- Summary

- Table Of Content

- Methodology

Industrial Metal Detectors Market Size :

Global Industrial Metal Detectors Market size is estimated to reach over USD 1,546.02 Million by 2030 from a value of USD 1,093.70 Million in 2022, growing at a CAGR of 4.5% from 2023 to 2030.

Industrial Metal Detectors Industry Scope & Overview :

An industrial metal detector is a device used to detect the presence of metallic objects or contaminants in products, raw materials, or on conveyor belts. They are designed to be integrated into conveyor systems, allowing for continuous metal detection in production lines. They are designed to ensure product quality, prevent damage to machinery, and enhance the quality of the product by identifying unwanted metal objects in food and pharmaceutical products.

Industrial Metal Detectors Market Insights :

Key Drivers :

Stringent government regulations associated with food quality and safety

Governments and regulatory bodies worldwide have implemented strict quality and safety standards in the food & beverage sector. Industrial metal detectors help companies comply with these regulations by ensuring that products are free from metal contaminants. As a result, metal detectors play a crucial role in detecting metal fragments or foreign objects entering into the food products during processing or packaging processes. For instance, in January 2022, U.S. Department of Agriculture launched Closer to Zero (C2Z) initiative in collaboration with Food and Drug Administration (FDA) to reduce and mitigate heavy metals including mercury, lead, and cadmium in foods consumed by infants and children. Thus, the food & beverage sector is subject to stringent regulations to prevent contamination and ensure consumer safety, resulting in market expansion.

Increasing adoption of metal detectors in pharmaceutical sector

The increasing adoption of metal detectors for quality control and maintaining safety standards in pharmaceutical sector is propelling the growth of the market. Metal contamination occurs in pharmaceutical products due the presence of metallic pieces or components such as fasteners, pins, buds, non-ferrous, or stainless-steel materials during the manufacturing process. Thus, metal detectors are used in pharmaceutical manufacturing processes to detect any metal fragments or contaminants in packaging materials, such as foil, blister packs, or containers. For instance, in May 2023, CASSEL Messtechnik GmbH launched Shark MultiSense metal detector with multi-frequency detection in pharmaceutical, food, chemicals & plastics industry. Analysis of market trends concludes that the rising need to maintain the overall quality of pharmaceutical products is driving the industrial metal detectors market demand.

Key Restraints :

High cost of investment in installation of industrial metal detectors

The high initial investment in the installation of metal detectors is restraining the growth of the market. Analysis of market trends concludes that the cost of purchasing and installing metal detection systems is a significant barrier, especially for small and medium-sized enterprises. Moreover, industrial metal detectors involve technical support, regular upgrades and repair services that add up to the overall costs of industrial metal detection systems. Therefore, the high initial investments for the detectors is hindering the expansion of the market.

Erratic generation of false alarms by industrial metal detectors

Industrial metal detectors produce false alarms due to vibration and electrical noise that destabilizes the magnetic fields in detection heads. The unstable magnetic fields result in inefficient detection of metal components. As a result, the detectors lead to false rejection and false acceptance of the contaminated products, resulting in poor quality of the food products. Analysis of market trends concludes that the limited adoption of the detectors due to occurrence of false alarms in food and pharmaceutical sector is hindering the growth of the market.

Future Opportunities :

Integration of industrial metal detectors with X-ray inspection technology

The integration of industrial metal detectors with inspection technologies such as X-ray inspection or vision systems presents potential opportunities for market proliferation during the forecast period. The integration of x-ray inspection is expected to enhance the detection capabilities of metal detectors allowing for simultaneous detection of metallic and non-metallic contaminants. For instance, in October 2021, Eagle PI. introduced generation of X-ray inspection software called TraceServer offering greater product traceability and ensuring overall quality assurance. Analysis of market trends concludes that the incorporation of X-ray inspection in metal detectors is emerging as one of many industrial metal detectors market opportunities that will drive market expansion during the forecast period.

Industrial Metal Detectors Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2017-2030 |

| Market Size in 2030 | USD 1,546.02 Million |

| CAGR (2023-2030) | 4.5% |

| By Product Type | Hand-Held/Portable, Conveyed Media, Gravity Fed Free Flowing, and Internal Pipeline |

| By Capability Type | Non-Ferrous, Non-Magnetic, and Hot Metal Detection |

| By End-User | Pharmaceutical, Food and Beverage, Mining, Textile, Chemicals, Plastics, and Rubber |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | CEIA, Easyweigh, Fortress Technology, Illinois Tool Works Inc., Loma Systems, Mettler-Toledo, Multivac Group, Nikka Densok, Nissin Electronics, Shanghai Techik, Thermo Fisher, WIPOTEC-OCS, Minebea Intec GmbH, CASSEL Messtechnik GmbH |

Industrial Metal Detectors Market Segmental Analysis :

By Product Type :

Based on the product type, the market is segregated into hand-held/portable, conveyed media, gravity-fed free flowing, and internal pipeline. In 2022, the Gravity-fed free-flowing segment accounted for the highest industrial metal detectors market share. Gravity-fed metal detectors are designed to detect metal contaminants in free-flowing materials such as chemicals or powdered materials. Gravity-fed metal detectors are highly stable and extremely sensitive, allowing for the reliable detection of very small contaminants. Moreover, gravity-fed metal detectors have the ability to reject contaminated products directly into a reject tank. Consequently, the high sensitivity of gravity-fed metal detectors is driving the proliferation of the market.

