- Summary

- Table Of Content

- Methodology

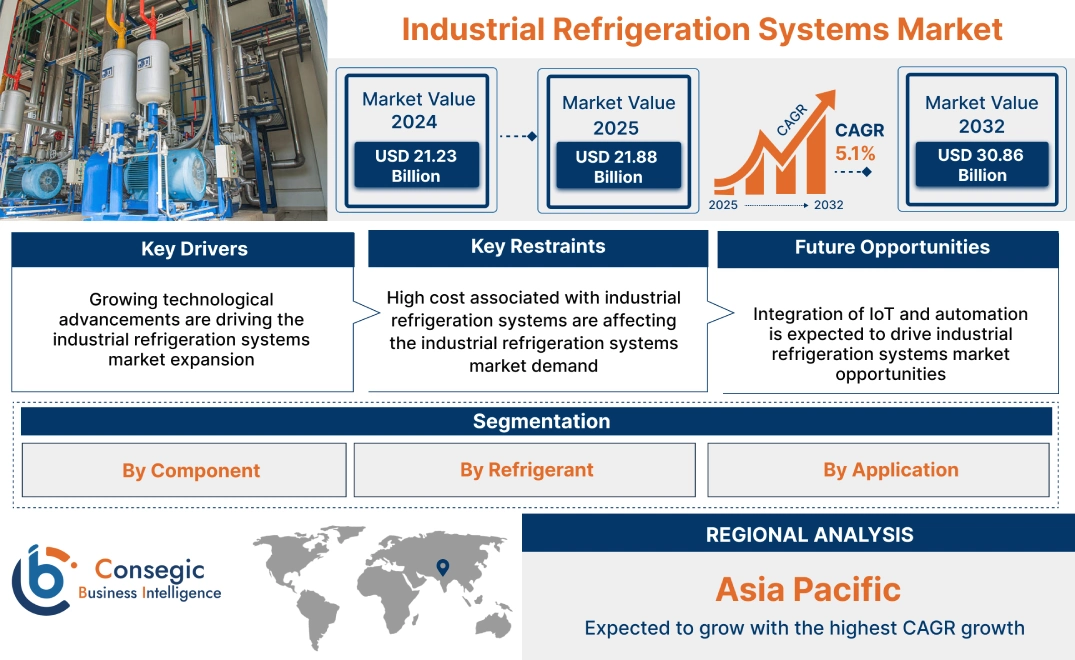

Industrial Refrigeration Systems Market Size:

Industrial Refrigeration Systems Market Size is estimated to reach over USD 30.86 Billion by 2032 from a value of USD 21.23 Billion in 2024 and is projected to grow by USD 21.88 Billion in 2025, growing at a CAGR of 5.1% from 2025 to 2032.

Industrial Refrigeration Systems Market Scope & Overview:

Industrial refrigeration systems are large-scale cooling solutions designed for various industrial processes and applications, ensuring efficient heat removal and maintaining precise temperature control for products and equipment. They are essential in industries including food processing, logistics, and manufacturing to ensure product quality, safety, and operational reliability. These systems handle significantly larger cooling loads as compared to commercial or residential refrigeration, often covering extensive areas such as storage facilities and processing plants.

