- Summary

- Table Of Content

- Methodology

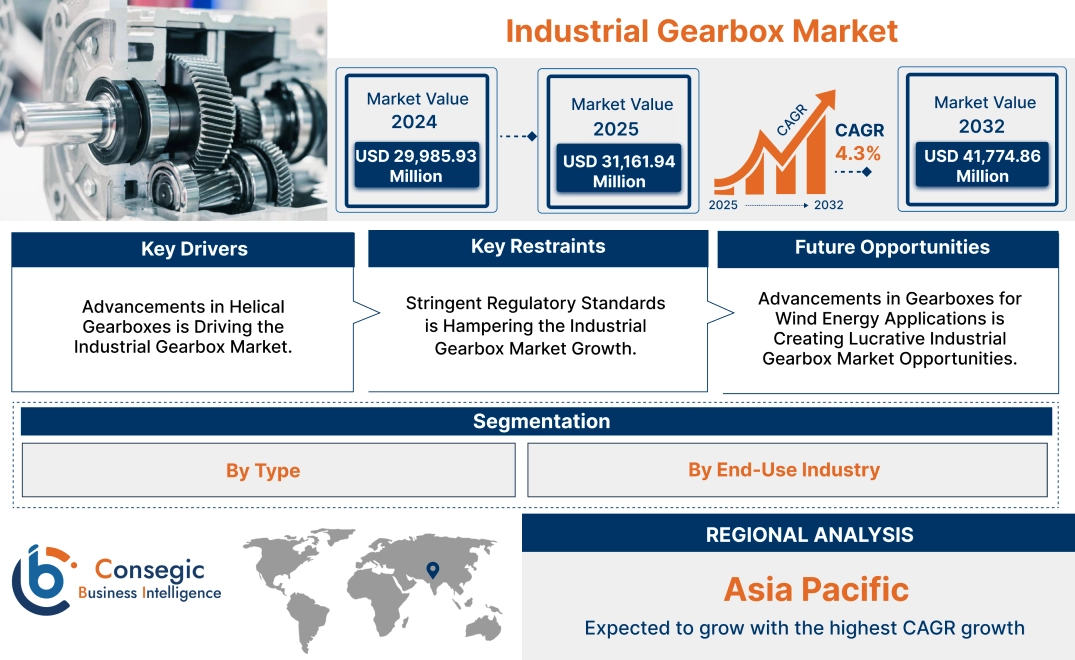

Industrial Gearbox Market Size:

Industrial Gearbox Market size is growing with a CAGR of 4.3% during the forecast period (2025-2032), and the market is projected to be valued at USD 41,774.86 Million by 2032 from USD 29,985.93 Million in 2024. Additionally, the market value for the 2025 attributes to USD 31,161.94 Million.

Industrial Gearbox Market Scope & Overview:

Industrial gear box is a device that alters the speed and torque output of a power source. The power source generally consists of electric motor or engine. Gearboxes achieve specific requirements of machines by using a system of gears with varying numbers of teeth. These teeth are arranged in different configurations. The primary advantages of using an industrial gearbox are the ability to optimize performance. Gearboxes also contribute to improved efficiency by allowing the power source to operate at its optimal speed range. The types of helical gearboxes, bevel gearboxes, worm gearboxes, planetary gearboxes, and others. The end-use industry for these gearboxes consists of energy & power, mining, construction, agriculture, automotive, manufacturing, and others.

