- Summary

- Table Of Content

- Methodology

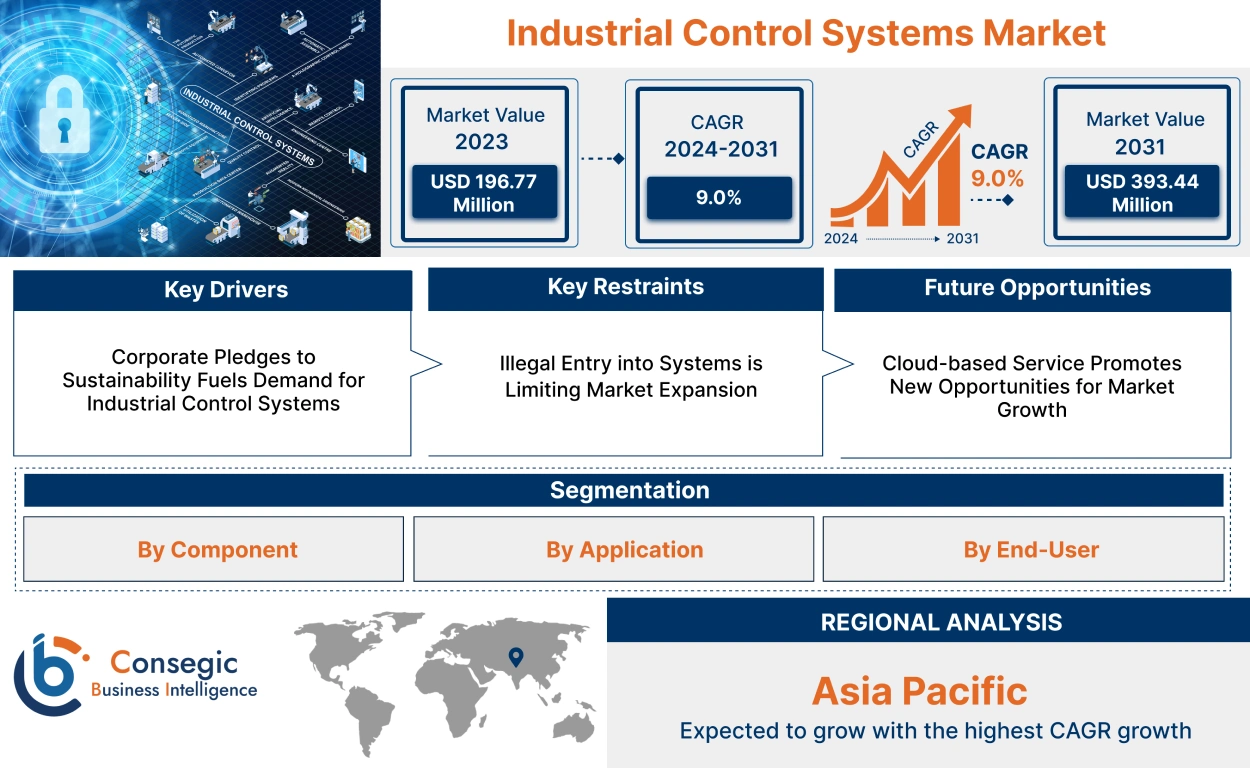

Industrial Control Systems Market Size:

Industrial Control Systems Market size is estimated to reach over USD 393.44 Billion by 2031 from a value of USD 196.77 Billion in 2023 and is projected to grow by USD 211.07 Billion in 2024, growing at a CAGR of 9.0% from 2024 to 2031.

Industrial Control Systems Market Scope & Overview:

Process control systems known as Industrial Control Systems (ICS) facilitate the management, control, and supervision of industrial processes in sectors such as manufacturing, power generation, and transportation. Additionally, these systems incorporate real-time process monitoring, automated control, process optimization, and safety management features. Through the integration of hardware and software components, ICSs are tailored to specific sector requirements. Furthermore, the advantages include increased efficiency, lowered operational costs, enhanced safety, and improved productivity, as well as the added benefit of remote monitoring and control. Lastly, the growing need for automation offers improved efficiency, cost reduction, and enhanced safety, and serves as a key driving factor for the market.