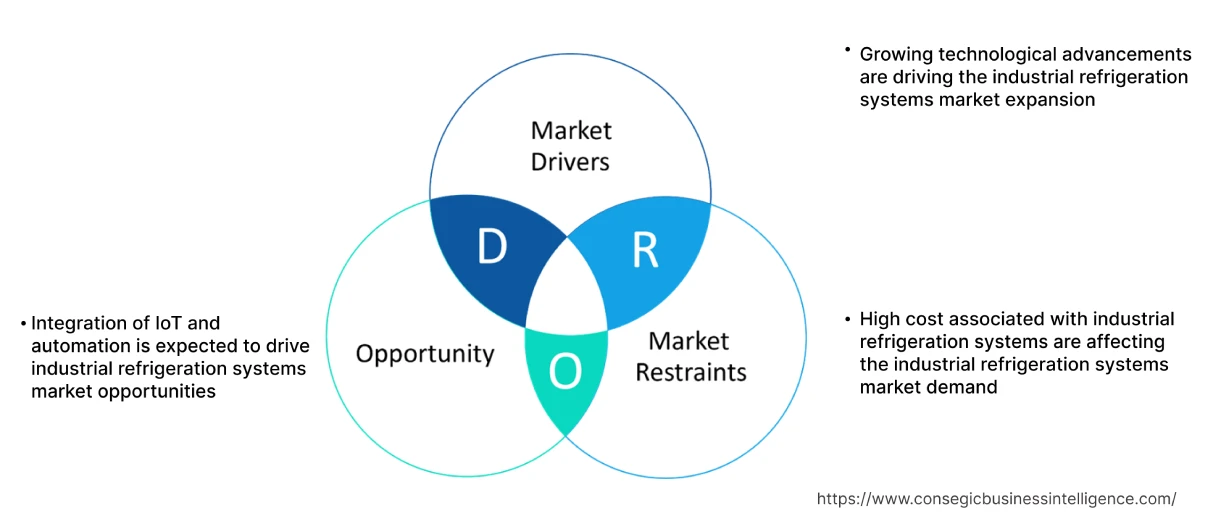

Key Drivers:

Growing technological advancements are driving the industrial refrigeration systems market expansion

Technological advancements in industrial refrigeration systems have been pivotal in driving market growth. Innovations such as the development of natural refrigerants and smart refrigeration systems have significantly enhanced efficiency and reduced operational costs. These advancements not only improve the environmental sustainability of industrial refrigeration but also boost system reliability, meeting the stringent demands of modern industries.

Moreover, smart refrigeration systems, equipped with advanced sensors and automation capabilities, optimize performance and minimize energy consumption. These technological advancements are reshaping the industrial refrigeration landscape, fostering sustainable practices and driving operational efficiencies across various sectors.

- For instance, in April 2025, Danfoss showcased its full range of products from two business areas of air conditioning heat and commercial refrigeration at the 36th China Refrigeration exhibition. Danfoss has launched innovative new compressor technologies, including the Skymagnet TGH285, an oil-free magnetic levitation heat pump compressor capable of high-pressure ratios, and the PSG 605-PSG 800 scroll compressors, designed for eco-friendly refrigerants and optimized for performance and reliability.

Thus, according to the industrial refrigeration systems market analysis, the growing technological advancements are driving the industrial refrigeration systems market size.

Key Restraints:

High cost associated with industrial refrigeration systems are affecting the industrial refrigeration systems market demand

High cost associated with industrial refrigeration systems is expected to restrict the market. These refrigeration systems are expensive, as they are made up of high-quality materials, available in large sizes, and require regular maintenance, owing to increased wear and tear.

Moreover, these refrigerators require additional space as they are large, which encourages small and mid-retail owners to lessen their adoption. Thus, the above analysis depicts that the aforementioned factors would further impact on industrial refrigeration systems market size.

Future Opportunities :

Integration of IoT and automation is expected to drive industrial refrigeration systems market opportunities

Integration of Internet of Things (IoT) technologies and automation within refrigeration systems presents potential opportunities for enhanced operational capabilities. By leveraging IoT sensors and connectivity, these systems enable real-time monitoring of temperature and other critical parameters. This capability not only facilitates proactive maintenance and early fault detection but also supports predictive maintenance strategies, reducing downtime and optimizing equipment lifespan.

Automation in refrigeration systems enhances energy efficiency through intelligent control and optimization algorithms. Automated systems can adjust operation parameters based on real-time data and demand patterns, leading to significant operational cost savings for end-users. As IoT continues to advance, its integration can reform the manner in which industrial refrigeration systems are managed and optimized, fostering a more sustainable and cost-effective approach to cold chain management.

- For instance, Kuhlman Inc.’s industrial refrigeration solutions are integrated with internet of things (IoT), which enable remote monitoring and control. Through IoT connected devices, operators gain immediate insights into system operations, allowing quick reaction to errors, refined maintenance timing, and data informed improvements to system efficiency.

Thus, based on the above industrial refrigeration systems market analysis, the growing integration of IoT and automation in refrigeration solutions is expected to drive the industrial refrigeration systems market opportunities.

Industrial Refrigeration Systems Market Segmental Analysis :

By Component:

Based on component, the industrial refrigeration systems market is segmented into compressor, condenser, evaporator, controls, and others.

