Industrial Vending Machines Market Scope & Overview:

Industrial vending machines are automated dispensing systems designed to manage and distribute tools, equipment, and consumables in industrial and manufacturing environments. These machines provide secure, real-time access to inventory while ensuring accurate tracking of usage and replenishment needs.

They are widely utilized in industries such as automotive, aerospace, and healthcare to optimize inventory control and reduce operational inefficiencies.These machines come equipped with advanced features such as user authentication, inventory monitoring, and integration with enterprise resource planning (ERP) systems.

They are capable of dispensing a variety of items, including personal protective equipment (PPE), tools, and maintenance supplies, ensuring streamlined inventory management. Industrial vending machines are designed to operate in demanding environments, providing durability, reliability, and ease of use.

End-users include manufacturers, maintenance teams, and warehouses seeking efficient solutions for managing inventory and ensuring operational continuity. These machines play a vital role in improving productivity, minimizing waste, and enhancing inventory accountability.

Industrial Vending Machines Market Size:

Industrial Vending Machines Market size is estimated to reach over USD 7,578.39 Million by 2032 from a value of USD 3,704.43 Million in 2024 and is projected to grow by USD 3,985.16 Million in 2025, growing at a CAGR of 9.4% from 2025 to 2032.

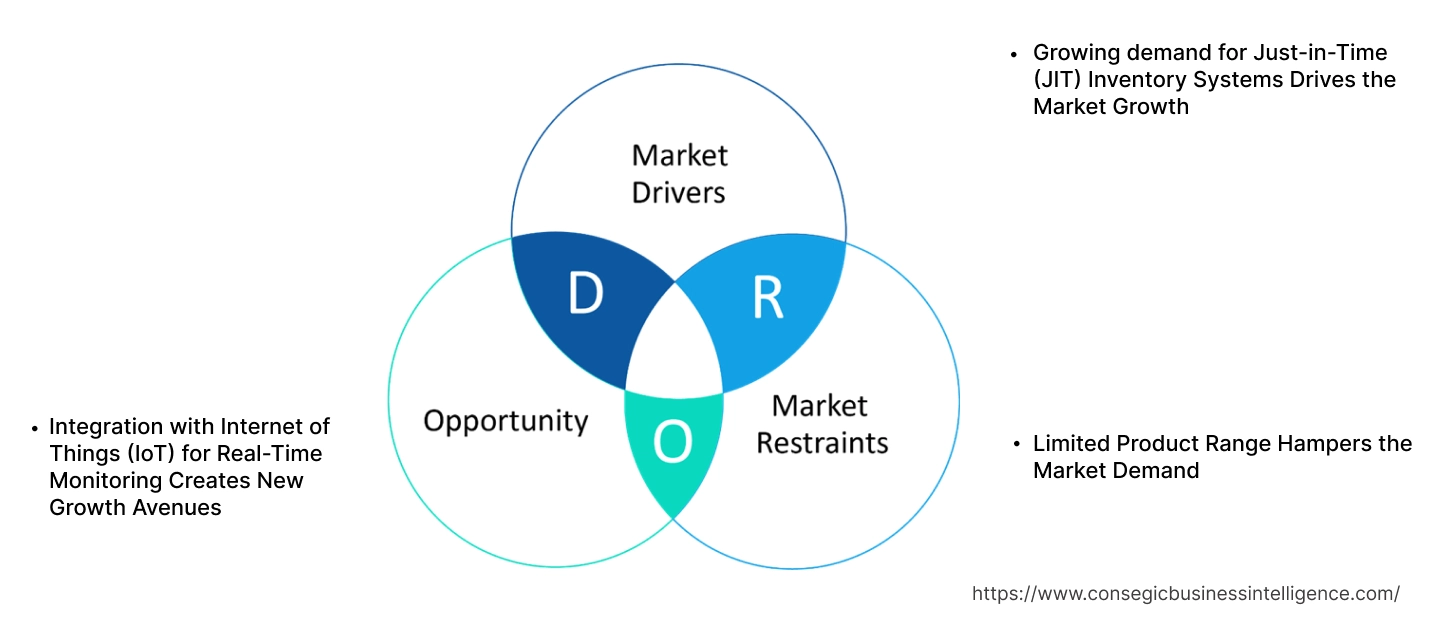

Industrial Vending Machines Market Dynamics - (DRO) :

Key Drivers:

Growing demand for Just-in-Time (JIT) Inventory Systems Drives the Market Growth

JIT systems focus on reducing excess inventory by ensuring that materials, tools, and parts are available only when needed, which minimizes storage costs and reduces waste. These vending machines support JIT by providing real-time access to items, dispensing tools and materials in precise quantities as required for production, and preventing overstocking.