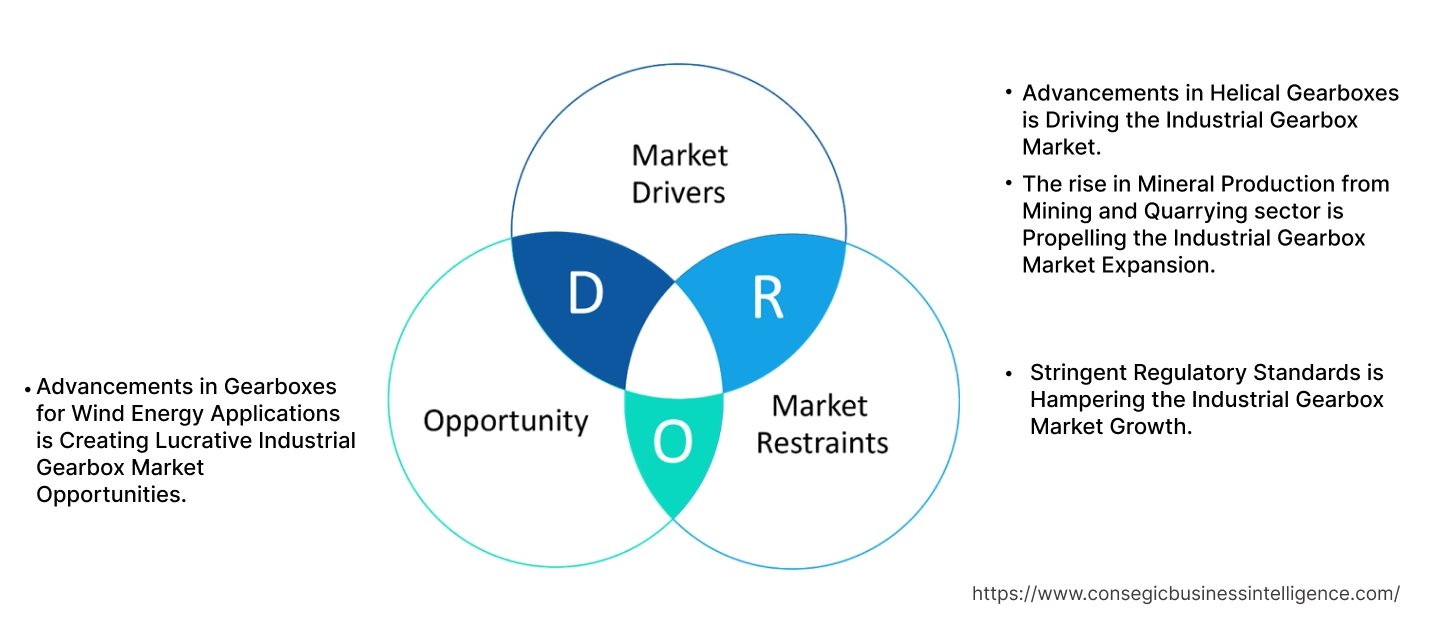

Key Drivers:

High Demand from Mining Industry to Drive Industrial Gearbox Market Growth.

A helical gearbox is a gear system that uses helical gears. The teeth are cut at an angle to the gear axis. Advancements in design, materials, and manufacturing processes are leading to helical gearboxes with improved performance characteristics. Innovations include optimized tooth geometry for smoother and quieter operation, enhanced materials for increased strength and durability, and more precise manufacturing techniques for greater efficiency. Novel helical gearboxes offer high torque to gear ratio.

For instance,

- In March 2023, Elecon introduced New EON. It is the latest addition to its EON gearbox line which consists of helical gearboxes. They are compact size and are highly efficient. They provide a high torque to gear ratio.

Thus, the development of novel gearboxes is driving the growth of the market.

The rise in Mineral Production from Mining and Quarrying sector is Propelling the Industrial Gearbox Market Expansion.

Mining and quarrying operations rely heavily on robust and powerful machinery, such as excavators, loaders, conveyors, crushers, and haul trucks, all of which require industrial gearboxes to function effectively. These gearboxes are essential for transmitting power, adjusting speed and torque, and enabling the heavy lifting and material handling necessary in these demanding environments. As requirement for minerals and raw materials rises, mining and quarrying activities intensify. This is leading to increased production volumes.

For instance,

- The data published by the India Brand Equity Foundation, states that the mineral production mining and quarrying sector in 2023 was 5.1% higher compared to the mineral production in 2022.

Hence, the rise in mining and quarrying activities influencing the use of gearboxes driving the industrial gearbox market expansion.

Key Restraints:

Stringent Regulatory Compliance to Hinder Industrial Gearbox Market Growth.

Stringent regulatory standards imposed by government bodies worldwide pose significant constraints in the market. These regulations, designed to protect the environment and public health. The manufacturing, application, and disposal of industrial gearboxes are subject to a variety of regulations concerning safety, environmental impact, and performance. Compliance with these standards involves substantial investments in research and development, testing, and certification processes. They add to the cost of gearbox production and potentially delaying product launches. Regulations related to material usage, noise emissions, and energy efficiency necessitate design modifications and the adoption of new technologies, further increasing costs. Thus, these factors hinder the development of the market.