The conveyed media segment is anticipated to emerge as the fastest-growing segment during the forecast period. Conveyed media metal detectors are integrated into conveyor systems wherein the products or materials pass through the detector for metal detection. The conveyed media metal detectors have the ability to detect ferrous and non-ferrous components in food products, thereby ensuring the product quality. For instance, in September 2022, Innovative Magnetic Technologies, Inc. launched low-cost vibratory conveyors called Vibra-Sep that segregate ferrous tramp metal from the product stream prior to entering metal detection equipment. Moreover, the conveyers provide high sensitivity in metal detection by eliminating the chances of unnecessary tripping. Thus, the application of conveyed media metal detectors in food processing, packaging, and manufacturing process is propelling the industrial metal detectors market growth.

By Capability Type :

Based on the capability type, the market is trifurcated into non-ferrous, non-magnetic, and hot metal detection. The non-ferrous segment accounted for the largest revenue share of 39.45% in the year 2022. Non-ferrous metal detection refers to the detection of metals that lack iron, such as aluminum, copper, brass, and lead. Thus, the detectors are capable of detecting non-ferrous metals for quality control and safety purposes. For instance, in April 2023, Mettler Toledo launched a new update for M30 R-Series metal detection systems called the SENSE software for the detection of ferrous and non-ferrous metal contaminants in food products. Analysis of industrial metal detectors market trends concludes that the the detection of non-ferrous components in a wide variety of food and pharmaceutical products is accelerating the the market proliferation of the market.

The non-magnetic segment is anticipated to witness the fastest CAGR growth during the forecast period. Non-magnetic metal detection involves the identification and removal of metals that lack magnetic properties, such as rubber, plastic, wood, feather, and paper. Analysis of industrial metal detectors market trends concludes that the non-magnetic materials are extensively used in the food & beverage, pharmaceutical, and chemical industry during the production and packaging process. Consequently, the detectors employ advanced technologies, such as multi-frequency or dual-frequency systems to ensure accurate and reliable detection of non-magnetic components, resulting in market expansion.

By End-User :

Based on the end-user, the market is divided into pharmaceutical, food and beverage, mining, textile, chemicals, plastics, and rubber. The food & beverage sector accounted for the largest revenue share in the year 2022. The food and beverage sector extensively utilizes the detectors to prevent metal contamination in food products and packaging. Metal detectors are employed throughout the production process, from raw material inspection to final product packaging. For instance, in May 2023, Minebea Intec GmbH launched a new metal detector called Mitus offering high-precision inspection of foreign objects in food and beverage sector. Therefore, the rising need to ensure consumer safety and compliance with food safety regulations is driving the proliferation of the market.

The pharmaceutical sector is expected to register the fastest CAGR growth during the forecast period. Metal detectors play a crucial role in the pharmaceutical sector for identification and removal of metal contaminants in pharmaceutical products, packaging materials, and raw ingredients. Assessment of market trends indicates that the application of metal detector systems for monitoring of ferrous and non-ferrous contaminants in granulated or powder-form dosage forms is contributing to the expansion of the market.

By Region :

The regional segment includes North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

North America accounted for the largest revenue share in the year 2022. The rising need to maintain food security and safety standards is driving the growth of the market. Regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the Canadian Food Inspection Agency (CFIA) enforce strict guidelines regarding product quality and safety. The industrial metal detectors market analysis concluded that the detectors play a crucial role in meeting these regulatory standards, leading to increased adoption and market proliferation in the region. Manufacturers are producing metal detection systems with advanced technologies to ensure the safety of a wide variety of food products. For instance, in June 2020, Advanced Detection Systems Inc. launched new metal detection system called ProScan Conveyor to enhance detection levels and improve user interface for the inspection of metal contaminants in packaged and dry food products. Therefore, technological advancements in the region coupled with strict government regulations is driving the expansion of the regional market.

