- Summary

- Table Of Content

- Methodology

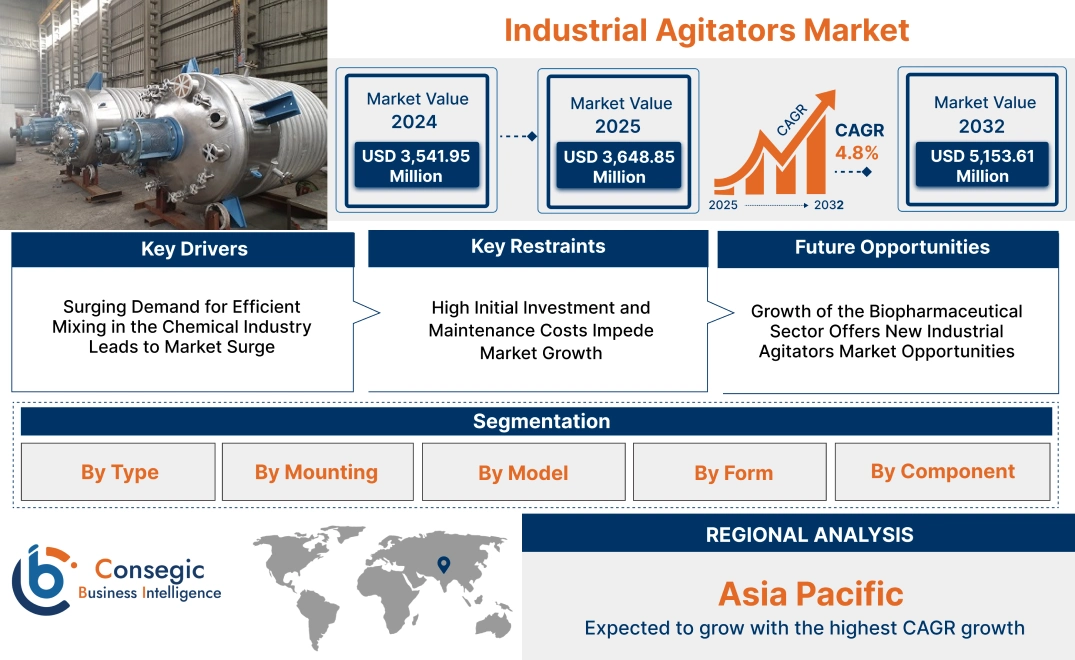

Industrial Agitators Market Size:

Industrial Agitators Market size is estimated to reach over USD 5,153.61 Million by 2032 from a value of USD 3,541.95 Million in 2024 and is projected to grow by USD 3,648.85 Million in 2025, growing at a CAGR of 4.8% from 2025 to 2032.

Industrial Agitators Market Scope & Overview:

Industrial agitators are mechanical devices used to mix or blend substances in various industrial processes. They are designed to ensure uniformity in mixing, dispersing, and blending fluids or solids. These agitators are known for their ability to enhance the speed and efficiency of the mixing process while minimizing energy consumption.

They are highly durable, versatile, and reliable. Their key features include adjustable speed, variable impeller configurations, and high resistance to corrosion and wear. These attributes make them ideal for applications that require precise mixing in demanding environments.

The primary benefits of these agitators include improved product consistency, reduced operational costs, and enhanced process efficiency. They are widely used in industries such as chemical processing, food and beverage, pharmaceuticals, and wastewater treatment. The devices support critical operations, including homogenization, emulsification, and suspending solids.

Key Drivers:

Surging Demand for Efficient Mixing in the Chemical Industry Leads to Market Surge

The chemical industry heavily relies on industrial agitators to blend raw materials into various chemical products. Agitators are essential for achieving uniform mixtures, enhancing reaction rates, and ensuring consistency in product quality. As the chemical industry experiences growth due to the increasing trend for specialty chemicals, polymers, and pharmaceuticals, the need for efficient and reliable mixing solutions also escalates. Industrial agitators are pivotal in improving operational efficiency, reducing energy consumption, and minimizing waste in the production process. For instance, in the production of pharmaceuticals, precise mixing is crucial for ensuring the consistency and safety of medications. Therefore, the expanding chemical industry drives its demand, as these systems help improve production processes and product outcomes.

