances. In industrial settings, lower frequency signals are more reliable as wireless devices need to communicate across large areas. Additionally, lower frequency bands are less susceptible to interference from other wireless devices and environmental factors. In industrial environments, many wireless devices and electronic equipment operate simultaneously and use lower frequencies to mitigate potential interference issues. Moreover, low-frequency bands consume less power and deliver maximum output and are vastly employed in cell battery devices including smart sensors and condition monitors. For instance, in March 2023, Quectel Wireless Solutions introduced the FGH100M Wi-Fi HaLow module with a frequency range of 850–950MHz. The device is launched for industrial IoT applications providing long-range data transmission and low power consumption and supports cell battery devices, hence contributing considerably in bolstering the market growth.

2000 MHz-3000 MHz segment referred to as mid-band spectrum is anticipated to register the fastest CAGR in the industrial wireless solution market in the upcoming years. The mid-band spectrum provides higher data transfer rates and lower latency compared to lower frequency bands. Additionally, the 2000 MHz-3000 MHz spectrum offers higher capacity compared to lower frequency bands, allowing for the connection of a larger number of devices and supporting data-intensive applications in industrial settings. Moreover, the mid-band spectrum offers a combination of speed and capacity that is well-suited for industrial IoT applications. The combination enables a large number of sensors and devices to communicate and transmit data in real time for monitoring, control, and data analytics. In conclusion, the above-mentioned factors are projected to boost the growth of 2000 MHz-3000 MHz segment during the forecast period.

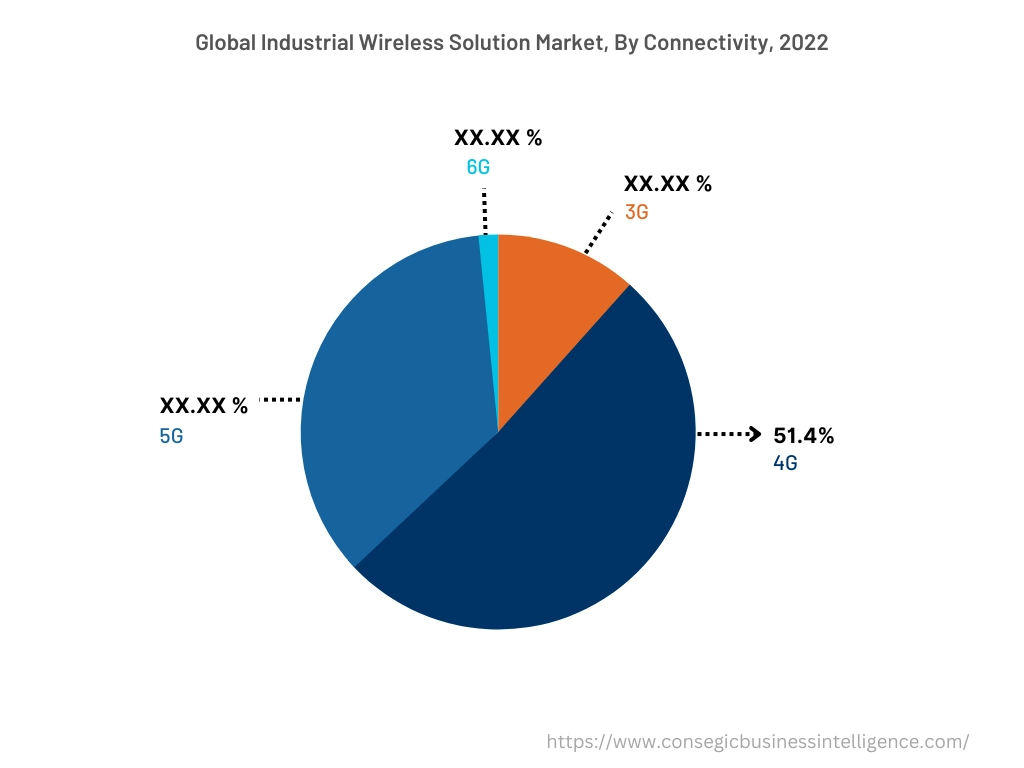

Based on the Connectivity :

The connectivity segment is divided into 3G, 4G, 5G, and 6G. 4G accounted for the maximum market share of 51.4% in 2022 as 4G technology has extensive coverage in many regions worldwide, including remote and rural areas. Additionally, 4G provides a cost-effective solution for wireless communication, further driving the growth of 4G connectivity segment. Moreover, 4G devices are more power-efficient than 5G devices, particularly important for battery-powered industrial applications, where reducing power consumption is crucial for extending the device's operational life. Furthermore, the adoption of 4G wireless solutions in various IoT applications to withstand the harsh conditions of industries is also contributing to the growth of 4G connectivity segment. For instance, in October 2019, Monnit Corporation launched ALTA 4G LTE industrial cellular gateway for IoT with battery-powered sensors to withstand harsh industrial environmental conditions. Additionally, ALTA 4G LTE communicates via cellular transmission, thus becoming ideal for remote locations and contributing significantly in driving the market growth.

