- Summary

- Table Of Content

- Methodology

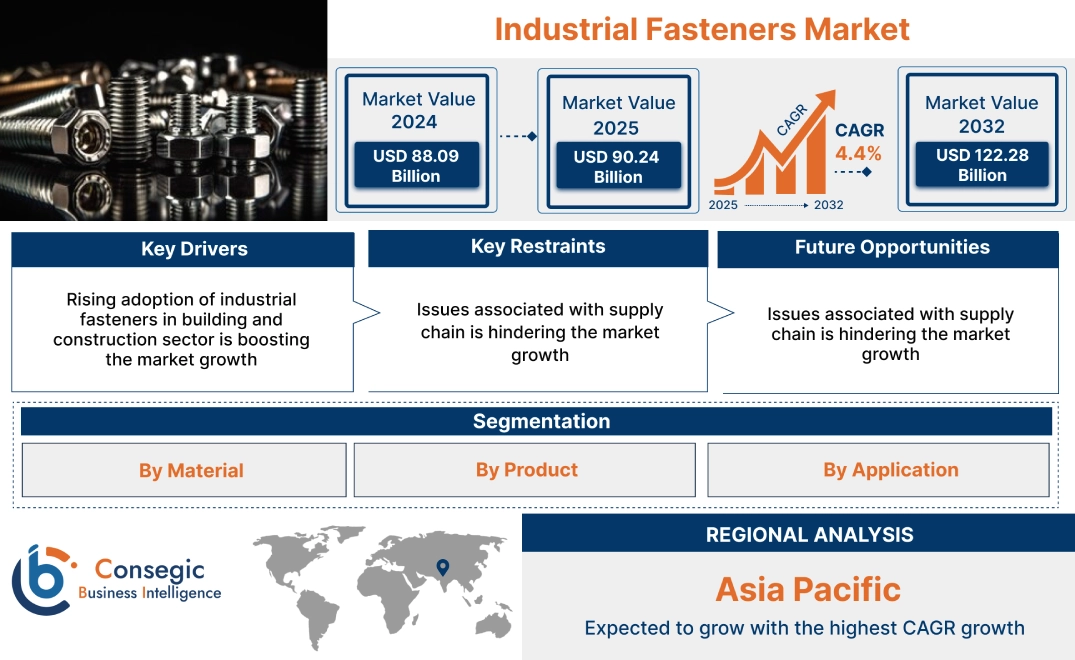

Industrial Fasteners Market Size:

Industrial Fasteners Market size is estimated to reach over USD 122.28 Billion by 2032 from a value of USD 88.09 Billion in 2024 and is projected to grow by USD 90.24 Billion in 2025, growing at a CAGR of 4.4% from 2025 to 2032.

Industrial Fasteners Market Scope & Overview:

Industrial fasteners are essential mechanical devices used to securely join two or more objects together, creating connections that can be permanent or semi-permanent. Fasteners are primary tools for mechanically joining components, whether it is securing a machine's parts or assembling a building. They play a critical role in ensuring the stability and strength of structures and machinery. Moreover, fasteners transfer loads between connected components, allowing structures and machines to withstand forces. They facilitate efficient assembly processes, enabling quick and easy connection of parts. Fasteners secure components, preventing movement or loosening under various conditions.