Future Opportunities :

Development of Nitrate-free Industrial Explosives Systems to Create Lucrative Market Opportunities.

Wind turbines are a crucial component of renewable energy generation. They rely heavily on gearboxes to convert the relatively slow rotation of the turbine blades into the high-speed rotation required by the generator. Ongoing development efforts are leading to wind turbine gearboxes with improved efficiency, reliability, and durability. These advancements include innovations in gear materials, lubrication systems, and overall design, enabling gearboxes to withstand the demanding operating conditions of wind turbines, including fluctuating loads, extreme temperatures, and remote locations. The increasing size and capacity of wind turbines necessitate more powerful and sophisticated industrial gearboxes.

For instance,

- In February 2024, NGC introduced two energy wind energy gearboxes. They have 10MW front-end integrated 3P1H high-speed gearbox and the 20MW fully integrated transmission chain gearbox. It reaches a torque density of 230+ kNm/t. The new sealing structure greatly improves reliability and minimizes the risk of oil leakage.

Thus, advancement in gearbox for wind energy applications is creating lucrative industrial gearbox market opportunities.

Industrial Gearbox Market Segmental Analysis :

By Type:

Based on type, the market is categorized into helical gearboxes, bevel gearboxes, worm gearboxes, planetary gearboxes, and others.

Trends in the Type:

- The rise in the focus of high efficiency and precision influences the use of helical gearboxes.

- The development of advanced machinery requires high torque density. This influences the use of planetary gearboxes.

The helical gearboxes segment accounted for the largest market share in 2024.

- The helical gearboxes segment dominates the industrial gearbox market trends.

- Helical gearboxes are a type of mechanical power transmission device that utilizes helical gears to alter the speed and torque between rotating shafts.

- They have teeth that are cut at an angle to the gear axis, resembling a helix or spiral.

- These gearboxes have a smoother engagement which contributes to higher efficiency and reduced vibration.

- Helical gears have a greater contact area between teeth. This allows them to handle higher loads and transmit more power. It makes them suitable for heavy-duty applications.

- For instance, in August 2022, Dana Limited, introduced New Brevini EvoMax. It is a Helical and Bevel-helical gearbox range for or marine and offshore applications. The gearboxes are designed to provide higher torque, greater efficiency, and longer service.

- Thus, as per the market analysis, this use of helical gearboxes is driving the growth of the segment.

The planetary gearboxes segment is expected to grow at the fastest CAGR over the forecast period.

- Planetary gearboxes, also known as epicyclic gearboxes, are a type of gear system characterized by their unique arrangement of gears.

- The configuration allows for high torque-to-weight ratios, compact size, and efficient power transmission.

- Industrial planetary gearboxes are employed in applications requiring these characteristics, such as robotics, aerospace, wind turbines, and heavy machinery.

- Their ability to achieve significant speed reduction and torque multiplication within a relatively small footprint makes them advantageous in space-constrained environments.

- Additionally, the load is distributed evenly among the planet gears, contributing to increased durability and reduced wear.

- Thus, these factors are influencing the development of the segment.