Industrial Control Systems Market Insights:

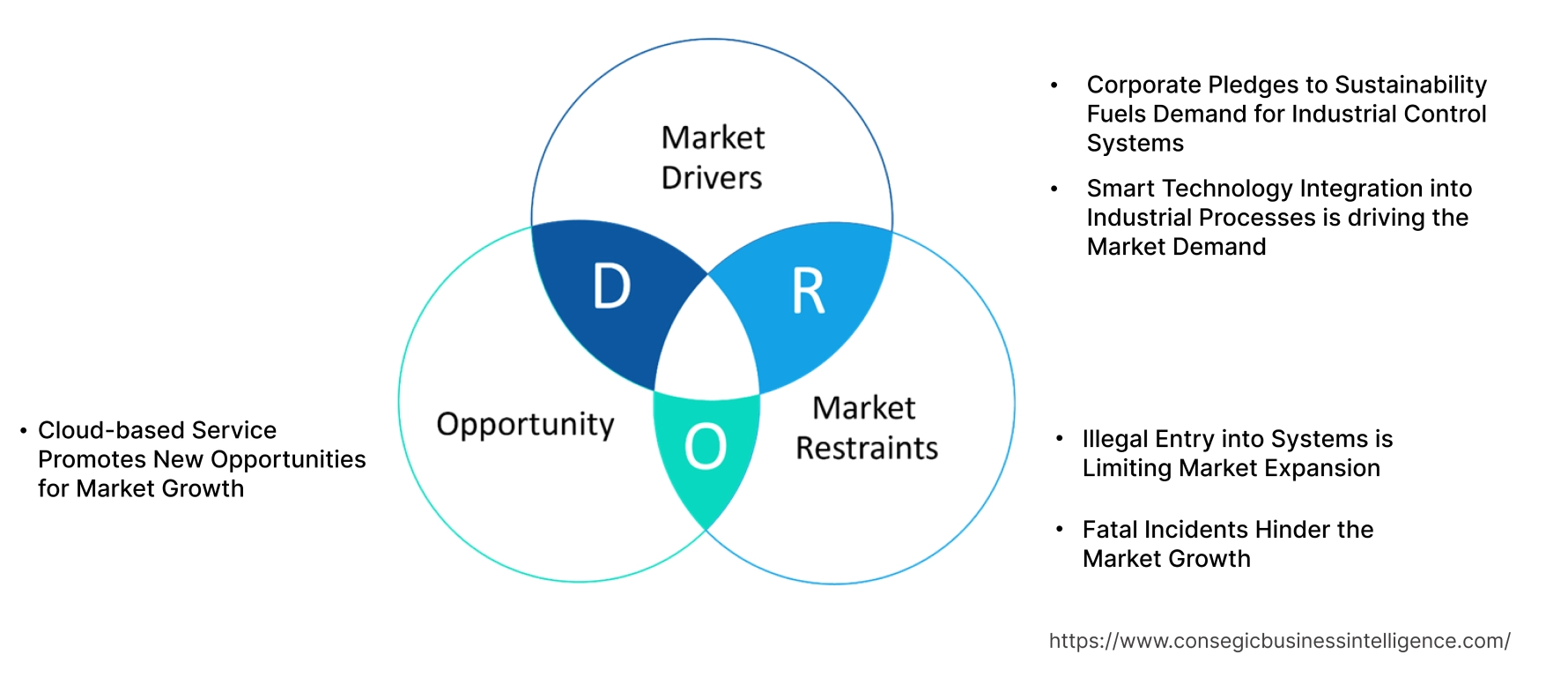

Key Drivers:

Corporate Pledges to Sustainability Fuels Demand for Industrial Control Systems

The increased demand for ICS is being driven by various industries aiming to reduce energy consumption and carbon emissions. This surge is attributable to both regulatory changes and corporate pledges to sustainability. Governments around the globe are implementing rules to decrease greenhouse gas emissions, like India's proposed regulations requiring industries to use a minimum amount of renewable energy. These rules are motivating industries to embrace advanced technologies such as ICS to enhance energy utilization. The growing emphasis on decarbonization is leading industries to invest in technologies that enhance operational efficiency and sustainability.