These systems also enhance workflow efficiency by ensuring that production lines have immediate access to necessary supplies, reducing downtime caused by shortages or delays in supply. As industries continue to adopt JIT practices to streamline operations and improve cost efficiency, the need for advanced, automated vending solutions that optimize inventory and ensure timely access to materials will continue to grow, driving the industrial vending machines market demand.

Key Restraints:

Limited Product Range Hampers the Market Demand

One key restraint in adopting industrial vending machines is the limitation in product range and inventory flexibility. These machines require specified products to be placed in each slot, which restricts the variety and quantity of items that are stored.

Due to limited space and predefined configurations, organizations are not able to stock all the tools, parts, or materials they need, limiting the availability of options for workers. This lack of flexibility is particularly challenging for businesses with diverse inventory needs or fluctuating requirements, as the machine does not accommodate seasonal changes or a wide range of items.

For companies that prioritize having an extensive selection of materials on hand, this constraint makes these vending machines less attractive as a long-term inventory solution, leading them to consider alternative systems that offer greater adaptability. Thus, the above factors limit the industrial vending machines market growth.

Future Opportunities :

Integration with Internet of Things (IoT) for Real-Time Monitoring Creates New Growth Avenues

The integration of Internet of Things ensures real-time tracking by connecting these machines to cloud-based platforms, helping businesses gain the ability to monitor inventory and providing valuable insights into stock levels and usage patterns.

This integration allows for automated replenishment, ensuring that materials and tools are always available when needed, reducing the risk of stockouts and improving operational efficiency. IoT-enabled vending machines also tracks consumption trends, helping companies optimize inventory management and make data-driven decisions to minimize waste.

Additionally, remote monitoring capabilities allow for proactive maintenance and faster issue resolution, further reducing downtime and improving machine longevity. This level of connectivity enhances the overall efficiency of inventory management processes, streamlining operations and reducing labor costs, making IoT-enabled vending machines an attractive solution for businesses seeking smarter, more automated systems. Thus, the aforementioned factors boosts the industrial vending machines market opportunities.

Top Key Players and Market Share Insights:

The Industrial Vending Machines market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global Industrial Vending Machines market. Key players in the Industrial Vending Machines industry include -

- Apex Supply Chain (USA)

- Airgas Inc. (USA)

- IVM, Inc. (USA)

- SupplyPro, Inc. (USA)

- AutoCrib, Inc. (USA)

- SecuraStock (Australia)

- CribMaster (USA)

- Fastenal Company (USA)

Industrial Vending Machines Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 7,578.39 Million |

| CAGR (2025-2032) | 9.4% |

| By Type |

|

| By Product |

|

| By End-User Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Industrial Vending Machines Market Segmental Analysis :