Key Restraints:

High Initial Investment and Maintenance Costs Impede Market Growth

The adoption of industrial agitators involves significant initial capital investment and ongoing maintenance expenses. These systems require specialized equipment and often need custom designs tailored to specific applications, further driving up costs. Additionally, maintenance is crucial to ensure optimal performance, but it can be costly and time-consuming, especially when considering the complex mechanical parts of these systems. For smaller manufacturers or businesses with limited budgets, the upfront and ongoing expenses can hinder adoption. The trend for routine maintenance and periodic upgrades also poses a barrier, limiting the industrial agitators market growth in price-sensitive regions. As such, the high cost of acquisition and maintenance restrains its widespread adoption.

Future Opportunities :

Growth of the Biopharmaceutical Sector Offers New Industrial Agitators Market Opportunities

The biopharmaceutical industry is experiencing rapid industrial agitators market growth, particularly in the development of biologics and vaccines. This sector needs specialized equipment to ensure precise mixing of sensitive ingredients without contamination. Industrial agitators, designed to handle delicate materials and maintain sterile environments, are essential for biopharmaceutical manufacturing. With the rising number of biologic drugs entering the market, the need for reliable and efficient agitation solutions will increase. For example, during the production of vaccines, maintaining the proper mixture and consistency is critical to ensure efficacy. As the biopharmaceutical industry continues to expand, agitators will play a crucial role in meeting the complex mixing requirements of these products. Therefore, the trend of the biopharmaceutical sector presents a significant industrial agitators market opportunity for the near future.

Industrial Agitators Market Segmental Analysis :

By Type:

Based on type, the market is segmented into top entry agitators, side entry agitators, bottom entry agitators, portable agitators, and static agitators.

The top entry agitators segment accounted for the largest revenue in industrial agitators market share in 2024.

- These agitators are widely used in industries including chemicals, pharmaceuticals, food and beverages, and water treatment due to their efficient mixing capabilities.

- They are suitable for high-viscosity materials and large tank applications, ensuring uniform blending and process efficiency.

- Their robust design and high torque capability allow for effective handling of solid-liquid and liquid-liquid mixtures.

- The demand for these agitators is rising due to their integration with automation and control systems, enhancing operational precision.

- Therefore, according to industrial agitators market analysis, these aforementioned factors contribute to the dominance of the top entry agitators in the industrial agitators market.

The portable agitators segment is anticipated to register the fastest CAGR during the forecast period.

- These agitators provide flexibility and ease of use, making them suitable for small-scale and batch processing applications.

- They are preferred in industries such as cosmetics, food processing, and pharmaceuticals due to their ability to facilitate quick and efficient mixing without requiring permanent installation.

- Advancements in battery-operated and lightweight designs have enhanced their usability across various industrial sectors.

- Thus, according to industrial agitators market analysis, the growing trend for cost-effective and versatile mixing solutions is fueling the industrial agitators market expansion of the portable agitators segment.