- In July 2023, Rockwell Automation, a global leader in industrial automation and digital transformation, published a report called "Five Key Operational Pathways to Accelerate Industrial Decarbonization." The report underscores the considerable challenge that businesses encounter when trying to reconcile profitability with decarbonization without any adverse effects.

Industrial control systems are increasingly in demand due to growing regulatory pressures and corporate sustainability efforts, as industries aim to decrease energy usage and cut down on carbon emissions.

Smart Technology Integration into Industrial Processes is driving the Market Demand

Companies in various sectors are making significant investments in cutting-edge technologies like data analytics, PLC, DCS, SCADA Systems, and others. These technologies enable the real-time supervision, management, and enhancement of industrial operations. They are instrumental in effectively regulating energy usage and contribute significantly to the efficient and safe operation of equipment components. This development is indicative of the broader movement toward digital transformation in the industrial domain, where data-centric insights and automation play pivotal roles.

- In September 2023, IOTech announced a strategic alliance with Advantech, a leading supplier of industrial IoT devices and automation technology. This joint effort is designed to provide advanced data processing solutions for intelligent manufacturing and industrial automation. Through this partnership, a new collection of combined edge hardware and software solutions will be developed, allowing manufacturers to streamline the exchange of data between machinery and control systems.

Therefore, as more industries adopt smart technologies, the demand for control systems is expected to rise.

Key Restraints :

Illegal Entry into Systems is Limiting Market Expansion

These systems play a vital role in overseeing different industrial operations, and any unauthorized entry could cause significant interruptions. These systems are frequently attacked by cyber-attacks, causing operational shutdowns, financial damages, and sometimes even possible danger to human life in specific sectors.

- In October 2023, BitSight discovered nearly 100,000 vulnerable ICSs globally, owned by various organizations. These exposed systems could potentially be exploited by attackers to gain control over critical infrastructure, including power grids, traffic lights, security systems, water systems, and more.

Therefore, the threat of unauthorized access not only poses a security risk but also hinders the adoption of systems by industries, thereby impacting market development.

Fatal Incidents Hinder the Market Growth

Control systems are essential to various industries and it manages everything from power generation to water treatment. However, when these systems fail or are compromised, the consequences are severe, leading to operational disruptions, financial losses, and in worst-case scenarios, fatal accidents. These incidents not only impact the immediate operations but also raise concerns about the safety and reliability of these systems, which discourage potential customers and slow down the market.

- In December 2022, a severe incident took place at Valmet's factory in India, resulting in the tragic death of a contractor's employee and injuries to two Valmet employees. Valmet manufactures flow control equipment at the Ambernath factory and employs around 100 people.

Therefore, the aforementioned issues hamper the industrial control systems market growth.

Future Opportunities :

Cloud-based Service Promotes New Opportunities for Market Growth

Cloud services enable collaboration across various manufacturing plants in different regions and there is a rising adoption in the industrial sector. There's also a rising demand for cloud-based services in OT environments as these services help organizations reduce costs, improve security, achieve sustainability, and leverage the benefits of digitalization.

- In June 2024, SUPCON launched the Universal control system (UCS) which revolutionizes the concept of industrial control systems and overcomes the traditional DCS technology. UCS architecture is software-defined, totally digitalized, and enabled with the cloud-based control system.

The growing adoption of cloud-based services and the increasing need for industrial automation in turn promote the industrial control systems market during the forecast period.

Industrial Control Systems Market Segmental Analysis :