5G is predicted to witness the fastest CAGR in the industrial wireless solution market in the upcoming years. 5G offers ultra-low latency, crucial for applications namely robotics, automation, and remote control of critical processes. The low latency ensures minimal delay in transmitting and receiving data, improving the efficiency and responsiveness of industrial systems. Additionally, 5G supports a significantly higher number of connected devices per square kilometer compared to 4G. The feature is essential for the deployment of dense industrial IoT networks with a vast array of sensors and devices, allowing industries to create more interconnected systems. Consequently, the low-latency and high-speed offered by 5G networks is anticipated to drive market growth in upcoming years.

Based on the Enterprise Size :

The enterprise size segment is bifurcated into large enterprise and small enterprise. Large enterprises accounted for the largest market share in 2022 as the enterprises have substantial financial resources, to invest in the development and implementation of advanced industrial wireless solutions. Additionally, large enterprises have extensive industrial operations with numerous facilities, assets, and processes. Industrial wireless solutions are better suited to scale and address the diverse needs of such large-scale operations. Moreover, large enterprises have dedicated research and development (R&D) departments focused on developing cutting-edge technologies and solutions. The enterprises invest in developing proprietary wireless technologies or collaborate with leading vendors to tailor solutions to specific requirements. Subsequently, the aforementioned factors are collectively responsible in bolstering the growth of large enterprises segment.

Small enterprises are predicted to witness the fastest CAGR in the industrial wireless solution market. The growth is attributed to the agile and flexible organizational structure, enabling enterprises to offer innovative and customized wireless solutions tailored to specific industrial needs. Additionally, small enterprises collaborate with technology providers, research institutions, and other partners to access cutting-edge wireless technologies. The partnerships help enterprises to offer competitive solutions without the need for large research and development (R&D) investments. Therefore, the above-mentioned factors are predicted to drive the adoption of industrial wireless solutions by small enterprises during the forecast period.

Based on the Industry Vertical :

The industry vertical segment is categorized into automotive, medical, power & energy, transportation, mining, industrial automation, manufacturing, and others. Manufacturing sector accounted for the largest market share in 2022 as industrial wireless solutions enable real-time monitoring and control of manufacturing processes and equipment. The solution enables operators to access data, adjust settings, and receive alerts remotely, leading to better process optimization and faster response to issues. Additionally, wireless sensors are utilized for quality control processes, enabling manufacturers to monitor and analyze data during production to identify defects, ensure product traceability, and maintain product quality standards. Consequently, the increasing adoption of industrial wireless solutions in the manufacturing sector to enable real-time monitoring of machines is accelerating the growth of the manufacturing segment.

The automotive segment is anticipated to register the fastest CAGR in the industrial wireless solution market during the forecast period. Industrial wireless solutions enable real-time communication and data exchange between robotic systems and production lines. The communication facilitates seamless coordination and synchronization during vehicle assembly, leading to improved production efficiency and reduced downtime. Additionally, wireless sensors are used to monitor various parameters during the manufacturing process, namely temperature, pressure, and vibration. The data is transmitted wirelessly to control centers, allowing manufacturers to detect anomalies and ensure product quality. Moreover, the emergence of advanced solutions offering low-energy connectivity to reduce the cost and weight of excess cabling is also contributing to market growth. For instance, in March 2023, Onsemi launched NCV-RSL15, an ultra-low power automotive-grade wireless microcontroller equipped with Bluetooth Low Energy connectivity. The advanced product reduces the cost and weight of excess cabling, leading to increased longevity of the vehicle, thus contributing considerably in bolstering the market growth.

Based on the Region :

The regional segment includes North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

North America accounted for the largest market share in 2022 as the region, particularly the United States, is at the forefront of technological advancements and innovation. The region has a robust ecosystem of research institutions, technology companies, and startups that continuously develop cutting-edge solutions for various industries, including industrial wireless applications. Additionally, North America has a diverse and strong industrial base, with well-established sectors including automotive, aerospace, pharmaceuticals, and electronics. The industries have significant demand for industrial wireless solutions to enhance productivity, streamline operations, and improve overall efficiency. Consequently, the robust ecosystem and expanding industrial sector are contributing remarkably in bolstering the market growth in the North America region.