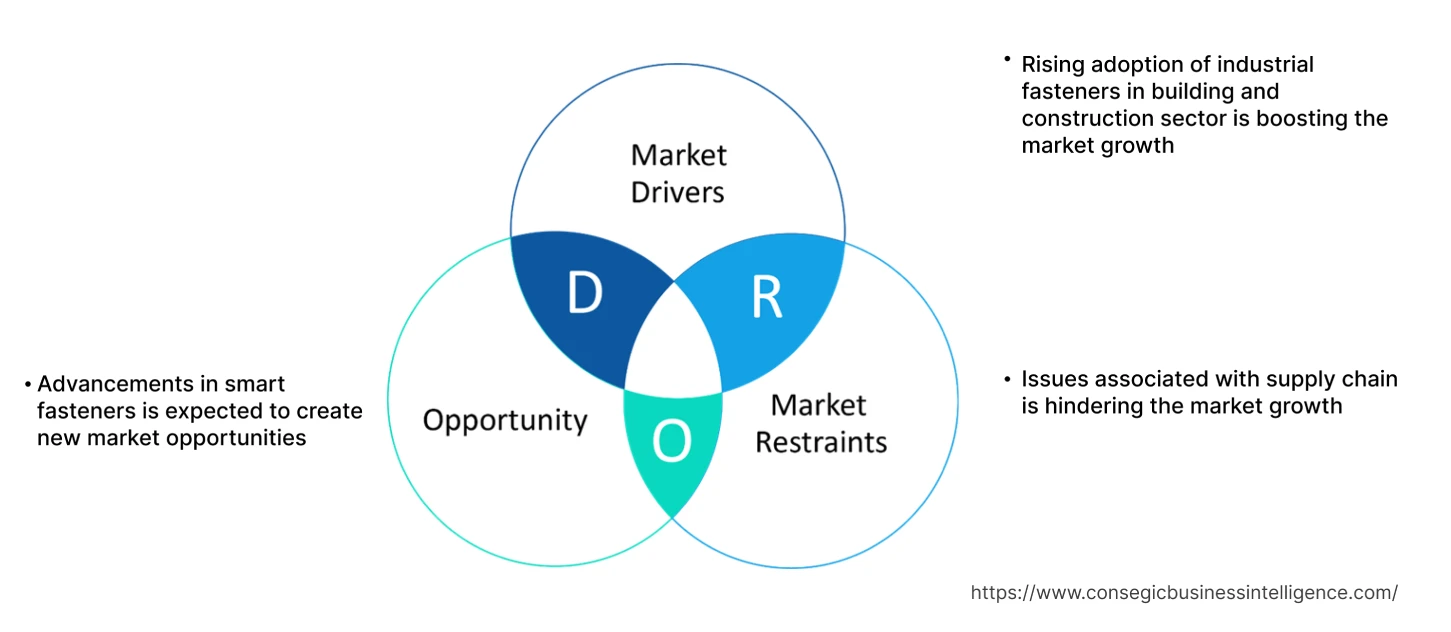

Key Drivers:

Rising adoption of industrial fasteners in building and construction sector is boosting the market growth

The use of industrial fasteners in building and construction sector is essential for joining structural components, ensuring stability, safety, and durability. They serve a variety of functions, from holding framing members together to securing fixtures and cladding. Fasteners such as bolts and screws are crucial for connecting beams, columns, and other load-bearing elements, ensuring the building's overall strength and stability. Moreover, properly installed and maintained fasteners minimize the risk of structural failure, protecting occupants and workers. High-quality fasteners that are resistant to corrosion and wear, contribute to the long-term longevity of a building.

- For instance, in January 2025, R&S Industrial Supplies acquired Salem, a construction and building materials and industrial fasteners distributor. The acquisition aims to optimize operations for improved customer service by merging the resources.

Thus, the aforementioned factors are boosting the adoption of fasteners, in turn driving the industrial fasteners market growth.

Key Restraints:

Issues associated with supply chain is hindering the market growth

Supply chain disruptions are significantly impacting the industrial fastener industry, leading to issues such as raw material shortages, logistics delays, and rising costs. Shipping delays and increased freight costs are making it difficult and expensive to deliver fasteners on time. Moreover, fluctuations in raw material prices, coupled with transportation costs, are increasing the overall cost of fasteners.

In addition, higher raw material and transportation costs can lead to higher prices for fasteners, which may affect project budgets. Thus, the market analysis shows that the aforementioned factors are restraining the industrial fasteners market demand.

Future Opportunities :

Advancements in smart fasteners is expected to create new market opportunities

Smart industrial fasteners are fasteners equipped with sensors and digital capabilities, allowing for real-time monitoring of their condition and the structural integrity of the components they secure. They measure parameters such as stress, temperature, and vibration, providing data for predictive maintenance and enhanced safety. Smart fasteners continuously monitor various parameters, providing engineers with a complete view of the fastener's condition. Early detection of issues enables timely intervention, improving safety in industries where reliability is crucial, such as aerospace or bridge construction.

- For instance, Hilti offers smart fasteners that enables unique identification and digital documentation on the worksite. The Tracefast technology from Hilti provides contractors with an easy-to-use and productive solution.

Thus, the ongoing advancements in smart fasteners are projected to drive industrial fasteners market opportunities during the forecast period.

Industrial Fasteners Market Segmental Analysis :

By Material:

Based on the material, the market is segmented into metal and plastic.

Trends in the Material:

- Rising adoption of metal fasteners for high strength and durability and improved resistance to movement is boosting the industrial fasteners market size.

- Increasing trend in adoption of plastic fasteners for lightweight construction, cost-effectiveness, corrosion resistance, and flexibility in design.