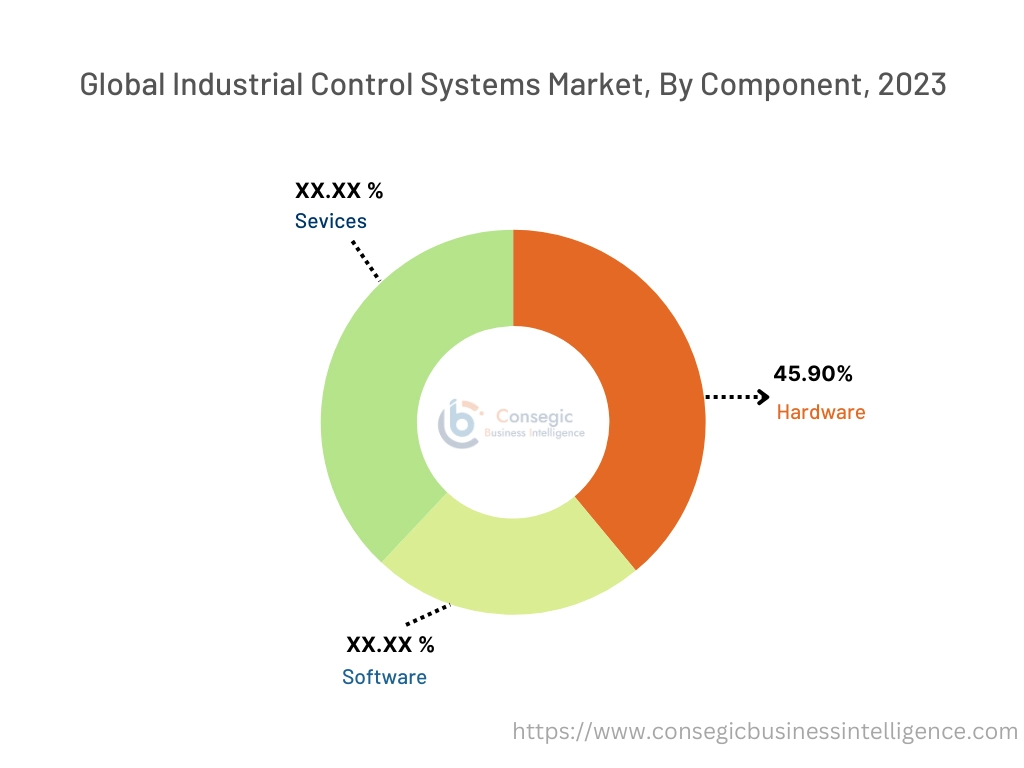

By Component:

Based on the component, the market is segmented into Hardware, Software, and Service.

Trends in the Component:

- Implementation of advanced process control software to optimize industrial processes by adjusting control parameters in real-time based on data analysis.

- This systems help in data analysis and helps to predict and perform maintenance before equipment failure occurs.

The hardware segment accounted for the largest revenue share of 45.90% in the year 2023 and is anticipated to register the fastest CAGR growth during the forecast period.

- The hardware segment of these control systems includes Programmable Logic Controllers (PLC), Intelligent Electronic Devices (IED), Remote Terminal Units (RTUs), Distributed Control Systems (DCS), Human-Machine Interface (HMI), Supervisory Control and Data Acquisition (SCADA). The surge in hardware drives industries to heavily invest in control systems to enhance efficiency, productivity, and security.

- Furthermore, as per the analysis, the rapid adoption of the Industrial Internet of Things (IIOT) and the preference for automated and control systems have fueled the market development for hardware components such as Distributed Control Systems (DCS).

- In February 2023, ABB introduced its latest ABB Ability Symphony Plus distributed control system (DCS) which is aimed at accelerating digital transformation in process automation.

- Thus, the hardware segment is driving the industrial control systems market trends due to the adoption of IIOT and industrial robots.

By Application :

Based on the application, the market is segmented into Manufacturing & Production Processes, Extraction & Pipeline Maintenance, Monitoring & Controlling, Safety & Security, Power Generation & Distribution, Robotics, and Others.

Trends in the Application:

- There is a growing trend towards the integration of robots on shop floors which are named cobots that work alongside human operations, enhancing productivity and safety.

The manufacturing & production process segment accounted for the largest revenue share in the year 2023 and is anticipated to register the fastest CAGR growth during the forecast period.

- This system is used in the manufacturing & production process to regulate the behavior of network connections, hardware, and software to support vital infrastructure such as machinery and equipment used in the production process. These systems need to work in synchrony for effective production.

- Real-time data obtained from connected industrial equipment and machinery is crucial for the adoption of systems like SCADA, DCS, and PLC, enabling predictive and prescriptive decision-making.

- In February 2024, Rockwell Automation, announced a multi-year partnership with Italy's Prometeon Tyre Group. The collaboration aims to deploy its Manufacturing Execution System (MES) for comprehensive digital integration across all of Prometeon Tyre Group's global facilities and boost digitalization strategy, enhancing manufacturing efficiency, sustainability, and technological advancement across its facilities in Italy, Turkey, Egypt, and Brazil.