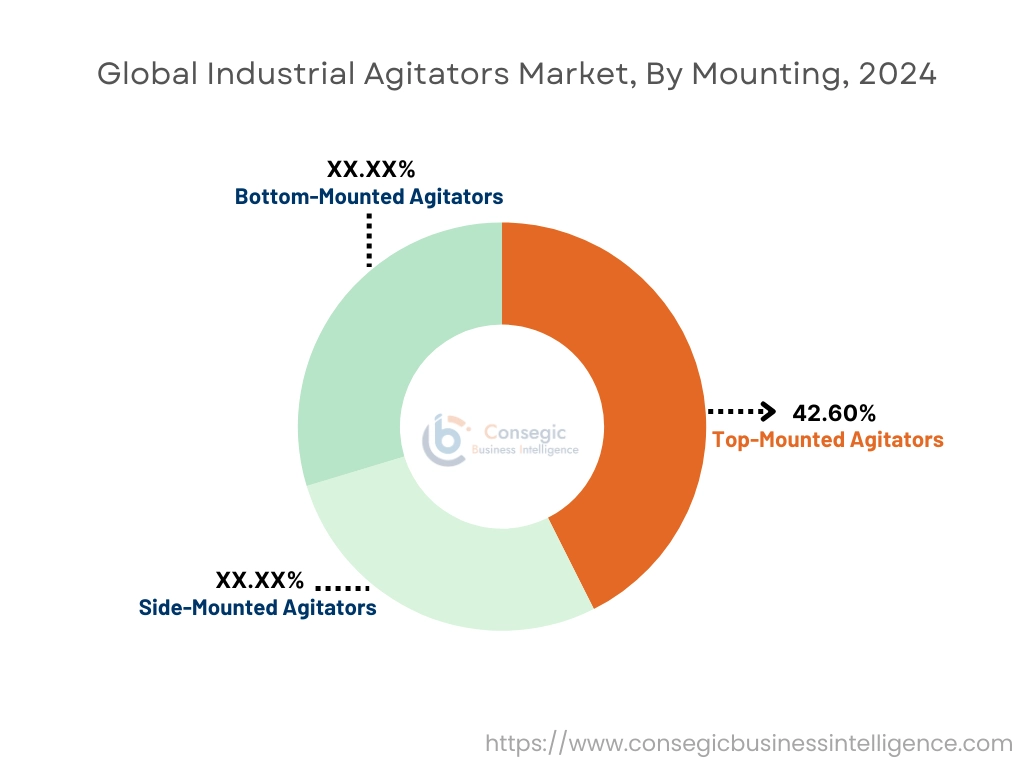

By Mounting:

Based on mounting, the market is segmented into top-mounted agitators, side-mounted agitators, and bottom-mounted agitators.

The top-mounted agitators segment accounted for the largest revenue in industrial agitators market share by 42.60% in 2024.

- These agitators are widely used in large-scale industrial applications, including chemical processing, wastewater treatment, and food production.

- They provide efficient mixing in deep tanks and reactors, ensuring homogenous blending of liquids and solids.

- Their ability to handle high-viscosity fluids and provide controlled agitation makes them an essential component in various manufacturing processes.

- The increasing focus on energy-efficient mixing solutions has driven the adoption of top-mounted agitators.

- Therefore, according to the industrial agitators market trends, these factors establish the top-mounted agitators segment as the highest revenue contributor to the market.

The bottom-mounted agitators segment is anticipated to register the fastest CAGR during the forecast period.

- These agitators are designed to facilitate uniform mixing while reducing dead zones, enhancing product quality in industries such as pharmaceuticals and food processing.

- Their integration with hygienic and aseptic mixing systems has increased their adoption in biotechnology and dairy production.

- The compact design and operational efficiency of bottom-mounted agitators make them a preferred choice for high-precision mixing applications.

- Thus, according to the market analysis, the increasing requirement for efficient and contamination-free mixing solutions is accelerating the trend of the bottom-mounted agitators segment.

By Model:

Based on model, the market is segmented into large tank agitators, portable agitators, drum agitators, and others.

The large tank agitators segment accounted for the largest revenue share in 2024.

- These agitators are extensively used in large-scale industrial applications, including petrochemicals, wastewater treatment, and mining.

- Their high-capacity mixing capability allows for efficient processing of bulk materials, reducing operational costs and improving production efficiency.

- The adoption of advanced impeller designs and automated control systems has enhanced their performance in various industries.

- Therefore, according to the market analysis, the increasing industrialization and expansion of manufacturing facilities are contributing to the strong market position of large tank agitators.

The drum agitators segment is anticipated to register the fastest CAGR during the forecast period.

- These agitators are designed for efficient mixing of small batches, making them ideal for laboratories, specialty chemicals, and food processing.

- Their portability and ease of use have driven their adoption in industries requiring frequent formulation changes.

- Advancements in motor efficiency and material compatibility have improved their performance and reliability.

- Thus, according to the market analysis, the growing need for compact and cost-effective mixing solutions is driving the expansion of the drum agitators segment.

By Form:

Based on form, the market is segmented into solid-solid mixture, solid-liquid mixture, liquid-liquid mixture, and liquid-gas mixture.

The solid-liquid mixture segment accounted for the largest revenue share in 2024.

- This segment includes agitators designed for applications such as slurry mixing, wastewater treatment, and chemical processing.

- Solid-liquid agitators are widely used in mining, pharmaceuticals, and food production for processes requiring thorough dispersion of solids in liquids.

- The rising ask for efficient homogenization and material suspension in industrial applications has propelled their market dominance.

- Therefore, according to the market analysis, the widespread adoption across multiple industries solidifies the strong revenue contribution of the solid-liquid mixture segment.

The liquid-gas mixture segment is anticipated to register the fastest CAGR during the forecast period.