The metal segment accounted for the largest revenue share in the industrial fasteners market share in 2024.

- Metal fasteners are mechanical devices, like bolts, screws, nuts, and rivets, which join two or more objects together.

- They provide a secure and often reusable connection, essential in construction, manufacturing, and various other industries.

- Their functions include holding components together, distributing loads, and ensuring structural stability.

- Fasteners provide critical support and stability, ensuring the integrity of structures and machinery. Fasteners secure covers, panels, and other elements, preventing them from becoming loose.

- For instance, Bagadia Industrial Fasteners offers various metal fasteners in its product portfolio. The products include eye bolts, t bolts, lifting hooks, stainless steel bolts, shank hooks, stainless steel nuts, and others.

- Therefore, the wide spread adoption of metal fasteners is boosting the industrial fasteners market growth.

The plastic segment is expected to register the fastest CAGR during the forecast period.

- Plastic fasteners are versatile components used to join materials in various applications.

- Their primary functions include secure fastening, noise reduction, and electrical insulation, making them suitable for industries such as automotive, aerospace, and electronics.

- The cushioning and shock absorption properties of plastic fasteners make them effective in reducing noise and vibration at fixation points, enhancing comfort in electronic devices and appliances.

- Plastic fasteners offer excellent electrical insulation, preventing electrical shorts or corrosion in electronics and other electrical applications.

- Thus, the rising demand for plastic fasteners is expected to boost the industrial fasteners market trends during the forecast period.

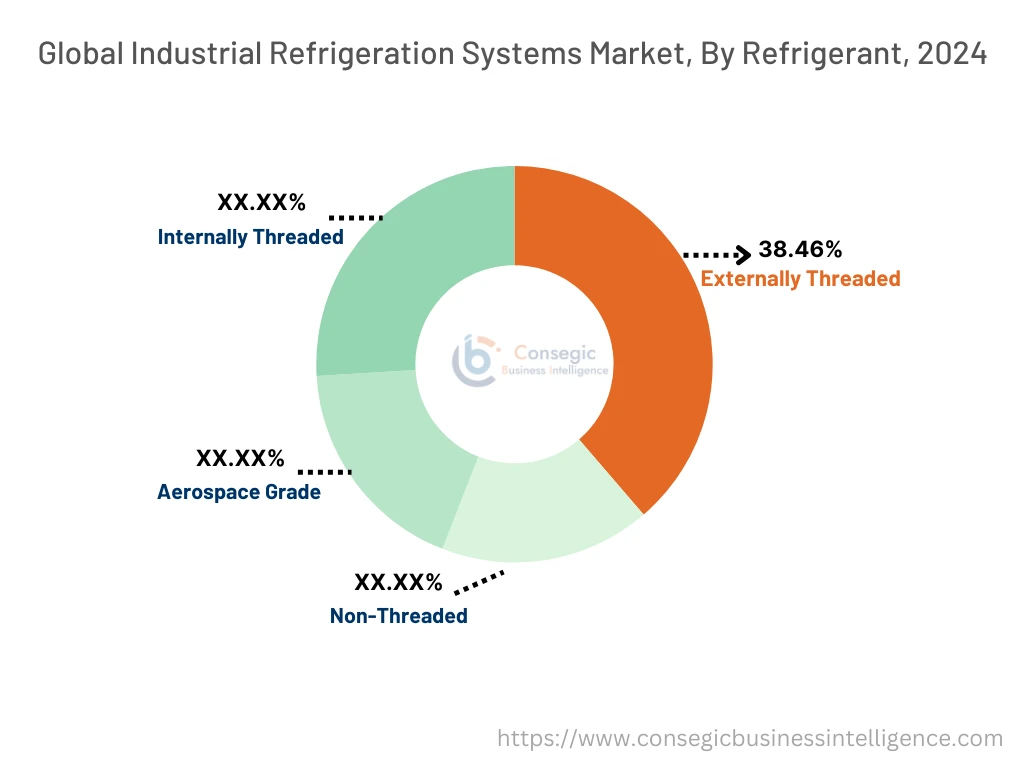

By Product:

Based on the product, the market is segmented into internally threaded, externally threaded, non-threaded, and aerospace grade.

Trends in the Product:

- Rising demand of non-threaded fasteners due to several benefits including quick installation, simplicity, low cost, and low profile is boosting the market growth.