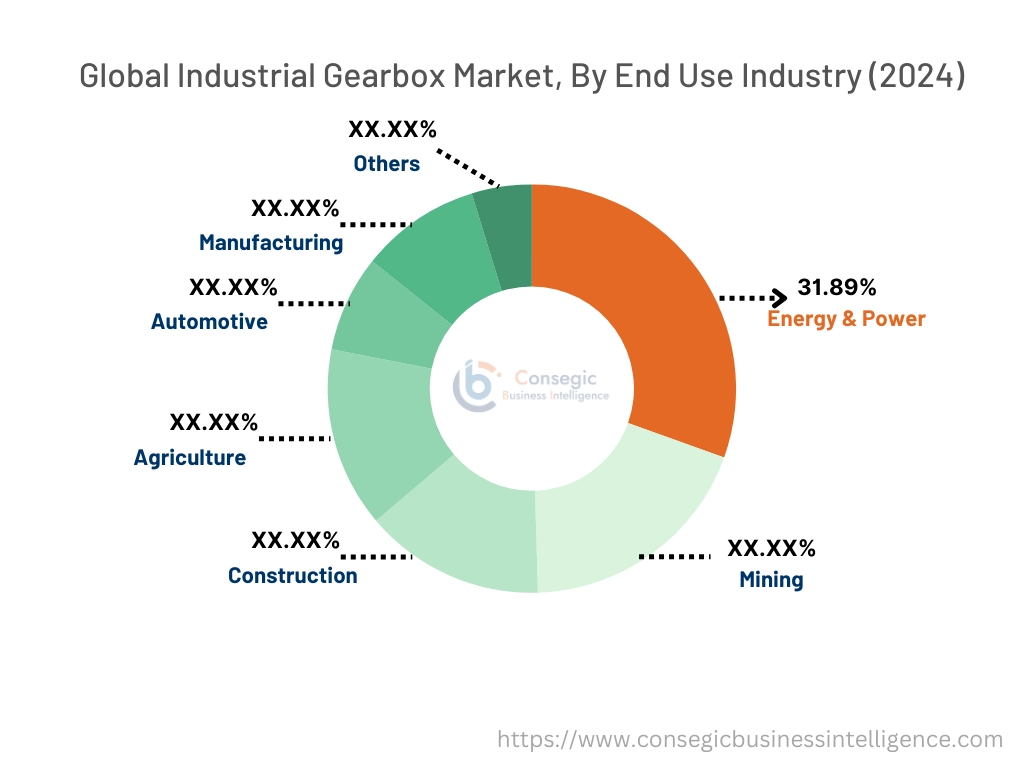

By End Use Industry:

Based on end use industry, the market is categorized into energy & power, mining, construction, agriculture, automotive, manufacturing and others.

Trends in the End Use Industry:

- There is a rise in the requirement for novel gearboxes with reduced friction and improved power transmission. They are crucial for maximizing energy output, especially in wind turbines.

- Increased use of lightweight and high-strength materials, such as composites and advanced alloys, to improve gearbox performance and reduce weight in various automotives such as EV’s.

The energy and power segment accounted for the largest market share of 31.89% in the year 2024.

- The energy and power segment dominates the industrial gearbox market trends.

- Power plants, whether conventional or renewable, rely on industrial gearboxes to efficiently convert mechanical energy into electrical energy.

- In conventional power plants, gearboxes are used in various equipment, including pumps, conveyors, and generators, ensuring smooth and reliable operation.

- Wind turbines use sophisticated gearboxes to transform the relatively slow rotation of the turbine blades into the high-speed rotation required by the generator to produce electricity.

- Manufacturers are introducing novel gearboxes for wind turbines.

- For instance, in 2024, NCG introduced a medium-speed gearbox for integrated wind turbine drivetrains. They are integrated with 20–22MW drivetrain.

- Thus, the rise in use of gearboxes in the energy and power sector is driving the industrial gearbox market demand.

The manufacturing segment is expected to grow at the fastest CAGR over the forecast period.

- Modern manufacturing processes are characterized by increasing automation and sophisticated machinery.

- They rely heavily on industrial gearboxes for efficient and precise power transmission.

- From robotic arms used in assembly lines to complex mechanisms within machine tools, gearboxes play a crucial role in controlling speed, torque, and motion.

- The ongoing trend of Industry 4.0, with its emphasis on smart factories and interconnected systems, further fuels the demand for advanced gearbox technologies capable of seamless integration and data-driven optimization.

- Based on the industrial gearbox market analysis, as manufacturers attempt to increase productivity, improve quality, and reduced downtime, the need for reliable and high-performance gearboxes continues to grow, in the coming years.