- These collective factors contribute to the anticipated evolution of the manufacturing & production process segment in the industrial control systems market opportunities.

By End-User:

Based on End-user, the market is segmented into Automotive, Oil and Gas, Chemical and Petrochemical, Energy & Utility, Food and Beverage, Metals and Mining, Water and Wastewater Management and others.

Trends in the End-User:

- Food and beverage manufacturers are adopting these control systems to optimize their processes, improve efficiency, and ensure product quality and safety due to the growing need for processed food, coupled with the rising inclination towards automation.

The automotive segment accounted for the largest revenue share in the year 2023.

- Automotive segment is deploying industrial control systems in their operations to increase productivity and reduce production costs.

- The advent of Industry 4.0 and digital twin technology which is a system that replicates the physical system in the digital realm and emerges as an effective method to safeguard control systems from cyber threats has resulted in the rapid adoption of this advancement in the automotive sector.

- In car manufacturing, these systems accumulate facts, process records, and execute real-time management features from sensors, actuators, microprocessors, and communication networks.

- The growing cost of labor and the intense pressure automotive manufacturers face to meet deadlines have led to increased use of control systems in the automotive sector.

- In May 2023, Altair conducted a survey that revealed that digital twin technology is being widely adopted in the automotive sector as a strategy for achieving sustainability goals. The survey, which involved over 2,000 professionals from various industries across 10 countries, found that 92% believe digital twins contribute to creating more sustainable products and processes.

- These factors collectively contributed to the automotive segment accounting for the largest revenue in the global industrial control systems market share in 2023.

The oil and gas segment is anticipated to register the fastest CAGR growth during the forecast period.

- These control systems in the oil & gas sector employ remote terminal units (RTU) to collect and analyze raw data fed from sensors and equipment.

- In the oil & gas sector maintaining flow is a crucial aspect and this control system helps in managing the pressure, flow, and meter gauge.

- Additionally, as per the analysis, ongoing utilization and improvement of oil and natural gas facilities and storage activities due to the rising need for natural gas in various applications are also contributing to the industry's development.

- According to Emerson, its industrial automation and control solutions, certified by ATEX and UL-HAZLOC, empower users to manage extensive data sets both onshore and offshore. Integrated PACEdge and Linux platforms cater to a broad spectrum of needs, including wellheads, well pads, pipelines, terminal and storage facilities, remote monitoring, and refinery machinery controls.

- Therefore, the ongoing utilization and improvement of oil and natural gas facilities and storage activities are anticipated to boost the market during the forecast period.

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

North America is estimated to reach over USD 137.71 Billion by 2031 from a value of USD 68.85 Billion in 2023 and is projected to grow by USD 73.86 Billion in 2024. The industrial control systems market growth is mainly driven by its deployment in oil & gas, energy and utilities, and manufacturing and other industries.

- In January 2023, Allied Electronics & Automation, a subsidiary of the globally recognized omni-channel solutions provider, RS Group plc stands as the leading authorized distributor of industrial control equipment in North America. They offer an extensive range of over 197,000 products specifically designed for optimization in industrial control systems.

Furthermore, trends including increased automation in various industries, advancements in technology such as cloud-based service in control systems and IIOT, and the need for efficient process control are projected to drive the market in North America during the forecast period.