- Increasing trend in adoption of internally threaded fasteners to offer strong, secure connections, particularly in situations where the host material may be weak or prone to stripping.

The externally threaded segment accounted for the largest revenue share of 38.46% in the market in 2024.

- Externally threaded fasteners, such as bolts and screws, are used to join components together in a way that allows easy assembly and disassembly.

- They function by coupling with internal threads in a nut or tapped hole to create a secure connection.

- The engagement of the external thread with an internal thread creates a friction-based joint that can withstand various loads and stresses.

- Externally threaded fasteners are available in various shapes, sizes, and materials, making them suitable for diverse applications.

- For instance, Facil offers various externally threaded fasteners in its product portfolio. The products vary in size, thread size, thread type, thread pitch and several other customizations.

- Therefore, the market trends analysis depicts that the aforementioned factors are boosting the industrial fasteners market demand.

The aerospace grade segment is expected to register the fastest CAGR during the forecast period.

- Aerospace graded fasteners are crucial for connecting aircraft components, ensuring structural integrity and safety during flight.

- These fasteners, such as bolts, nuts, and screws, are designed to withstand extreme conditions, including high pressures, temperature fluctuations, and vibrations.

- Their primary functions include transferring loads, securing connections, and facilitating assembly and maintenance.

- Aerospace fasteners join various parts of an aircraft, ranging from the fuselage to the wings and interior structures, ensuring a strong and reliable assembly.

- Thus, the market analysis shows that the rising adoption of aerospace grade fasteners is expected to boost the industrial fasteners market trends during the forecast period.

By Application:

Based on the application, the market is segmented into automotive, aerospace, building and construction, industrial machinery, home appliances, lawns and gardens, motors and pumps, furniture, and others.

Trends in the Application:

- Rising demand of fasteners in home appliances for increased durability, structural integrity, and reduced vibration.

- Increasing trend in adoption in fasteners in automobiles due to their strength, durability, and corrosion resistance is boosting the industrial fasteners market size.

The automotive segment accounted for the largest revenue share in the industrial fasteners market share in 2024.

- Fasteners are the primary means of mechanically joining and securing various components in a vehicle. This includes several automotive components ranging from the engine and transmission to the chassis and body panels.

- High-strength fasteners, like bolts and rivets, are crucial for providing the necessary support and strength to the vehicle's frame and other structural components.

- Fasteners, when properly engineered and installed, can contribute to crash safety by absorbing and dissipating energy during an impact, reducing the risk of injury to occupants.

- The use of fasteners ensures efficient assembly processes, allowing quick and secure joining of parts, and contributing to the overall durability and reliability of the vehicle.

- Therefore, the market analysis states that the aforementioned factors are boosting the industrial fasteners market expansion.

The aerospace segment is expected to register the fastest CAGR during the forecast period.

- Aerospace fasteners are critical for joining aircraft components and transferring loads, ensuring structural integrity and safety during flight.

- They are designed to withstand extreme conditions, including aerodynamic forces, temperature fluctuations, and potential corrosion.

- These specialized fasteners are used in various parts of an aircraft, including the fuselage, wings, and flight control surfaces.

- Thus, the market analysis depicts that the aforementioned factors are expected to boost the industrial fasteners market opportunities during the forecast period.