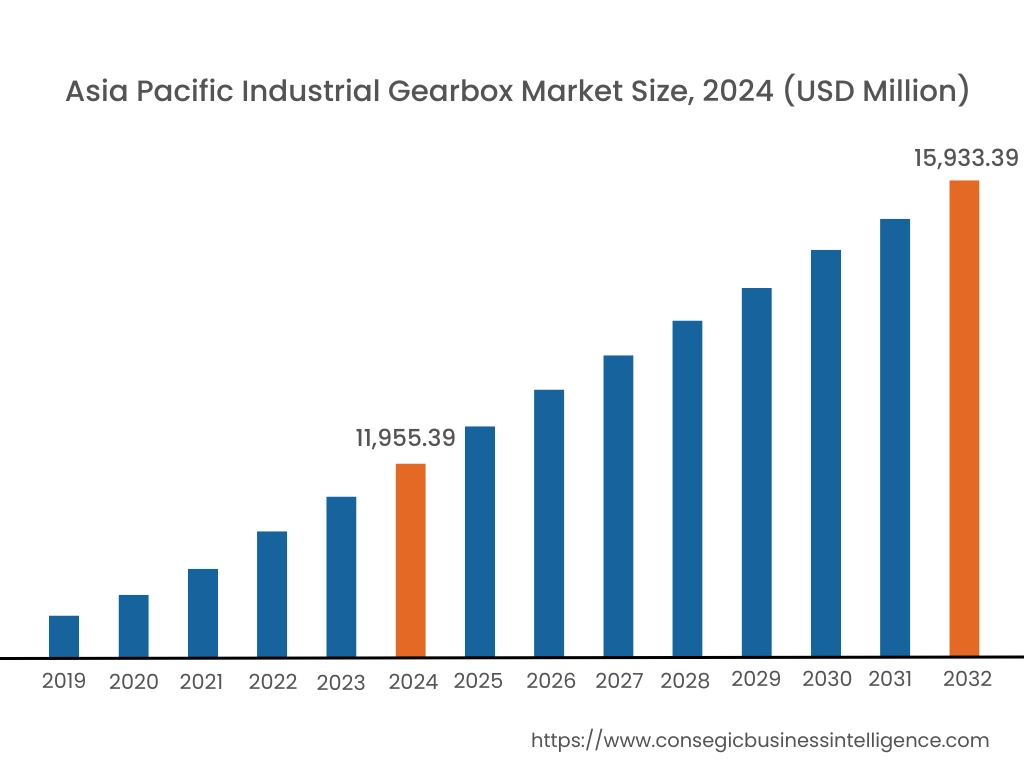

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

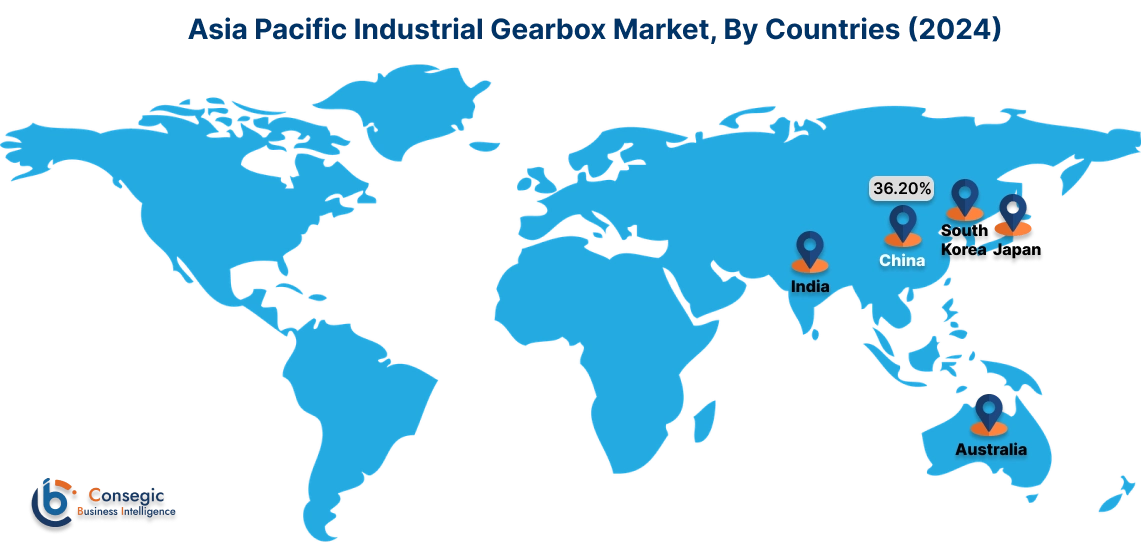

In 2024, Aisa Pacific accounted for the highest industrial gearbox market share at 39.87% and was valued at USD 11,955.39 Million and is expected to reach USD 15,933.39 Million in 2032. In Asia Pacific, China accounted for the highest market share of 36.20% during the base year of 2024. The Asia-Pacific region is rich in mineral resources, and rapid industrialization and infrastructure development in many countries within the region are fueling the trends for these raw materials. This increased requirement translates directly into expanded mining operations, which rely heavily on heavy-duty machinery equipped with industrial gearboxes. Excavators, loaders, conveyors, crushers, and other mining equipment all utilize robust gearboxes to transmit power, adjust speed and torque, and perform the demanding tasks required in mining environments. As mining activity grows in the Asia-Pacific region to meet global resource demands, the associated requirement for industrial gearboxes to support these operations is expected to remain strong.