Trends in the component:

- Due to escalating energy expenses and stricter environmental rules, the industrial refrigeration sector is shifting towards energy-saving practices. Companies are investing in technologies like variable speed compressors, thermal energy storage, and improved insulation to cut down on energy usage.

- To reduce their environmental impact, the food and beverage sector is modernizing its refrigeration systems. With energy efficiency as a top priority, manufacturers are developing affordable, high-performing cooling technologies.

- Thus, the above factors are driving the industrial refrigeration systems market demand and trends.

The compressor segment accounted for the largest revenue share in the year 2024.

- To lower operating expenses and environmental impact, industrial refrigeration is moving towards energy-efficient compressors. Companies are implementing advanced technologies like variable speed drives and two-stage compression to use less energy.

- Government regulations supporting energy conservation are also pushing industries to adopt these high-efficiency compressors. With sustainability as a key focus, manufacturers are developing new compressor models to meet this growing demand.

- For instance, in October 2023, Emerson introduced a new modular refrigeration system using CO₂ scroll compressors, specifically targeting small to medium-sized European retail stores. The Copeland units offer adaptable installation options for both indoor and outdoor use and can be configured as packaged or split systems.

- Thus, based on the above analysis, these factors are further driving the industrial refrigeration systems market growth and trends.

The controls segment is anticipated to register the fastest CAGR during the forecast period.

- The industrial refrigeration sector is seeing a significant increase in demand for adaptable and remotely managed technologies.

- Wireless control, cloud dashboards, and remote diagnostics enable facility managers to monitor and change refrigeration operations from anywhere. These tools improve issue response times and optimize energy consumption.

- Adaptive controls, which adjust cooling based on environmental conditions, further enhance efficiency. The trend towards scalable and economical solutions ensures continued growth of remote and adaptive refrigeration controls.

- Thus, based on the above analysis, these trends are expected to drive the industrial refrigeration systems market share during the forecast period.

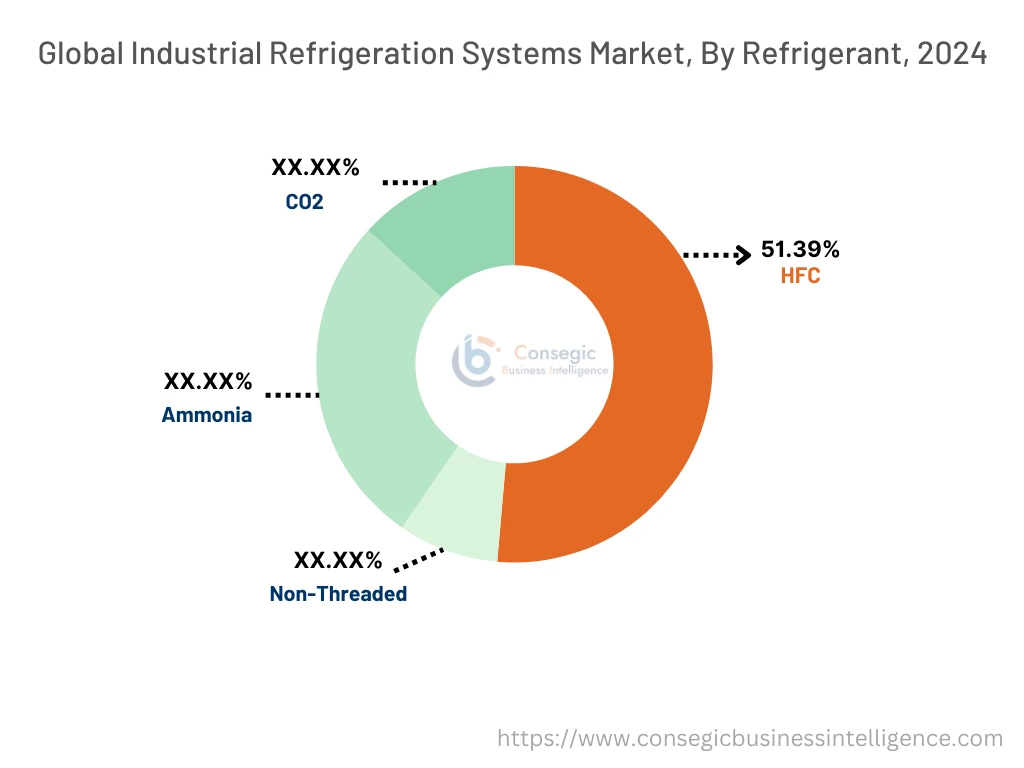

By Refrigerant:

Based on refrigerant, the industrial refrigeration systems market is segmented into ammonia, CO2, HFC, and others.