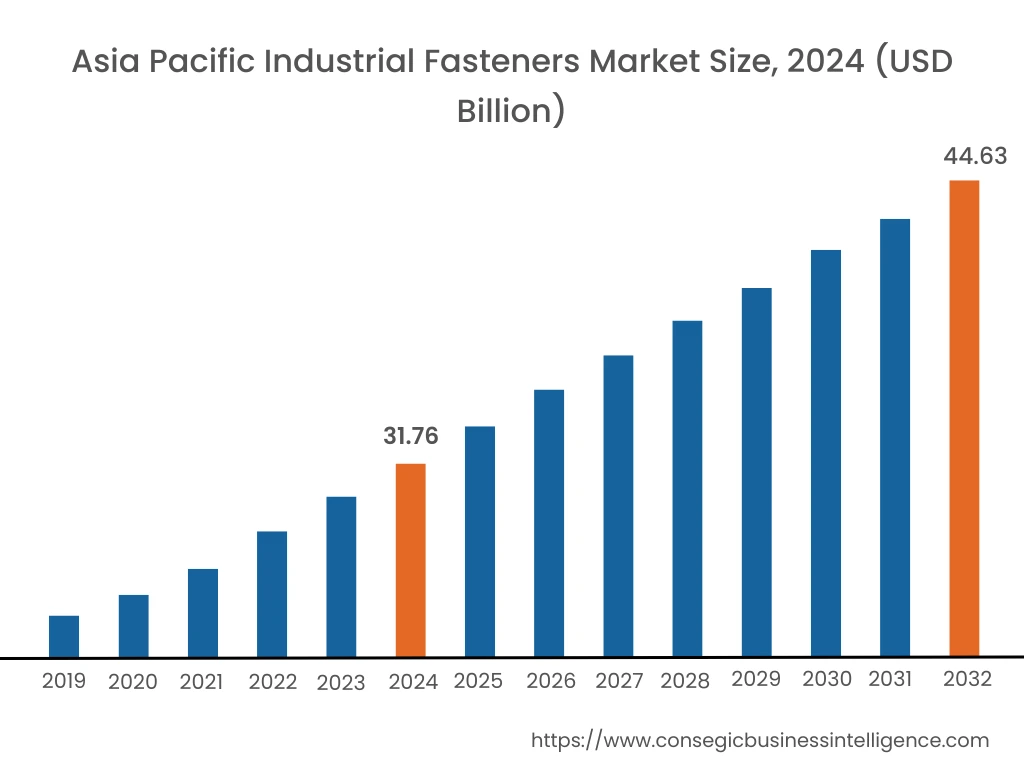

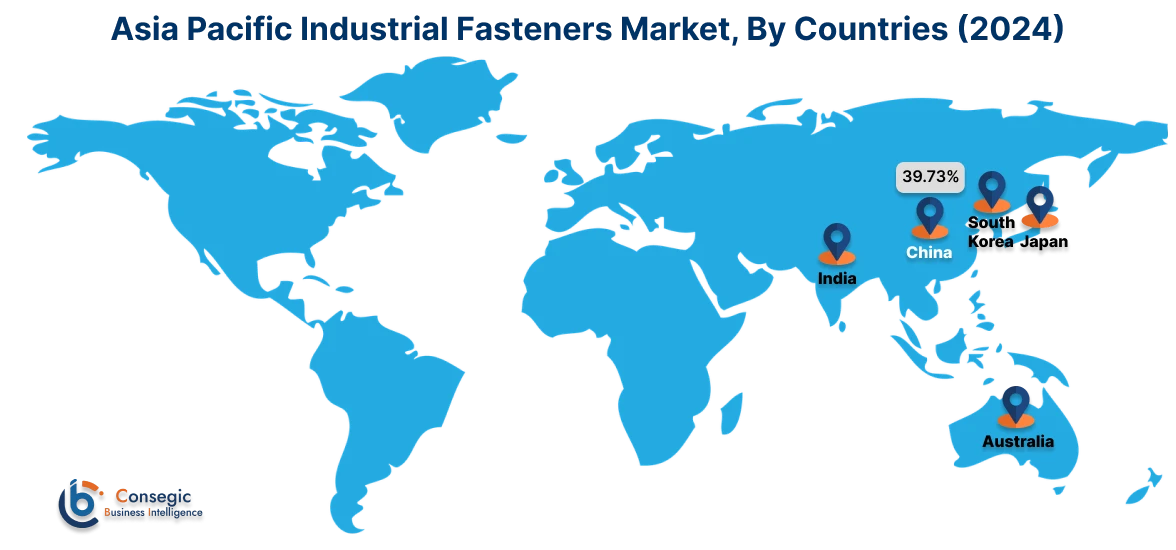

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

Asia Pacific region was valued at USD 31.76 Billion in 2024. Moreover, it is projected to grow by USD 32.57 Billion in 2025 and reach over USD 44.63 Billion by 2032. Out of this, China accounted for the maximum revenue share of 39.73%. The market is driven by wide spread, well-established manufacturing, automotive, and construction industries in the Asia Pacific region. Moreover, the rising government investments in infrastructure development, housing projects, and smart city initiatives are boosting the industrial fasteners market expansion.

- For instance, in the Union Budget 2025-26, India allocated a budget of USD 128.64 billion for infrastructure development, accounting for 3.1% of the total GDP. Thus, the rising investments in infrastructure development and construction activities is boosting the market demand.

North America is estimated to reach over USD 34.56 Billion by 2032 from a value of USD 25.03 Billion in 2024 and is projected to grow by USD 25.63 Billion in 2025. The industrial fasteners market analysis shows that the market in North America is primarily growing due to wide applications of fasteners in industries including aerospace and industrial machinery among others.