- These agitators are used in aeration, fermentation, and gas dissolution processes across industries such as biotechnology and water treatment.

- The increasing trend for aeration solutions in wastewater treatment plants and biopharmaceutical production has boosted their adoption.

- Technological advancements in impeller design and gas dispersion techniques have enhanced the efficiency of liquid-gas mixing systems.

- Thus, according to the market analysis, the rising need for advanced mixing solutions in gas-involved processes is accelerating the expansion of the liquid-gas mixture segment.

By Component:

Based on component, the market is segmented into heads, impellers, sealing systems, and others.

The impellers segment accounted for the largest revenue share in 2024.

- Impellers are a critical component in industrial agitators, directly influencing mixing efficiency and process performance.

- They are widely used in industries such as chemical processing, pharmaceuticals, and food production for effective blending, dispersion, and homogenization.

- Advancements in impeller design, including high-shear and axial flow impellers, have improved mixing performance and energy efficiency.

- Therefore, according to the market analysis, the continuous ask for optimized impeller technology in industrial applications solidifies its dominance in the market.

The sealing systems segment is anticipated to register the fastest CAGR during the forecast period.

- Sealing systems are essential for preventing leaks and contamination in industrial mixing processes, particularly in hygienic and hazardous environments.

- Industries such as pharmaceuticals, food processing, and specialty chemicals require advanced sealing solutions to maintain product integrity.

- Innovations in mechanical seals and magnetic drive systems have enhanced the reliability and longevity of agitators.

- Thus, according to the market analysis, the growing emphasis on process safety and contamination control is driving the need for advanced sealing systems.

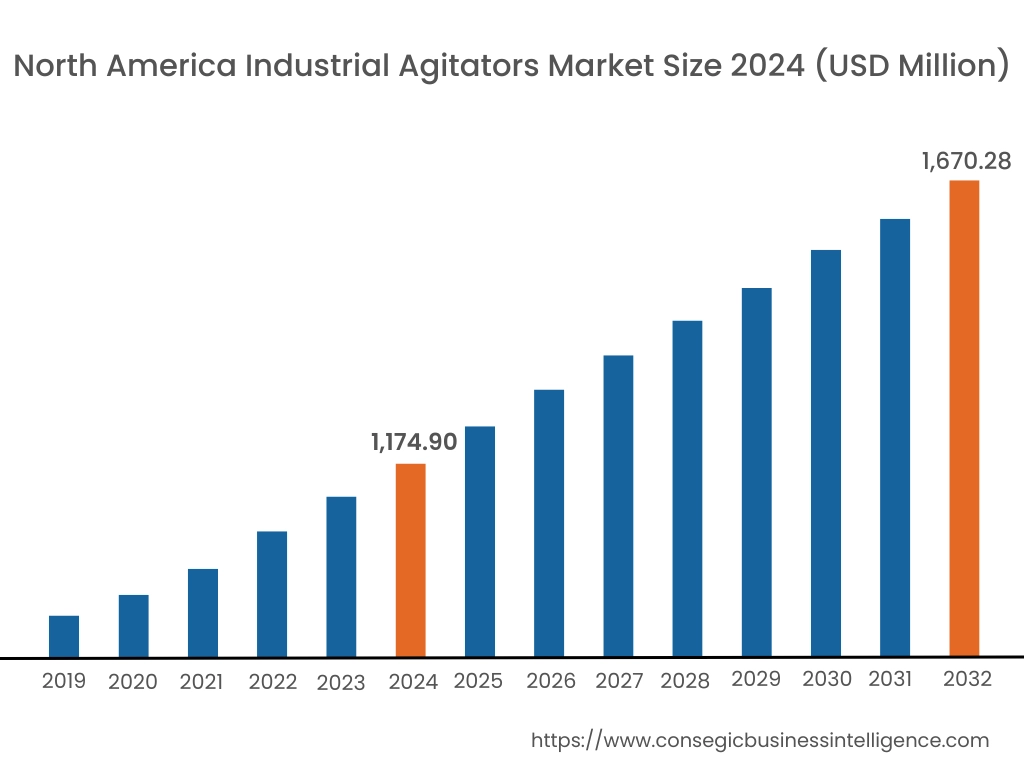

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

In 2024, North America was valued at USD 1,174.90 Million and is expected to reach USD 1,670.28 Million in 2032. In North America, the U.S. accounted for the highest share of 71.41% during the base year of 2024.