Trends in the refrigerant:

- Factors including rapid urbanization in developing countries, increasing need for cold storage, and growing need for environmentally sustainable refrigerants are driving the segment growth.

- The development of new refrigerant types that are both energy-efficient and environmentally friendly is creating opportunities for manufacturers to differentiate themselves and strengthen their position in the market.

The HFC segment accounted for the largest revenue share of 51.39% in the year 2024.

- HCFCs (hydrofluorocarbons) offer beneficial thermodynamic characteristics, including strong refrigeration capacity and coefficient of performance (COP), and are suitable for low-pressure applications.

- Industrial manufacturing sectors such as food and beverage, pharmaceuticals, chemical/petrochemical, and other sectors rely significantly on refrigeration to control product and process temperatures, ensuring safety and optimal conditions.

- Moreover, maintaining precise temperatures is crucial for maximizing product yield and preventing spoilage. The development of these industrial sectors has directly increased the need for refrigerants, including HCFCs.

- Therefore, these factors would further supplement the industrial refrigeration systems market

The ammonia segment is anticipated to register the fastest CAGR during the forecast period.

- The innovations in technology are making ammonia based industrial refrigeration systems safer, more efficient, and more versatile.

- Low-charge ammonia systems mitigate toxicity risks, expanding their use in commercial settings. Hybrid ammonia-CO₂ systems are becoming popular due to their increased energy efficiency and safety.

- Smart monitoring, IoT integration, and AI-driven optimization are further improving ammonia system performance. These developments are making ammonia a practical and scalable option for a wider range of industries.

- For instance, Hillphoenix’s ammonia industrial refrigeration solutions are commonly used in industrial, processing, and manufacturing applications. It is a naturally occurring chemical represented by the formula NH3, indicating its nitrogen and hydrogen composition.

- These developments in the ammonia segment are anticipated to further drive the industrial refrigeration systems market trends and share during the forecast period.

By Application:

Based on application, the market is segmented into food & beverage, chemical & petrochemical, pharmaceutical, utility, and others.

Trends in the application:

- Industrial refrigeration is seeing a significant increase in the use of CO₂ critical systems because they are environmentally friendly and highly efficient. These systems are especially valuable in cold storage, food processing, and supermarket refrigeration, where both sustainability and reliable operation are essential.

- Environmental sustainability is increasingly shaping the market landscape, prompting a shift towards eco-friendly refrigerants such as ammonia, carbon dioxide, and hydrocarbons. These alternatives offer lower environmental impact and higher energy efficiency as compared to traditional refrigerants, aligning with global efforts to reduce greenhouse gas emissions and improve energy conservation practices.

The food & beverage segment accounted for the largest revenue share in the year 2024.

- The growing need for frozen and processed foods is encouraging the food and beverage sector to adopt advanced refrigeration systems.

- As global supply chains become more complex, efficient cold storage and processing are crucial for maintaining food quality and safety.

- Large-scale distributors are investing in modern refrigeration to extend shelf life and reduce waste.

- The rise of online grocery services also necessitates temperature-controlled logistics. These factors are compelling food businesses to implement high-efficiency refrigeration that meets food safety regulations.

- Thus, based on the above analysis, these factors are driving the industrial refrigeration systems market growth.

The chemical & petrochemical segment is anticipated to register the fastest CAGR during the forecast period.

- The growing specialty chemicals and biotechnology sectors are driving the need for specialized refrigeration systems.

- These industries require precise temperature control during manufacturing, storage, and transport to ensure product quality.

- Companies are investing in custom refrigeration solutions to meet these specific needs. As these sectors continue to expand, refrigeration technology will evolve to accommodate their unique requirements.