- For instance, in April 2025, NAFCO launched aerospace manufacturing facility worth USD 40 million. NAFCO has expertise in precision machining component and aerospace fasteners.

The industrial fasteners market analysis shows that in Europe, the market is primarily driven by emerging aerospace and automotive industries, leading to the adoption of fasteners, thereby boosting the market growth. In Latin America, Middle East, and Africa, the market growth is primarily due to rising urbanization, leading to adoption of fasteners in the construction of smart cities, development projects, and others.

Top Key Players and Market Share Insights:

The industrial fasteners industry is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global industrial fasteners market. Key players in the industrial fasteners industry include -

- Acument Global Technologies, Inc. (United States)

- ATF, Inc. (United States)

- Birmingham Fastener and Supply, Inc. (United States)

- Dokka Fasteners A S (Norway)

- Eastwood Manufacturing (United States)

- Elgin Fastener Group LLC (United States)

- Hilti Corporation (Liechtenstein)

- Illinois Tool Works, Inc. (United States)

- LISI Group - Link Solutions for Industry (France)

- Manufacturing Associates, Inc. (United Kingdom)

- MW Industries, Inc. (United States)

- Nifco Inc (Japan)

- SESCO Industries, Inc. (United States)

- Slidematic (United States)

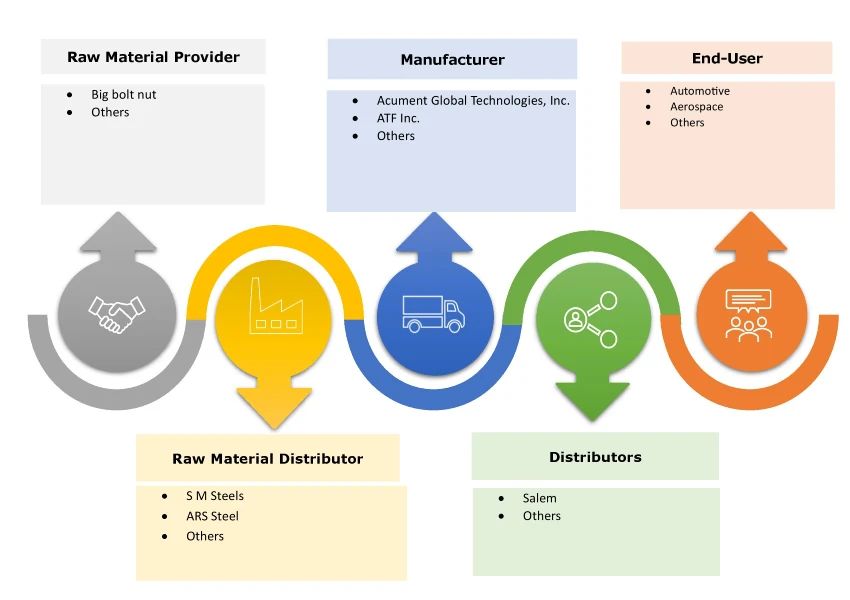

Industrial Fasteners Market Ecosystem:

Industrial Fasteners Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 122.28 Billion |

| CAGR (2025-2032) | 4.4% |

| By Material |

|

| By Product |

|

| By Application |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the industrial fasteners market? +

Industrial Fasteners Market size is estimated to reach over USD 122.28 Billion by 2032 from a value of USD 88.09 Billion in 2024 and is projected to grow by USD 90.24 Billion in 2025, growing at a CAGR of 4.4% from 2025 to 2032.

What are the major segments covered in the industrial fasteners market report? +

The segments covered in the report are material, product, application, and region.

Which region holds the largest revenue share in 2024 in the industrial fasteners market? +

Asia Pacific holds the largest revenue share in the industrial fasteners market in 2024.

Who are the major key players in the industrial fasteners market? +

The major key players in the market are Acument Global Technologies, Inc. (United States), ATF, Inc. (United States), Birmingham Fastener and Supply, Inc. (United States), Dokka Fasteners A S (Norway), Eastwood Manufacturing (United States), Elgin Fastener Group LLC (United States), Hilti Corporation (Liechtenstein), Illinois Tool Works, Inc. (United States), LISI Group - Link Solutions for Industry (France), Manufacturing Associates, Inc. (United Kingdom), MW Industries, Inc. (United States), Nifco Inc (Japan), SESCO Industries, Inc. (United States), and Slidematic (United States).