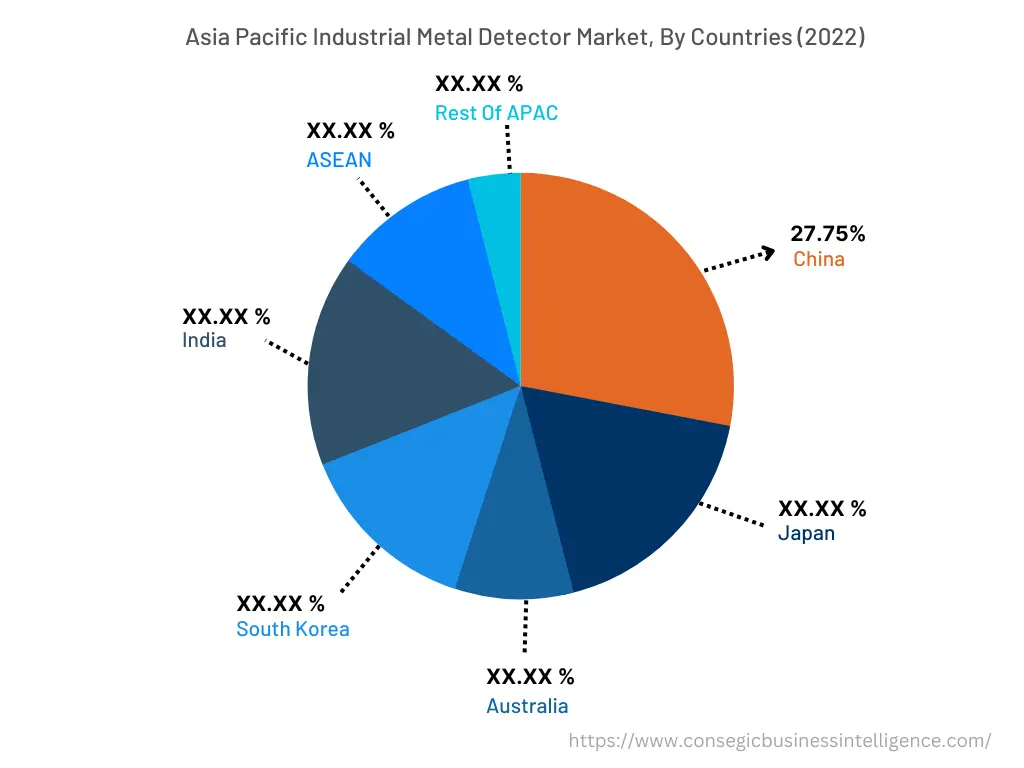

The Asia-Pacific region accounted for a revenue share of USD 313.35 million in 2022 and is expected to reach USD 450.66 million in 2030, registering a CAGR of 4.8%. Additionally, in the region, China accounted for the largest revenue share of 27.75% in the year 2022. Asia-Pacific region is a hub for majority of manufacturing industries including food and pharmaceutical sector. Assessment of market trends indicates that the demand for the detectors to ensure safety and security in the aforementioned industries is propelling the proliferation of the market. Moreover, the rising demand for packaged food and beverages among consumers due to the changing lifestyle is propelling the expansion of the market. Furthermore, the implementation of strict quality and safety standards in the food & beverage sector by the government is further contributing to the proliferation of the regional market.

Top Key Players & Market Share Insights :

The industrial metal detectors market is characterized by the presence of major players providing advanced metal detection systems to maintain safety and security standards. The major companies operating in the industrial metal detectors industry are adopting several business strategies in research and development, product innovation, and application launches that accelerate the growth of the industrial metal detectors market. Key players in the Industrial Metal Detectors market include-

- Fortress Technology

- Illinois Tool Works Inc.

- Loma Systems

- Mettler-Toledo

- Multivac Group

- Nikka Densok

- Nissin Electronics

Recent Industry Developments :

- In December 2022, Fortress Technology Inc. launched high performance food metal detector featuring four standard belts for inspection of confectionery, and packaged meats and fish products.

- In November 2020, SPH Engineering launched drone-integrated metal detection system for inspection of magnetic and non-magnetic items in limited access areas.

Key Questions Answered in the Report

What is Industrial Metal Detector? +

Industrial metal detector is a device used for identification and detection of ferrous and non-ferrous contaminants in food, pharmaceutical, and chemical industry.

What specific segmentation details are covered in the industrial metal detectors report, and how is the dominating segment impacting the market growth? +

By capability type segment has witnessed non-ferrous as the dominating segment in the year 2022, due to its ability to detect aluminium, copper, brass, and lead in food products.

What specific segmentation details are covered in the industrial metal detectors market report, and how is the fastest segment anticipated to impact the market growth? +

By end-user segment has witnessed pharmaceutical industry as the fastest-growing segment during the forecast period due to its ability to detect contaminants in pharmaceutical products, packaging materials, and raw ingredients.

Which region/country is anticipated to witness the highest CAGR during the forecast period, 2023-2030? +

Asia-Pacific region is expected to register fastest CAGR growth during the forecast period due to the growing manufacturing industry of food products in the region.