- For instance, in June 2024, TANFAC Industries Limited (TANFAC) secured USD 81 million framework agreement with a major Japanese specialty chemical firm. Under this five-year agreement, TANFAC will supply refrigerant gas, with the supply commencing in the latter half of the fiscal year 2025-26. TANFAC has also announced an expansion of its manufacturing facility located in Cuddalore, India, which is specifically aimed at accommodating the production of refrigerant gases.

- These factors are anticipated to further drive the industrial refrigeration systems market trends during the forecast period.

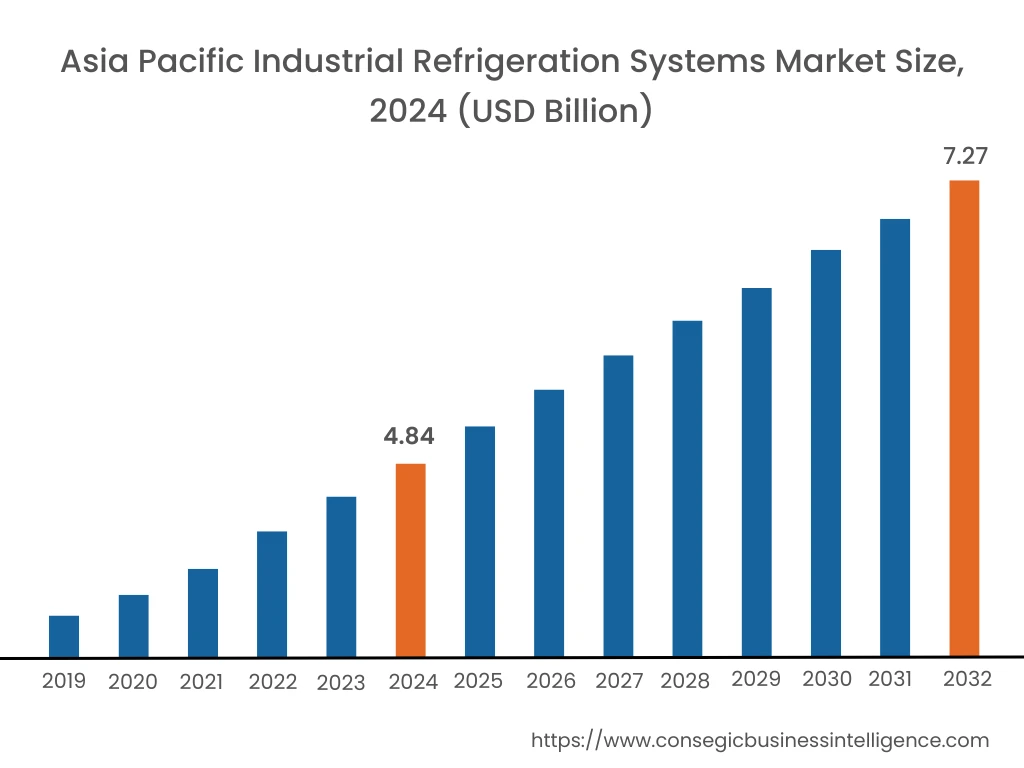

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

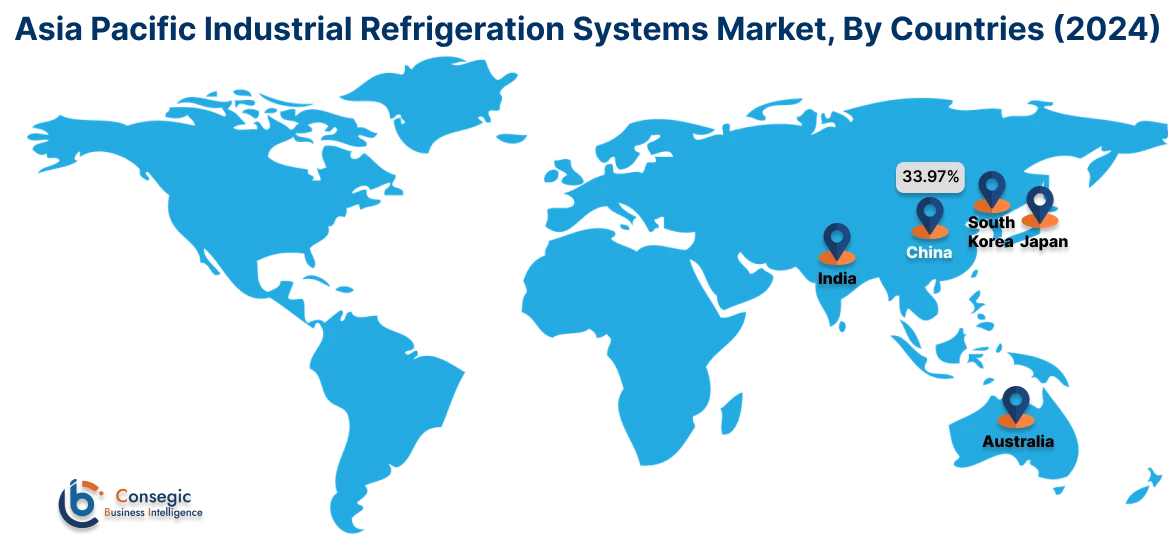

Asia Pacific industrial refrigeration systems market expansion is estimated to reach over USD 7.27 billion by 2032 from a value of USD 4.84 billion in 2024 and is projected to grow by USD 5.00 billion in 2025. Out of this, the China market accounted for the maximum revenue split of 33.97%. Asia-Pacific is emerge as a critical region in the industrial refrigeration market, propelled by rapid industrialization, urbanization, and expanding cold chain infrastructure. Countries in the region are witnessing increasing investments in food processing and healthcare industries, boosting the need for reliable refrigeration systems to maintain product quality and safety. Further, the region's evolving consumer preferences and regulatory landscapes are shaping the adoption of advanced refrigeration technologies, with a focus on efficiency and environmental sustainability. These factors would further drive the regional industrial refrigeration systems market during the forecast period.

- For instance, in April 2025, Daikin invested USD 58.28 million to establish its third research and development center in Neemrana, Rajasthan. This significant investment is the largest of its kind in the HVAC and refrigeration sector within India, aims to develop products for both domestic and international markets, as stated by Daikin India.