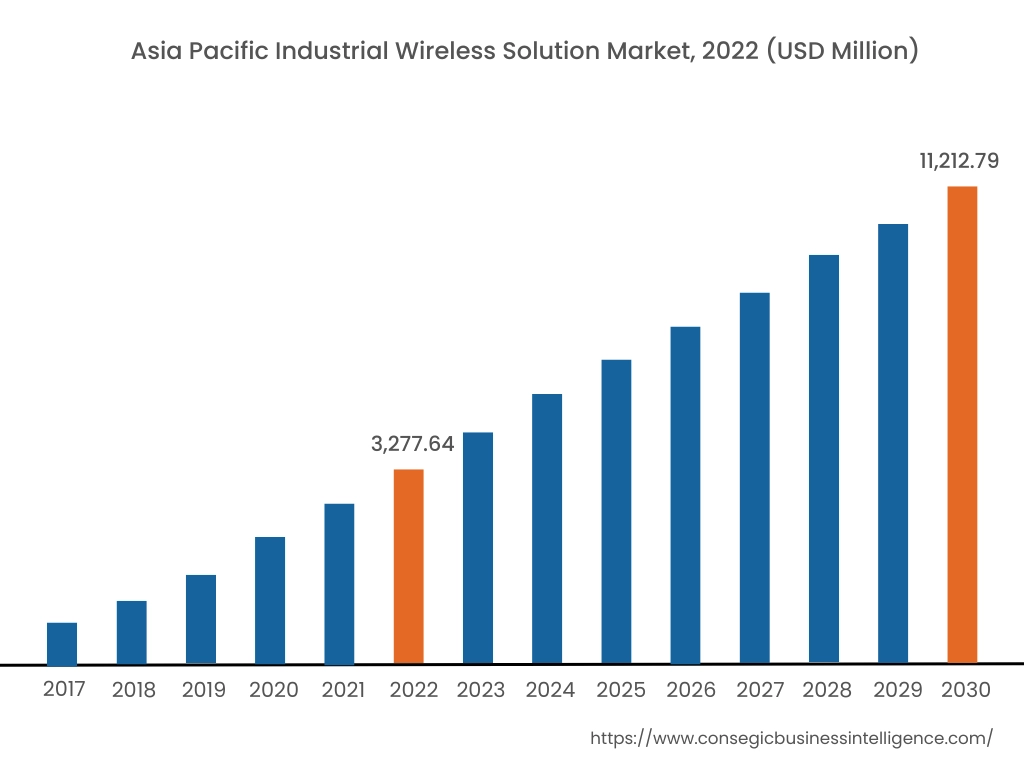

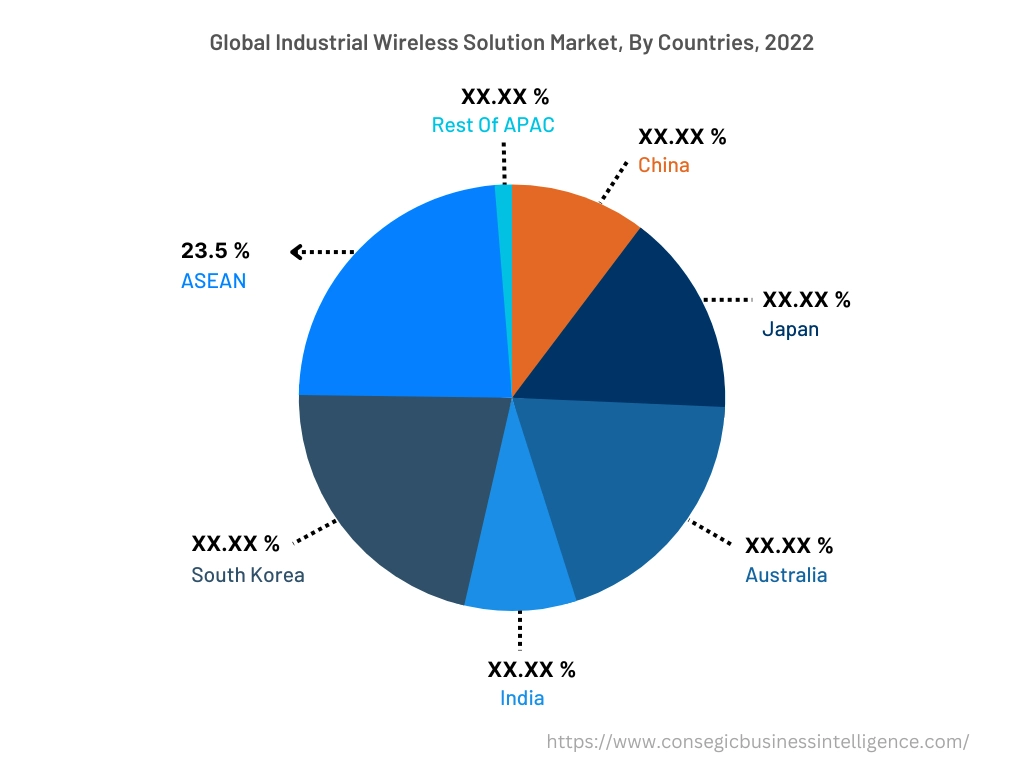

Asia Pacific accounted for USD 3,277.64 million in 2022 and is expected to reach USD 11,212.79 million in 2030 in the industrial wireless solution market. In addition, in the region, ASEAN accounted for the maximum revenue share of 23.5% in the year 2022. The growth of the market is attributed to the expanding manufacturing powerhouses, which raise the demand for advanced industrial wireless solutions to improve production efficiency. Additionally, the concept of Industry 4.0 and smart manufacturing is gaining momentum in the Asia Pacific region. Industries are increasingly adopting automation and robotics to enhance productivity and efficiency, driving the demand for industrial wireless solutions. Moreover, the presence of key players in the region including Yokogawa Electric Corporation and Huawei Technologies Co., Ltd. constantly apply strategic decisions to expand the reach in international markets. For instance, in July 2020, Yokogawa Electric Corporation introduced advanced temperature and pressure sensors wireless industrial IoT (IIoT) solutions for North America, Europe, and Southeast Asian markets. The sensors facilitate the online collection of temperature and pressure data from tanks and furnaces to detect signs of equipment abnormalities.

Top Key Players & Market Share Insights:

The landscape of the industrial wireless solution market is highly competitive and has been examined in the report, along with complete profiles of the key players operating in the industry. In addition, the surge in innovations, acquisitions, mergers, and partnerships has further accelerated the growth of the transit card market. Major players in the market include-

- NEXCOM International Co., Ltd.

- Advantech Co., Ltd.

- ProSoft Technology, Inc.

- Siemens AG

- Eaton Corporation PLC

- ABB

- HMS Networks

- Phoenix Contact India Pvt. Ltd.

- Belden Inc.

- Cisco Systems, Inc.

- WiTricity Corporation

- Emerson Electric Co.

Recent Industry Developments :