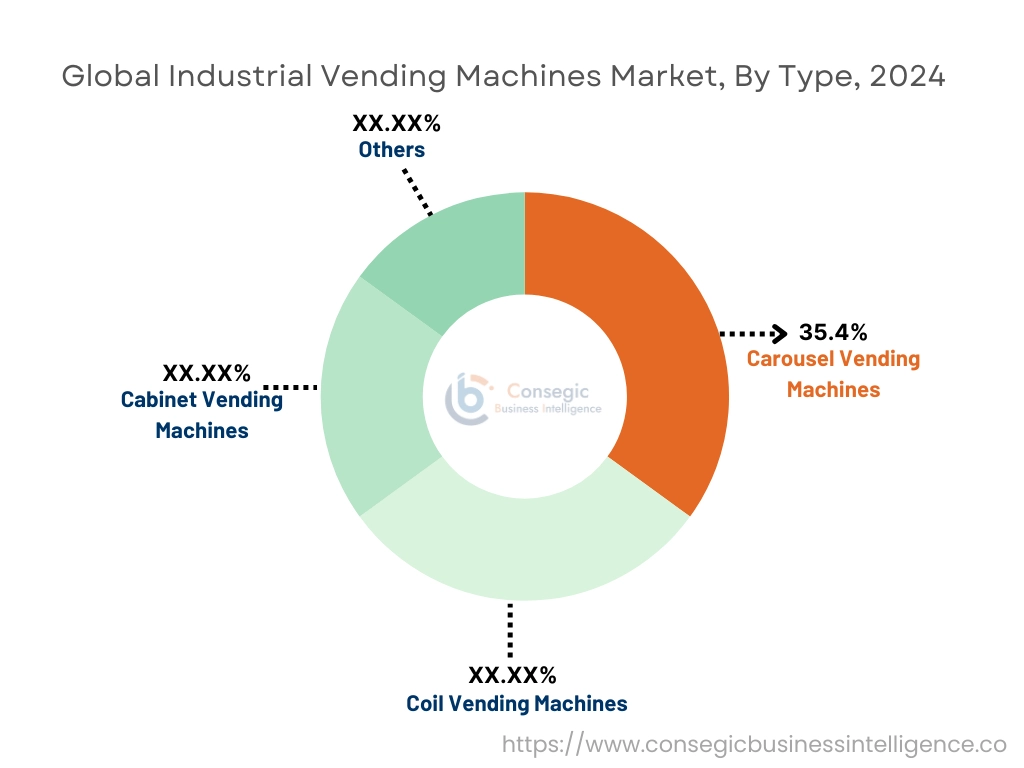

By Type:

Based on type, the market is segmented into carousel vending machines, coil vending machines, cabinet vending machines, and others.

The carousel vending machine segment accounted for the largest revenue of 35.4% of the total industrial vending machines market share in 2024.

- Carousel vending machines are widely used due to their flexibility in dispensing a variety of products, including tools, personal protective equipment (PPE), and maintenance supplies.

- Their rotating design allows for efficient storage and easy retrieval of items, making them suitable for industries requiring quick access to critical equipment.

- These machines are particularly popular in manufacturing and automotive sectors where operational efficiency and inventory control are prioritized.

- As per industrial vending machines market analysis, the adoption of carousel vending machines reflects trends toward improving workplace safety and optimizing inventory management practices.

The cabinet vending machine segment is projected to grow at the fastest CAGR during the forecast period.

- Cabinet vending machines are ideal for storing larger or more expensive tools and equipment, ensuring security and accountability in industrial environments.

- Advanced cabinet machines are equipped with RFID or biometric authentication systems, enhancing security and reducing the risk of unauthorized access.

- Their application is expanding in aerospace and oil & gas industries where tracking high-value items is critical for operational efficiency.

- As per the industrial vending machines market trends, the increasing use of connected cabinet vending systems, which integrate with cloud-based inventory management platforms, further supports their adoption.

By Product:

Based on product, the market is segmented into personal protective equipment (PPE), maintenance, repair, and operations (MRO) supplies, tools, and others.

The PPE segment accounted for the largest revenue of the total industrial vending machines market share in 2024.

- Industrial vending machines are extensively used to dispense PPE items such as gloves, helmets, and masks, ensuring workplace safety and compliance with regulatory standards.

- The adoption of PPE vending machines has increased significantly in industries like manufacturing and oil & gas, where safety protocols are strictly enforced.

- Vending machines for PPE enable real-time tracking and reporting, helping organizations monitor usage and reduce wastage.

- As per industrial vending machines market analysis, the focus on improving workplace safety and reducing downtime drives the dominance of PPE vending solutions.

The tools segment is projected to grow at the fastest CAGR during the forecast period.

- Tools vending machines are gaining popularity in sectors like automotive and aerospace, where efficient tracking and management of tools are critical for production workflows.

- These machines minimize tool misplacement and ensure that essential equipment is always available, enhancing operational efficiency.

- Advanced tools vending solutions integrate with inventory management systems, enabling automated reordering and reducing manual intervention.

- The increasing adoption of precision tools in industrial operations underscores the importance of tools vending machines in maintaining productivity and accountability, fueling the industrial vending machines market growth.

By End-User Industry:

Based on end-user industry, the market is segmented into manufacturing, oil & gas, automotive, aerospace & defense, and others.

The manufacturing segment accounted for the largest revenue share in 2024.

- Industrial vending machines are widely deployed in manufacturing facilities to streamline inventory management and ensure the availability of essential supplies such as tools and PPE.

- These machines support lean manufacturing practices by reducing waste, improving inventory accuracy, and minimizing downtime.

- Manufacturers benefit from the integration of vending systems with enterprise resource planning (ERP) platforms, enabling real-time inventory monitoring and data-driven decision-making.

- As per industrial vending machines market trends, the manufacturing sector’s emphasis on operational efficiency and cost control drives their adoption in the market.

The oil & gas segment is projected to grow at the fastest CAGR during the forecast period.