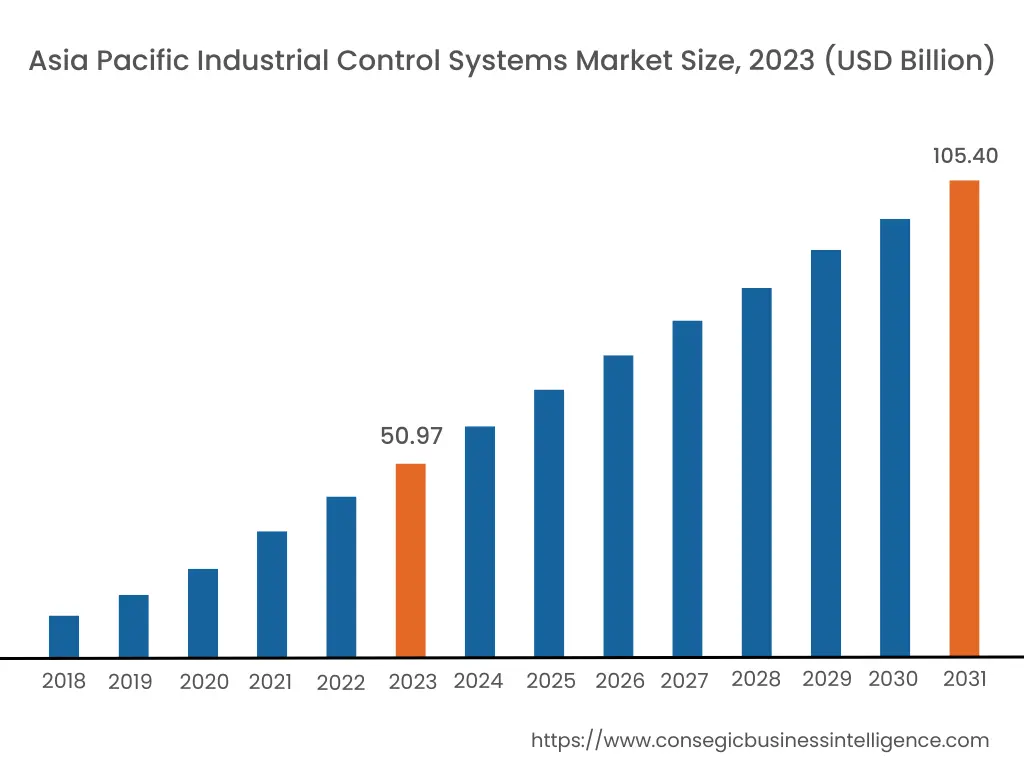

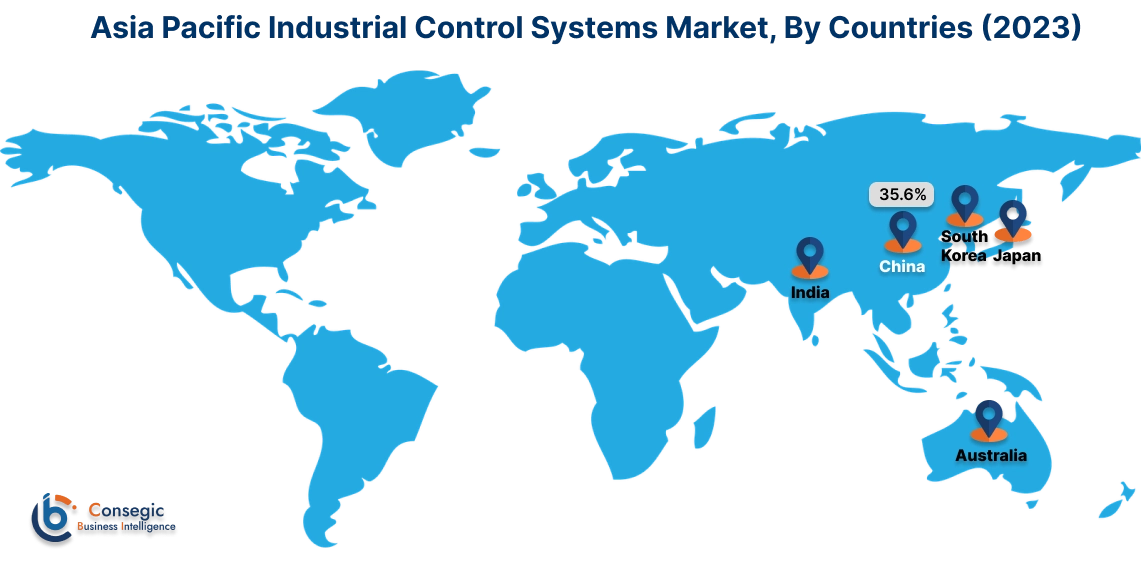

Asia Pacific region was valued at USD 50.97 Billion in 2023. Moreover, it is projected to grow by USD 54.82 Billion in 2024 and reach over USD 105.40 Billion by 2031. Out of this, China accounted for the maximum revenue share of 35.6%.

The market has lucrative prospects due to the growing urbanization and industrialization of the Asia-Pacific region. Also, the advancement of smart production lines and Industry 4.0 is driving the industrial control systems market trend.