North America market is estimated to reach over USD 11.79 billion by 2032 from a value of USD 8.16 billion in 2024 and is projected to grow by USD 8.41 billion in 2025. In North America, the market is growing due to increasing focus on upgrading existing systems to more energy-efficient and eco-friendly solutions, driven by regulatory mandates and the industry's commitment to reducing carbon emissions. The United States and Canada are leading this transition, with significant investments in research and development to enhance refrigeration technologies. Further, the proactive approach to environmental sustainability, is also witnessing a shift towards natural refrigerants and energy-efficient systems, fostering growth in the region's industrial refrigeration market. These factors would further drive the regional market.

- For instance, in March 2024, Hillphoenix Industrial formed a strategic partnership with Cool Refrigeration Systems & Solutions. With this partnership, Cool Refrigeration will represent Hillphoenix's industrial CO₂ refrigeration products in the Eastern U.S. and Canada.

According to the analysis, the industrial refrigeration systems industry in Europe is projected to witness significant development during the forecast period. Stringent environmental regulations are pushing the European refrigeration market towards high-efficiency systems. Companies in the region are increasingly using natural refrigerants like ammonia and CO₂ to decrease emissions and energy expenses.

Additionally, countries in the Latin American region are increasingly adopting industrial refrigeration solutions to support agricultural exports, food processing, and pharmaceutical manufacturing. Government initiatives aimed at enhancing food safety standards and healthcare infrastructure further contribute to the market's growth. Further, the expanding e-commerce sector, particularly for food and perishables, requires efficient cold chain logistics and warehousing, further driving the need for industrial refrigeration system in the Middle East & Africa.

Top Key Players and Market Share Insights:

The global industrial refrigeration systems market is highly competitive with major players providing solutions to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the market. Key players in the industrial refrigeration systems industry include-

- M&M Refrigeration, Inc. (U.S.)

- Johnson Controls (U.S.)

- Daikin Industries Ltd. (Japan)

- Ingersoll-Rand (U.S.)

- United Technologies Corporation (U.S.)

- EVAPCO, Inc (U.S.)

- Bitzer (Germany)

- Industrial Frigo SRL (Italy)

- Emerson (U.S.)

- Frick India Limited (India)

- GEA (Germany)

- Dorin (Italy)

- Howden Group (U.K.)