- The oil & gas industry relies on vending machines for managing critical supplies in remote and hazardous environments, ensuring workplace safety and operational continuity.

- These machines are used to dispense specialized tools, safety equipment, and replacement parts, reducing delays caused by manual inventory management.

- Advanced vending systems equipped with IoT connectivity provide real-time usage data, enabling proactive maintenance and efficient supply chain management.

- The focus on enhancing safety and compliance in oil & gas operations supports the growing adoption, thereby boosting the industrial vending machines market expansion.

Regional Analysis:

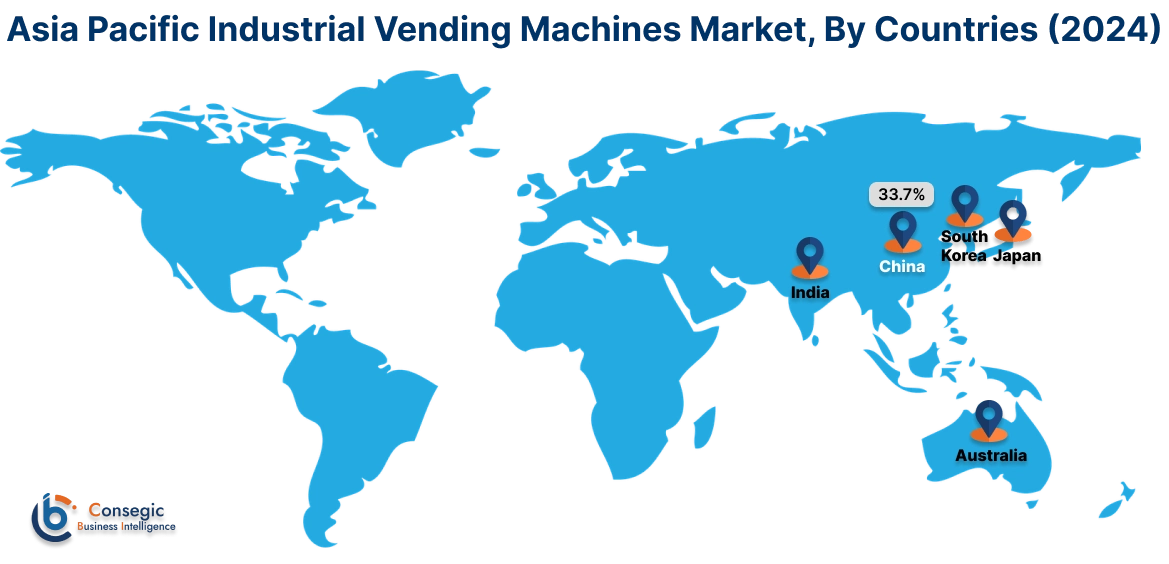

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

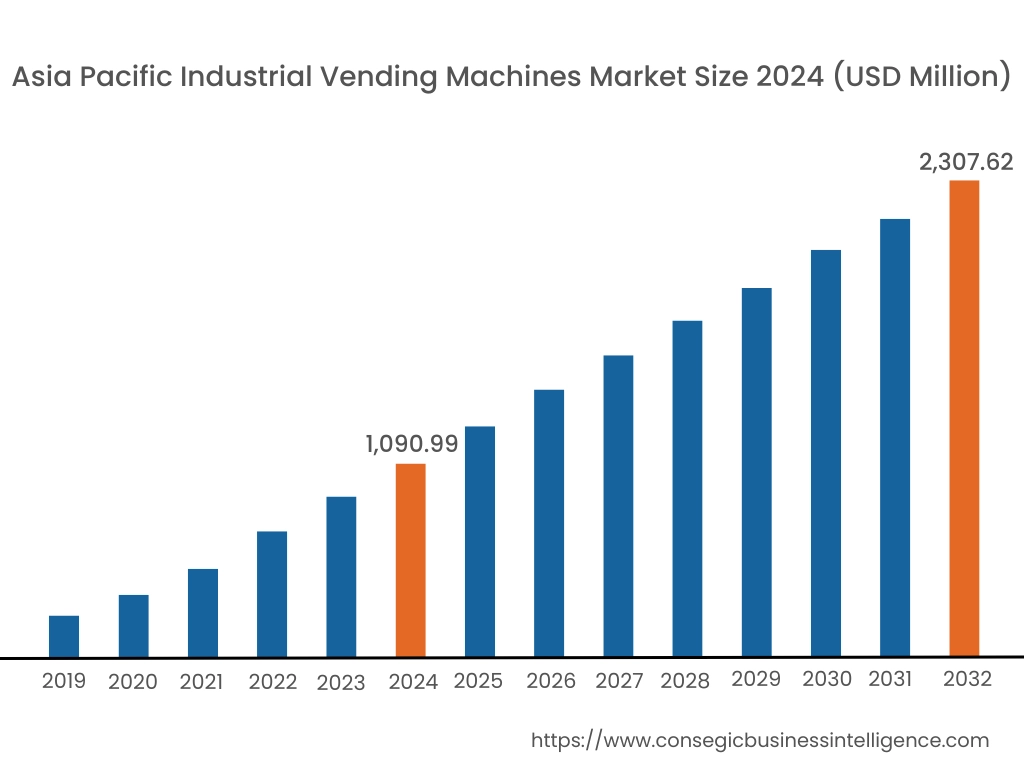

Asia Pacific region was valued at USD 1,090.99 Million in 2024. Moreover, it is projected to grow by USD 1,176.98 Million in 2025 and reach over USD 2,307.62 Million by 2032. Out of this, China accounted for the maximum revenue share of 33.7%. The Asia-Pacific region is witnessing rapid advancements in the industrial vending machines market, attributed to growth in industrialization and a strong push for automation across various sectors. A prominent trend is the increasing implementation of vending solutions in manufacturing facilities to streamline supply chains and minimize waste. Analysis indicates that government initiatives promoting smart factory concepts and investments in advanced manufacturing technologies are contributing to industrial vending machines market demand in this region.

North America is estimated to reach over USD 2,456.16 Million by 2032 from a value of USD 1,228.79 Million in 2024 and is projected to grow by USD 1,319.38 Million in 2025. This region maintains a significant share in the industrial vending machines sector, driven by the growth in adoption of automated inventory management solutions. A notable trend is the integration of Internet of Things (IoT) technologies, enabling real-time monitoring and data analytics to optimize inventory control. Analysis indicates that the focus on reducing operational downtime and enhancing workplace efficiency contributes to the industrial vending machines market expansion in North America.

European countries are pivotal in the industrial vending machines market, emphasizing lean manufacturing practices and stringent regulatory compliance. A significant trend is the deployment of vending solutions to manage personal protective equipment (PPE) and tools, ensuring safety standards are met. Analysis suggests that the commitment to sustainable operations and efficient resource utilization drives the adoption of these systems in this region.