- In April 2023, Deutsche Telekom AG offered cost-effective 5G bandwidth with the frequency range of 3.7 to 3.8 GHz to a German manufacturer Arburg for industrial IoT applications.

- In July 2022, WiTricity Corporation signed a global license agreement with Wiferion. allowing Wiferion to utilize WiTricity's wireless charging IP in the space of industrial applications.

Key Questions Answered in the Report

What is an industrial wireless solution? +

An industrial wireless solution refers to a comprehensive and reliable communication network specifically designed for industrial environment, enabling seamless data transmission and control between various devices and systems.

What specific segmentation details are covered in the industrial wireless solution market report, and how is the dominating segment impacting the market growth? +

4G technology dominate the market and has extensive coverage in many regions worldwide, including remote and rural areas. Additionally, 4G provides a cost-effective solution for wireless communication, further driving the growth of 4G connectivity segment.

What specific segmentation details are covered in the industrial wireless solution market report, and how is the fastest segment anticipated to impact the market growth? +

2000 MHz-3000 MHz segment referred to as mid-band spectrum is anticipated to register the fastest CAGR as the spectrum provides higher data transfer rates and lower latency compared to lower frequency bands. Additionally, the 2000 MHz-3000 MHz spectrum offers higher capacity compared to lower frequency bands, allowing for the connection of a larger number of devices and supporting data-intensive applications in industrial settings.

Which region is anticipated to witness the highest CAGR during the forecast period, 2023-2030? +

Asia Pacific is anticipated to witness the fastest CAGR during the forecast period due to the expanding manufacturing powerhouses, which raise the demand for advanced industrial wireless solutions to improve production efficiency.