- Danfoss (Denmark)

- Kirloskar Group (Japan)

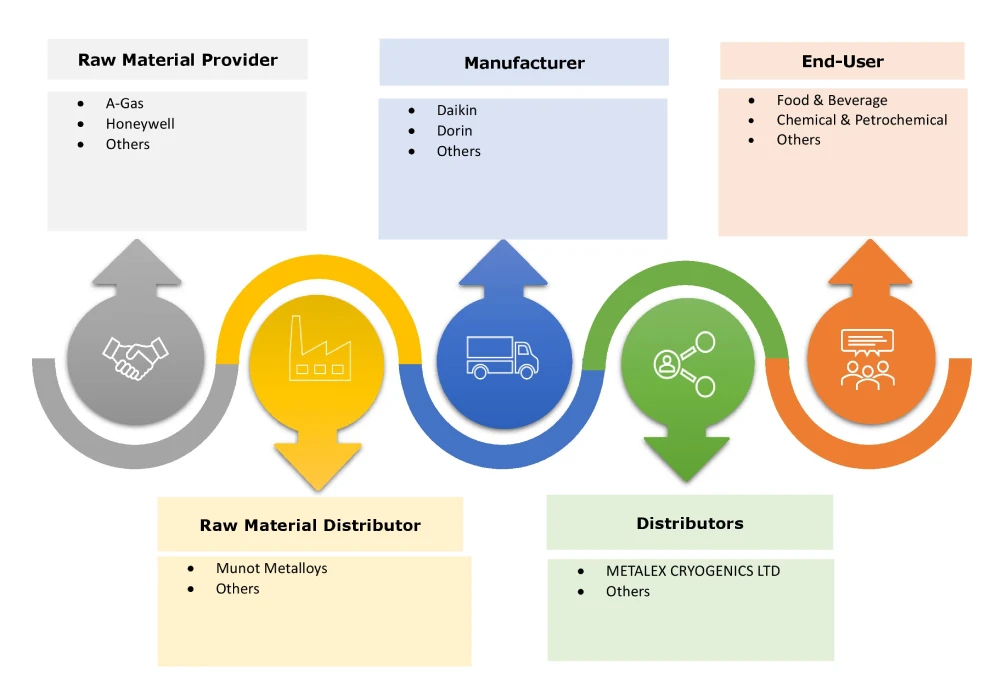

Industrial Refrigeration Systems Market Ecosystem:

Recent Industry Developments :

Product Launch:

- In November 2023, Daikin unveiled their new hybrid and electric refrigeration systems for transport at the SOLUTRANS exhibition in Lyon. Daikin's new line of fully electric and plug-in hybrid products aims to decrease emissions from traditional engines. Further, the company also showcased its latest transport refrigeration innovations, including the Exigo trailer refrigeration unit and the Daikin Telematics connectivity platform.

Industrial Refrigeration Systems Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 30.86 Billion |

| CAGR (2025-2032) | 5.1% |

| By Component |

|

| By Refrigerant |

|

| By Application |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Industrial Refrigeration Systems Market? +

Industrial Refrigeration Systems market size is estimated to reach over USD 30.86 Billion by 2032 from a value of USD 21.23 Billion in 2024 and is projected to grow by USD 21.88 Billion in 2025, growing at a CAGR of 5.1% from 2025 to 2032.

Which is the fastest-growing region in the Industrial Refrigeration Systems Market? +

Asia-Pacific is the region experiencing the most rapid growth in the market.

What specific segmentation details are covered in the Industrial Refrigeration Systems report? +

The industrial refrigeration systems report includes specific segmentation details for component, refrigerant, application, and region.

Who are the major players in the Industrial Refrigeration Systems Market? +

The key participants in the market are M&M Refrigeration, Inc. (U.S.), Johnson Controls (U.S.), Daikin Industries Ltd. (Japan), Ingersoll-Rand (U.S.), United Technologies Corporation (U.S.), EVAPCO, Inc (U.S.), Bitzer (Germany), Industrial Frigo SRL (Italy), Emerson (U.S.), Frick India Limited (India), GEA (Germany), , Dorin (Italy), Howden Group (U.K.), Danfoss (Denmark), Kirloskar Group (Japan), and others.