In the Middle East and Africa, the industrial vending machines market is influenced by efforts to enhance operational efficiency and manage resources effectively in industries such as oil and gas, construction, and mining. The focus is on utilizing vending solutions to control the distribution of high-value tools and safety equipment, reducing loss and ensuring compliance with safety protocols. Analysis suggests that the adoption of these technologies is supported by the need to optimize resource utilization and maintain stringent safety standards in challenging environments.

Latin American countries are increasingly recognizing the benefits of industrial vending machines in improving inventory management and operational efficiency. A notable trend is the integration of vending solutions in sectors like automotive, aerospace, and manufacturing to monitor tool usage and reduce downtime. Analysis indicates that economic growth and the pursuit of competitive manufacturing practices are key factors influencing the industrial vending machines market opportunities in this region.

Key Questions Answered in the Report

What is the size of the Industrial Vending Machines Market? +

The Industrial Vending Machines Market size is estimated to reach over USD 7,578.39 Million by 2032 from a value of USD 3,704.43 Million in 2024 and is projected to grow by USD 3,985.16 Million in 2025, growing at a CAGR of 9.4% from 2025 to 2032.

What are the key segments in the Industrial Vending Machines Market? +

The market is segmented by type (carousel vending machine, coil vending machine, cabinet vending machine, and others), product (personal protective equipment, maintenance, repair, and operations supplies, tools, and others), and end-user industry (manufacturing, oil & gas, automotive, aerospace & defense, and others).

Which segment is expected to grow the fastest in the Industrial Vending Machines Market? +

The cabinet vending machine segment is projected to grow at the fastest CAGR during the forecast period, driven by advancements in security features and growing adoption in industries requiring high-value tool tracking.

Who are the major players in the Industrial Vending Machines Market? +

Key players in the Industrial Vending Machines Market include Apex Supply Chain (USA), AutoCrib, Inc. (USA), SecuraStock (Australia), CribMaster (USA), Fastenal Company (USA), Airgas Inc. (USA), IVM, Inc. (USA), SupplyPro, Inc. (USA).