- In March 2024, the CUBIC product line was regionally launched for Rockwell Automation, Inc. CUBIC serves fast-growing markets like renewable energy, mining, data centers, chemicals, and food & beverage, as well as infrastructure in the Asia Pacific region with IEC-61439 compliant modular enclosure systems for power and electric panels.

As per the industrial control systems market analysis, Europe is anticipated to observe huge progress that is supported by rising industrial automation techs like SCADA or PLC. Increasingly manufactured goods and energy production agencies provide an increasing need for industrial control systems market opportunities throughout the area.

The market for industrial control systems in the Middle East & Africa is on a path of gradual advancement, motivated by various trends such as greater infrastructure development and the growth of smart metropolitan areas which are encouraging industrial control systems market demand, especially in countries like Saudi Arabia, UAE and South Africa.

The increasing use of IoT and machine-to-machine technologies in numerous areas such as transport, chemicals, and agriculture across Latin America particularly in Brazil, Argentina, and Mexico.

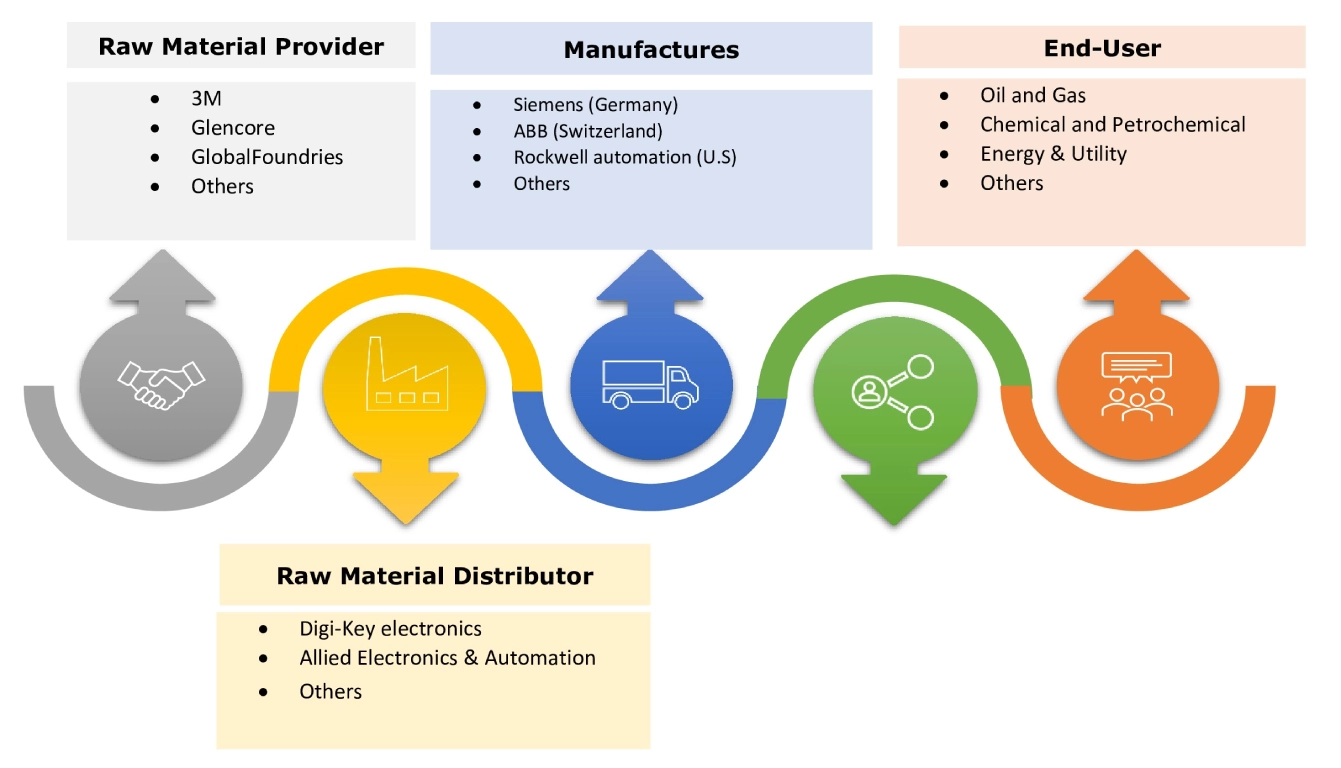

Industrial Control Systems Market Competitive Landscape:

The industrial control systems market is highly competitive with major players providing control systems to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the industrial control systems market. Key players in the global industrial control systems industry include-

- Bosch Industriekessel GmbH (Germany)

- Siemens (Germany)

- Omron Corporation (Japan)

- Emerson Electric Co. (U.S)

- Mitsubishi Electric Corporation (Japan)

- Rockwell Automation (U.S)

- ABB (Switzerland)

- Honeywell International Inc. (U.S)

- Schneider Electric (France)

- Yokogawa electric (Japan)

Recent Industry Developments :

Product launches

- In July 2024, Nozomi Networks Inc., launched the first OT and IoT security sensor embedded in Mitsubishi Electric PLCs. This allows for the analysis and prevention of process-related attacks and harmful user actions without compromising other resources or hindering important networks.

Mergers & Acquisitions

- In March 2024, Siemens AG acquired the industrial drive technology (IDT) division of ebm-papst. This strategic acquisition aims at enhancing Siemens Xcelerator portfolio and reinforces Siemens's market stake as a premier solutions provider for flexible production automation.

- In July 2024, Johnson Controls International plc sold its residential and light commercial HVAC branch to the Bosch Group in an all-cash transaction. This sale encompasses North American ducted business and a global Residential joint venture with Hitachi, Ltd., with a 60% stake held by Johnson Controls and the remaining 40% owned by Hitachi. The entire transaction amounts to $8.1 billion, of which about $6.7 billion is attributable to Johnson Controls.

Partnerships & Collaborations

- In June 2024, DirectDefense, Inc., announced a partnership with Dragos, a global leader in OT cybersecurity. This collaboration combines DirectDefense's managed security services expertise with Dragos's advanced technology for OT cyber threat visibility, detection, and response. The partnership aims to tackle threats against control systems, enhancing security in this critical area.

- In January 2023, Schneider Electric, a global pioneer in the digital transformation of energy management and automation, and BitSight, a leader in cyber risk detection and management announced a strategic partnership. This collaboration aims to enhance the detection of Operational Technology (OT) cybersecurity exposure by identifying misconfigured connected devices.

Government Initiative

- In July 2024, the Cybersecurity and Infrastructure Security Agency (CISA) issued four advisories related to ICS. These advisories, which include National Instruments IO Trace, Hitachi Energy AFS/AFR Series Products, National Instruments LabVIEW, and Hitachi Energy IED Connectivity Packages and PCM600 Products, offer up-to-date information on current security issues, vulnerabilities, and others.

Industrial Control Systems Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 393.44 Billion |

| CAGR (2024-2031) | 9.0% |

| By Component |

|

| By Application |

|

| By End-User |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Industrial Control Systems Market? +

Global Industrial Control Systems Market size is estimated to reach over USD 393.44 Billion by 2031 from a value of USD 196.77 Billion in 2023 and is projected to grow by USD 211.07 Billion in 2024, growing at a CAGR of 9.0% from 2024 to 2031.

What specific segmentation details are covered in the Industrial Control Systems report? +

The Industrial Control Systems report includes specific segmentation details for components, applications, end-users, and regions.

Which is the fastest segment anticipated to impact the market growth? +

In the component segment, the hardware segment is the fastest-growing segment during the forecast period due to the surge in industrial automation drives industries to heavily invest in control system advancements for enhanced efficiency, productivity security, and others.

Who are the major players in the Industrial Control Systems Market? +

The key participants in the Industrial Control Systems Market are Bosch Industriekessel GmbH (Germany), Siemens (Germany), ABB (Switzerland), Rockwell Automation (U.S), Honeywell International Inc. (U.S), Schneider Electric (France), Emerson Electric Co. (U.S), Mitsubishi Electric Corporation (Japan), Yokogawa Electric (Japan), Omron Corporation (Japan) and others.

What are the key trends in the Industrial Control Systems Market? +

The Industrial Control Systems Market is being shaped by several key trends including the growing demand for advanced process control software, industries moving towards more sustainability and adopting smart manufacturing technologies, and others.