For instance,

- According to the data published by the India Brand Equity Foundation, states that states that, in 2024, the mineral production by mining has increased by 8% compared to 2023.

Thus, as per the market analysis, the rise in mining activity is influencing the industrial gearbox industry in this region.

North America is experiencing the fastest growth with a CAGR of 5.4% over the forecast period. North America's diverse energy landscape, encompassing both traditional and renewable sources. They rely heavily on industrial gearboxes for various applications. In conventional power generation, gearboxes are essential components in equipment used for power transmission and distribution. However, the rapid growth of renewable energy, particularly wind power, is a major factor fueling the requirement for specialized gearboxes. Wind turbines, a key technology in the transition to cleaner energy, require robust and reliable gearboxes to convert the rotational energy of the blades into electricity. Thus, these factors are influencing the development of the market in this region.

Europe makes a significant contribution to the industrial gearbox market analysis. The European automotive sector market is mature, creating requirements for gear. From the machinery used in stamping and welding car bodies to robotic arms that assemble components, industrial gearboxes are essential for efficient and precise manufacturing. The growing trend of automation and the increasing complexity of modern vehicles, including electric and hybrid models, further drives the growth of sophisticated gearbox technologies. Thus, the industrial gearbox market growth is driven by the rise in the use of gearboxes for the automotive sector.

The Middle East and Africa (MEA) regions are witnessing notable industrial gearbox market demand characterized by significant potential. Increased investment in local manufacturing capabilities and a growing emphasis on industrial development are driving the trend for advanced gearbox technologies. Specifically, R&D initiatives targeting helical gearbox design, materials, and manufacturing processes are leading to improved performance, efficiency, and durability. Collaborations between research institutions, universities, and industrial players are fostering innovation and accelerating the development of customized gearbox solutions tailored to the specific needs of the Middle East & Africa market, thus driving the industrial gearbox market share in this region

Latin America is an emerging region with significant potential for innovation. Latin America's significant agricultural output relies on a variety of machinery, including tractors, harvesters, planters, sprayers, and irrigation systems. As the agricultural sector in Latin America modernizes and adopts more advanced technologies, the requirement for high-performance gearboxes increases. Factors such as expanding agricultural land, growing populations, and increasing requirement for food contribute to the growth of agricultural activities. As per the market analysis, this subsequently drives the need for agricultural machinery and, in turn, industrial gearboxes.

Top Key Players and Market Share Insights:

The global industrial gearbox market is highly competitive with major players providing precise products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Industrial Gearbox market. Key players in the Industrial Gearbox industry include-

- Elecon Engineering Company Limited (India)

- Nanjing High Speed Gear Manufacturing Co., Ltd. (China)

- Teksmithe Steel Solutions (India)

- Cone Drive (United States)

- Dana Brevini (Italy)

- Sumitomo Heavy Industries, Ltd. (Japan)

- Bonfiglioli S.P.A (Italy)

- NSK Ltd. (Japan)

- Triveni Engineering & Industries Ltd. (India)

- ZF Friedrichshafen AG (Germany)

Recent Industry Developments :

Product Launche:

- In February 2024, NGC introduced two energy wind energy gearboxes. They have 10MW front-end integrated 3P1H high-speed gearbox and the 20MW fully integrated transmission chain gearbox. It reaches a torque density of 230+ kNm/t. The new sealing structure greatly improves reliability and minimizes the risk of oil leakage.

Industrial Gearbox Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 41,774.86 Million |

| CAGR (2025-2032) | 4.3% |

| By Type |

|

| By End Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Industrial Gearbox market? +

In 2024, the Industrial Gearbox market is USD 29,985.93 Million.

Which is the fastest-growing region in the Industrial Gearbox market? +

North America is the fastest-growing region in the Industrial Gearbox market.

What specific segmentation details are covered in the Industrial Gearbox market? +

Type, and End Use Industry segmentation details are covered in the Industrial Gearbox market.

Who are the major players in the Industrial Gearbox market? +

Elecon Engineering Company Limited (India), Nanjing High Speed Gear Manufacturing Co., Ltd. (China), Sumitomo Heavy Industries, Ltd. (Japan) are some of the major players in the market.