The North American industrial agitators market is seeing steady progress, with the United States and Canada leading consumption. The region’s well-established manufacturing base in industries such as chemicals, food processing, and pharmaceuticals boosts industrial agitators market trend. Increasing automation and the adoption of energy-efficient technologies are shaping industry trends. Additionally, the shift toward sustainable manufacturing practices drives the ask for agitators designed to reduce energy consumption and enhance productivity.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 5.2% over the forecast period.

Asia-Pacific is the fastest-growing market, with China and India at the forefront of this growth. The region’s expanding industrial sector, including chemicals, textiles, and food and beverages, is significantly contributing to industrial agitators market demand. The growing focus on industrialization and infrastructure development in emerging economies is pushing need for efficient and cost-effective mixing solutions. As a result, there is increased adoption of advanced agitator technologies, including those that optimize performance and reduce operational costs.

In Europe, the industrial agitators market is mature and robust, driven by industries such as automotive, pharmaceuticals, and chemicals. The region's strong emphasis on regulatory compliance and environmental sustainability leads to demand for agitators with low environmental impact. The push for innovation in manufacturing processes also encourages the adoption of high-performance, energy-efficient agitators. Major European countries like Germany and the UK are key markets, with companies focusing on providing customized solutions for diverse industrial applications.

The Middle East and Africa (MEA) market for industrial agitators is expanding, fueled by the growth in the oil and gas, chemicals, and mining industries. Countries such as Saudi Arabia, UAE, and South Africa are investing in infrastructure and industrial sectors, increasing the need for effective mixing solutions. However, the market in some regions is constrained by economic fluctuations and political instability. Despite these challenges, the need for durable, high-efficiency products remains strong due to the region’s focus on resource extraction and processing industries.

In Latin America, industrial agitators are in demand, particularly in the chemical, food and beverage, and mining sectors. Countries like Brazil and Mexico lead the market, supported by their large industrial sectors. Economic development and urbanization continue to contribute to market performance. Manufacturers are focusing on providing cost-effective, energy-efficient agitators to meet the needs of local industries. Despite facing some economic volatility, Latin America presents significant growth potential as industries modernize and expand their manufacturing capabilities.

Top Key Players & Market Share Insights:

The Global Industrial Agitators Market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the Global Industrial Agitators Market. Key players in the Industrial Agitators industry include-

- SPX FLOW, Inc. (United States)

- Xylem Inc. (United States)

- Silverson Machines Inc. (United Kingdom)

- Statiflo International Ltd. (United Kingdom)

- Teralba Industries Pty Ltd. (Australia)

- Sulzer Ltd. (Switzerland)

- Ekato Group (Germany)

- Philadelphia Mixing Solutions Ltd. (United States)

- Dynamix Agitators Inc. (Canada)

- Mixer Direct Inc. (United States)

Recent Industry Developments :

Mergers and Acquisitions:

- In February 2025, Honeywell International announced plans to split into three separate companies, focusing on aerospace, automation, and advanced materials. This strategic move aims to unlock significant value for shareholders and align with the differing strategic needs of the businesses.

Industrial Agitators Market Report Insights:

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 5,153.61 Million |

| CAGR (2025-2032) | 4.8% |

| By Type |

|

| By Mounting |

|

| By Model |

|

| By Form |

|

| By Component |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Industrial Agitators Market? +

In 2024, the Industrial Agitators Market was USD 3,541.95 million.

What will be the potential market valuation for the Industrial Agitators Market by 2032? +

In 2032, the market size of Industrial Agitators Market is expected to reach USD 5,153.61 million.

What are the segments covered in the Industrial Agitators Market report? +

The component, form, model, mounting, and type are the segments covered in this report.

Who are the major players in the Industrial Agitators Market? +

SPX FLOW, Inc. (United States), Xylem Inc. (United States), Sulzer Ltd. (Switzerland), Ekato Group (Germany), Philadelphia Mixing Solutions Ltd. (United States), Dynamix Agitators Inc. (Canada), Mixer Direct Inc. (United States), Silverson Machines Inc. (United Kingdom), Statiflo International Ltd. (United Kingdom), Teralba Industries Pty Ltd. (Australia) are the major players in the Industrial Agitators market.